Sebo 370 comfort User manual

SE

0 370

electronic

SE

BO

370 electronique

(I

For Household Use Only

Pour utilisation domestique seulement

For warranty purposes please retain a copy

of

your original purchase receipt.

5arder

LIne

copie de votre

rec;u

en

cas de besoin d'utrlisaton de

la

garantie.

MPORTANT SAFETY INSTRUCT ONS

When using an electrical appliance, basic precautions must always be followed,

including the following

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE

WARNIN

G:

To

reduce the risk of fire, electric shock,

or

injury:

1.

Do not leave appliance when plugged in. Unplug from outlet when not

in

use and before servicing.

2.

Do

not

use

outdoors

or

on

wet

surfaces.

3.

Do

not

use near small children

or

pets. Do not allow

to

be used as a toy. Close attention is necessary

when used

by

or

near children.

4.

Use only as described

in

this manual. Use only manufacturer's recommended attachments.

5.

Do not use with damaged cord

or

plug. If appliance is not working as it should, has been dropped,

damaged, left outdoors, or

dropped

into water, return it to a service center.

6.

Do

not

pull

or

carry

by

cord, use cord as a handle, close a

door

on cord,

or

pull cord around sharp edges

or

corners. Do

not

run appliance over cord. Keep cord away from heated surfaces.

7.

Do

not

unplug by pul'Iing on cord.

To

unplug, grasp the pl'ug,

not

the cord.

8.

Do

not

handle plug or appliance with wet hands.

9.

Do

not

put

any object into openings. Do not use with any opening blocked; keep free

of

dust, lint, hair,

and anything that may reduce air flow.

10. Keep hair, loose clothing, fingers, and all parts

of

body

away from openings and moving parts.

Do

not

place fingers or other

body

parts under vacuum unless unplugged.

111.

Do not

pick

up anything that is burning

or

smoking, such as cigarettes, matches, or hot ashes.

12. Do not use without dust bag and/or filters

in

place.

13. "fum off all controls before unplugging.

14. Use extra care when cleaning on stairs.

15. Do not use

to

pick

up

flammable or combustible liquids such as gasoline

or

use

in

areas where

they

may

be present.

16. Machines can cause a fire when operated near flammable vapors or materials. Do

not

operate this

machine near flammable flu'ids,

dust

or vapors.

17. Maintenance and repairs must be done by qualified personnel.

18. Use only identical replacement parts. See instructions for Servicing

of

Appliances.

19. Do

not

use machine as a step.

20. Do

110t

leave machine

in

one place with machine turlled on, for extended periods.

21. Do

110t

use the handle

in

the

dust

bag housing cover

to

carry the machine.

SAVE

THESE INSTRUCTIONS

mportant Safeguards

Accidents due to misuse can only be prevented by those using the machine.

To

guard against injury, basic safety

precautions should be observed, including the following:

WARNING: ELECTRIC SHOCK COULD OCCUR IF USED

Read and follow all safety instructions. OUTDOORS OR ON WET SURFACES

This vacuum cleaner

is

designed to be safe when used to perform cleaning functions. Should damage

occur

to

electrical or mechanical parts, cleaner should be repaired by SEBO

or

aljthoriLed SEBO dealer before using

in

order to avoid further damage

to

machine or physical injury to user.

A damaged

power

cord could cause electrical shock

and/or

fire.

To

minimize this possibility observe the

following precautions:

Do not run cleaner over

power

cord.

Avoid closing doors on

power

cord, pulling it around sharp edges, or placing

sharp~edged

objects

upon it.

Wind cord no tighter than is necessary

to

retain it on the cord hooks.

When disc;:onnecting

power

cord from electrical outlet, grasp the p'lug. Pulling it out by the cord itself

can damage cord insulation and internal connections to plug.

Your vacuum cleaner creates suction and contains a revolving brush.

