Seametrics TX800 Series User manual

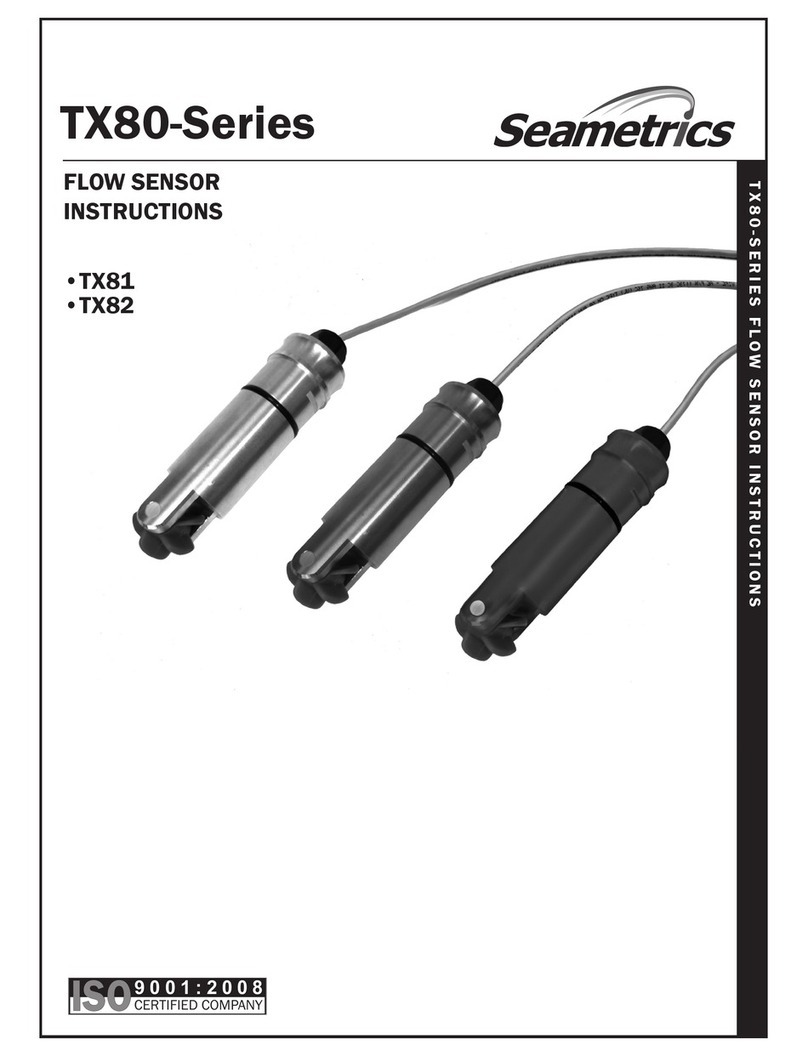

TX800-Series

FLOW SENSOR

INSTRUCTIONS

•TX81x

•TX82x

TX800SERIES FLOW SENSOR INSTRUCTIONS

9001:2008

CERTIFIED COMPANY

ISO

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com

Page 2

General Information

Generial Information, Features .................................................................................................................................Page 3

Specications..............................................................................................................................................................Page 4

Installation

Fitting Installation, Distorted Flows, Meter Installation, Orienting the Meter ....................................................... Page 5

Straight Pipe Recommendations ..............................................................................................................................

Page 6

Full Pipe Recommendations......................................................................................................................................Page 7

Connections

FT430, FT440 ............................................................................................................................................................. Page 8

FT450, Connecting to PLC's ......................................................................................................................................Page 9

Operation and Maintenance

Modularity, Output, Fittings, Minimum Flow, Flow Rate Tables, Calibration (“K-Factor”) ..................................Page 10

Rotor Replacement, Signal Troubleshooting, Sensor Replacement ....................................................................Page 11

Parts List ...................................................................................................................................................................Page 12

Troubleshooting

Problem, Probable Cause, Things to Try.................................................................................................................Page 13

Features ......................................................................................................................................................................Page 3

Specications..............................................................................................................................................................Page 4

Distorted Flows, Orienting the Meter........................................................................................................................Page 5

Straight Pipe Recommendations ..............................................................................................................................

