Seiko 7T85 Quick start guide

Other Seiko Watch manuals

Seiko

Seiko 7R68 User manual

Seiko

Seiko STOPWATCH S143 User manual

Seiko

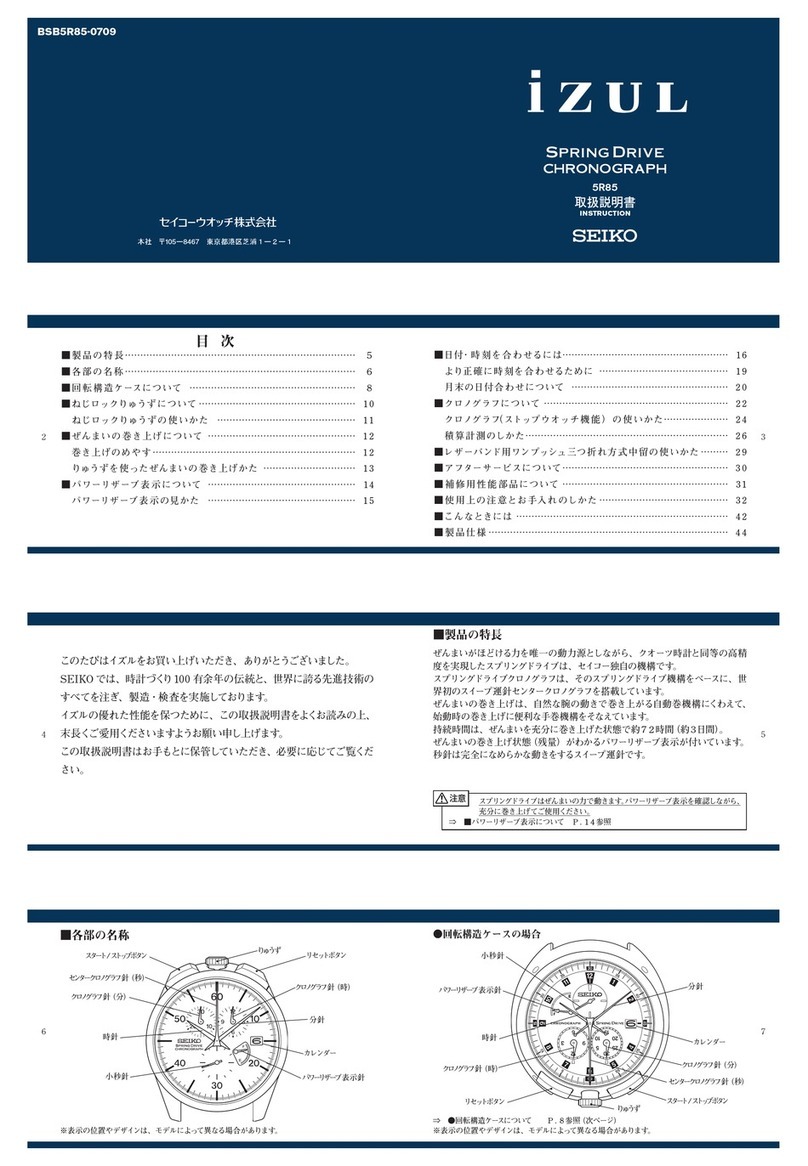

Seiko Spring Drive IZUL 5R85 User manual

Seiko

Seiko PROSPEX SNE567 User manual

Seiko

Seiko ANALOGUE QUARTZ SOLAR V145 User manual

Seiko

Seiko SGED97 User manual

Seiko

Seiko KINETIC 7D56 User manual

Seiko

Seiko SSA447 User manual

Seiko

Seiko 7T84 User manual

Seiko