To

avoid bodily injury from suction or

moving parts, vacuum cleaner brush should not be placed against, or

in

close proximity

of

loose clothing, jewelry,

hair or

body

surfaces while cleaner

is

connected

to

electrical outlet. Cleaner should not be used to vacuum

clothing whil'e it is being worn.

keep

children away from machine when

in

operation or plugged

in.

If used on plush carpet or carpet with thick padding, turn off unit when handle

lis

in

upright position. When using

accessory tools, keep floor brush off carpet by keeping handle

in

Ilocked position and lowering

hand~e

with one

hand

to

raise brush off floor. Operate accessories with other hand.

Always plug your cleaner into a standard wall outlet. Use of extension cord or lignt socket with inadequate cur-

rent-carrying capacity could result

in

electric snock or fire hazard.

Disconnect cleaner from electrical outlet before servicing, such as changing bags or filters.

You

could receive

bodily injury from moving parts

of

macnine shoulld switch accidentally be turned on. Disconnect cleaner from

electrical outlet before detac'hing powerhead.

Do not use your vacuum cleaner

in

areas where flammable and/or explosive vapor or dust is present to avoid

possibility

of

fire or explosion. Some cleaning f,luids can produce such vapors. Areas on which cleaning fluids

have been used shou'ld be completely dry and thoroughly aired before being vacuumed.

To

avoid fire ha;mrd,

do

not pick up matches, fireplace ashes, or smoking material with cleaner.

Keep your work area well lighted to avoid picking up harmful matenials (such as liquids, sharp objects, or burning

substances) and avoid tripping accidents.

Use care when operating the cleaner on irregular surfac:es such as stairs. A falling cteaner could cause bodily

injury and/or mechanical damage. Proper storage

of

machine

in

an out-of-the-way area immediately after use

will also prevent accidents caused by tripping over cleaner.

Store your vacuum indoors

in

a cool,

dry

area not exposed

to

the weather

to

avoid electrical shock and/or

cleaner damage.

Exercise strict supervision

to

prevent injury when using vacuum cleaner near children or when

chi1ld

is al,lowed

to

operate vacuum cleaner. Do not allow children

to

play with vacuum cleaner and never leave cleaner plugged

in

arld unattended.

SAVE THESE INSTRUCTIONS

VACUUM CLEANERS WITH ROTATING BRUSHES

CAN DAMAGE

SOME

TYPES OF FLOORS

WARNING

The quality, condition, coating, texture, age, and manufacturing technique of

all

floor surfaces

vary.

Therefore,

upright vacuums with rotating brushes, including your SEBO, may damage some floor coverings or surfaces.

High-gloss hardwood floors, Berber carpets, cushion vinyl, and some wool loop carpets

are

particularly vulnera-

ble

to

damage by rotating brushes. When possible, consult the materials supplied by your floor's manufacturer

for information on proper upkeep and cleaning.

To

ensure that your new SEBO vacuum cleaner

is

compat1ible

with your floor, please test the vacuum cleaner on each type

of

flooring surface in a small inconspicuous area to

determine if any damage occurs. If damage occurs, stop using vacuum cleaner immediately!

WARN NG

As with all vacuum cleaners with rotating brushes, (lOlding the vacuum cleaner

in

a stationary position on the

floor for

an

extended period

of

time may damage any type

of

floorir)g.

Therefore, use a normal, continuous, back-and-forth motion when

the

vacuum is

in

use. When using the hose

and attachments, make sure the handle is

in

the upright, locked position, and watch that the brush roller

does not remain

in

contact with the flooring surface. Also,

do

not tilt the powerhead on

to

the floor when

using the hose. These situations can cause marking or damage.

Caution! -Safety Advice

Do not re-use bags.

Do not wash filters.

Do not remove any screws.

Do not leave machine plugged-in when not

in

use.

Do not place brush head (powerhead) over rug / carpet edges.

OPERA ING INSTRUCT ONS

HOW TO START

In

addition, to the safety instructions, you should be aware

of

specific limitations of your machine.

