1

2

3

4

Frame

(For reference)

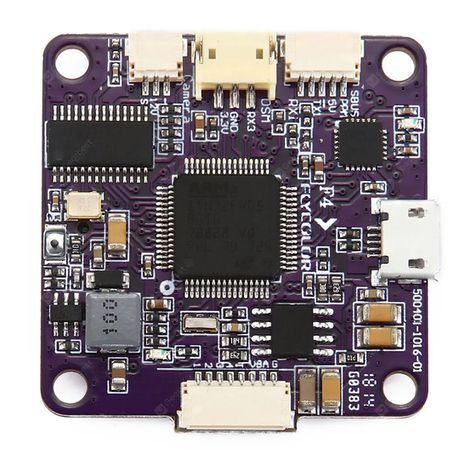

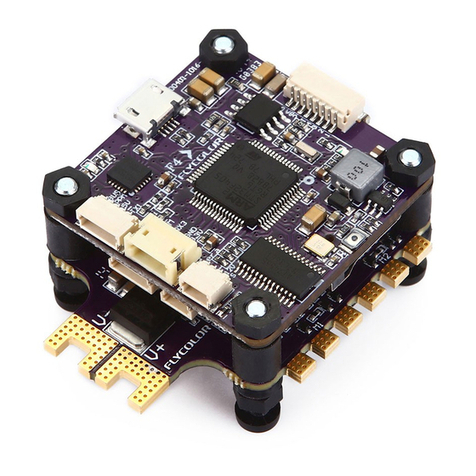

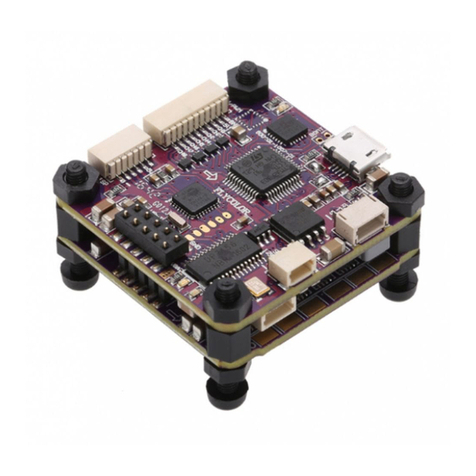

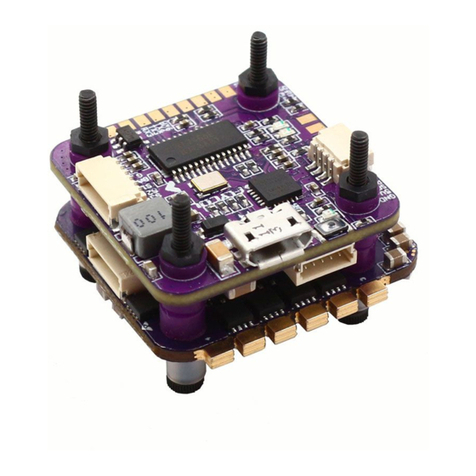

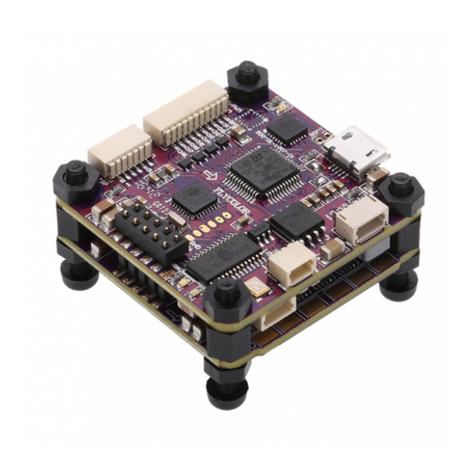

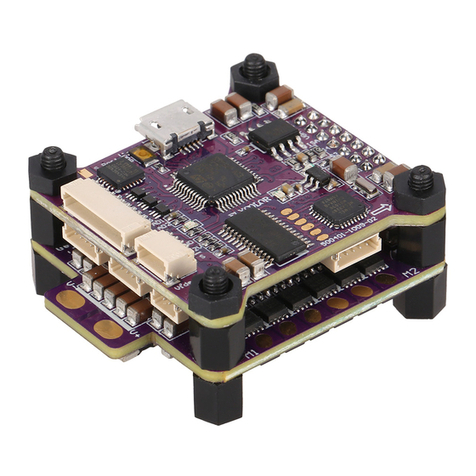

Flight Controller*

(For reference)

