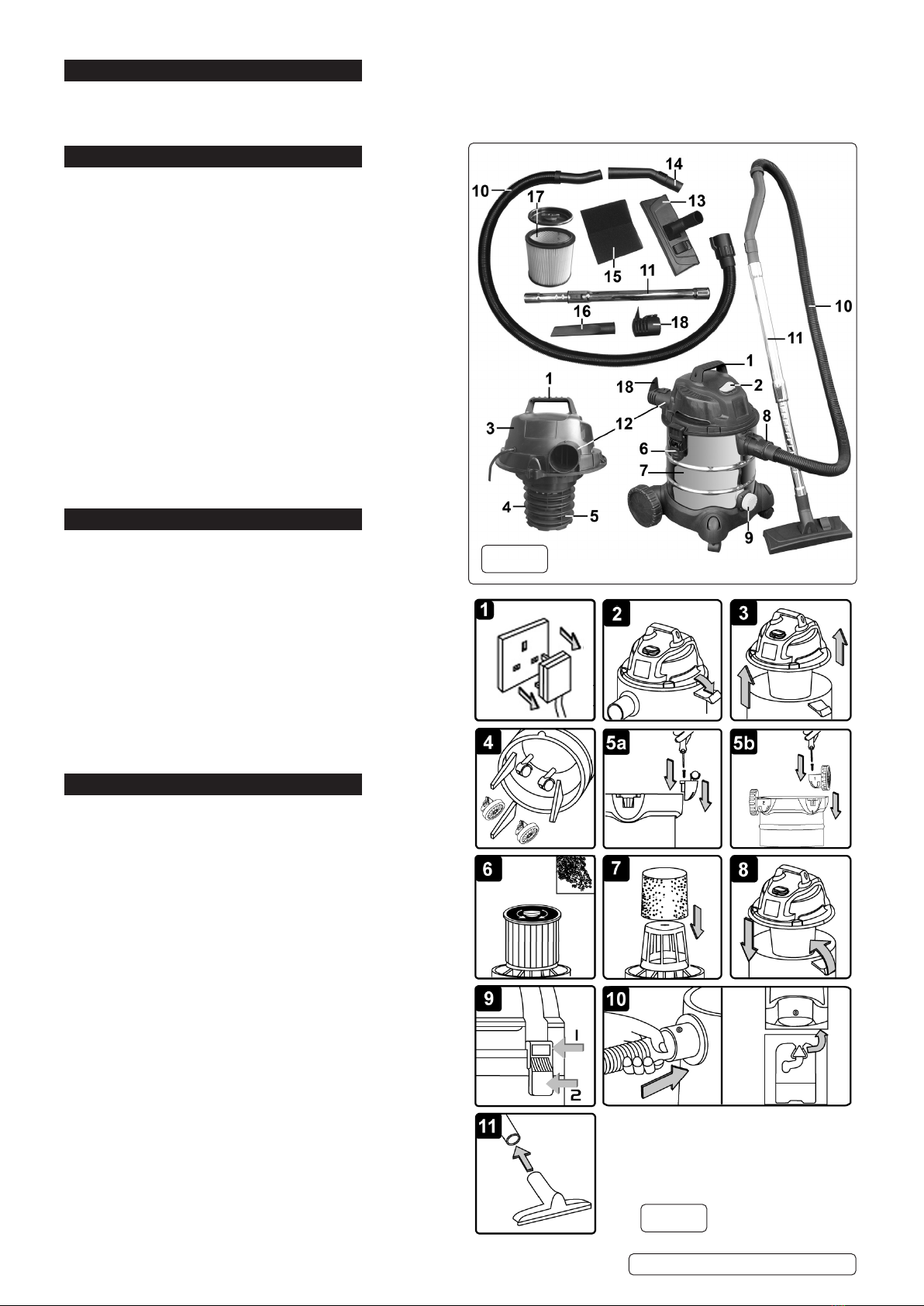

that the blue on/off switch is above the vacuum hose

connector. (fig.2.8)