'Because

of

your machine's aggressive cleaning power, do not use the machine on long shag, delicate or

Ihand

woven carpets. These fine carpets may be damaged by the brushes.

Please try your machine

in

an

inconspicuous

spot

of

each kind

of

flooring it is supposed to be used on

to determine whether the flooring

is

likely

to

face physical damage.

If so,

don't

use machine.

Before turning on your machine, ensure that you have a firm hold on the handle grip to keep the

machine from moving forward.

1.

Turn the

quick

release cord hook

in

the up position.

2.

Release the power cord plug from the power cord and lift the cord off the upper cord hook.

NOTE:

To

reduce the risk of electric shock, this machine has a polarized plug; one blade

i's

wider than

the other. This plug will fit

in

a pol'arized outlet only one way. If the plug does not

,fit

futly

in

the outlet,

reverse the plug. If it still does not fit, contact a qualified electrician

to

install the

proper

outlet. Do not

change the plug

in

any way.

3.

With the switch

in

the "0"

(OFF)

position, plug the polarized

power

cord into a 120 Volt outlet located

near the floor.

NOTE: Only connect

to

the outlet type specified on the

seriall

number plate underneath the machine.

WARNING!

• DO NOT plug

in

if

switch

is

in

the"I" (ON) position. Personal injury or

damage could result

• DO NOT use outlets above counters. Damage to items

in

the

surrounding area could occur.

1----l-

2----1

12

3 13

4

5

6

7 14

15

16

17

18

19

20

21

22

10

11

+-----12

2

"'--Ht-13

/"'1l~~---27

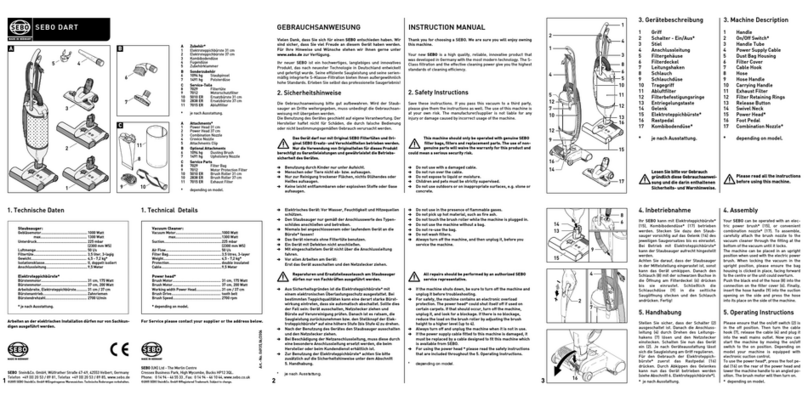

SESO 370 electronic

SESO 370 electronique

1 Handle grip

2 l=iandle assembly

3

Ba9'

full ifldicator

4

On

I Off switch

5 Cover release latch

6 Exhaust filter cover

7 Front cover

8 Motor cover

9 Power head

10 Locking catch

11

Foot pedal

12

Hose

13 Retaining ring

14

Cable

15

Attachment tube handle

16

Handle catch

17

Carrying handle

18 Cable hook

19

Attachment tube

20 Dust bag housing

21

Crevice nozzle

22 Upholstery nozzle

23 Pile adjustment knob

Assembling the vacuum cleaner

Put the power head

(9)

on

the floor with swivel

neck

(26)

and support lever

(27)

upright. Turn

the locking catch

(10)

on

tile

filter bag housing

(20)

to the left and place it carefully on the

swivel neck and the support lever. Then turn

the locking catch back.

To

lock the handle turn the handle catch

(16)

at the handle joint of the filter bag housing

(20)

forward, then slide the handle assembly

(2)

in

as

far

as

possib'le and lock

it

with the handle

catch.

Insert the attachment tube

(19)

into its storage

position on the side of the machine. The

attachment tube handle

(15)

must be placed on

the projection

(24).

Slide the proper end of the

hose into the tube

(19).