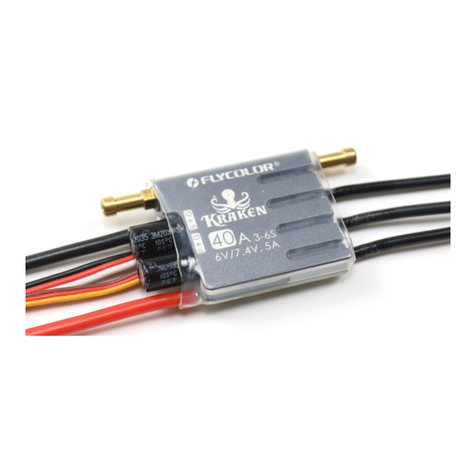

RAPTOR

BL Heli

390 4in1

ATTENTION

01 Main features

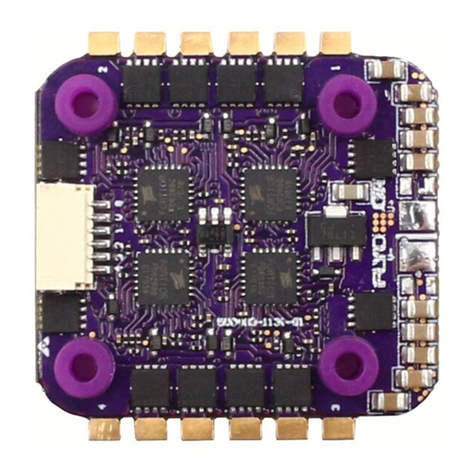

02 Specification

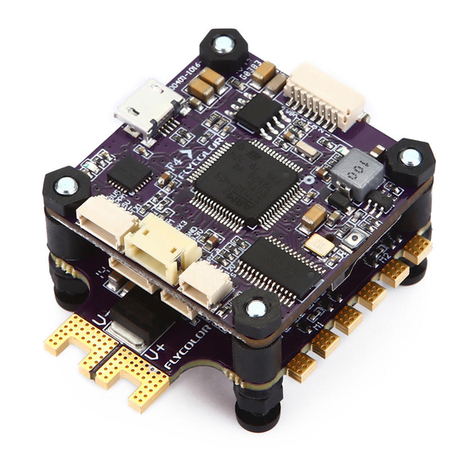

03 Part list / Install Dimensions

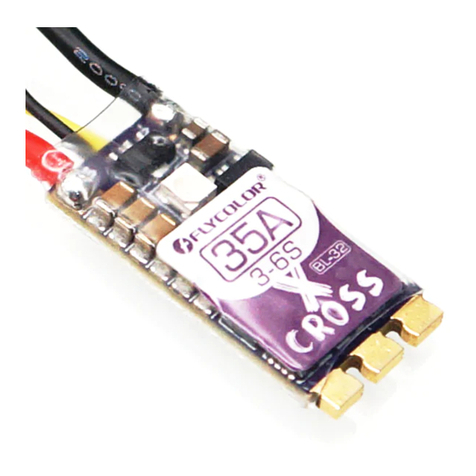

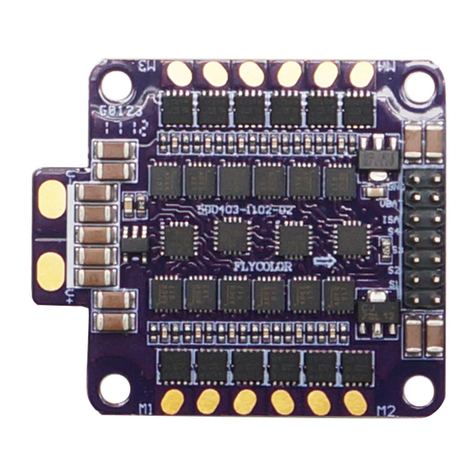

Raptor390 4in1 ESC

BEC

Raptor390 4in1-20A 20A 30A 2-4S 41.5x36x5mm

9.5g

No

130-330 Multi

Raptor390 4in1-30A 30A 40A 2-4S 41.5x36x5mm

9.5g

No

170-450 Multi

Raptor390 4in1 E SC

Nylon spacer M3*5+6

Nylon Nut M3

Nylon screw M3*12

1

