SEFRAM SDS3 User manual

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 1 sur 15 - 1 -Page 1 sur 15 - 1 - - 1 - - 1 - - 1 -

Version with display panel

And DP measurement

PLACE GUTENBERG - 59175 TEMPLEMARS (France)

Tel: +33(0)3 20 60 49 49 - Fax: +33(0)3 20 95 59 62

Email: contact@sefram.eu Web: www.sefram.eu

MANAGEMENT AND MONITORING

OF INDUSTRIAL PROCESSES

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 2 sur 15 - 2 -Page 2 sur 15 - 2 - - 2 - - 2 - - 2 -

SUMMARY:

DESCRIPTION :

The SDS3 is a sequencer for the command and control of dust-

removal equipment.

It can be equipped of the differential or relative pressure measure

(pressure drop).

It is equipped with a T1 time (pulse time), a T2 time (rest/idle), a

T3 time (rest time between two cycles), a T4 time which performs a

cleaning cycle if the sequencer has not operated for a set number of

hours, a manual running, an electrical fault control, a possibility to

execute a preset number of cycles at fan stop, three pilots for

pneumatic valves.

In option, it can be equipped of a relay output for fault or alarm

report of information and of a loop control input (I1: fan or other).

If the device is equipped of the pressure measure, it is equipped

with a loop control to DP measure (2 thresholds), two P alarms

(high and low), a P threshold for accelerated cycle, a T2A time

(accelerated idle time).

The device is adjustable depending on the use.

All the operating parameters are adjustable through sensitive keys

on the front.

The value of each parameter and the pressure are displayed on a

LED display.

Comment: this data sheet is drawn up on the basis of a device

equipped with the pressure drop measure. If the device is not

equipped with the pressure drop measure, the functions relating

to this are not validated. The options on the device, define the

terminal board and the Glands configurations.

The information concerning the device equipped with the

pressure measure are in grey colour.

Page

- DESCRIPTION

2

- CHARACTERISTICS

3

- PRESENTATION OF THE

FRONT PANEL

4

- PRESENTATION OF THE

KEYBOARD

4

- ADJUSTMENTS &

RUNNING

- HIDDEN MENU

5

10

- THE SIGNALLING IN

FRONT PANEL

10

- CONTROL / FAULTS

DISPLAY

11

- CONNECTIONS

11

- SPARE REQUIREMENT

AND FIXING

- RELAY OUTPUT

12

13

- PRECAUTIONS

13

- CALIBRATION

13

- SPECIFICITIES

AVAILABLE ON REQUEST

13

- GENERAL

INSTRUCTIONS FOR

SAFETY, ASSEMBLY,

COMMISSIONING, AND

MAINTENANCE

14

- WARRANTY

15

- CONFORMITY

15

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 3 sur 15 - 3 -Page 3 sur 15 - 3 - - 3 - - 3 - - 3 -

CHARACTERISTICS:

- Mains Voltage (rated voltage):

100 to 240V 50-60 Hz

- Maximum power consumption (rated current):

0.7A (if supplied in 85V )

0.3A (if supplied in 230V )

- Input characteristics:

Voltage: 24VDC supplied by the device

Charging current +/- 10mA

- Relay contact characteristics:

Max. free dry contacts: 250VAC-62.5VA

220VDC-60W (resistive load)

(to protect by the user)

- Operating Temperature:

0° to 60° C

- Storage Temperature:

-20° to 70° C

- Box:

ABS or polycarbonate material IP65 IK07

- Protection:

By 2 fuses 1A temporised –250V

SEQUENCER:

- Maxi number of outputs

3

- Pulse time of an output (T1)

from 3/100th to 255/100th of a second

- Idle time between two outputs T2

(T2A if eqquiped with DP)

from 1 to 255 seconds

- Idle time between two cycles (T3)

from 0 to 255 minutes

- Forced declogging time (T4)

from 0 to 255 hours

- Number of cycles if fan stop

0 from 255 cycles

- Number of cycles manual running

0 from 255 cycles

DP MEASUREMENT:

- Scale

0-500 daPa

- Proof pressure

750 mbar effectif

- Burst pressure

1 bar effective

- Humidity of measurable fluids

100% Hum.Rel.