Page 6

Full Pipe Recommendations......................................................................................................................................Page 7

Connection Diagrams..............................................................................................................................................Page 8-9

Flow Rate Table.........................................................................................................................................................Page 10

Rotor Replacement...................................................................................................................................................Page 11

Parts Explosion, Parts List .......................................................................................................................................Page 12

Troubleshooting ........................................................................................................................................................Page 13

TABLE OF CONTENTS

TABLES AND DIAGRAMS

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com Page 3

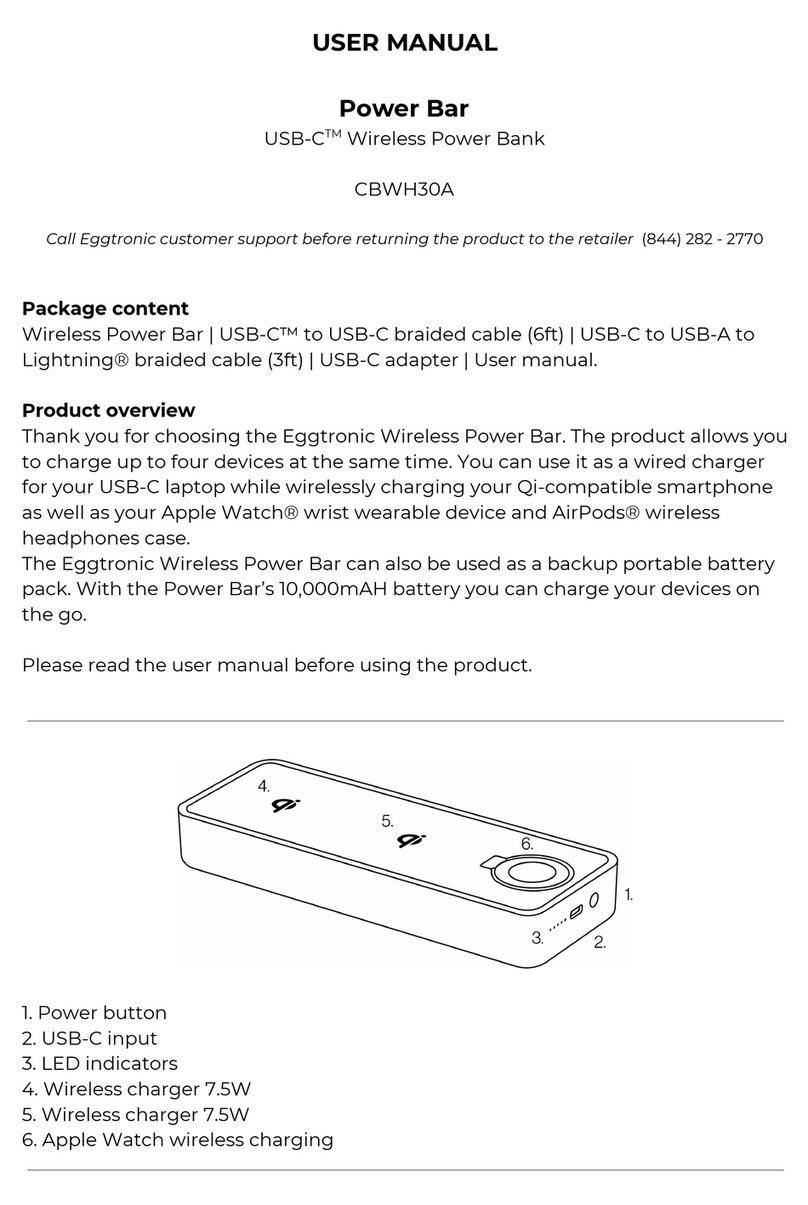

Rotor

O-Ring

Cable-Seal Strain Relief

U-Clip Insertion Point

Bearing Housing

Fitting

Features

Caution: U-clip

must be installed

before use.