2

3

4

1

4

8

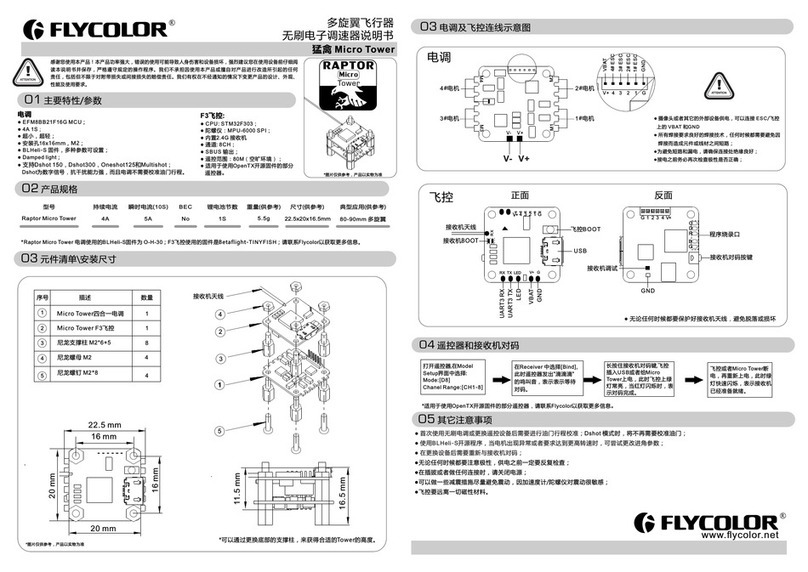

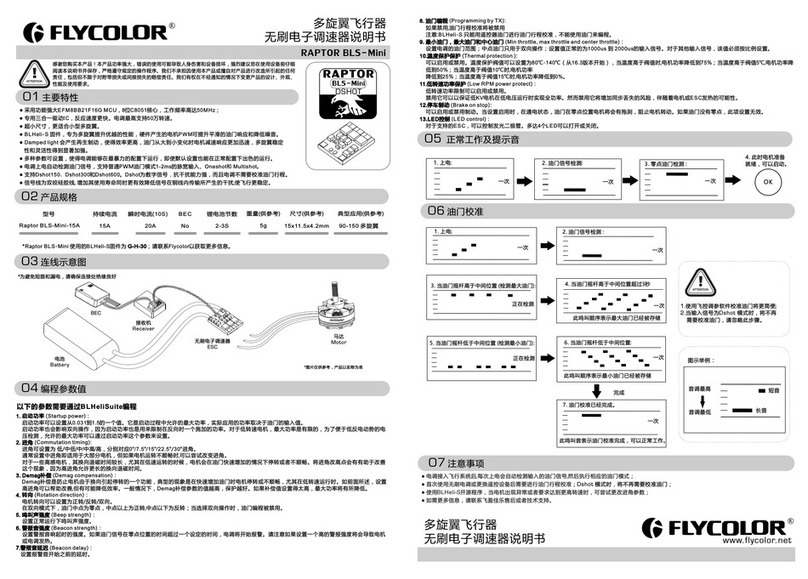

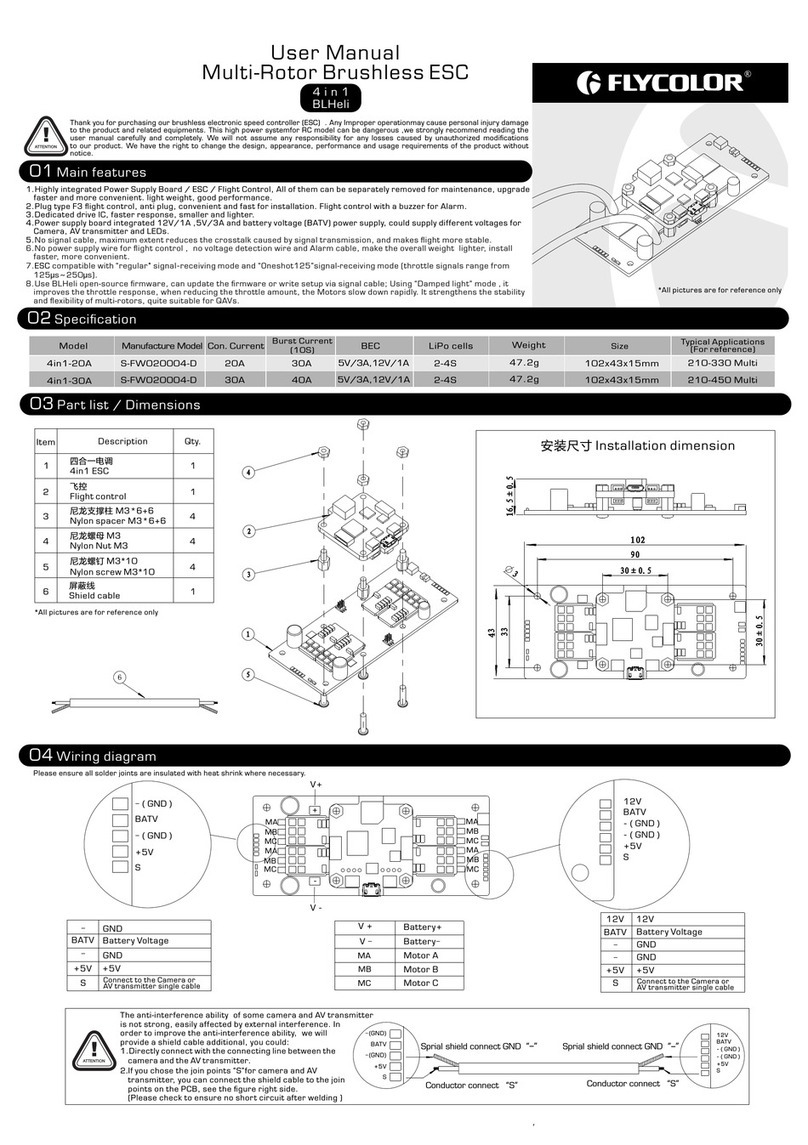

04 Wiring diagram of ESC

ATTENTION

05 E SC Programming parameter

www.flycolor.net

06 Attention

36

41.5

30.5

30.5

* Compatible with the general F3 FC. Reco mmend

the Flycolor Raptor390 Tower F3 Flight Controller.

Install Dimensions(mm)

12

34

Battery v+

Battery v-

3#Motor

1#Motor

1#Motor

4#Motor

4#Motor

4#Motor

2#Motor

2#Motor

2#Motor

3#Motor

3#Motor

1#Motor GND S1 S2 S3 S 4

4