- Measurable fluids

non aqueous, non corrosive

- Nature of the materials in contact with fluid

Epoxy, ceramic Al2O3, silicone, RTV, metal

- Precision

class 2 on the maxi sensor scale (100 mbar)

→ from 0 to 60°C. This class takes account of linearity,

hysteresis, temperature effects and repeatability

- DP response time

1 second

- High and low alarms response time

5 seconds

- Threshold for accelerated running response

time

5 seconds

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 4 sur 15 - 4 -Page 4 sur 15 - 4 - - 4 - - 4 - - 4 -

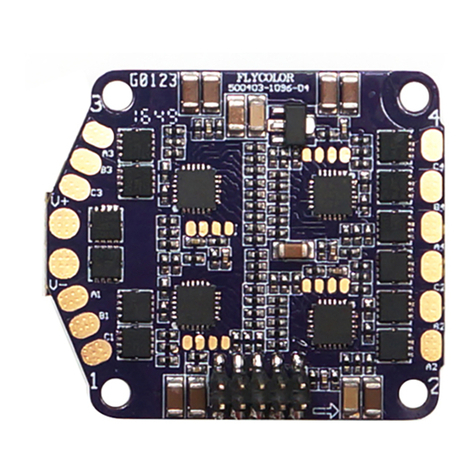

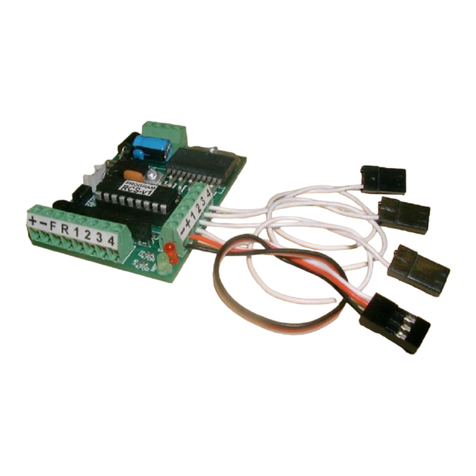

PRESENTATION OF THE FRONT PANEL:

Note 1: If the option pressure drop measurement is not validated by the presence of the sensor in the equipment, the

front panel remains unchanged but the menu steps associated with the pressure drop measurement are not

accessible.

PRESENTATION OF THE KEYBOARD:

The keyboard consists of five sensitive keys. To activate them, we need to approach the finger in front of the

wished key through the transparent cover.

The access to « Reset », « + », « - » and « Select » keys is locked by the « padlock » key. To lock or unlock the

keyboard, it is necessary to keep the finger on the « padlock » key more than three seconds.

The keyboard is automatically locked if there is no longer activity on this one during more than three minutes.

Remark: if keys don’t react any more as wished, wait approximately one minute before redoing an attempt. This

waiting allows make an automatic re-calibration of them.

Signalling

IN OPTION (note 1)

Adjustments associated to

load loss measure

Sequencer parameters

adjustments

Red Led: Lit up if the keyboard is

locked

« Padlock » key

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 5 sur 15 - 5 -Page 5 sur 15 - 5 - - 5 - - 5 - - 5 -

ADJUSTMENTS AND RUNNING:

The various parameters are set as follows:

- Press the « SELECT » key until the yellow led « menu » lights up opposite the parameter to be set and operate

the keys « + » and « - » to obtain the desired value.

- Then return to the “CYCLE” position (or “pressure reading” position if it’s equipped with the DP) using the

« SELECT » key. Each parameter is recorded in a memory by moving to the following step or on automatic return

to the “CYCLE” position (or « pressure reading » position if it’s equipped with the DP).

