20L WET & DRY VALETING MACHINE WITH

ACCESSORIES 1400W

MODEL NO: PC310.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS,

WARNINGS & CAUTIONS. USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT

IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURYAND WILL INVALIDATE THE

WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

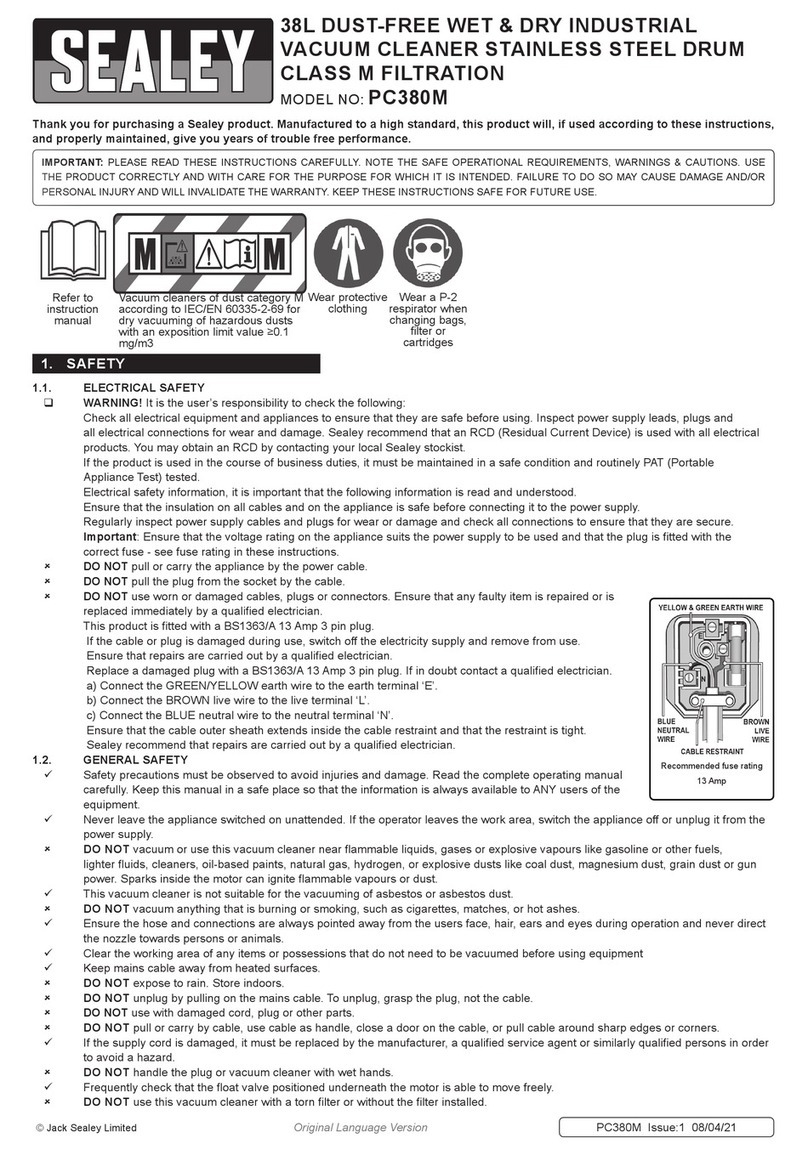

1.1. ELECTRICAL SAFETY

WARNING! It is the user’s responsibility to check the following:

9Check all electrical equipment and appliances to ensure that they are safe before using.

Inspect power supply leads, plugs and all electrical connections for wear and damage. Sealey

recommend that an RCD (Residual Current Device) is used with all electrical products.

Electrical safety information. It is important that the following information is read and

understood:

9Ensure that the insulation on all cables and on the appliance is safe before connecting it

to the power supply.

9Regularly inspect power supply cables and plugs for wear or damage and check all

connections to ensure that they are secure.

Important: Ensure that the voltage rating on the appliance suits the power supply to be used

and that the plug is tted with the correct fuse.

8DO NOT pull or carry the appliance by the power cable.