GENERAL INFORMATION

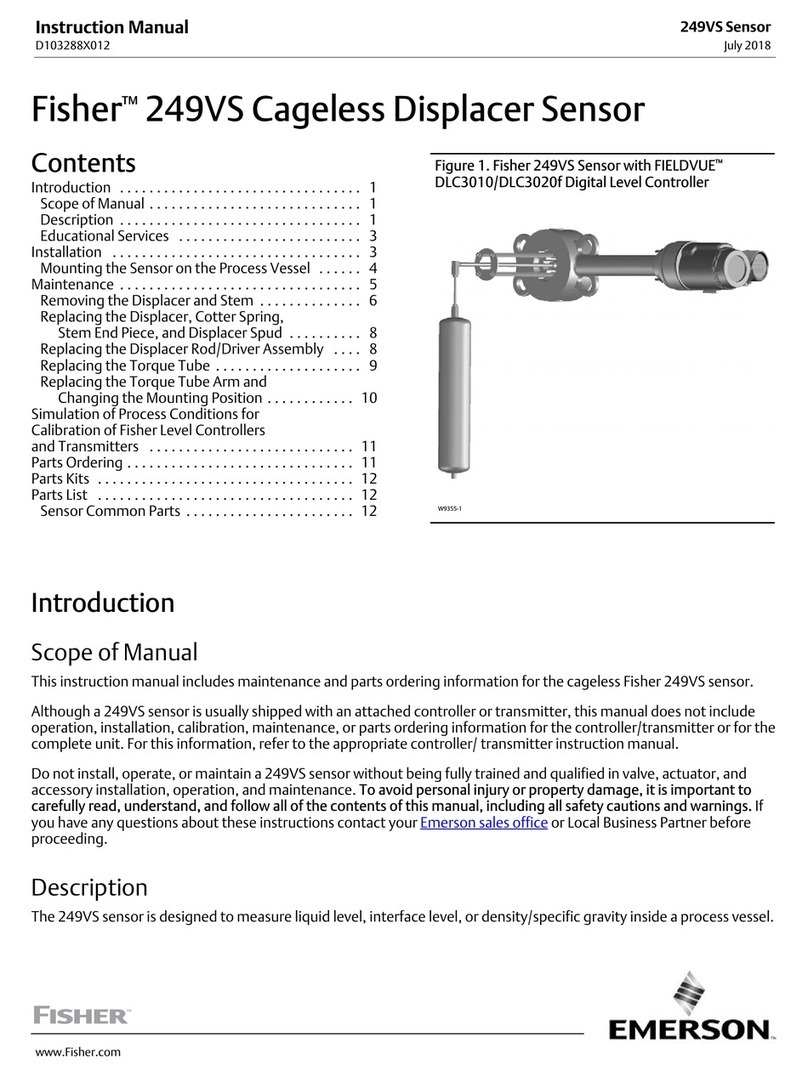

The TX800-Series are insertion turbine meters designed for use

in 1-1/2" to 8" pipe. High-quality jewel bearings and precision

shafts ensure long life and low friction. Available in 316

stainless steel, brass and PVC, sensor bodies are machined

from solid rod for maximum low-ow performance. The TX800-

Series use special ttings that ensure ease of installation and

correct depth setting in the pipe.

The rotation of the turbine is detected by a non-drag Hall-effect

sensor. Output is a pulse-type square wave, which can be sent

long distances (up to 2,000 feet) without a transmitter. This

signal can be connected directly to Seametrics controls and

displays, as well as PLC's, counters, and computer cards.

Seametrics TX800 meters are ideal for chemical proportioning

applications. If no display is required, a simple divider such as

the PD10 provides adjustable pump pacing. For rate and total

display, as well as pump pacing, the FT420 ow indicator can

be mounted directly on the TX800-Series, or remotely on a wall

or panel. The FT415 offers a battery-operated rate/totalizer

where power is not available.