Comment:

- The return to the “CYCLE” position (or “pressure reading” position if it’s equipped with the DP) is automatic

after 30 seconds (unless in « cycle » position).

- Each parameter can be viewed at any time during the operating of the device.

The visualisations 1 to 7 and 13 are only used if the sequencer is equipped with the DP.

1) DP measurement view:

Display the DP measurement.

If there is an error, alternating display of the type of fault.

If button + pressed, display of nxx with xx = EV will be actuated at the next blast

If cleaning is in running, rapid flashing of the led of the menu opposite to the corresponding time.

If manual operation is in course or fan stoppage cycles are in course, the menu led opposite the fan/manu

flashes rapidly.

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 6 sur 15 - 6 -Page 6 sur 15 - 6 - - 6 - - 6 - - 6 -

2) DP control selection:

Choose "AdP" or "SdP".

"AdP": for cycle controlled by the DP measurement.

"SdP": for cycle not controlled by the DP measurement.

3) Maxi DP setting:

If the DP measurement exceeds this threshold for longer than one second, the DP order becomes « on »

4) Mini DP setting:

If the DP measurement goes below the DP threshold for longer than one second, the DP order becomes

« off »

Note: If Maxi DP=Mini DP=000 then the DP order is mechanically controlled « on »

5) High DP Alarm Setting:

If the DP measurement goes above this threshold for longer than 5 seconds high DP alarm.

If the DP measurement goes below this threshold for longer than 5 seconds no high DP alarm

Note: if the high DP alarm is set at 000, it is inactive (no high alarm generated).

6) Low DP Alarm setting:

If the DP measurement goes below this threshold for longer than 5 seconds low DP alarm.

If the DP measurement goes above this threshold for longer than 5 seconds no low DP alarm.

Note: if the low DP alarm is set at 000, it is inactive (no low alarm generated).

7) Threshold for accelerated operation setting (T2A threshold):

If the DP measurement goes above this threshold for longer than 5 seconds accelerated operation.

If the DP measurement goes below this threshold for longer than 5 seconds normal operation

In accelerated operation, the T2 time is replaced by the T2A time.

Note: if this threshold is set at 000, the function is inactive (still in normal operation).

8) Cycle view:

If cleaning is running, display of the time countdown (T2, T3 or T2A if it’s equipped with the DP) with

rapid flashing of the led of the menu opposite the corresponding time.

If there is a fault, display of the type of fault.

If manual running or fan stoppage cycles are in course, the led-menu opposite the fan/manu flashes rapidly.

If key + pressed, display of nxx with xx = EV will be actuated at the next blast.

9) Type of stop setting:

Choose "Fcy" or "Sto".

"Fcy": to stop at the end of the cycle.

"Sto": to stop cycle to the running SV (stop on image).

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 7 sur 15 - 7 -Page 7 sur 15 - 7 - - 7 - - 7 - - 7 -

10) Number of outputs setting

Number of output(s) in the cleaning cycle

11) T1 setting:

Pulse time of an output (in 1/100th of second).

12) T2 Setting:

Idle time between two outputs (in seconds).

13) T2A Setting: (if presence of the DP measurement sensor)

Accelerated idle time between two outputs (in seconds).

14) T3 Setting:

Idle time between two cycles (in minutes).

0: inactive.

15) Setting T4:

Maximum non-cleaning time (in hours).

0: inactive.

If the sequencer has not performed any cycle for the set number of hours, the cycle in course ends up (if

stopped on image) and a cleaning cycle is launched.

Comment: the T4 time is initialised at each impulse on an EV.

16) Number of fan stoppage cycles setting:

Define the number of cycles to be carried out at the time of detection of the fan stoppage

0: inactive.

17) Manual running:

The cycle in course terminates and the number of set cycles is carried out without taking into account the

DP order or the input loop control I1.