To

connect the hose with the filter bag housing

insert the black hose end into the connecting

tube

(25)

and slide it

in

completely.

To

unlock

the hose press the retaining ring

(13)

at the

projecting sections.

1.

Poignee du manche

2.

Assemblage du manche

3.

Indicateur "sac plein"

4.

Interrupteur AllumelEteint

5.

Levier de degagement du couvercle

6.

Couvercle du filtre d'echappement

7.

Couvercle avant

8.

Couvercle du moteur

9.

Tete

de

I'aspirateur

10.

Attachement du levier

11. Pedale

12. Tuyau

13. Anneau

de

retenue

14. Cordon

15. Attachement du tuyau supplementaire

16.

Attachement de

la

poignee

17. Poignee de transport

18. Crochet du cordon

19. Tuyau supplementaire

20. Logement du double sac apoussiere

21. Suceur pour

les

recoins

22. Suceur pour les tissus d'ameublement

23. Bouton de reglage

de

la

pile

Assemblage de I'aspirateur

Placer

la

lete de I'aspirateur

(9)

sur

Ie

sol avec

Ie

pivot du manche

(26)

et

Ie

levier de support

(27)

vers

Ie

haut. Tourner vers la gauche

Ie

levier

verrouilleur

(10)

du logement du sac

11

poussiere

(20)

et

Ie

placer doucement sur

Ie

pivot du

manche et sur

Ie

support

du

levier. Replacer

ensuite

Ie

levier fermoir vers I'arriere.

Pour verrouiller

Ie

manche, tourner

Ie

loquet du

manche

(16)

au

joint du manche du logement du

sac filtre

(20)

vers I'avant, puis inserer I'assemb- lage

du

mancile

(2)

aussi profondement que

possible et I'attacher avec

Ie

loquet du manche.

Inserer

Ie

tube supplementaire

(19)

dans sa posi- tion d'entreposage sur

Ie

cote de I'aspirateur.

Le

manche du tube supplementaire

(15)

do

it

etre

place sur

la

saillie

(24).

Placer

Ie

bout correct du

tuyau dans

Ie

tube

(19).

Pour brancher

Ie

tuyau

au

logement du sac filtre,

engager

Ie

bout du tuyau noir dans

Ie

tube

de

connexion

(25)

et

I'inserer completement. Pour

degager

Ie

tuyau, faire pression sur

I'an~neau

de

retenue

(13)

11

I'endreit de la saillie.

Preparation / Franzosisch

23

Maintenance / Entretien

Brush control

The electronic brush control monitors the

operation of the brush.

Green light: Brush correctly set and running.

Green light and red light: Adjust the brush

setting by turning the Pile adjustment knob

(23)

to a lower number.

If the lights still

show

at position number one

the brush strip is worn out and must be

replaced.

Red light: The brush has become blocked and

is

not turning. Switch off. Unplug from the

outlet and clear the blockage.

Filter level indicator

If warning light

(3)

comes on check:

a)

Is

the dust bag full?

b)

Is

there a blockage

in

the hose

or

power

head?

Swivel neck latch

To

release the machine from the upright

postion depress the foot pedal

(11)

Changing the paper bag

If red light

(3)

shows, change paper filter bag.

To

do this first pull cover release latch

(5)

-forward and lift the cover from the dust bag

housing. Slide the dust bag sealing plate

(28)

from the holder

(29).

Slide the sealing plate

(28)

of

a new bag into the holder and push firmly in.

Insert cover into

dLJst

bag housing. Push it

forward then lock it

in

place by pushing down

the cover release latch.

Changing the motor filter

Hospital Grade Filter (30, Part-No. 1875) needs

to be replaced after using 20 filter bags to

maintain HIGH GRADE FILTRATION. Lift the

front

of

the filter slightly and slide it

out

of

its

slot. Insert a new Hospital Grade Filter.

N.

B.

The Hospital Grade Filter

is

not

washable.