TABLES AND DIAGRAMS

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com

Page 4

Specications*

Pipe Sizes EX11x/15x: 3” to 10” EX21x/25x: 10” to 48” (up to 72” optional)

Materials Shaft/Fitting 316 SS or Brass

Electrodes Hastelloy

Electrode Cap PVDF

Housing Cast powder-coated aluminum

Valve Assembly (15x/25x only) Bronze (stainless optional) with bronze ball valve

O-Ring (15x/25x only) EPDM

Power Full Power 12-25 Vdc, 250 mA

Low Power 12-25 Vdc, 40 mA average with 250 mA peaks

Flow Range 0.28 to 20 ft/sec (0.08 - 6.09 m/sec)

Fitting Size Required EX11x/21x EX15x/25x

1-1/2” FNPT 2” FNPT

Temperature Ambient 0˚to 160˚F (-17˚to 72˚C)

Fluid 32˚to 200˚F (0˚to 93˚C)

Pressure 200 psi (14 bar)

Minimum Conductivity 20 microSiemens/cm

Calibration Accuracy +/- 1% of full scale

Output Square wave pulse, opto isolated, 550 Hz@20ft/sec 6mA max, 30 Vdc forward

ow standard; reverse ow optional

Empty Pipe Detection Software, defaults to zero ow

Regulatory

GENERAL INFORMATION

*Specications subject to change. Please consult our website for the most current data (www.seametrics.com).

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com Page 5

INSTALLATION

Fitting Installation

TX800-Series meters require special ttings. The meter tting

must rst be installed in the pipeline. Straight pipe of at

least ten times the diameter upstream of the meter and ve

diameters downstream is strongly recommended in order to

achieve proper accuracy. These are minimum values. As the

diagrams on the the next page will show, you may need more

straight run under specic adverse circumstances.

If you can’t provide enough run to smooth out the turbulence

caused by valves, ttings, and changes in direction, some

decrease in accuracy may result. This does not mean that

the ow meter’s reading is meaningless, however. In some

applications (for instance, where the ow meter is part of

a control system, operating a valve or controlling chemical

addition), a repeatable reading may be more important than

a highly accurate one.

TX800-Series PVC meter tees are supplied with some

upstream straight pipe. The length provided may be less

than ten diameters upstream and ve downstream. It is not

advisable to connect directly to the end of these ttings with

a ow-disturbing device such as a valve or elbow. If possible,

straight pipe should be added to the upstream end of these

ttings.

Distorted Flows

A PVC tting is usually installed by solvent welding. The

stainless steel and brass meter ttings have female pipe

threads, requiring the appropriate male threaded ttings.

Saddle ttings (size 3” and above) require a hole to be cut in

the pipe. The recommended hole size is 1-3/4”. Caution: Never remove the u-clip retainer when

the pipe is under pressure. Always remove

pressure from the pipe before you attempt to

remove the meter. Removal under pressure

may result in damage or serious injury.

Meter Installation

After the meter tting is installed in the pipeline, the meter

can be installed in the tting. After noting the direction of the

ow arrow, press the meter into the tting as far as it will go.

Retain the meter in place by inserting the U-clip. The pin can

be installed from either side. It may be necessary to rotate the

probe back and forth slightly to start the pin into the slots on the

probe. Slide the pin in as far as it will go.

