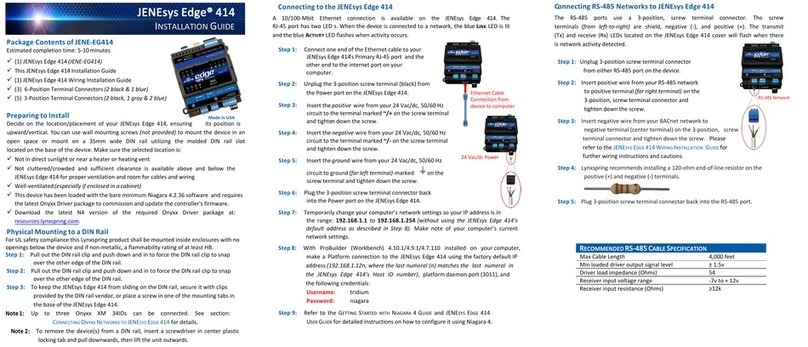

Seco BVFD163 User manual

AC LINE CONNECTIONS

C501 C502

DS3S2S1E1E2

TB501

JMP504

JMP505

1 2 3

1 2 3

C503

IC503 JMP501: SELECT INPUT TYPE

1 & 2 = CURRENT INPUT

2 & 3 = VOLTAGE INPUT

JMP502: SELECT RANGE

1 = 0 - 5 VDC INPUT

2 = 0 - 10 VDC INPUT

3 = 4 - 20 mA INPUT

4mA

ZERO

SET

MAX MIN

DECEL ACCEL

BOOST

SLIP

COMP

BRAKE

CURRENT

BRAKE

TIME TORQUE

LIMIT

IL503

T501

IC504 C504

C505

C506

IL504

ENABLE

FAULT

POWER

C509

IL501 IL502

J501 IC502

TRIP RESTART

UV

JMP503JMP506

COAST BRAKE

IC11

J502

R1

C508

C507

J503

115V 230V FU502

FU501

JMP501

IC501 T502

U V W L1 L2

U V W L1 L2

TB502

BVFD163 & BVFD163WD DIMENSIONS BVFD163 & BVFD163WD CIRCUIT BOARD LAYOUT

FORWARD

RUN

START

REVERSE

JOG

STOP

Motor run

BVFD163 & BVFD163WD QUICK START GUIDE

Variable-frequency drives for 3-phase and single-phase AC motors

Danaher Motion

www.danahermotion.com

13500-J South Point Blvd, Charlotte, NC 28273 USA

Phone: (540) 633-3400; Fax: (540) 639-4165

Document Number: 250-0385, Revision 0; Printed in the U.S.A. - December 2004

Copyright © 2004 by

Danaher Motion

All rights reserved. No part of this manual may be reproduced or transmitted in any

form without written permission from Danaher Motion. The information and technical

data in this manual are subject to change without notice. Danaher Motion and its

Divisions make no warranty of any kind with respect to this material, including, but not

limited to, the implied warranties of its merchantability and fitness for a given purpose.

Danaher Motion and its Divisions assume no responsibility for any errors that may

appear in this manual and make no commitment to update or to keep current the

information in this manual. KC0304

Printed in the United States ofAmerica.

4mA ZERO SET

The 4mA ZERO SET trimpot sets zero speed when a 4-20mA input signal is used.

Maximum Speed (MAX)

The MAX setting determines the motor speed when the speed adjust potentiometer

is turned full CW.

Rotate the speed adjust potentiometer full CW. Using a hand-held tachometer or

analog frequency meter as a reference, adjust the MAX trimpot until the desired

speed or frequency is reached.

Minimum Speed (MIN)

The MIN setting determines the motor speed when the speed adjust potentiometer is

turned full CCW. It is factory set to zero speed. The MIN setting range is 0 to 30%

MAX setting.

To calibrate MIN, turn the speed adjust potentiometer CCW. Adjust the MIN trimpot

until the motor has stopped (for zero speed setting), or is running at the desired

minimum speed.

Deceleration Time (DECEL)

The DECEL setting determines the time the motor takes to ramp to a lower speed.

Decel is factory set for the fastest deceleration time (full CCW).

To set the deceleration time:

1. Set the speed adjust potentiometer to maximum (full CW) and wait for the

motor to come to maximum speed.

2. Set the speed adjust potentiometer to minimum speed (full CCW) and note the

time the motor takes to decelerate to minimum speed.

3. If the deceleration time differs from the desired time, adjust the DECEL trimpot

until the desired time is reached. Rotating the DECEL pot CW increases the

deceleration time.

Acceleration Time (ACCEL)

The ACCEL setting determines the time the motor takes to ramp to a higher speed.

ACCEL is factory set for the fastest acceleration time (full CCW).

To set acceleration time:

1. Set the speed adjust potentiometer to zero (full CCW) and wait for the motor to

come to a stop (or minimum speed).

2. Set the speed adjust potentiometer to maximum speed (full CW) and note the

time the motor takes to accelerate to maximum speed.

3. If the acceleration time differs from the desired time, adjust the ACCEL trimpot

until the desired time is reached. Rotating the ACCEL trimpot CW increases

the acceleration time.

Slip Compensation (SLIP COMP)

The SLIP COMP setting controls speed regulation during load changes.

The SLIP COMP range is 0 - 5 Hz at base speed and load.

Increase the motor speed to maximum. Slowly load the motor until the AC phase

current is at its maximum (100%). If the motor shows any signs of slowing, rotate the

SLIP COMP trimpot CW until the motor shaft rotates at the original set speed.

BOOST

The BOOST setting is used to increase motor torque at low speeds. The minimum

setting is sufficient for most applications and does not need to be adjusted. If the

motor stalls or runs too slowly due to excessive slip at very low speeds (below 10 Hz),

the boost trimpot may need adjustment.