Changing the exhaust filter

Change the exhaust filter (31. Part-No. 1878)

always with the

motor

filter (30). Press the

button and slide the exhaust cover

(6)

to the

side.

Never use the machine without correctly

attached filters.

Controles de

la

brosse

Le

contr61e electronique de

la

brosse surveille

Ie

tonctionnement

de

la brosse.

Voyant

vert;

La brosse fonctionne

de

fa<;on

normale.

Voyants vert

et

rouge. Ajuster les parametres de

la brosse

en

tournant

Ie

bouton

de

reglage

(23)

vers un numero plus petit.

5i les voyants sont toujours allumes lorsque

Ie

bouton est sur

Ie

plus petit numero, la bande

de

la

brosse est usee et doit etre remplacee.

Voyant rouge:

La

brosse est bloquee et ne peut

pas tourner. Eteindre I'aspirateur,

Ie

debrancher et

debloquer la brosse.

Indicateur

du

niveau du filtre

Si

Ie

voyant d'alerte

(3)

s'allume, verifier

si

:

a)

Le

sac apoussiere est plein,

b} Le tuyau

ou

la

tete de I'aspirateur est bloque.

Loquet du pivot

du

manche

Pour

en

lever I'aspirateur de la position relevee,

appuyer sur

la

pedale (11)

Changement

du

sac

en

papier

Si

Ie

voyant rouge

(3)

est allume, changer

Ie

sac du

filtre

en

papier. Pour ce faire, tirer vers I'avant sur

Ie

levier de degagement

(5)

du couvercle et soulever

Ie

couvercle du logement du sac apoussiere. Faire

glisser

la

plaque de fermeture herrnetique

(28)

du

nouveau sac dans son receptacle et appuyer ferme- ment. La pousser vers I'avant puis I;attacher

en

poussant

Ie

levier

de

degagement du couvercle vers

Ie

bas.

Changement

du

filtre

du

moteur

Les filtres de qualite H6pital (30, piece

nO

1875)

doivent etre changes apres I'utilisation de 20 sacs

filtrants afin de maintenir un BON NIVEAU DE

FILTRATION. Soulever h'lgerement I'avant du filtre et

Ie

faire glisser hors de

sa

fente. Inserer un nouveau

filtre de qualite H6pita!.

N.B. :

Le

filtre de qualite H6pital n'est pas lavable.

Changement

du

filtre de I'echappe-

ment

II

faut toujours changer

Ie

filtre de I'echappement

(31, piece

nO

1878) avec

Ie

filtre du moteur

(30).

Appuyer sur

Ie

bouton et faire glisser

Ie

couvercle de

I'echappement

(5)

vers

Ie

cote.

Ne jamais utiliser I'aspirateur sans attacher

correctement lasftltres.

Clearing blockages

Blockages

in

the hose can be cleared by taking

the hose off the machine and reversing it

in

the

connecting tube

(25),

holding it upright with

one hand blocking the

top

and switching on

the machine.

If

necessary rapidly lift your hand

on and off the end

of

the hose.

Changing the brush strip

To

replace brush strip: Remove brush strip

cover

(32).

Turn

brush roller so that the brush

strip can then be pulled out. Ensure that the

new brush strip is fully inserted.

Replace the brush strip before the bristles

wear down

to

the level of the support rod.

Maintenance

CAUTION -Maintenance and

repairs must be done by qualified

personnel.

WARNING -

To

reduce the risk of

electric shock -unplug before

cleaning or servicing.

Degager les blocages

Les blocages du tuyau peuvent etre degages

en

deconnectant

Ie

tuyau et

en

inversant

Ie

tuyau

de connexion

(25),

en

Ie

tenant verticalement

avec une main bouchant

la

sortie, puis

en

allu-

mant I'aspirateur.

Si

necessaire, enlever puis

remettre rapidement

la

main sur

la

sortie du

tuyau.