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 8 sur 15 - 8 -Page 8 sur 15 - 8 - - 8 - - 8 - - 8 -

- Fan stoppage operation:

If the stoppage of the fan is detected, the cycle in course terminates and the defined number of cycles is carried out.

Comment: if the re-start of the fan is detected during the execution of the parameterised number of cycles, a classic

operation is started.

The fan stoppage can be detected in 2 ways (set in the factory): through loss of the input I1 or, if it’s equipped with

the DP, through the disappearance of pressure (as soon as it becomes lower than a value variable from 5 to 20

daPa).

If there is a DP sensor present, the setting of the type of detection of the fan stoppage takes place through a hidden

menu:

- Access to the concealed menu: activate the « Reset » key at least one second, release it, less than one second

after activate the « Select » key at least one second, release it.

- Mode selection with the + and - keys:

- « PEt » display: detection of the stop fan through loss of I1 output

- « Pdp » display: detection of the stop fan through DP drop

- Choice validation using the « Select » key

- If « PdP » choice:

- set the stop fan detection value (from 5 to 20 daPa)

- Value validation using the « Select » key

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 9 sur 15 - 9 -Page 9 sur 15 - 9 - - 9 - - 9 - - 9 -

- Operating of the sequencer:

if the device is not equipped with the DP sensor:

Conditions for the cleaning start-up:

oinput I1=1 (closed input) (representative of an external controller)

If loss of the input I1, the sequencer executes the quantity of defined cycles when fan is off and stops. If the number

of parameterised cycles is set at 0: the sequencer stops immediately or terminates the cycle in course according to

the chosen stoppage mode.

If the device is equipped with the DP sensor:

Conditions for cleaning start-up:

oinput I1=1 (closed input) (representative of the fan operation or of another control according to the

detection method of the fan stoppage)

oDP order present (if cycle controlled by DP: « AdP » choice)

-If fan stoppage detection is through TOR input:

oIf loss of the input I1, the stoppage of the fan is established: the sequencer carries out the parameterised

number of cycles and stops. If the parameterised number of cycles is set at 0: the sequencer stops

instantly or terminates the cycle in course according to the chosen stoppage mode.

- If fan stoppage detection is through pressure drop:

oIf loss of input I1, the sequencer stops instantly or terminates the cycle in course according to the chosen

stoppage method.

oIf the fan stoppage is established: the sequencer carried out the parameterised number of cycles and

stops. If the number of parameterised cycles is set at 0: the sequencer stops instantly or terminates the

cycle in course according to the chosen stoppage mode.

- If loss of the DP order (if cycle controlled by DP: « AdP » choice), the cycle stops instantly or terminates the

cycle in course according to the chosen stoppage mode.

Note: When the controller is switched on, a 10 seconds delay prohibits cleaning.

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 10 sur 15 - 10 -Page 10 sur 15 - 10 - - 10 - - 10 - - 10 -

HIDDEN MENU

- Access the hidden menu by pressing the « Reset » button for longer than 1 second, release it, less than 1 second after

press the « Select » button for longer than 1 second, release it.

- The menu led "DP reading" is blinking rapidly (if DP option is present).

- Mode choose of detection of stop (with "+" et "-" buttons)

- "PEt" display: detection of the stop fan through loss of the input I1

- "PdP" display: detection of the stop fan through DP drop

- Choice validation using "Select" button and passing to next step.

- The menu led "maxi/mini DP" is blinking rapidly (if DP option is present and choice "PdP).

- Adjust the stop fan detection value (from 5 to 20 daPa)

- Validation of the value using the "Select" button and passing to next step.

- The menu led "DP high alarm / low alarm" is blinking rapidly (if DP option is present).

- Visualisation of the recording of the maxi DP value and by pressing "+" ou "-" button, visualisation of

the recording of the mini DP value

- Passing to next step by pressing the "Select" button.

