Installation

Wall Mounting. Usingthefourscrewsprovided, attach

the two foot brackets to the sides of the enclosure. Then

attachthe unit toany secure surfaceby inserting screws

through the mounting holes in the foot brackets.

Panel Mounting. Follow the dimensions given for

“Panel Cutout”. Be sure to include the four corner

screw holes. After cutting and drilling, place the front

plate on the front side of the panel with its gasket

against the panel, and the remainder of the square

housing on the back side. Slide the screws through the

four holes drilled in the panel, and into the threaded

holes in the housing. Tighten until the gasket is firmly

compressed against the panel.

Expose Terminals. Removethe four screws which hold

the front plate to its flange. Remove the front plate. The

display board is attached to this front plate. It is also

connected to the power board by a ribbon cable. For

convenience, this cable can be disconnected while

making connections. Connections can be made inside

the enclosure, or the terminals can be unplugged for

easier access, by gently tugging on them.

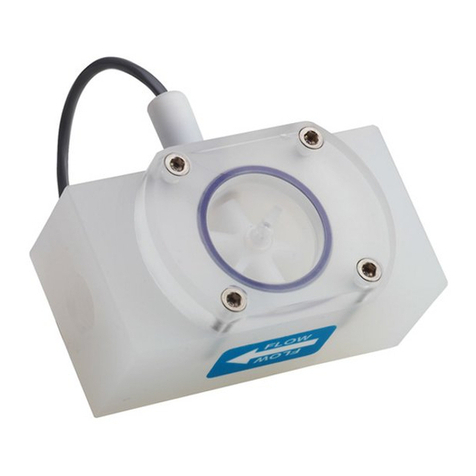

Sensor Connection. Followthe “Connections”diagram

to connect either two or three wires from the flow meter

or flow sensor.

MonitorAlarm Connection.Connect thealarm devices

to the appropriate relay terminals. Note that the relays

havebothnormally-open (NO)and normally-closed (NC)

contacts.

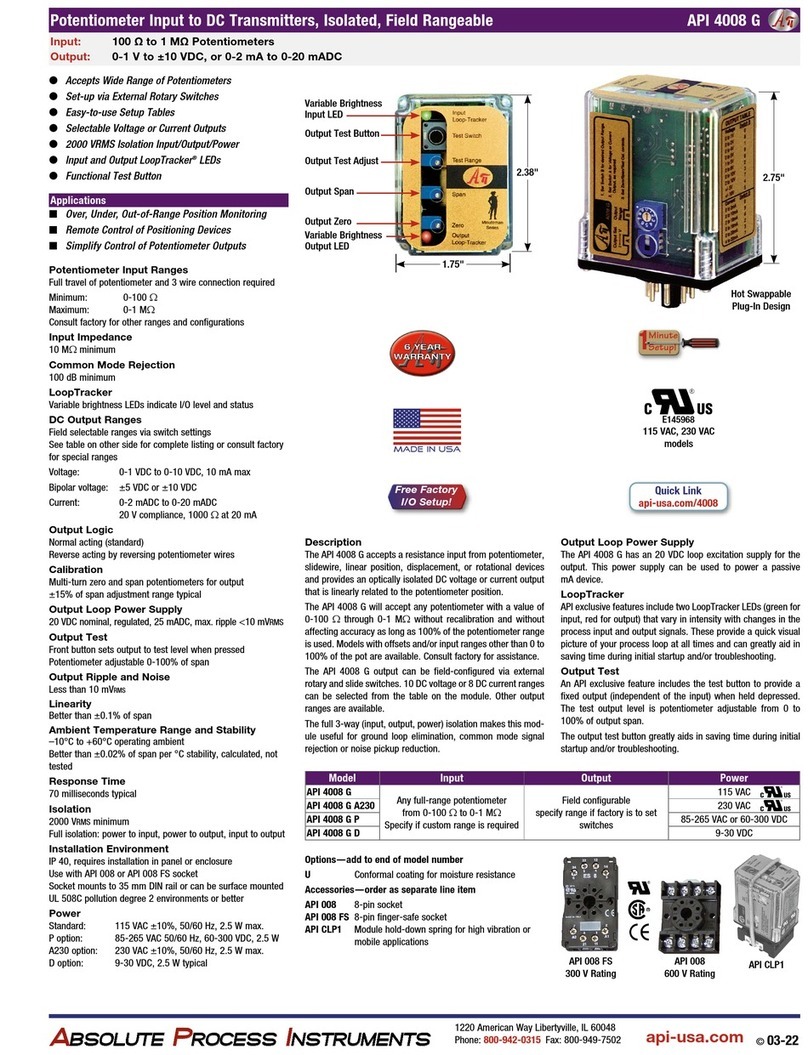

Analog Connection. This output can be configured 4-

20 mA, 0-10 V or 0-5 V by placing a jumper in the cor-

rect position on the analog header. The swith next to

the header selects active (powered) or passive

(unpowered) output. When using the 12 VDC powered

input you may only select passive output.

