2. INTRODUCTION

Highpoweredunitsdesignedforusewithpowertools.ModelNo.DFS35Misalsosuitableforusewithairpowertools.CertiedforClassM

dustextractioninaccordancewithEUdirectives,whichprotectstheoperatorfromdustparticleshazardoustohealth.SuppliedwithØ36mm

exiblehose,multi-diametertooladaptor,crevicetool,powertoolcordclamps,ClassMbaglter,ClassMcartridgelterandfoamlter,

ModelNo’sPC35110V&PC35230Varealsosuppliedwithinsertsforliquidcollectionandhardoors.Canbesettocontinuoussuctionor

in synchronisation with a power tool via an electronically controlled outlet or pneumatic tool via the air outlet (DFS35M only). Fitted with a

self-cleaningltertechnologydesignedtopreventlterblockageswhilstinuse.Fittedwithfourcastorsformanoeuvrability.Awet&dryoor

cleaning kit is available for DFS35M, order Model No. DFS35MKIT.

3. SPECIFICATION

MODEL NO:............................................................ DFS35M

Airow: .....................................................................180m³/hr

Drum Size: ....................................................................... 35L

Drum Type: ................................................................. Plastic

MaximumVacuumPressure: ................................... 220mbar

Motor Power:...............................................................1000W

Optional Accessories: ....... DFS35MKIT-AccessoryFloorKit

Power Tool Capacity: ..................................................2000W

Supply:...........................................................................230V

Vacuum Accessories Diameter:............................ Ø10-35mm

Consumable Parts:

DFS35CF..........................................Cartridge Filter Class M

DFS35FF ............................................................. Foam Filter

DFS35PB................................ Dust Bag Class M (Pack of 5)

4. CONTENTS

4.1. Unpack the carton carefully.

4.2. Locate the two side clasps which hold the motor housing in place.

4.3. Undo the clasps, remove the motor housing and take out the loose items from the drum.

4.4. Check and identify each component as listed below. If anything is missing or damaged

please contact your Sealey stockist immediately.