Remarks: mini DP value is checked two minuts after fan running detection.

Maxi DP value isn’t checked between the beginning of a declogging shot and three seconds

after this shot.

- The menu led "Cycle" is blinking rapidly.

- Visualisation of the number of thousands of cycles and by pressing "+" ou "-" button, visualisation of

the number of units. (Example: Number of thousands 175, Number of units 293, for 175293 cycles)

- Return to user menu by pressing the "Select" button.

THE SIGNALLING IN FRONT PANEL:

A) I1 Led: lit up if input TOR I1 is closed (fan control or other)

B) T2A Led: lit up if period time between two shots = T2A

C) Alarm Led:

Lit up if DP high alarm.

flashing if DP low alarm

D) DEF Led: lit up if fault presence (electric fault or configuration)

E) DP Led: lit up if DP order presence

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 11 sur 15 - 11 -Page 11 sur 15 - 11 - - 11 - - 11 - - 11 -

CONTROL / FAULTS DISPLAY:

The faults are displayed in visual DP measurement position (alternating with the measurement) or in visual cycle

position. They are displayed in order of priority according to the following list and are coded as below:

1) "CFx" if configuration fault when the device is switched on (x represents a code error), verification of the

parameters is then necessary:

- CF0: zero DP

- CF1: DP scale

- CF2: DPMAX threshold

- CF3: DPMIN threshold

- CF4: number of EV

- CF5: T1 time

- CF6: T2 time

- CF7: low DP alarm threshold or high DP alarm threshold

- CF8: T2A time

- CF9: threshold for passing into T2A

2) "dEF" if electrical fault “output always supplied” (short circuit)

Appears if a current consumption has been detected on one of the outputs whilst it is inactive.

3) "dxx" if electrical fault “open circuit” on the output

Appears if no electrical consumption has appeared during the activation of this SV.

xx represents the number of the EV which has generated the fault.