Changement de

la

bande

de

la

brosse

Pour remplacer

la

bande de la brosse, enlever

Ie

couvercle de

la

bande de

la

brosse

(32)

puis

tourner la brosse de

fac;:on

que

la

bande puisse

etre tiree. S'assurer que

la

nouvelle bande de

la

brosse est bien inseree.

Remplacer

la

bande

de

la

brosse avant que les

poils de

la

brosse soient uses jusqu'a

la

tige de

support.

Entretien

ATTENTION -L'entretien et les

reparations doivent etre effectues

par

un

reparateur qualifie.

AVERTISSEMENT -Pour redulre les

risques de chocs electriques,

debrancher I'apparell avant Ie net-

toyage

ou

.I'entretien de l'apparell.

#9703AM 370 Light Gray Machine

Pos. Part # Description

1 1037EH Handle grip (incl. pos. 2, 3 + 12)

2 1596HG Handle cover

3 0127 Screw M4 x 10

4 1954DG Power supply cord

5 1848 Handle tube

6 1831HG Dust bag housing

7 1835DG Internal Cover

8 5289 Seal

9 5842 Seal

10 5424DG Retaining ring

11 1823HG Attachment clip

12 5359HG Grommet

13 0502 Terminal block 2-wire

14 1030UL Cable clamp

15 1812HG Cover

16 1814HG Carrying Handle

17 5146 Stop spring

18 1813HG Cable hook

19 1859DG Handle catch

20 0161 Clip 4 DIN 6799

21 0850DG Locking catch

22 1811 Locking rod

23 1265UL Terminal block

24 1807HG Connector

25 1836UL Female contact holder

26 1851 Sound insulation

27 1047 Vac motor seal

28 1843/2 Vac motor 120 V

(incl.Pos. 29 + 30)

05118S Carbon brush set (After 2001)

0511/1 Carbon brush set (Before 2001)

29 1821UL Motor cover

30 1822 Support for motor

31 1027 Leaf spring

32 1073 Clamp

33 1824 Connecting rod

34 1875 Micro-Hospital-Filter

35 1935ER Printed circuit board w/switch

1903 PC Board cover

36 1860 Fitting

37 1852HG Suction pipe cover

38 1869HG Lens, bag light indicator

39 1830DG Switch button

40 1862 Return spring

41 1833UL Internal cable

42 1878 Exhaust filter

43 1802HG Exhaust filter cover

44 1853SE Motor cover

45 1804HG Dust bag housing bumper

46 1846HG Front cover complete

(incl. pos., 47-50)

47 1818DG Cover release

48 6040 Seal, cover release

49 1819 Bearing cover

50 1847 Bag holder, complete

(incl. pos. 51 + 52)

51 5091 Safety catch spring

52 1817 Safety catch

53 5093AM Filter bag

54 5045DG Extension Tube

55 5040HG Hose complete

56 1491DG Upholstery nozzle

57 1092DG Crevice Nozzle

58 0102 Screw 3.9 x 13

59 0103 Screw 3.9 x 16

60 1884HG Retaining button

61 1524 Terminal block cover

62 1081DG Mounting clip with screw

63 1329DG Dusting brush

1

SEBO ELECTRONIC 370 Bag Housing ith Handle

#9703AM 370 - Light Gray

2

#9703AM 370 Light Gray Machine

Pos. Part # Description

100 2543HG Chassis

101 2005ER Metal plate set for 370

102 2522HG Bumper

103 2525 Axle

104 2528 R Foot pedal - orange

105 2010 Axle spring

106 2014 Axle clamp

107 2614HG Wheel, complete

108 2524 Pile adjustment axle

109 2608HG Pile adjustment wheel

110 2622HG Pile adjustment knob

111 4019 Spring

112 2241UE Brush motor 120 V, 150 W

05095S Carbon brush set

0512/1 Carbon brush set for 2241ER

(Before 2001)

113 2025 Motor pulley

114 2049 Drive belt

115 2609UL Swivel neck assembly

116 2611UL Wire, swivel neck

117 2602HG Swivel neck cover

118 2467 Plastic bearing inside

119 0155 Washer

120 2613 Swivel Support

121 2624 Micro switch support, cpl.