8DO NOT pull the plug from the socket by the cable.

8DO NOT use worn or damaged cables, plugs or connectors. Ensure that any faulty item is

repaired or is replaced immediately by a qualied electrician.

If the cable or plug is damaged during use, switch o the electricity supply and remove

from use.

Ensure that repairs are carried out by a qualied electrician.

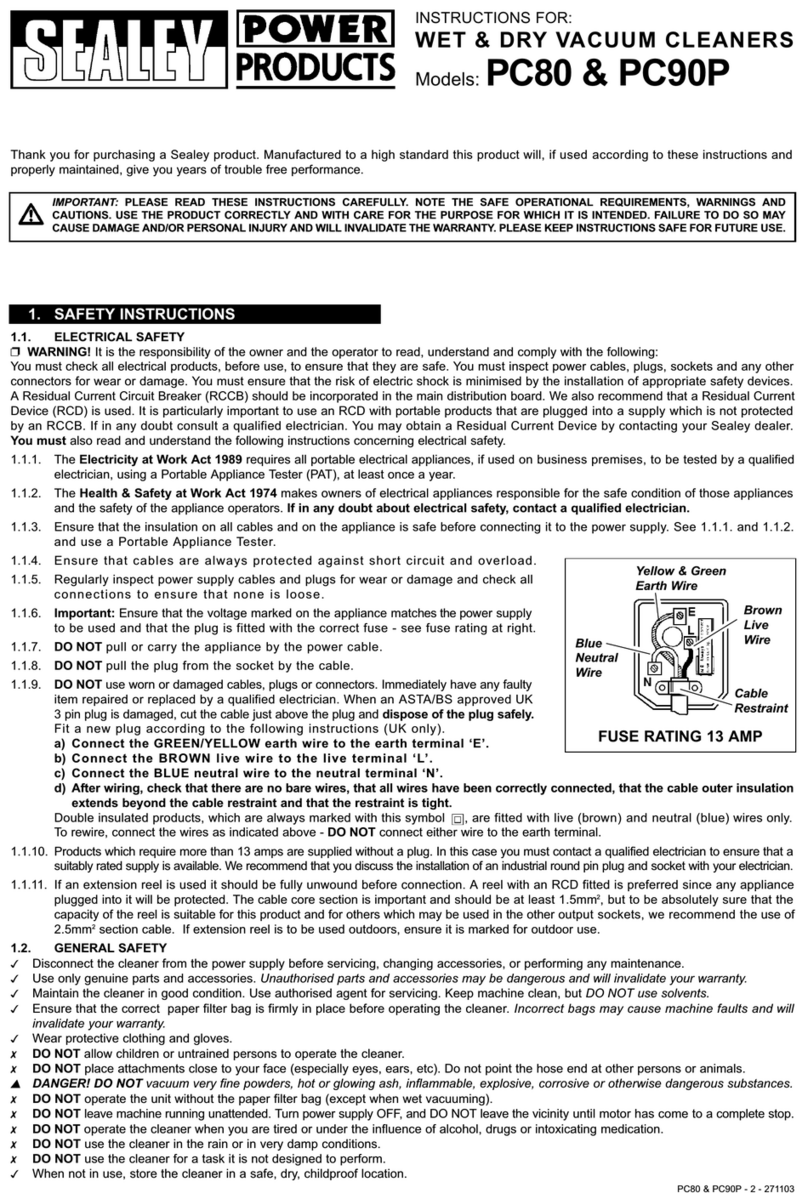

1.2. GENERAL SAFETY

9Children from age 8 years and above, persons with reduced physical, sensory, or mental capabilities those with lack of experience and

knowledge can use the appliance, if they have been given supervision or instruction concerning use of the appliance in a safe way to

understand the hazards involved.

9Children shall NOT play with the appliance

9Cleaning and user maintenance on the appliance shall not be made by children without supervision.

9The plug must be removed from the socket-outlet before cleaning or maintaining the appliance.

9Disconnect the appliance from its power source during service and when replacing parts and, if that the removal of the plug is foreseen,

it shall be clearly indicated that the removal of the plug has to be such that an operator can check from any of the points to which he

has access that the plug remains removed.