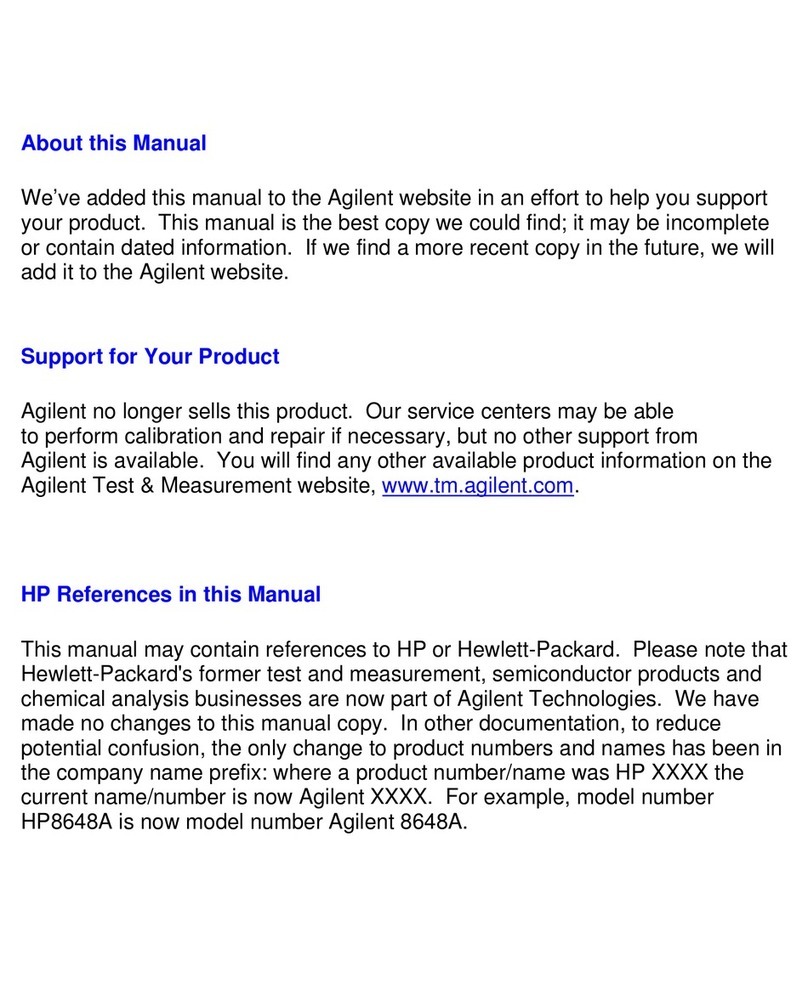

Horizontal (3 o’clock or 9 o’clock position) is the preferred

installation orientation, since it improves low-ow performance

and avoids problems with trapped air and sediment. (See

Orienting the Meter diagram below.) Bottom (6 o’clock), top

(12 o’clock), and vertical pipe installations are all acceptable if

required by the piping layout.

Orienting the Meter

Fair

Unacceptable if pipe

contains air

Best

Position

Fair

Unacceptable if pipe

contains sediment

Faster flow causes

meter to read high

FLOW

Distorted flow

profile

10X

Diameter Minimum

5X

Diameter Minimum

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com

Page 6

INSTALLATION

Straight Pipe Recommendations (X = diameter)

5X10X

Reduced Pipe

Two Elbows In Plane

Two Elbows, Out Of Plane

Expanded Pipe

Swirling Flow

Propeller Meter

Partially Open

Buttery Valve

Spiral Flow

5X

5X

20X

20X

30X

20X

5X10X

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com Page 7

INSTALLATION

Caution: These ow sensors are not recommended for installation

downstream of a boiler feedwater pump where installation fault may

expose the ow sensor to boiler pressure and temperature. Maximum

recommended temperature is 130°F (Plastic), 200°F (Metal).