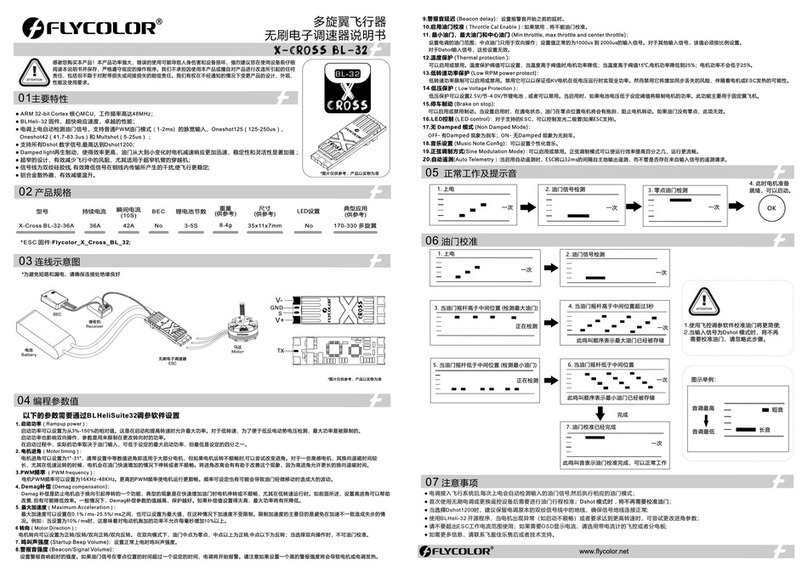

User Manual

Multi-Rotor Brushless ESC

Thank you for purchasing our product. Any Improper operation may cause personal injury damage to the

product and related equipments. This high power system for RC model can be dangerous ,we strongly

recommend reading the user manual carefully and completely. We will not assume any responsibility for any

losses caused by unauthorized modifications to our product. We have the right to change the design,

appearance, performance and usage requirements of the product without notice.

