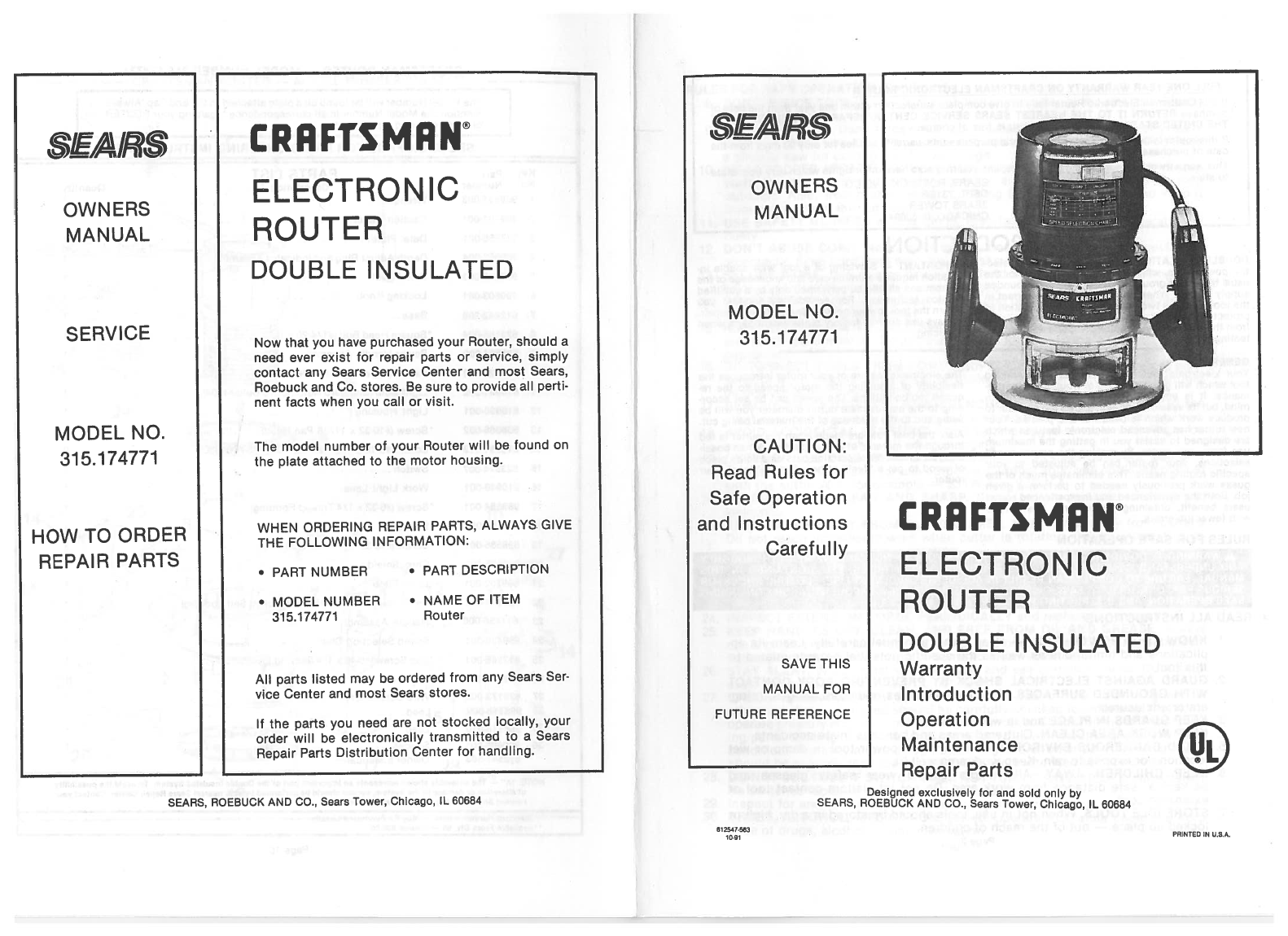

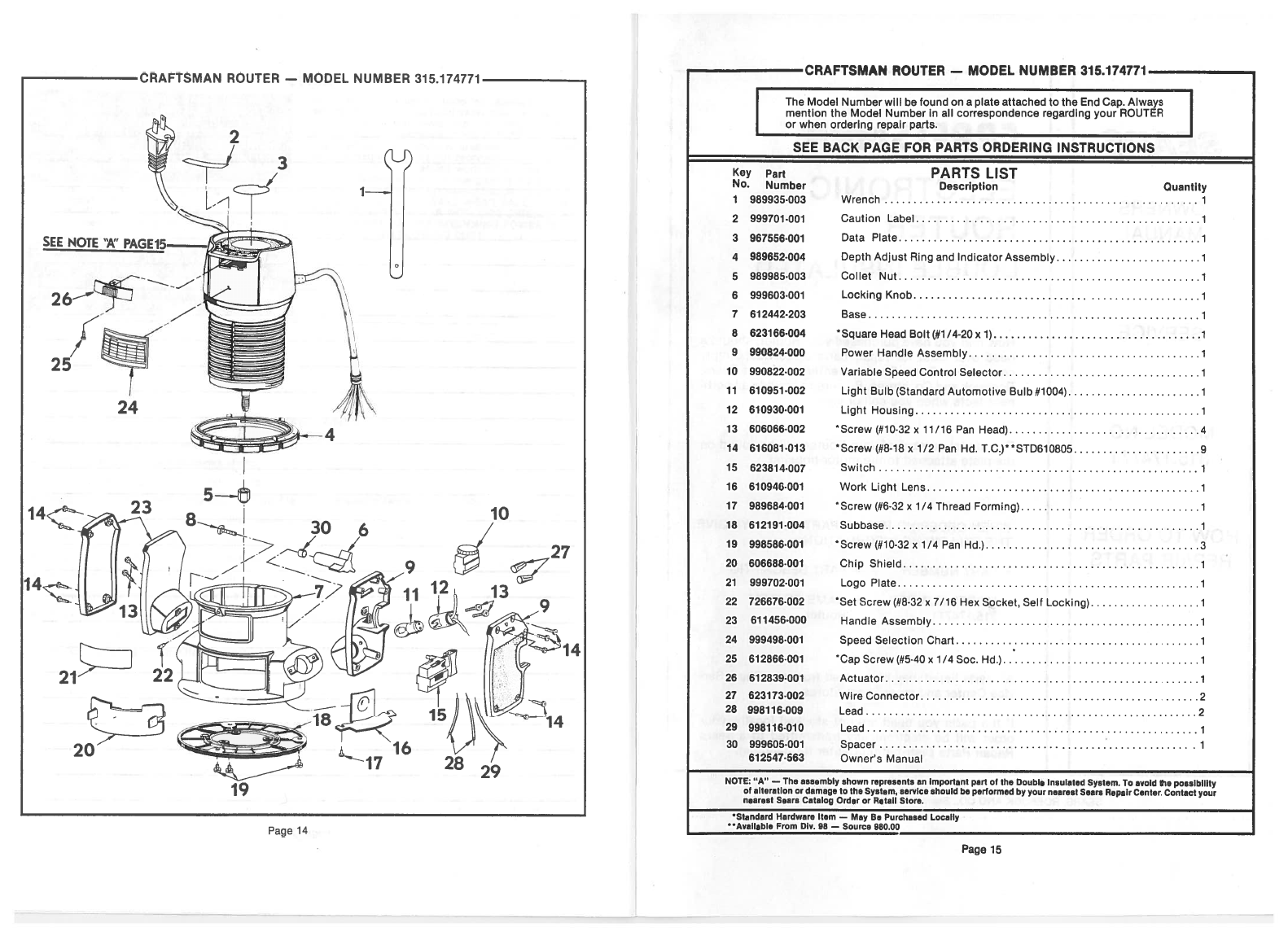

Sears CRAFTSMAN 315.174771 User manual

Other Sears Wood Router manuals

Popular Wood Router manuals by other brands

Clarke

Clarke Contractor CR3 Operation & maintenance instructions

Vision Engraving & Routing Systems

Vision Engraving & Routing Systems 1624R installation guide

Triton

Triton TMNRTR Operating/safety instructions

Status

Status RH1800 Original instructions

Asist

Asist AE4F120DN Instructions for use

Sealey

Sealey SV20 Series manual