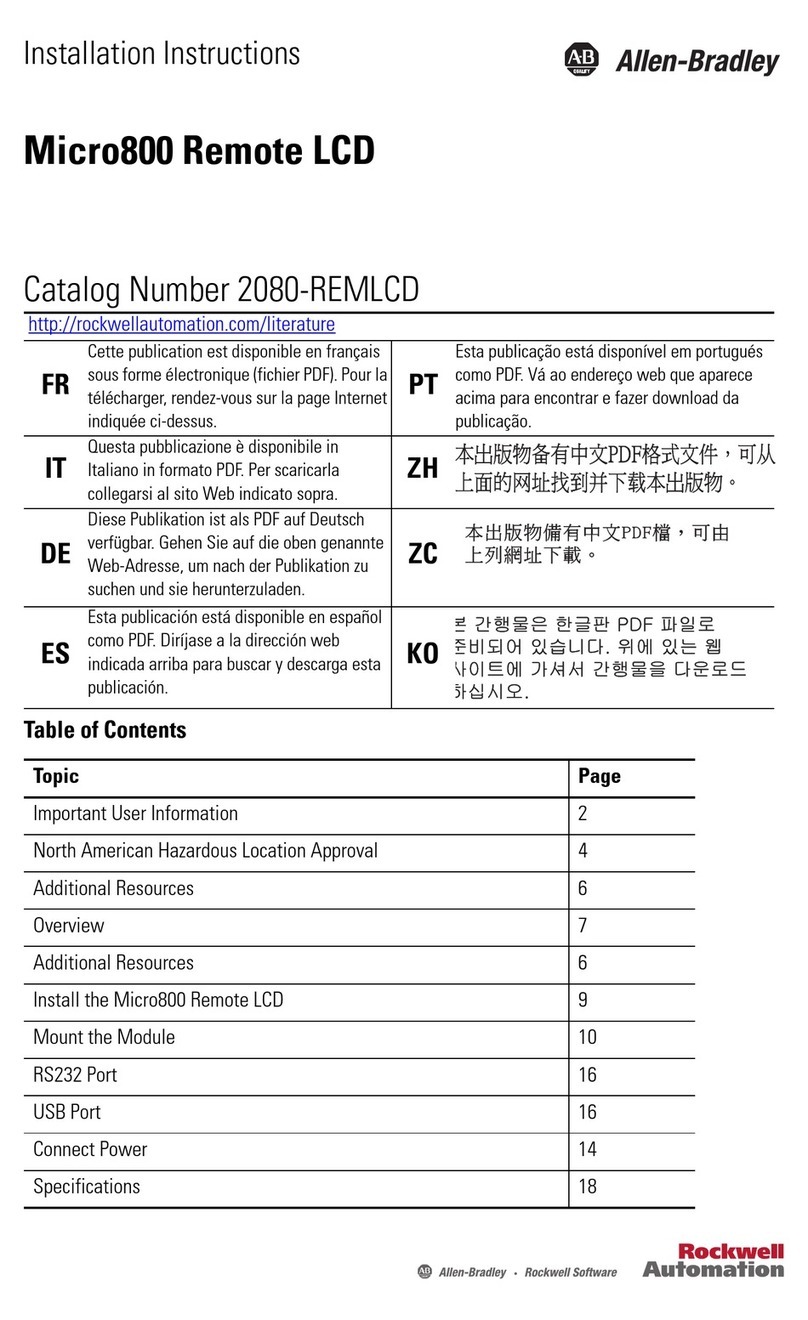

CONNECTIONS:

The connections must be made when the voltage supply is off.

The connection terminals are accessible after taking off the cover.

Depending on the configuration of the device, some terminals may not be present.

Cable conductors will be flexible and have a section included between 0,5 and 1,5 mm².

Supply voltage

85V to 264V

50/60Hz

Fault / alarm

information output

Fan or other

input loop control

General protection of the device:

2 fuses F1 and F2:

1A temporised –250VAC

Can only be changed by SEFRAM

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 12 sur 15 - 12 -Page 12 sur 15 - 12 - - 12 - - 12 - - 12 -