122 0531 Micro-switch

123 2605 Switch. lever

124 0849UL Wire on neck to switch

125 2572ER Electronic controller

126 2030ER Brush assembly, cpl. (incl

pos. 127)

127 2046 Brush strip

128 2047 Bearing block- right hand

129 2091 Bearing block- left hand

130 2458 Brush roller pulley

131 2653HG Support lever with spring

133 2623AM Cover, complete

134 2542 Brush strip cover w/screw

135 0111TL Screw AM5 x 30

136 0102 Screw 3.9 x 13

137 0103 Screw 3.9 x 16

138 0105 Screw 3.9 x 19

139 0174 Screw 3.9 x 22

140 0141 Locking washer

SEBO ELECTRONIC 370 Po er Head

#9703AM 370 - Light Gray

--

A3

::x>

4

2

1

~

B

2

1

5

C

1

20

3-

A Attachments

1

2

3

4

B

1

2

3

4

5

C

1

2

3

A

1

2

3

4

B

1

2

3

4

5

C

1

2

3

1491 dg Upholstery Nozzle

1092

dg

Crevice Nozzle

1081

dg

Attachment

clamp

1329

dg

Dusting Brush

Optional Attachments

1495 AM Extension Hose

1084 hg Straight Tube

1090 hg Upholstry Nozzle

1325 hg Wall- and Floor Brush

1383 AM Combination Nozzle

Service Parts

5093 AM Paper Bag

1878

AM

Exhaust Filter

1875 AM Micro Filter

Accessoires

1491

dg

Suceur pour les tissus

d'

ameublement

1092

dg

Suceur pour les recoins

1081 dg Collier

de

serrage pour les

accessoires

1329

dg

Brosse apoussiere

Accessoires en option

1495 AM Tuyau de rallonge

1084 hg Tuyau droit

1090 hg Suceur pour les tissus

d'ameublement

1325 hg Brosse combinaison sols/murs

1383 AM Suceur mixte

Pieces de rechange

5093 AM Sacs apoussieres

en

papier

1878

AM

Filtre

d'lkhappement

1875 AM Micro-filtre

WARNING! Electric shock could occur if used outdoors or

on

wet suriaces!

AVERTISSEMENT! Utiliser cet appareil sur une suriace mouillee

ou

aI'exterieur peut causer

un

choc electrique

Technical Details Wiring

Diagram

I

Schema

Electrique

Voltage

Vacuum

motor

Airflow

Dust bag

Brush

motor

Brush width

Brush drive

Brush strip

Height

Width

Weight

120 volt

8,6 amp.

117 cfm

5,3 liters

1,4 amp.

12 3/4 inches

non slip drive belt

with electronic

overload protection

replaceable

48 inches

14 inches

16 Ibs

Details techniques

Voltage 120 V

Moteur aspiration 8.6 Amp.

Colonne

d'eau

204 cm

Sac apouissiere 5.3 litres

Moteur

de

la

brosse 1.4 Amp.

Largeur

de

la

brosse

32

cm

Transmisson Courroie

de

transmission

de la brosse anti-derapage avec controle

electronique contra

la

surcharge

Bande

de

la brosse Remplayable

Hauteur 122

cm

Largeur 36 em

Poids 8 kg

06570-02.2007

Static "Electrode" / "Electrode" statique

Handle

Tube

/ Hose /

120 V

Tuyau

du

manche

Tur-au

Resi~

Resistance

ON-OFF

switch I

Interrupteur

Electronic

Control

/

Contr61e

e.fectronique

Vacuum Motor /

Moreur

d'aspiration

SEBO America, LLC

7472

S.

Tucson Way Suite 190

Centennial, CO 80112

Tel.

(8GO)

334-6614

(303) 792-9181

Fax (303) 792-9196

E-mail: info@sebo-

vacuums.com

www.sebo-vacuums.com

FLOOR CARE

EQUIPMENT

LTD.