Full Pipe Recommendations

Better InstallationPossible Problem

Air can be trapped Allows air to bleed off

Better InstallationPossible Problem

Allows air pockets to form at sensor Ensures full pipe

Post-valve cavitation can create air pocket Keeps pipe full at sensor

Better InstallationPossible Problem

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com

Page 8

CONNECTIONS

POWER

SENSOR

ENGD

+

_

_

+

S

PULSE

OUT 2

PULSE

OUT 1

+

_

+

_

RED

WHITE

BLACK

+

_7-45Vdc

Supply

Flow

Sensor

FT430 Pulse

Pass-thru

Pulse Responsive

Metering Pump

_

+

S

_

+

_

+

_

+

FT430

FT440

POWER

SENSOR

ENGD

+

_

_

+

S

PULSE

OUT 2

PULSE

OUT 1

+

_

+

_

RED

WHITE

BLACK

+

_9-30 Vdc

Loop Power

Supply

Flow

Sensor

FT440

Electronic

Metering Pumps

_

+

S

_

+

_

+

_

+

4-20mA

Device

+

_

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com Page 9

CONNECTIONS

Connecting to PLC's and other non-Seametric Controls

Red

White

Black

Red

White

Black

Signal

+DC Voltage

Ground

Signal

+DC Voltage

Ground

Figure 1

Figure 2

Input Designed for Current

Sinking (NPN) Devices

Input Designed for Current

Sourcing (PNP) Devices

2.2k Ohm Pull-up

Resistor

NPN

Device

NPN

Device

Red

White

Black

Red

White

Black

Signal

+DC Voltage

Ground

Signal

+DC Voltage

Ground

Figure 1

Figure 2

Input Designed for Current

Sinking (NPN) Devices

Input Designed for Curren

t

Sourcing (PNP) Devices

2.2k Ohm Pull-up

Resistor

NPN

Device

NPN

Device

FT450

POWER

SENSOR

ENGD

+

_

_

+

S

PULSE

OUT 2

PULSE

OUT 1

+

_

+

_

RED

WHITE

BLACK

Micropower

Flow Sensor

FT450 Pulse

Pass-thru

Pulse Responsive

Metering Pump

Current Sinking

Polarity-Sensitive

Lithium C,

3Vdc

Replaceable

Battery

_

+

S

_

+

_

+

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com

Page 10

OPERATION AND MAINTENANCE

Calibration (“K-factor”)

The K-factor represents the actual number of pulses per gallon

the meter produces during a ow test. This number can be

entered into your electronic control to make it read properly.

If the TX800-Series meter is ordered with a tee tting, it is

factory-calibrated in the tting and the K-factor is indicated

on the side of the tting. For saddle and weldolet K-factors,

see the K-factor calculator located at the bottom of the www.

seametrics.com home page.

Find Your K-Factory Here

10031295

MF81T-P200

K: 53.6

Modularity

Any of the TX800-Series ow sensors can have electronic

modules mounted directly to them, either at the time of order

or by adding an adaptor kit in the eld (part number 102632).

Alternatively, the ow sensor and indicator or transmitter can

be installed remote from each other. The FT420 is an indicating

transmitter (rate, total, 4-20 mA output), and the AO55 is a

blind 4-20 mA transmitter. For data logging, add the DL76. The

FT520, which provides batching and other functions, is suitable

for remote installation.

Output

The output is a current-sinking pulse (square wave) compatible

with many controls in addition to the Seametrics indicators and

transmitters. The most common of these are water treatment

controllers and programmable logic controllers (PLC’s). For

these units, it is sometimes necessary to provide a pull-up

resistor if the controller does not provide for a current-sinking

output. (See the section on “Connecting to PLC’s and other

controllers” before connecting to a non-Seametrics control.)

Fittings

Since the TX800-Series sensors are not adjustable, they must

be purchased with ttings appropriate to the application. The

TX81x is sized for ttings of 1 1/2” to 3”. The TX82x is for ttings

of 4” and 8”. Each tting insures that the ow sensor is installed

at the correct point. Every ow sensor and every tee tting is

wet calibrated. Saddle ttings are normally not wet calibrated,

because they are eld-installed on a pipe. In PVC however it is

possible to order a saddle pre-installed on a standard length of

pipe, in which case the entire assembly is wet-calibrated. For

all other saddles, the K-factor (pulses per gallon) is established

through testing with various standard schedules of pipe and

provided with the saddle.

Minimum Flow

As with any other ow sensor, there is a rate below which the

TX800-Series sensor cannot read. Check the ow rate table

below for the minimum ow rate detectable by the sensor for

a given pipe size.