To adjust the BOOST setting:

1. Run the motor at the lowest continuous frequency/speed required.

2. Monitor the motor phase current (with a true RMS meter) while very slowly

turning the BOOST trimpot CW until the motor operates properly, or 100% of

the motor nameplate current is reached.

Note: Use the absolute minimum amount of BOOST necessary to achieve proper

motor operation. Improper use of the BOOST feature may cause motor and/or drive

overheating and failure. If proper motion operation cannot be achieved with the

above procedure, please contact your Danaher Motion representative for assistance.

TORQUE LIMIT

The TORQUE LIMIT setting determines the maximum torque for accelerating and

driving the motor. TORQUE LIMIT is factory set at 100% of rated motor current.

Althought the TORQUE LIMIT trimpot can be set up to 100% of the drive nameplate

rating, continuous operation beyond the drive nameplate rating may cause damage to

the motor and/or drive.

To set the torque limit:

1. With no power applied to the drive, connect a (true RMS) ammeter in series with

one of the motor leads.

2. Set the TORQUE LIMIT trimpot to full CCW.

3. Carefully lock the motor shaft. Ensure that the motor is firmly mounted.

4. Apply line power. The motor should be stopped.

5. Set the speed adjust potentiometer to maximum speed. The motor should

remain stopped.

6. Slowly rotate the TORQUE LIMIT trimpot clockwise (CW) until the ammeter

reads 100% of maximum motor current.

7. Set the speed adjust potentiometer to zero speed.

8. Remove power from the drive.

9. Remove the lock from the motor shaft.

10. Remove the ammeter in series with the motor lead.

BRAKE CURRENT

The BRAKE CURRENT setting controls the amount of braking current applied,

ranging from 0 - 100% of drive rating.

To set brake current:

Rotate the BRAKE CURRENT trimpot CW to increase the amount of current applied.

Rotate the BRAKE CURRENT trimpot CCW to decrease the amount of current

applied.

BRAKE TIME

The BRAKE TIME setting controls the amount of time brake current is applied to the

drive. The BRAKE TIME range is 1 to 10 seconds.

To set the brake time:

Rotate the BRAKE TIME trimpot CW to increase the amount of time the drive takes to

break. Rotate the BRAKE TIME trimpot CCW to decrease the amount of time the

drive takes to brake.

CALIBRATION SETTINGS

JUMPER SETTINGS

J

MP

504

J

MP

504

J

MP

503

J

MP

505

J

MP

506

1 & 2 for Volta

g

e Inpu

t

2 & 3 for Current In

p

u

t

1

&

2 to Coas

t

2

&

3 to Brak

e

1 & 2 to Tri

p

2

&

3 to Restar

t

1

&

2 for 115VA

C

2

&

3 for 230VA

C

TRIP:

Drive has a low volta

g

e fault & must b

e

manuall

y

re-enabled to restart

.

R

E

S

TART

:

Drive has a low volta

g

e fault & wil

l

momentaril

y

stop then auto-restart whe

n

input volta

g

e returns to minimum level

.

11

5

= 11

5

VA

C

INP

U

T D

OU

BLER M

O

D

E

2

30

= 2

30

VA

C

INP

U

T M

O

D

E

1 =

0

-

5

VD

C

INP

UT

2 =

0

- 1

0

VD

C

INP

UT

3

= 4 - 2

0

mA INP

UT

1 2

3

1 2

3

J

MP

503

1 2

3

1 2

3

1 2

3

J

MP

505

J

MP

506

BRAKE

COAST

T

TRIP

RE

S

TAR

T

UV

J

MP

501

J

MP

501

11

5V

2

30V

WARNIN

G!

Usin

g

230 VAC input in Doubler mod

e

will dama

g

e the drive

!

1-Phase Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .* 115/230 VAC

1 or 3 -Phase Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230 VAC

Maximum Horsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 HP

Maximum Continuous Output Current . . . . . . . . . . . . . . . . . . . . . . . † 4.0 AC

AC Amps In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 / 10 amps

AC Voltage Input Range . . . . . . . . . . . . . . . . . . . . . . . . .115/230 VAC ± 10%

50/60 Hz single phase

Standard Carrier Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 KHz

Output Frequency Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 - 120 Hz

Adjustable Maximum Output Frequency Range . . . . . . . . . . . . .30 - 120 Hz

Acceleration Time Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 12 secs

Deceleration Time Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 12 secs

Analog Input Voltage Range

(S1 [-] to S2 [+]) . . . . . . . . . . . . . . . 0 - 5 VDC, 0 - 10 VDC, 4 - 20 mA

Input Impedance, S1 to S2 . . . . . . . . . . . . . . . . . . . . . . . . . . . .~ 100K ohms

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.5G max (20 - 50 Hz)

0.1G max (> 50 Hz)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.2 lbs

Ambient Operating Temperature Range . . . . . . . . . . . . . . . . . . . .10° - 40° C

SPECIFICATIONS

* Connect only 115 VAC line input to the 115 VAC terminals. Application of 230 VAC line input when set for

115 VAC will result in severe damage to the motor and drive.

† Derate current by 2% per degree if the operating temperature is above 40°C. Under no circumstances may

the ambient temperature exceed 55°C.

This manual suits for next models

1

Other Seco Controllers manuals

Popular Controllers manuals by other brands

ZPA Pecky, a.s.

ZPA Pecky, a.s. MODACT MOK 125 Installation and operating instructions

Bray

Bray SERVO PRO 70 Series Operation and maintenance manual

TAC

TAC Xenta 511 Installation instruction

Pactera

Pactera MARS installation guide

Elstat

Elstat Nexo CMS200 product manual

EUCHIPS

EUCHIPS EULP50D-2HMC-0 quick start guide