5. ASSEMBLY

5.1. Ensure the electrical supply is disconnected.

5.2. Undo the clasps.

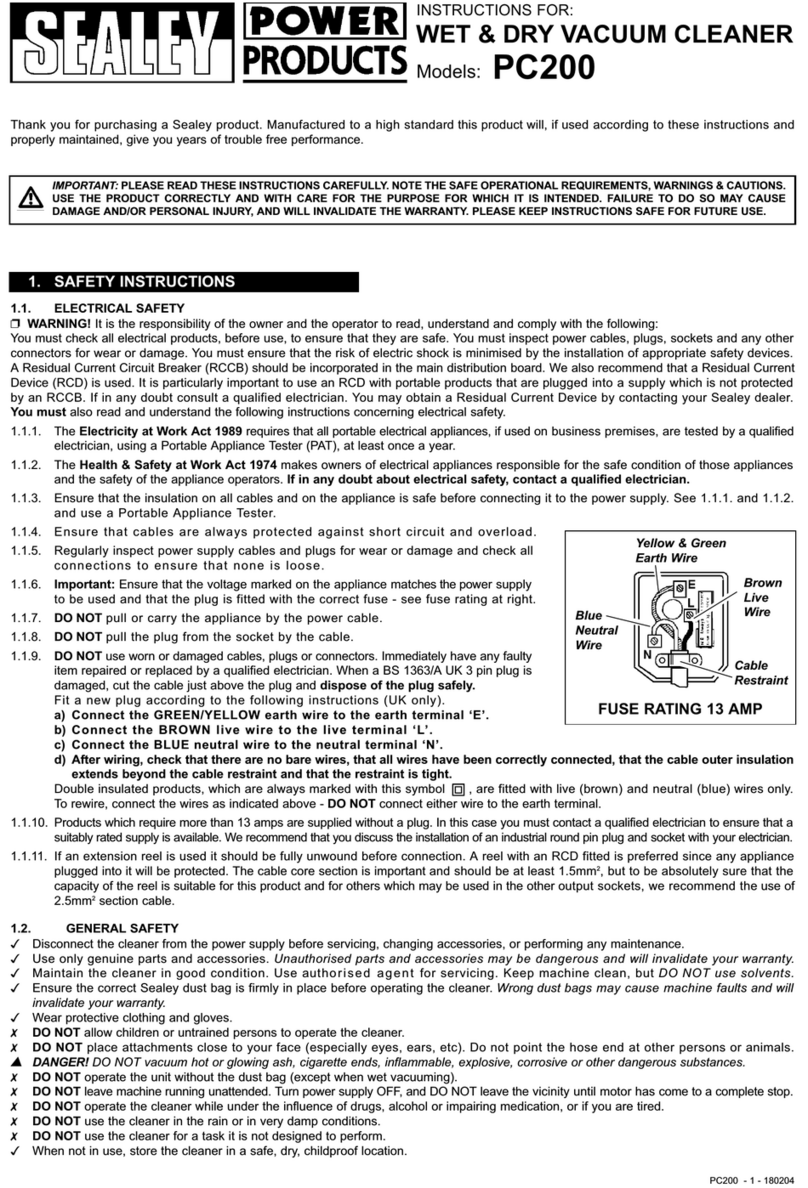

5.3. Liftothemotorhousingassembly(g.1).

5.4. Fordryvacuumcleaningusethelockingcartridgeltersupplied.

5.5. For dry vacuum cleaning and containment use the vacuum bag supplied.

5.6. Forwetvacuumcleaningtthesuppliedfoamlter.

NOTE: DO NOToperatethecleanerwithoutalterttedasthiswilldamagethevacuumcleaner

and invalidate your warranty.

5.7. Replace the motor housing onto the container.

5.8. Align the motor housing with the clasps and snap closed by hooking the top of the clasp into the location in the motor housing and

pressing the handles down over centre.

