DO2 INSTRUCTIONS

Seametrics • 253.872.0284 Page 13 seametrics.com

TROUBLESHOOTING

Erratic Readings

Erratic readings can be caused by a poor connection, damaged cable, moisture

in the unit, or a damaged transmitter. In most cases, erratic readings are due to

moisture getting into the system.

The rst thing to check is the connection. Look for moisture between contacts

or a loose or broken wire. Next, check the cable for cracking or fraying. If the

connections and cable appear OK, but the readings are still erratic, the transmitter

may be damaged. Contact Seametrics for evaluation and repair. Erratic and

erroneous readings can also occur due to improper grounding. See Grounding

Issues, below.

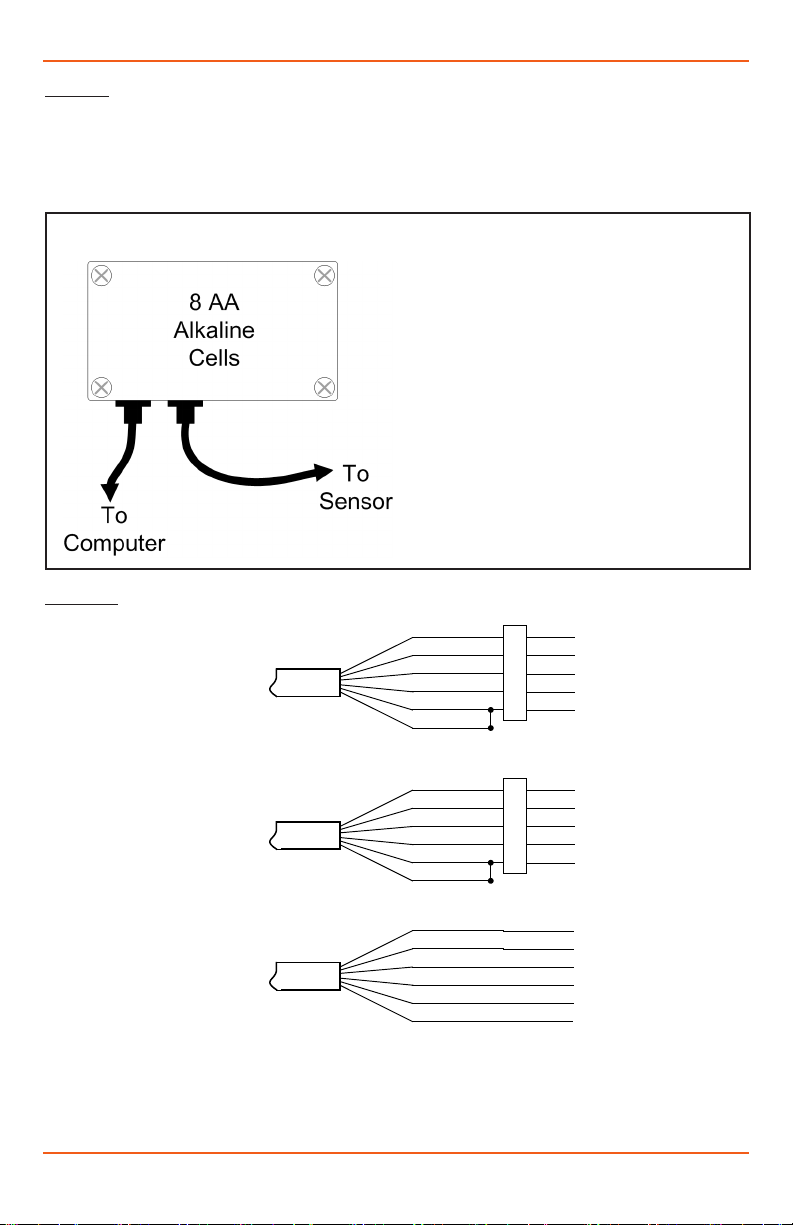

Grounding Issues

It is commonly known that when using electronic equipment, both personnel and

equipment need to be protected from high power spikes that may be caused by

lightning, power line surges, or faulty equipment. Without a proper grounding system,

a power spike will nd the path of least resistance to earth ground – whether that path

is through sensitive electronic equipment or the person operating the equipment. In

order to ensure safety and prevent equipment damage, a grounding system must be

used to provide a low resistance path to ground.

When using several pieces of interconnected equipment, each of which may have its

own ground, problems with noise, signal interference, and erroneous readings may

be noted. This is caused by a condition known as a Ground Loop. Because of natural

resistance in the earth between the grounding points, current can ow between the

points, creating an unexpected voltage dierence and resulting erroneous readings.

The single most important step in minimizing a ground loop is to tie all equipment

(sensors, dataloggers, external power sources and any other associated equipment)

to a single common grounding point. Seametrics recommends connecting the

shield to ground at the connector end.