● Using C8051F390 MCU ,pipelined 8-bit C8051 core with 50 M Hz maximum operating frequency.

makes the Using dedicated 3in1 drivers, faster response.●4in1 ES C installation faster and more convenient ;

ESC maximum speed is limited to 400k eR PM.

● Only need to use very short signal cable to connect flight controller. The interference caus ed by the signal

transmission is reduced to the maximum extent, and the flight is more stable.

● Use BLHeli open-source firmware; Using “Damped light” mode , it impr oves the throttle response, when

reducing the throttle amount, the Motors slow down rapidly. It strengthens the stability and flexibility of multi-

rotors, quite suitable for QAVs.

There are tuneable parameters that can make the code run well even in the most demanding situations, ●

although default settings will work excellently in normal operating environments.

Supports regular 1-2m s pulse width input, as well as Oneshot125 (125-250us), Oneshot42 (41.7-83.3us) and Multishot (5-25us). The input signal is ●

automatically detected by the E S C upon pow er up.

Con. Current Bu rst Current

(10S)

Size

( For reference )

Weight

LiPo cells Typical Application

( For reference )

Model

Item Description Qty.

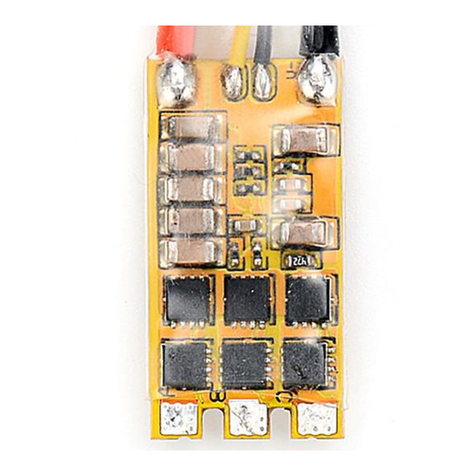

ESC additional provide:

One 5-Pin cable (5 J R terminals) for connection

with Flight Controlle r;

One 14 AW G power input cable(XT60 terminal).

*All pictures are for reference only

● All welding requires good welding technology,

short circuit between the element or the wire

should be avoided at any time.

● Please ensure all solder joints are insulated

with heat shrink where necessary.

● Please double-check the polarity is correct

before power up.

GN D S1 S 2 S3 S4

FC 4# signal output

FC 3# signal output

FC 2# signal output

FC 1# signal output

FC GND

Warning:Please do not us e these pad s.

Default values are mark ed in dark gray.

*:Only enabled for some ES Cs. From code rev 14.4, damped light is default on the ESCs that support it. For prior code revisions, high is default.

**: Default startup power varies by E SC. Generally the default power is lower for larger ESCs.

***:For code revs 14.4 and before, dither range was 7/15/31/63.

1. Closed loop P gain sets the proportional gain for the rpm control loop. This setting controls the gain from speed error to motor power.

2. Closed loop I gain sets the integral gain for the rpm control loop. Th is setting controls the gain from integrated speed error (summed over time) to

motor power.

3. Closed loop mode sets the range of speeds that the control loop can operate on.

- For the high range, throttle values from 0% to 100% linearly correspond to rpm targets from 0 to 200000 electrical rpm

- For the middle range, throttle values from 0% to 100% linearly correspond to rpm targets from 0 to 100000 electrical rpm

- For the low range, throttle values from 0% to 100% linearly correspond to rpm targets from 0 to 50000 electrical rpm

- When closed loop mode is set to off, the control loop is disabled.

4.Multi gain scales the power applied to the motor for a given input. Note that this is only for PWM input, for PPM input it has no effect. Beware that a

low multi gain will also li mit the maximum power to the motor.

5. Startup is always done with the direct startup method, which runs the motor using back emf detection from the very start. In this mode power is given

by the throttle used, but limited to a maximum level. This maximum level can be controlled with the startup power parameter. Beware that setting

startup power too high can cause excessive loading on ESC or motor!

6. Commutation timing can be adjusted in three steps. Low is about 0°, mediumlow 8°, medium 15°, mediumhigh 23° and high 30°. Typically a medium

setting will work fine, but if the motor stutters it can be beneficial to change timing.