1½” 2” 3” 4” 6” 8”

Min 2.8 5 11.5 19.8 45 78

Max 190 314 691 1190 2700 4680

Flow Rate (Gallons per Minute) Flow Rate (Liters per Minute)

1½” 2” 3” 4” 6” 8”

Min 10.60 18.93 43.53 74.95 170.34 295.26

Max 719.23 1189 2616 4505 10221 17716

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com Page 11

Rotor Replacement

It is unusual for a rotor to require replacement due to damage

sustained in normal service. More commonly, the meter is

dropped while it is out of the pipe. Another reason for rotor

replacement is shaft wear after long service. Rotors are easily

eld-replaced.

To install a rotor, follow these steps:

1. Unscrew the threaded bearing housings to expose

the shaft ends. If bearings are being replaced,

back them completely out.

2. Remove the rotor. Put the new rotor in its place.

3. Thread in one bearing housing part way, then the

other. Take care to start the end of the shaft into

the bearing hole before tightening further.

4. Screw in bearing housings until they bottom

Note: Do not use excessive force.

5. Check for free spin. Blowing lightly on the rotor

should result in it spinning rapidly and coasting to a

smooth stop.

Rotor Replacement

Signal Troubleshooting

The ow sensor has only one moving part, the rotor. If this is

turning properly and there is no signal, the magnetic sensor

is not operating properly. To check the signal, apply 12 Vdc

regulated* power to the red (+) and black (-) leads. Set a

multimeter to voltage reading. Put the positive multimeter

lead on the red wire and the negative lead on the white wire.

Slowly turn the rotor. Voltage reading should swing between

+12 Volts and 0 Volts as the rotor turns. If it does not, the

solid-state magnetic sensor is not working properly. Checking

for continuity is not a useful test of these sensors.

*NOTE: An unregulated power supply can exceed max voltage of

micro powered sensor (gray cable) and damage sensor.

Sensor Replacement

It is very unusual for a sensor to require replacement in

normal use. The primary cause of sensor failure is overvoltage

(inadvertent connection of line voltage, for example) or

incorrect polarity on hookup. The sensor is replaced by

removing the strain relief, then threading out the sensor

retainer plug. Remove the entire sensor capsule by pulling

on the cable. The new sensor capsule can then be installed,

orientation is not critical. Replace the retainer plug, and then

replace and tighten the strain relief.

OPERATION AND MAINTENANCE

Caution: Never remove the u-clip retainer when the pipe is under pressure. Always remove

pressure from the pipe before attempting to remove the meter. Removal under pressure may

result in damage or serious injury.