9Before operation, please check if the local power supply is the same as it’s rated in the specication.

9If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualied persons in order to avoid a hazard.

9Remember to turn o the appliance and remove the plug every time after use or when being repaired.

9Keep machine away from strong sunlight and high temperatures in case plastic is damaged.

8DO NOT use this machine as a pump.

8DO NOT pull the appliance by the hose.

8DO NOT stand on the hose or appliance.

8DO NOT immerse the head unit in water or wash with water in case that water goes into the electronic parts and causes personal injury.

8DO NOT use this appliance in any combustible and explosive places in case the motor sparks and causes a re.

8DO NOT jam the air inlet as this may cause temperature rises and damage to the motor.

8DO NOT use the appliance to collect combustible and explosive materials such as petrol, oils etc.

8DO NOT use the appliance to collect sharp objects like pins and screws as this may damage internal components.

8DO NOT use for ash, hot embers etc.

8DO NOT use the appliance to collect powders that can easily block the ventilation holes and damage the motor.

8DO NOT overturn the machine in case water goes into the motor and damages the motor.

8DO NOT use a cleaning agent or detergent containing solvent.

8DO NOT collect combustible and explosive objects such as glowing cigarettes, gasoline, etc.

8DO NOT collect objects which can easily attach on the lter such as calcareousness powder, gesso and graphite powder because those will

block the ventilation damage motor.