3410 -25th Street

N.E.

Calgary, Alberta

T1

Y

6C1

Tel.

(403) 250-5005

Fax (403) 250-5057

Other manuals for 370 comfort

7

Table of contents

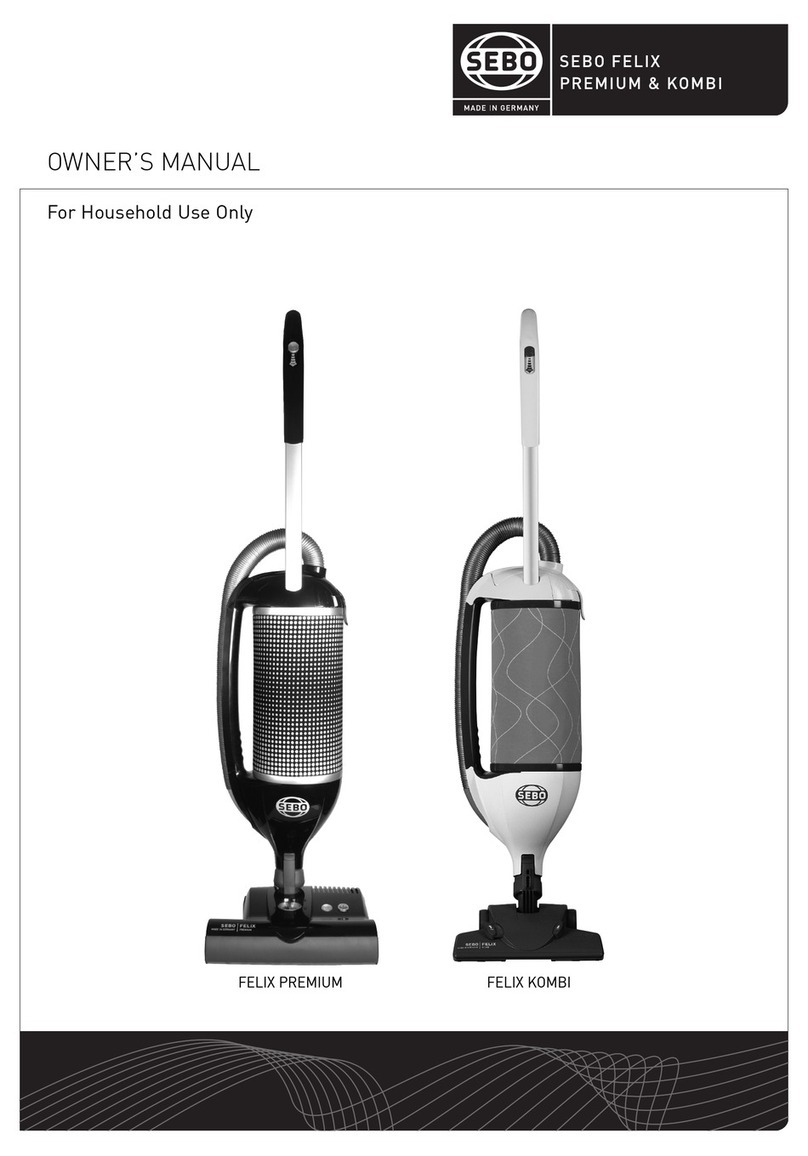

Other Sebo Vacuum Cleaner manuals

Sebo

Sebo AIRBELT C User manual

Sebo

Sebo Automatic X-series User manual

Sebo

Sebo BS 36 Comfort User manual

Sebo

Sebo AIRBELT D4 User manual

Sebo

Sebo duo User manual

Sebo

Sebo automatic X Series User manual

Sebo

Sebo Automatic X4 User manual

Sebo

Sebo 470 Comfort User manual

Sebo

Sebo AUTOMATIC X Series User manual

Sebo

Sebo AIRBELT K User manual