5.10. Align the ridges on the rim of the power head with the two side clasps. Place the upper part of each clasp over the ridges and snap the

clasps into place by pressing on the lower part of each clasp in turn. (fig.2.9)

5.11. Align the arrow symbol on the large end of the vacuum hose with the pin on the front inlet of the drum. Push the fitting into the inlet and

lock in place by turning the fitting clockwise. (fig.2.10)

5.12. Choose the desired nozzle and push it onto the telescopic suction tube. (fig.2.11)

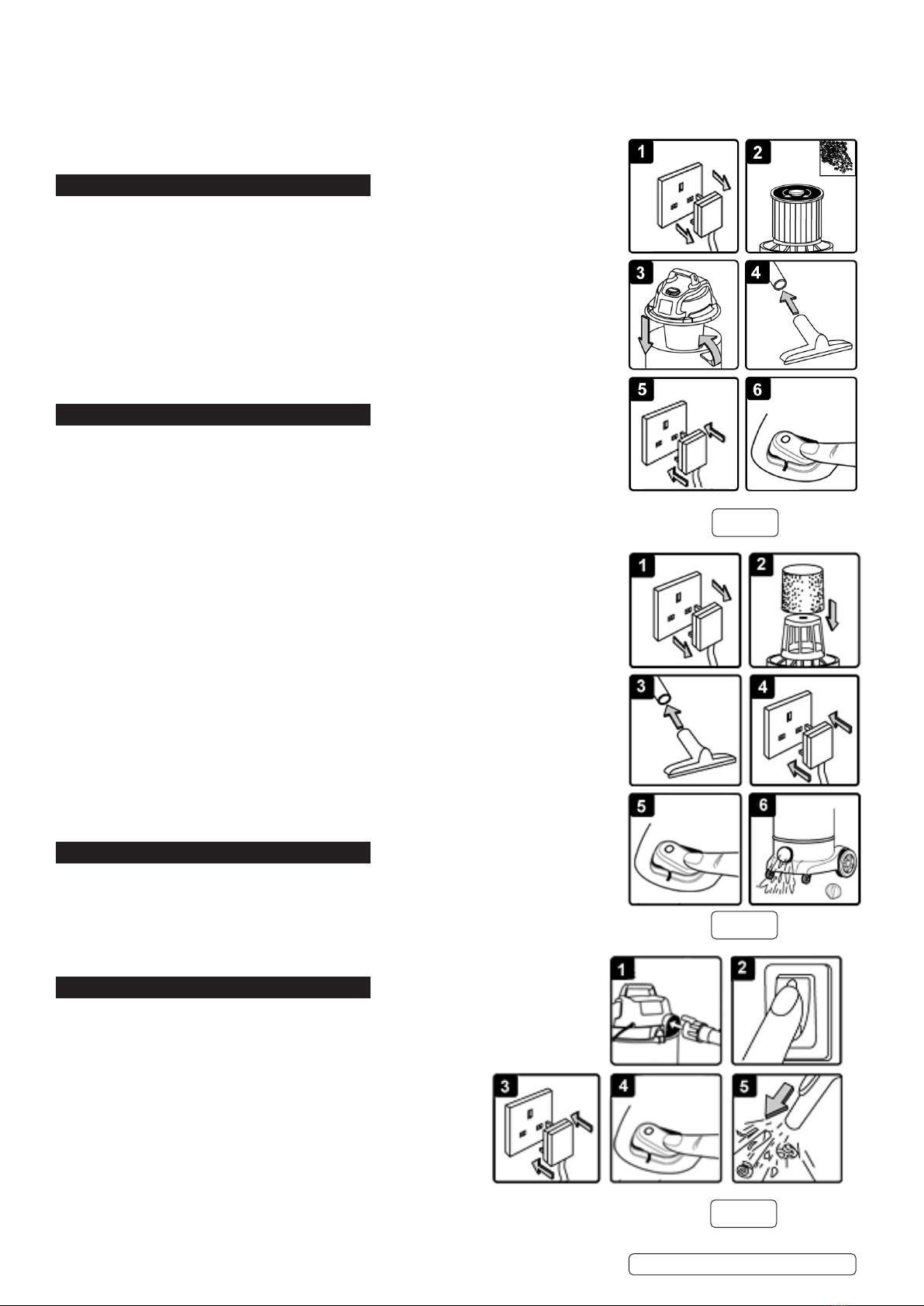

6. DRY VACUUM CLEANING

WARNING! Ensure you read, understand and apply Section 1 ‘Safety Instructions’.