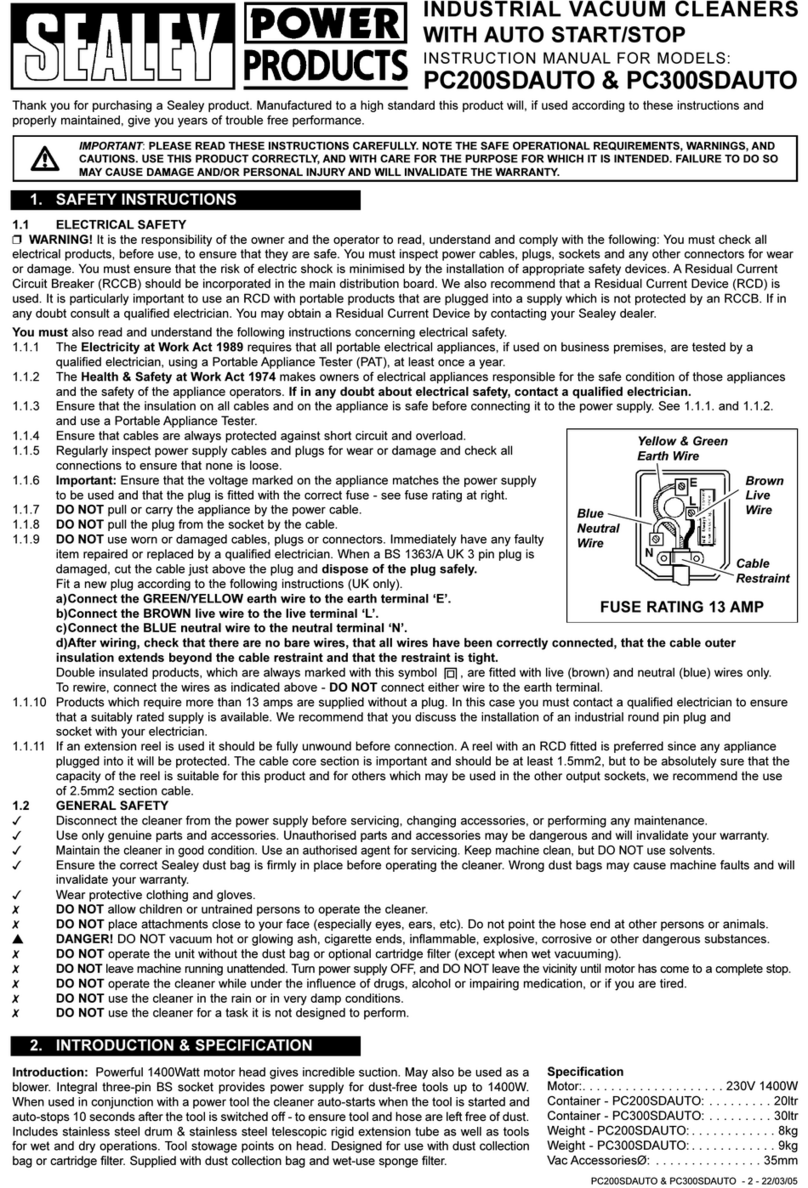

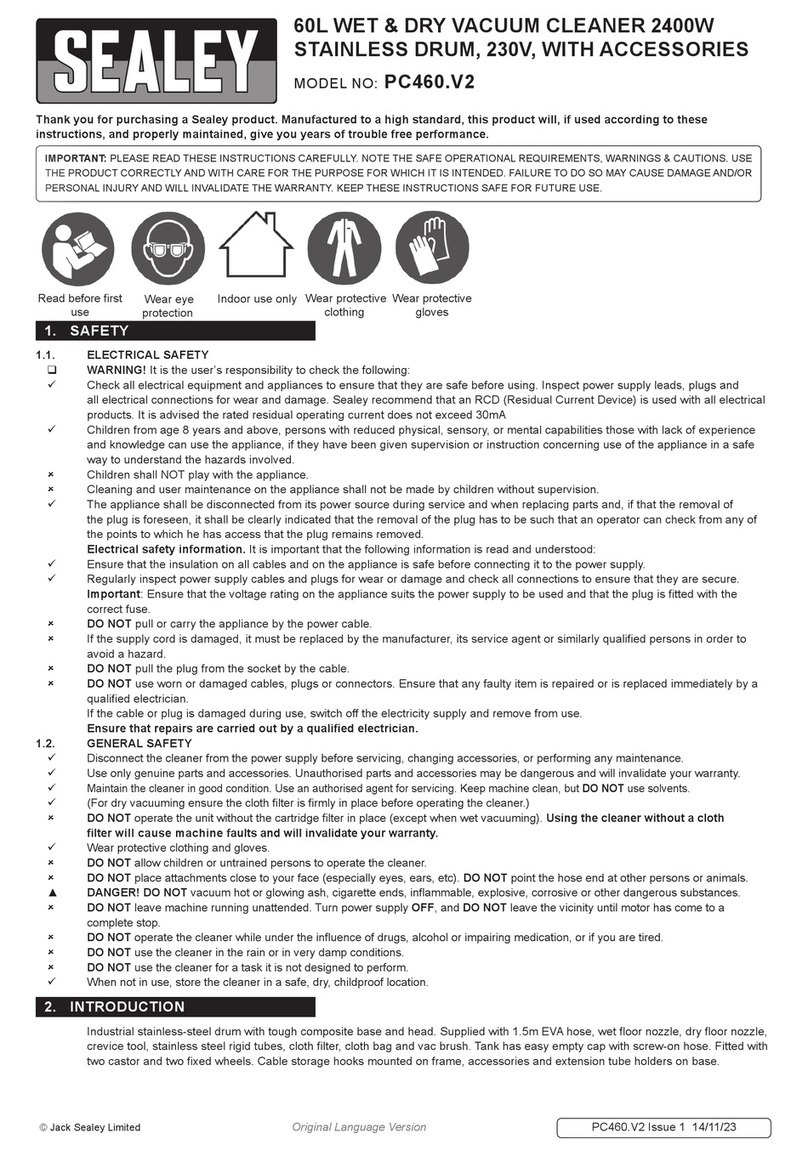

2. INTRODUCTION

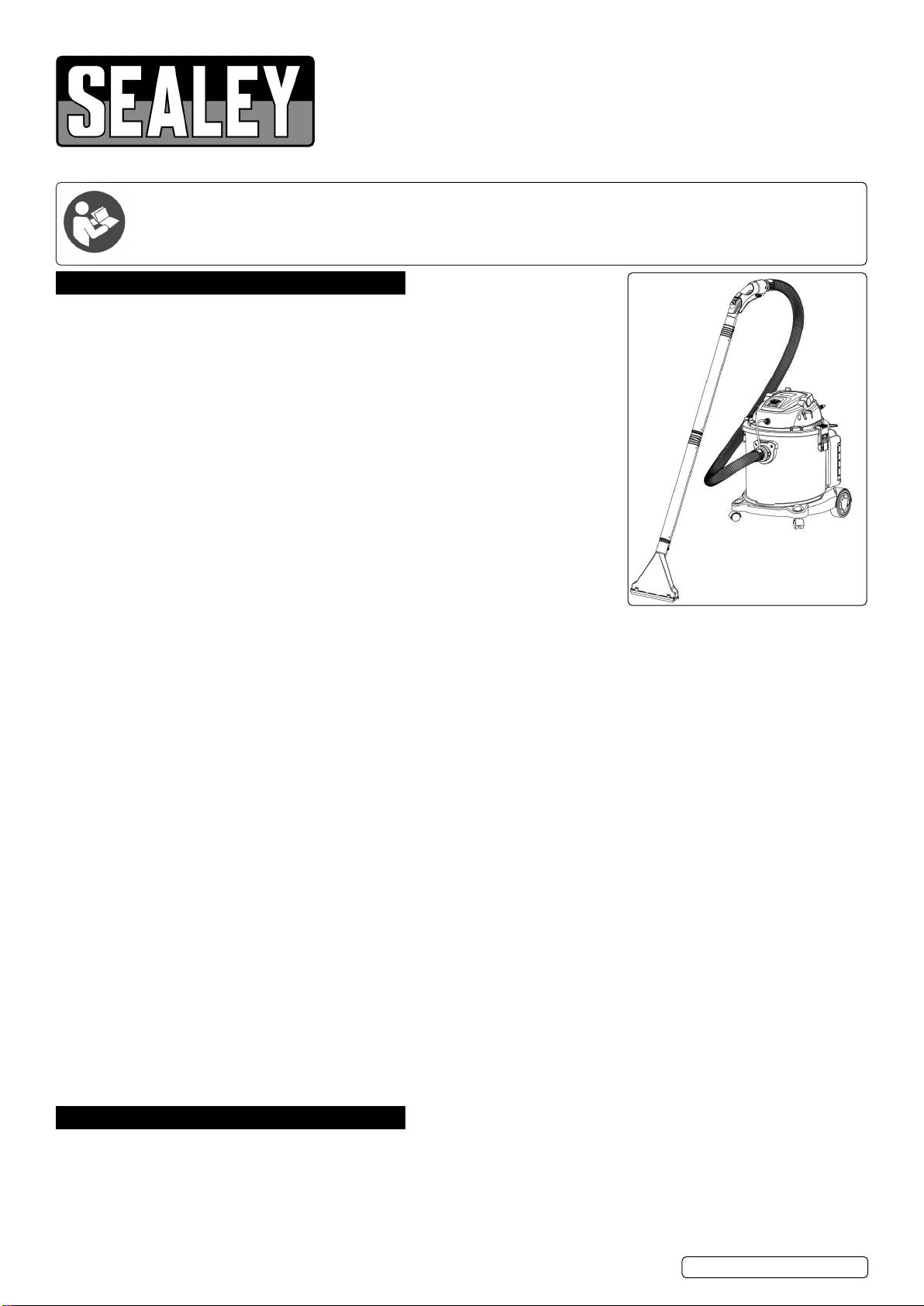

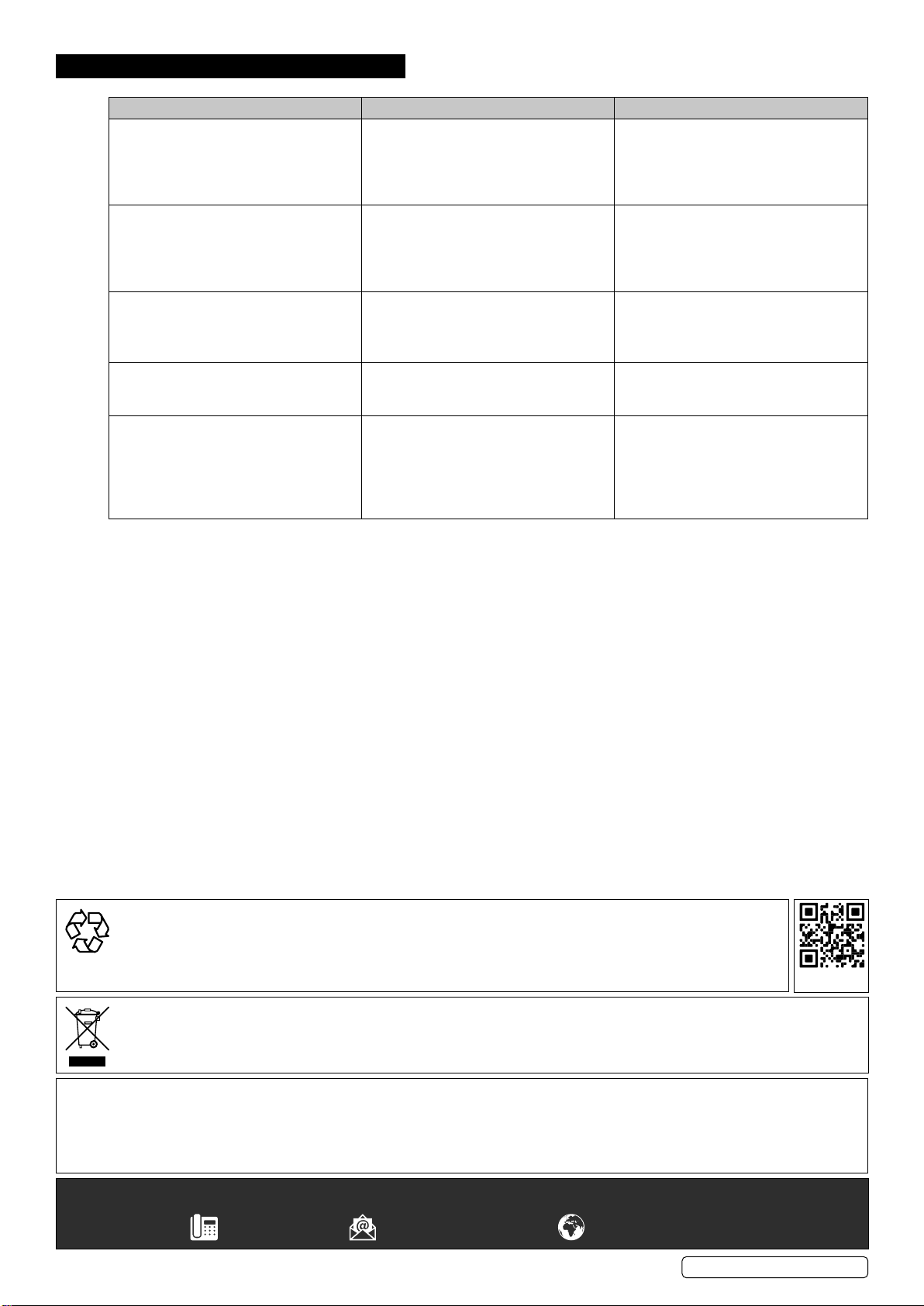

Cleans carpets, car interiors, fabrics and upholstery. Constructed from high-impact plastic which is dent resistant and rustproof. Supplied

with carpet lance, handheld lance, full wet and dry vacuum accessory kit, including aluminium rigid extension tube, cartridge filter and

foam filter. Powerful pump forces cleaning fluid into fabric/carpet and 1400W suction power leaves surface virtually dry after one pass.

Features safety shut-off for wet operation. Large capacity drum with external detergent tank for easy filling. Fitted with two fixed wheels

and two castors. Cable storage hook, accessories and extension tube holders on head, plus additional accessory storage slots on base.

PC310.V2 Issue 1 06/12/23

Original Language Version

© Jack Sealey Limited