7.Pwm frequency:

-High: High pwm frequency is around 20kHz. -Low: Low pwm frequency is around 8kHz.

-Damped light : This mode adds loss to the motor for faster retardation. Damped light mode always uses high pwm frequency. This mode is only

supported on some ESCs (where fet switching is sufficiently fast).

8.Pwm dither is a parameter that adds some variation to the motor pwm off cycle length. This can reduce problems (like throttle steps or vibration) in

rpm regions where the pwm frequency is equal to harmonics of the motor commutation frequency, and it can reduce the step to full throttle. It is

primarily beneficial w hen running damped ligh t mode. Dither is not applied in closed loop mode.

9.Demag compensation is a f eature to protect from motor stalls caused by long winding demagnetization time after commutation. The typical symptom

is motor stop or stutter upon quick throttle increase, particularly when running at a low rpm. As described earlier, setting high commutation timing

normally helps, but at the cost of efficiency.

Generally, a higher value of the compensation parameter gives be tter protection. If demag compensation is set too high, maximum power can be

somewhat reduced.

10. The rotation direction setting can be used to reverse motor rotation.

11.The input pwm polarity setting can be used to inverse the throttle b ehaviour. This is intended to be used with receivers that provide negative pwm.

When using P PM inpu t it must be set to positive.

Programming paramet ers that can only be accessed from configuration software (BLH eliSuite):

- Throttle minimum and maximum values for PPM input (will also be changed by doing a throttle calibration).

- Throttle center value for bidirectional operation with P PM.

- Beep strength, beacon strength and beacon delay.

- Programming by TX. If disabled, the TX can not be used to change parameter values (default is enabled).

- Thermal protection can be enabled or disabled (default is enabled).

Temperature is above 140℃, motor power is limited to 75%;Above 145℃, motor power is limited to 50%;Above 150℃, motor power is limited to 25%.

Above 155℃, motor power is lim ited to 0%.

- PWM input can be enabled or disabled (default is disabled). If disabled, only 1-2ms P PM an d 125-250us OneShot125 are accepted as valid input

signals.

- Power limiting for low RPMs can be enabled or disabled (default is enab led). Disabling it can be n ecessary in order to achieve full power on some low

kV motors running on a low supply voltage. However, disabling it increases the risk of toasting motor or ESC.

- Brake on stop can be enable d or disabled (from rev14.5 ,default is disabled),When enabled, brake will be applied when throttle is zero. For nonzero

throttle, this setting has no effect.

Programming paramet ers below in table that can be accessed from the configuration software (BL HeliSuite) via connect the flight controller :

0.50

0.50

1.25

0.125

31

/

/

/

/

/

0.75

0.75

0.188

1.00

1.00

0.25

1.5

1.5

0.38

2.0

2.0

0.50

3.0

3.0

0.75

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

56 7 8 9 10

1.00

4.0

4.0

11

/

/

/

/

/

/

/

/

1.25

6.0

6.0

12

/

/

/

/

/

/

/

/

1.50

8.0

8.0

13

/

/

/

/

/

/

/

/

0.25

0.25

LowRange

1.00

0.063

Medium

*DampedLight

7

High

Bidirectional

/

3

Function

1 - Closed loop P gain

2 - Closed loop I gain

3 - Closed loop mode

4 - Multi gain

5 - Startup power**

6 - Commutation timing

7 - Pwm frequency

8 - Pwm dither***

9 - Demag compensation

10 - Rotation direction

11 - Input pwm polarity

High

0.38

0.38

Off

1.12

0.094

Med-High

/

15

/

/

/

4

0.17

0.17

MidRange

0.88

0.047

Med-Low

Low

3

Low

Reversed

Negative

2

0.13

0.13

HiRange

0.75

0.031

Low

High

Off

Off

Normal

Positive

1

● User need to calibrate th e throttle range when starting to use a new E SC or another transmitter.

● BLHeli open-source firmware, when some abnormality occurs in ES C driving the motor or n eed the motor to reach a high er RP M, user can try to

change the timing.

● User also can connect the fl ight control to the computer to update the firmware or change the setup via .configuration software ( BLHeliSuite )

● Please contact Flycol or sales or technical support for more information.

User Manual

Multi-Rotor Brushless ESC

251400-1059,V 1.0