Reminder: DO NOT vacuum hazardous substances. Use of an incorrect cartridge

filter will invalidate your warranty.

6.1. Ensure the machine is unplugged from the power supply. (fig.3.1)

6.2. Remove the power head and fit the locking cartridge filter down over the filter basket as

described in section 5.7.

6.3. Reposition power head onto the drum body,clip in place. (fig.3.3)

6.4. Insert the larger end of the flexible hose into the front inlet on the container and lock in

place. Push the required attachment onto the free end of the hose (fig.3.4). Plug in

power supply. fig.3.5)

6.5. Switch to the ‘On’ (position ‘I’). (fig.3.6)

6.6. Switch to the ‘Off’ position (‘0’) when finished.

7. WET VACUUM CLEANING

WARNING! Ensure you read, understand and apply Section 1 ‘Safety

Instructions’. Reminder: Remove plug from power supply before opening

unit.

DO NOT vacuum solvents, explosives, inflammable and/or hazardous liquids

such as petrol, oil, spirits, paint, thinners, acids etc.

7.1. Ensure the machine is unplugged from the power supply. (fig.4.1) Make sure the tank is

clean and free from dust and dirt.

7.2. Remove the cartridge filter and fit a foam filter over the filter basket. (fig.4.2) Refit the

power head onto the drum.

7.3. To the same flexible hose used in dry cleaning fit the desired nozzle (fig.4.3)

7.4. Ensure the switch is ‘Off’ (position ‘0’) before plugging into the power supply.

7.5. Press the switch to ‘On’ (position ‘I’). (fig.4.5)

NOTE: To vacuum large quantities of liquid, from a sink or tank etc, DO NOT immerse the

nozzle completely in the liquid, leave a gap at the top of the nozzle opening to allow an air

inflow. The machine is fitted with a float valve which stops the suction action when the tank

has reached its maximum capacity. The user will notice an increase in motor speed.

When this happens, turn off the machine, disconnect from power supply, remove the power

head from the container and empty the liquid into a suitable receptacle or drain (fig4.6).

To continue vacuuming, refit the power head and proceed. After wet vacuuming, turn the

machine off and unplug from power supply. Empty the container and clean and dry the

inside and outside before storage.

7.6. Remember! After wet vacuuming the foam filter must be removed and a cartridge filter

must be fitted before dry vacuuming again.

WARNING! Not designed for liquid storage. Always empty liquids after

use and before storing.