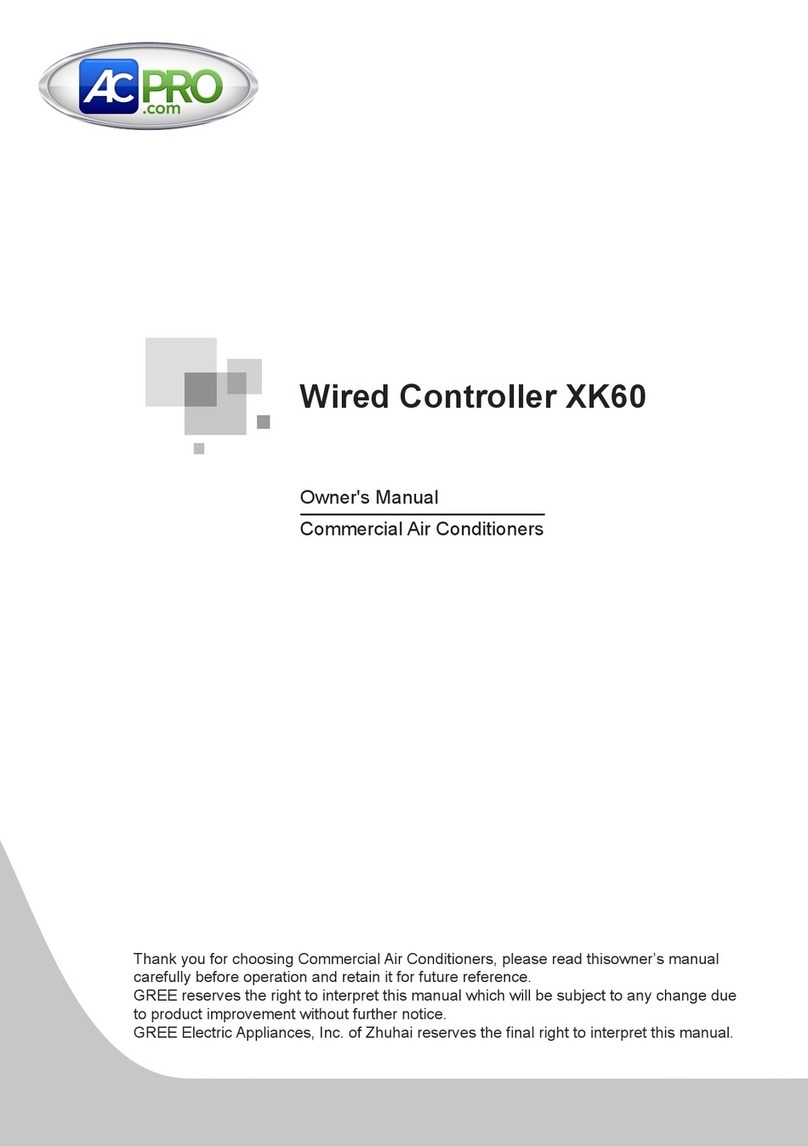

SPACE REQUIREMENT AND FIXING:

+ : dirty air side

- : clean air side

Connections for

6/8 mm tube

Instantaneous

connections for

4/6 mm tube

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 13 sur 15 - 13 -Page 13 sur 15 - 13 - - 13 - - 13 - - 13 -

RELAY OUTPUT:

Relay supplied if no fault nor alarm (contact between terminals located C and NO)

Relay cut if presence of a fault or alarm (contact between terminals located C and NF):

-electric fault “output always supplied”

-electric fault “open circuit” on the output

-High DP alarm

-Low DP alarm

PRECAUTIONS:

-Avoid dusty air entering at the pressure taps.

-Take the necessary precautions to fit to the device characteristics/data (humidity, maxi pressure, etc.).

-For special operating conditions : consult us

-Work interventions must always be carried out by duly qualified staff

CALIBRATION:

The device leaves our workshops, adjusted at 0, for zero pressure and at maxi for the maxi pressure value of the

range.

Settings carried out when device stabilised and at 20° C.

It is possible to adjust the zero pressure:

-Put the device out-of-pressure (disconnect the pressure taps)

-Place it in the pressure reading mode (using « SELECT »)

-Activate the « - » key during more than one second

-Release the key « - »

-Before one second, activate « RESET » key during more than one second

-Then re-connect the pressure

SPECIFICITIES AVAILABLE ON REQUEST:

Other DP sensor scale

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 14 sur 15 - 14 -Page 14 sur 15 - 14 - - 14 - - 14 - - 14 -

General instructions for safety, assembly, commissioning, usage and maintenance

to read before working on the device

I. GENERAL

These instructions must be read jointly with:

+the standard NFC15-100

+the technical data sheet specific to the device

The Sefram devices are designed to be assembled,

commissioned and used in compliance with the

characteristics/data given in the technical data sheet.

Always adhere to all of directives, legislation, orders

and most recent standards in force for the stated field of

application.

The assembly, commissioning, usage and maintenance

operations must always be carried out by qualified and

authorised personnel.

Personnel working on the devices must be familiar with

the safety rules and requirements in force regarding the

components, devices, machines and electrical

installations.

II. RECEPTION - STORAGE

After unpacking the device, check that this latter has not

been damaged during transport; for certain devices,

remove the protective film from the cover. The material

must be stored inside in a dry place.

In the event of a problem, please contact Sefram.

III. ASSEMBLY

The assembly operations must be carried out by

qualified, skilled and authorised personnel. Personnel

working on these devices must be familiar with the

safety rules and requirements in force.

The box must be mounted vertically.