6. CONTROLS

6.1. FUNCTION SYMBOLS

6.1.1. For use as Wet & Dry Cleaner:

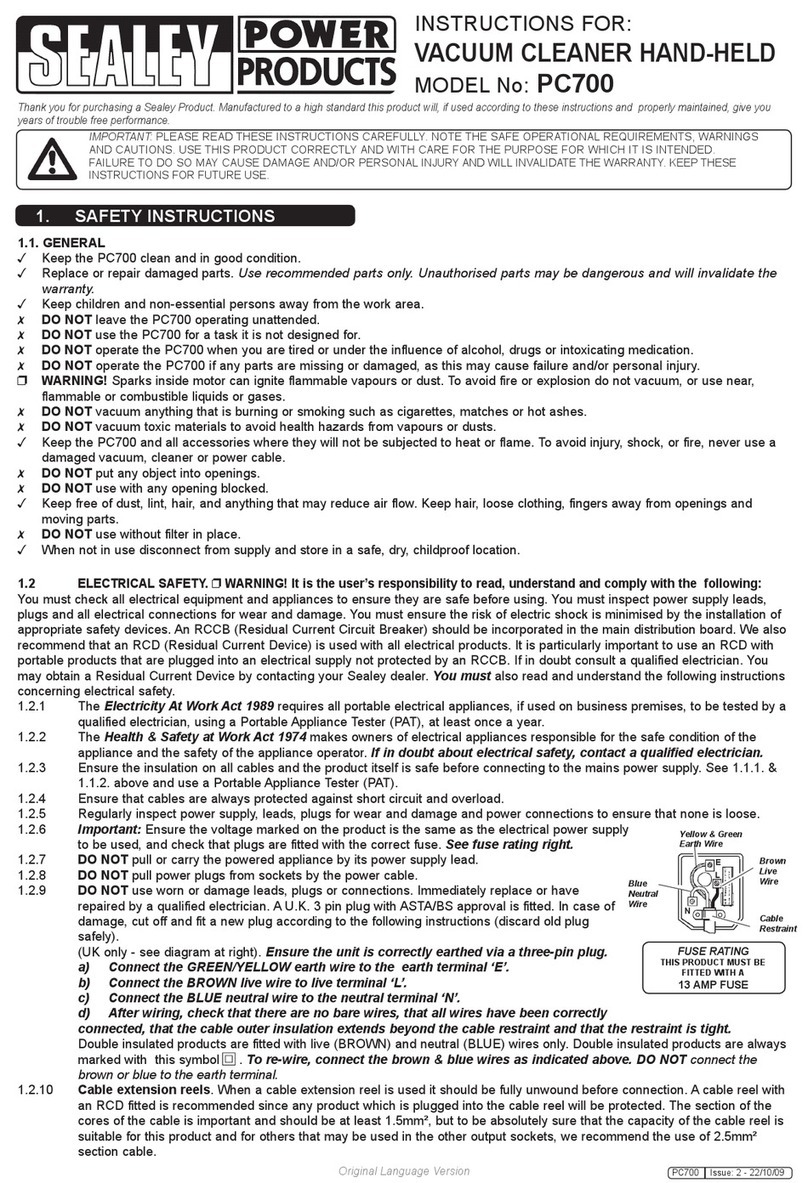

6.1.1.1. DepressSelectorSwitch(g.2.A)andPowerSwitch(g.2.B).

6.2. FOR USE WITH AN ELECTRIC POWER TOOL.

6.2.1. LeaveSelectorSwitch(g.2.A)inraisedpositionanddepressthePowerSwitch(g.2.B).

6.2.2. Inthisposition,anysingleelectrictoolcanbeconnected(uptoamaximumof2000W).

Poweringthetoolwillswitchthevacuumcleaneron.Whenthetoolisswitchedo,the

vacuumcleanerwillrunforafurther8/10seconds.Afterthistheltercleaningprocess

will operate.

6.3. FOR USE WITH AN AIR TOOL.

6.3.1. LeaveSelectorSwitch(g.2.A)inraisedpositionanddepressthePowerSwitch(g.2.B).

6.3.2. Connecttheairsupplytotheairinletconnector(g.2)andthetooltotheairoutletconnector(g.2).Aquicktconnectoris

included.Whenairowtothetoolisdetected,thecleanerwilloperate.Whenthetoolisswitchedo,thevacuumcleanerwillrunfor

afurther8/10seconds.Afterthistheltercleaningprocesswilloperate.

NOTE: Continuousoperationoftheselfcleaningsystemformorethan60secondsmaycausethethermalprotectiontotrip,resettingafter

20minutes.(Forfullerltercleaningseesection9.)

6.3.3. Thewarninglamp(g.2.C)willilluminatewhenahighvacuumsituationisdetected.Thiscouldbecausedbyablockedhoseor

nozzle,blockedlterorafullbag.

6.4. Iftheexhaustairspeeddropsbelow20m/secthewarninglamp(g.2.C)illuminates(inaccordancewithIEC/EN60335-2-69).

7. DRY VACUUMING

WARNING! Ensure you read, understand and apply Section 1 ‘Safety Instructions’. Reminder: DO NOT vacuum hazardous

substances,hotashesorembers.Useofanincorrectcartridgelterwillinvalidateyourwarranty.

7.1. Category M Cartridge Filter. To pickup dust of Class M the dust bag MUST be installed in the appliance. To vacuum Class ‘M’ dust

ALWAYSusethelterelementFig.3.

g.1

1 Motor Housing

2 Vacuum Drum

3 Hose

4 Crevicetool36mm

5 Cartridge Filter Class M

6Foam Filter

7 Dust Bag Class M

8 Adaptor

9Multi adaptor

10 Air inlet

g.2

DFS35M Issue 4 14/07/2020

Original Language Version

© Jack Sealey Limited