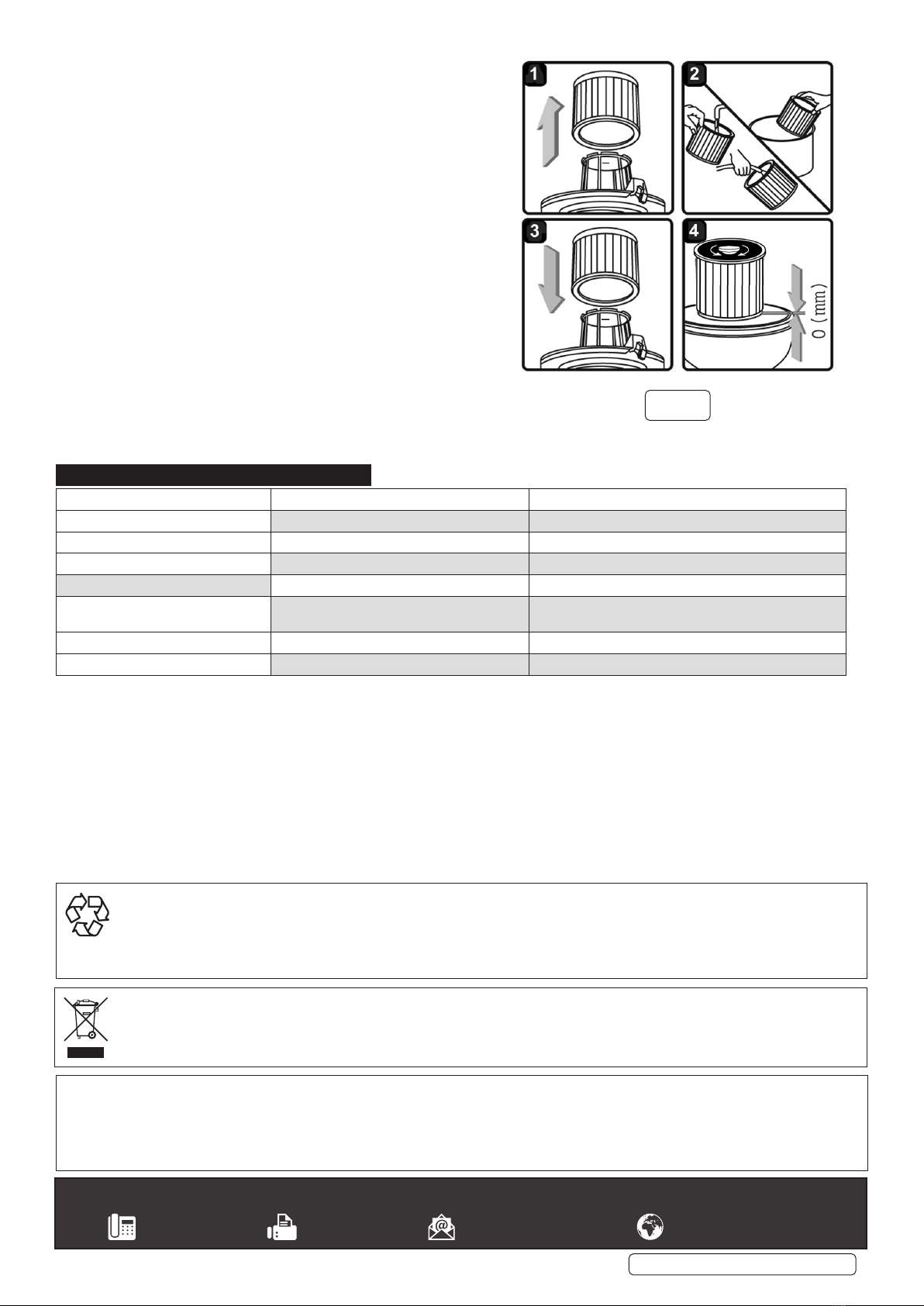

8. BLOWING

8.1. Push the large end of the flexible hose into the blow connection in the top section. (fig.5.1)

8.2. Ensure the power switch is turned off (fig.5.2) and plug in the power supply. (fig.5.3)

8.3. Switch on the power (position ‘I’). (fig.5.4)

8.4. The unit will now blow through the hose and can be used to clear obstructions within the pipe. (fig.5.5)

WARNING! If after a few seconds the hose is still blocked turn of the unit and clear

the hose manually.

9. MAINTENANCE

9.1. GENERAL MAINTENANCE.

9.1.1. Ensure the machine is unplugged from the power supply.

9.1.2. Disconnect the hose from the container.

9.1.3. Undo the clasps and remove power head from the container.

9.1.4. Clear out any dirt or debris from the container and hose.

9.1.5. Clean the foam filter by washing it in a mild soapy solution.

9.1.6. Check that the telescopic suction tube operates smoothly

and check the power cable to make sure has not received any

damage.

g.3

g.4

g.5

Original Language Version

© Jack Sealey Limited PC200SD.V3 Issue 4 (4,F) 08/09/20