For material connected permanently to the network, a

quickly accessible cut-off device must be incorporated

into the cabling installation of the building.

The device supply must be equipped with a device for

protection against risks of over-current and fault

isolation. The number of poles protected must be

appropriate to the neutral regime of the building and to

the regulations in force.

The equipment must be connected to the PE protection

mass by green/yellow wires (NFC15-100).

The device is compatible with the neutral regimes TT,

TN or IT;

Nevertheless, we recommend that the device is

supplied through the intermediary of an insulation

transformer for which the primary is supplied between

phases and not between phase and neutral, so as to

avoid any accidental over-voltage caused when the

neutral is cut before the phases.

In the event of a problem, please contact Sefram.

IV. COMMISSIONING AND USAGE

Commissioning is authorised only after duly

establishing that the device, the machine or the

installation in which the device has been integrated in a

compliant manner, satisfies all of the directives,

legislation, orders and most recent standards in force.

Commissioning operations must be carried out by

qualified, skilled and authorised personnel. Personnel

working on these devices must be familiar with the

safety rules and requirements in force.

Note: correct operational functioning does not in itself

constitute an indication of conformity to the

recommendations for the use of the material in

complete safety.

Also read the maintenance recommendations which

equally apply during commissioning and use.

In the event of a problem, please contact Sefram

V. MAINTENANCE

The device does not require any special maintenance.

For devices equipped with the pressure measurement,

in order to retain a precise pressure measurement, an

annual calibration is advised particularly at « zero »

(see § calibration on the technical data sheet)

The following operations are recommended; they

constitute a minimum:

- Before any work intervention, we recommend

that the dust is removed before opening the

box,

- The device must not be opened in an

excessively dusty environment,

- The settings must be carried out in the shortest

lapse of time so as not to engender any risks,

- The integrity of the joints must be checked:

remove any trace of dust or other deposit,

- Remove any trace of dust which could have

penetrated during the setting operation,

- Always ensure that the transparent cover is

correctly closed.

Maintenance operations must be carried out by

qualified, skilled and authorised personnel. Personnel

working on these devices must be familiar with the

safety rules and requirements in force.

In the event of a problem or any questions during these

operations please contact SEFRAM.

ATEX version : See FI 72.0344 instructions

SEQUENCER CONTROLLER

WITH OR WITHOUT

DIFFERENTIAL PRESSURE MEASUREMENT

Technical Notice

FI 72.0308.0316E

Page 15 sur 15 - 15 -Page 15 sur 15 - 15 - - 15 - - 15 - - 15 -

WARRANTY:

The Warranty does not apply in the following cases:

-Breakage through dropping or knocks to non-packaged products

-Damage caused by abnormal use of the device, connecting error, surges/overvoltages, overpressure, etc.

-Any intervention on the device apart from the connections

In case of failure, no action is permitted and the unit must be returned to the following address:

For ATEX devices : no intervention

Any action on the devices is forbidden. You must send us back the device in our workshops,

otherwise the certification and the guarantee are lost.

CERTIFICATE:

The SDS3 respects the European directives ( CEM, BT and ATEX ), which concerns it.

However, it must be used correctly in applications for which it is intended, and should be linked

or near CE approved products.

Certificate available on request.

We keep the right to make any modifications to our devices that we consider to be appropriate.

SEFRAM

PLACE GUTENBERG

59175 TEMPLEMARS

FRANCE

Table of contents

Other SEFRAM Controllers manuals

Popular Controllers manuals by other brands

ADLINK Technology

ADLINK Technology PXIe-3985 user manual

RCS

RCS OMEGA-3v6s FULL INSTRUCTION MANUAL

Lippert Components

Lippert Components Sway Command installation manual

REMKO

REMKO Wi-Fi stick Smart-Control Operating and installation instructions

Crestron

Crestron CLS-EXP-DIMFLV installation guide

YASKAWA

YASKAWA CIMR-V BA0001B quick start guide