Seiko SPC167P1 User manual

Seiko

Seiko 4R37A Quick start guide

Seiko

Seiko 1E20 User manual

Seiko

Seiko YT57B Quick start guide

Seiko

Seiko 8X53 Series User manual

Seiko

Seiko 4F56 User manual

Seiko

Seiko 5D44A Installer manual

Seiko

Seiko 8M26A Installer manual

Seiko

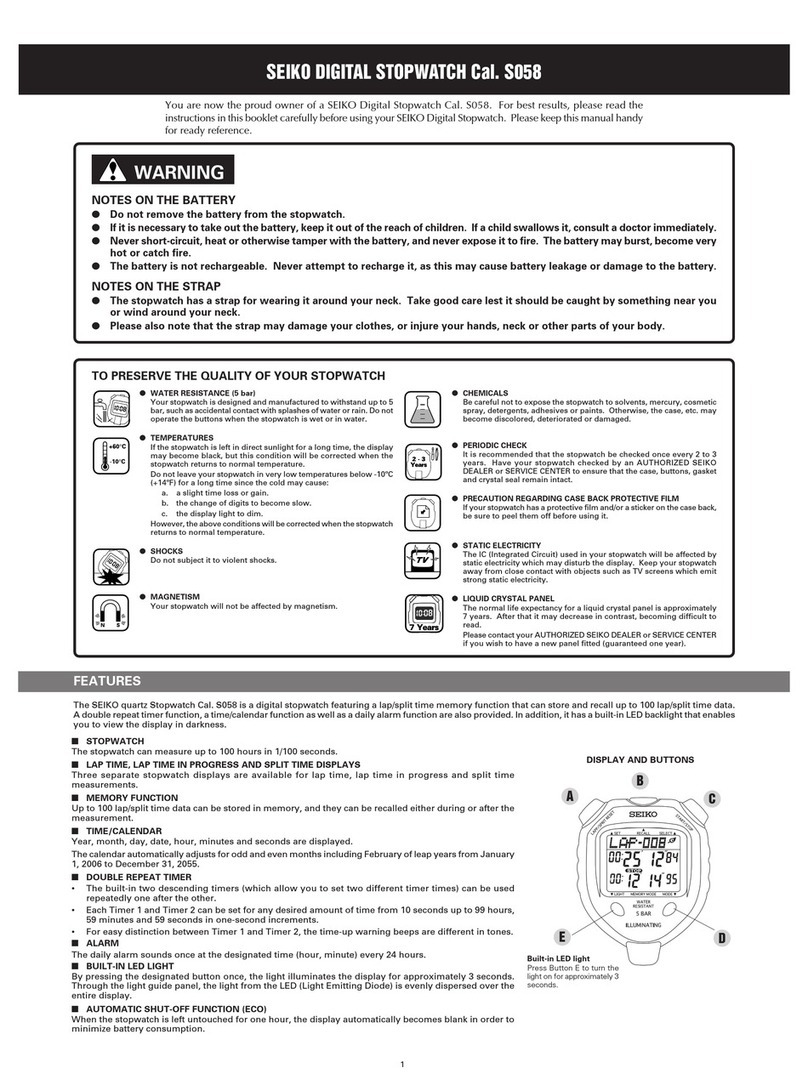

Seiko Cal. S058 User manual

Seiko

Seiko UC-2000 User manual

Seiko

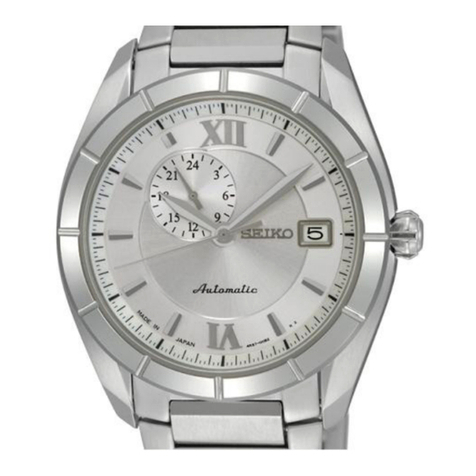

Seiko Presage SSA439J User manual