Power Connection. Connect AC or DC power as

desired to the appropriate terminals. For safety, if using

AC power, be sure to connect the ground terminal

provided to a good earth ground. If using DC power, be

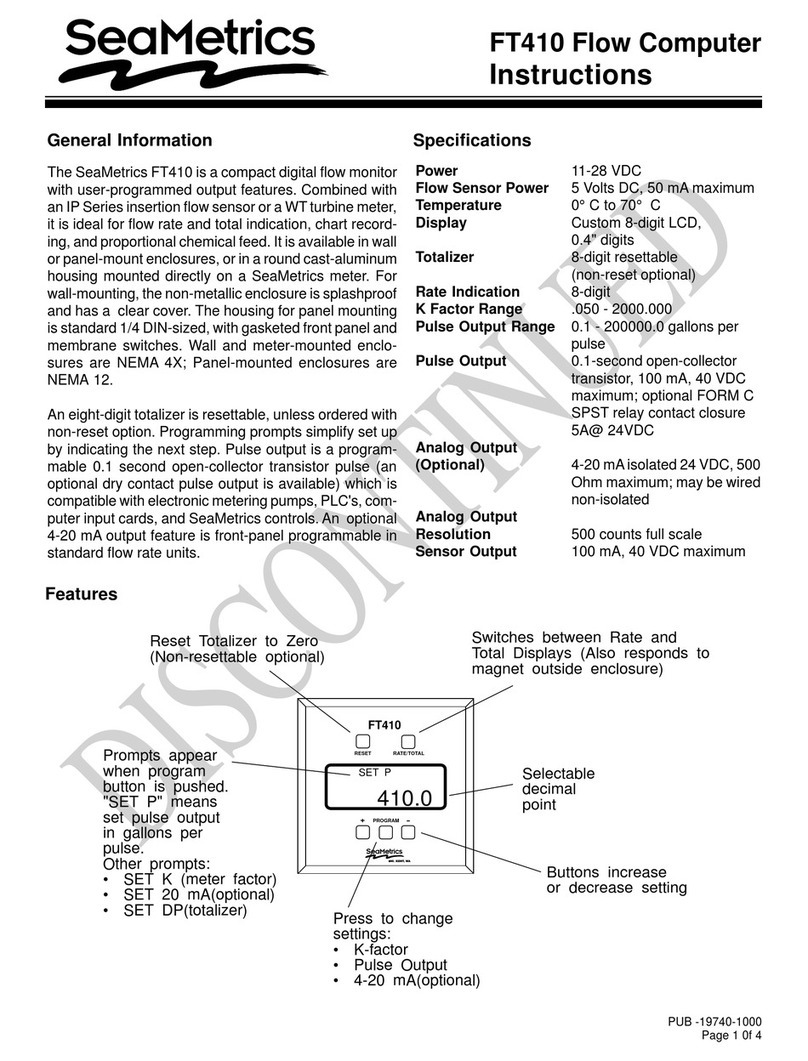

Settings

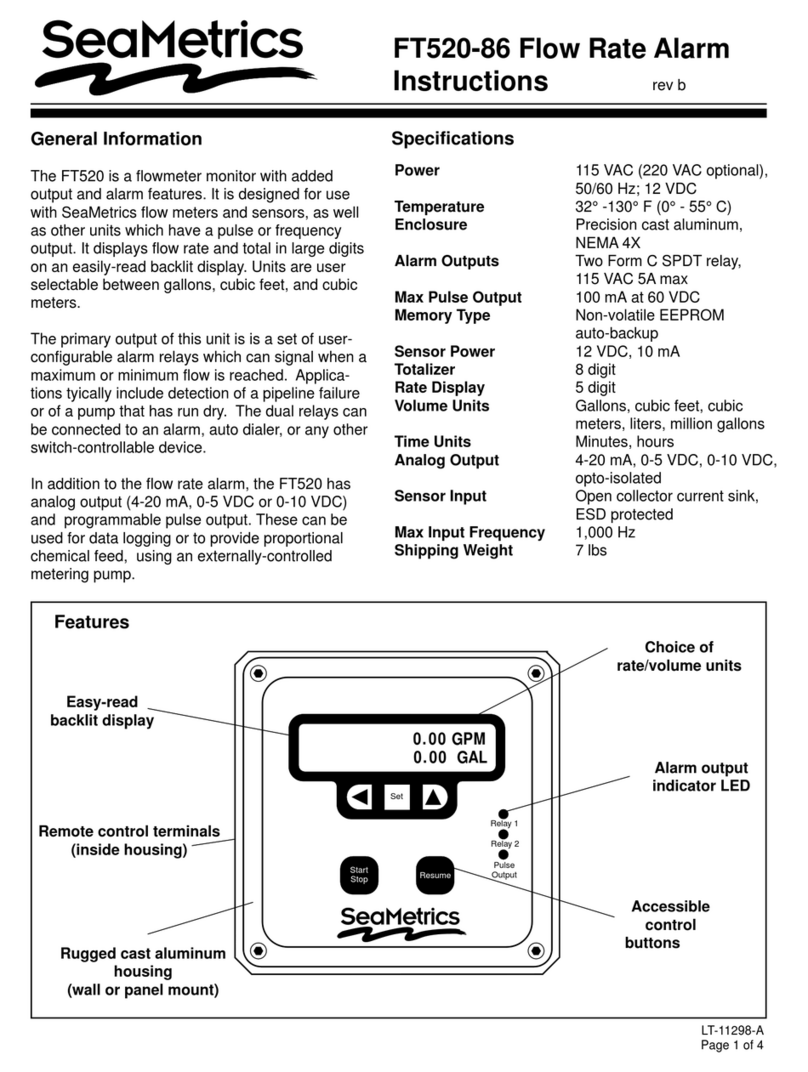

Set Units. Press . Use to select volume

units. Use to select the particular unit desired

(gallons, liters, etc.). Then use to switch to time

units. Again, select the unit desired. Press for

next menu item.