Shaft

Turbine Rotor

Bearing

Housing

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com

Page 12

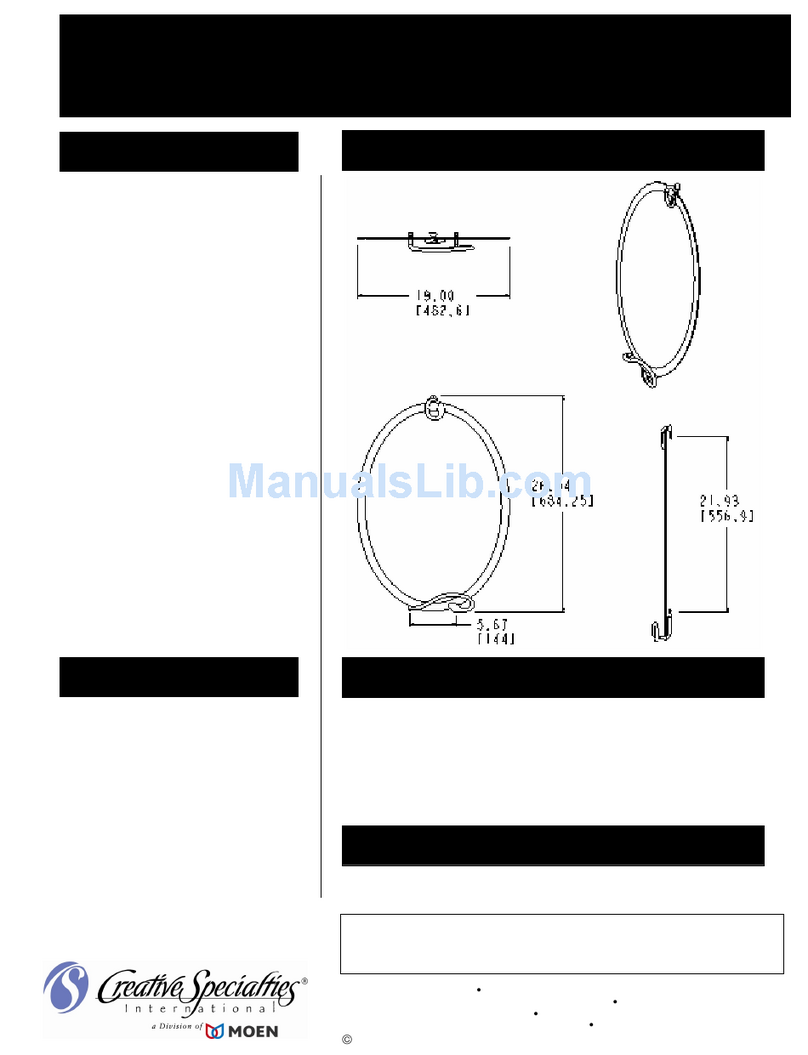

OPERATION AND MAINTENANCE

TX800 Series Parts List

1a

8

9

6a

4a

7a

3a

2a

11

15

14

13

12

TX800 Series Parts

White Housing

1a thru 7a

Blue Housing

1b thru 7b

1 Upper housing/

electronics

Contact service

representative

for your specic

model

Contact service

representative

for your specic

model

2 Housing Gasket/Seal 102025 100411

3 Lower housing Not eld

replaceable

Not eld

replaceable

4 Housing screw/washer

kit (4 each)

100414 100414

5Plug, steel (battery units) 100360 100360

6 Strain relief kit, small

(includes 2)

100364 100364

7 Strain relief kit, large

(includes 1) (externally

powered units)

101850 101850

8 Sensor pickup 100508 (Micropower, green cable,

FT450)

100419 (Standard, blue cable,

FT430/440)

9 Sensor retaining screw 100298

10 U-clip, retainer 100154

11 O-ring 100264 (EPDM)

100219 (Viton®)

12 Body See distributor

13 Bearings (includes 2) 103315

14 Rotor assembly 101862

(Kynar®/tungsten carbide)

15 Rotor repair kit (#13 &

#14 above)

101912

(Kynar®/tungsten carbide)

5a

10

Blue Housing

1b

6b

4b

7b

3b

2b

5b

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com Page 13

TROUBLESHOOTING

Problem Probable Cause Try...

No signal after installation Insufcient ow Reduce pipe size if possible, use different type of

sensor

Bad connections to control electronics Reconnect if necessary

Incompatible control Use different power supply

Add pull-up resistor (see page 9)

Damaged or missing rotor Obtain new rotor and replace (see page 11)

Failed magnetic sensor Replace magnetic sensor

Inaccurate metering Not enough straight pipe between meter

and severe ow disturbance

Move meter away from ow

Wrong K-Factor entered Check K-Factor (see page 10), enter correct

K-Factor in your control

Magnetic sensor failing to pick up each

blade

Replace magnetic sensor and rotor

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com

Page 14

TX800 SERIES INSTRUCTIONS

Seametrics • 253.872.0284 • www.seametrics.com Page 15

Seametrics • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • www.seametrics.com LT-65200048r1.1-20161018

10/18/16

This manual suits for next models

2

Table of contents

Other Seametrics Accessories manuals

Seametrics

Seametrics INW CT2X User manual

Seametrics

Seametrics CT2X User manual

Seametrics

Seametrics TempHion User manual

Seametrics

Seametrics EX80 Series User manual

Seametrics

Seametrics Multi-Parameter Smart Sensor User manual

Seametrics

Seametrics IP800 Series User manual

Seametrics

Seametrics PT2X User manual

Seametrics

Seametrics INW LevelSCOUT User manual

Seametrics

Seametrics DO2 User manual

Seametrics

Seametrics TX81 Series User manual