Set Decimal. Use to select zero, one, or two

decimalplaceson the flowunits. Press toadvance

to the next menu.

Set K-Factor. The unit will not function properly

until this number is entered. It is simply the number

of pulses which the flow meter or flow sensor puts

out per gallon of liquid. It is marked on the Model/

Serial tag of SeaMetrics flow meters and flow

sensor fittings. On adjustable flow sensors, the K-

factor must be taken from the chart in the flow

sensor instructions, based on pipe size. Press

for next menu item.

Set Pulse Out. An output pulse is activated at the

selected volume intervals if this feature is in use.

Otherwise, it does not need to be set. Press for

next menu item.

Set Time Period. This is the monitoring period at

Caution: When the

control is powered up, relay

or analog outputs may be

present. If this could be a

hazard, wait to make external

connections until program-

ming is complete.

2 of 4

!

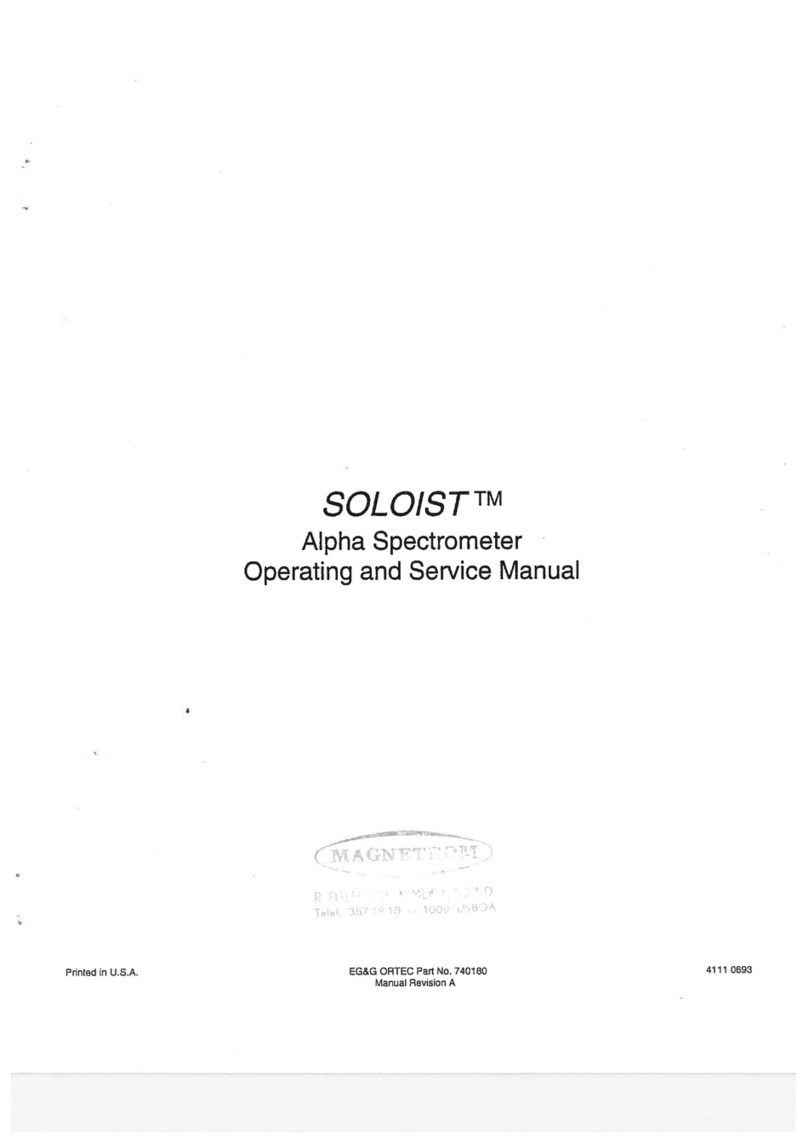

SETTINGSOPERATION MODE

SET

SET

SET

SET

SET

SET

SET

TO CLEAR TOTAL

PRESS UP & LEFT

SET 20 mA RATE

123456 GPM

return to

operation mode

Flow

Monitor

Set Pulse Out

1.00 Gal

GAL

MINUTE

0:00:00

0 GAL

ELAPSED

0 GPM

0 GAL

Flow

Rate

SET

SET

Alarm Point:

1234 GAL

Time Period:

12 HOURS

Set Decimal

0.00

Set K-factor

60.00

Displays

SET

SET