Seiko 7D Series Owner's manual

Other Seiko Watch manuals

Seiko

Seiko Time Keeper ViB+ User manual

Seiko

Seiko 5D88 User manual

Seiko

Seiko PSZ471P1 User manual

Seiko

Seiko 4R35B Quick start guide

Seiko

Seiko 7d46A Quick start guide

Seiko

Seiko 4F56 User manual

Seiko

Seiko 9R66 User manual

Seiko

Seiko 7T82 User manual

Seiko

Seiko H249 User manual

Seiko

Seiko 8M26A Installer manual

Seiko

Seiko 6N76A Quick start guide

Seiko

Seiko H021 User manual

Seiko

Seiko 5M54A Quick start guide

Seiko

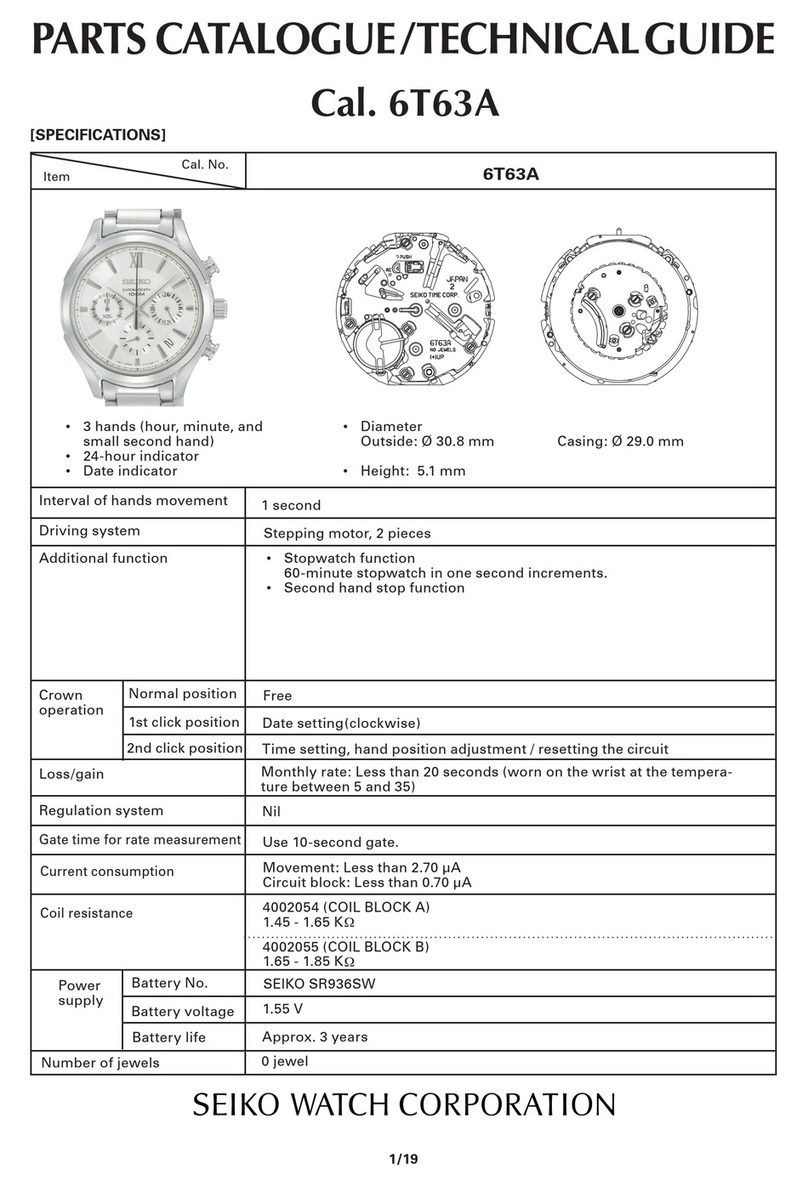

Seiko 6T63A Quick start guide

Seiko

Seiko SSB367 User manual

Seiko

Seiko 6R15 User manual

Seiko

Seiko Pulsar Y182 User manual

Seiko

Seiko Astron 3X22 User manual

Seiko

Seiko SPL053P1 User manual

Seiko

Seiko ASTRON User manual

Popular Watch manuals by other brands

Casio

Casio QW 5513 Operation guide

Piaget

Piaget 560P Instructions for use

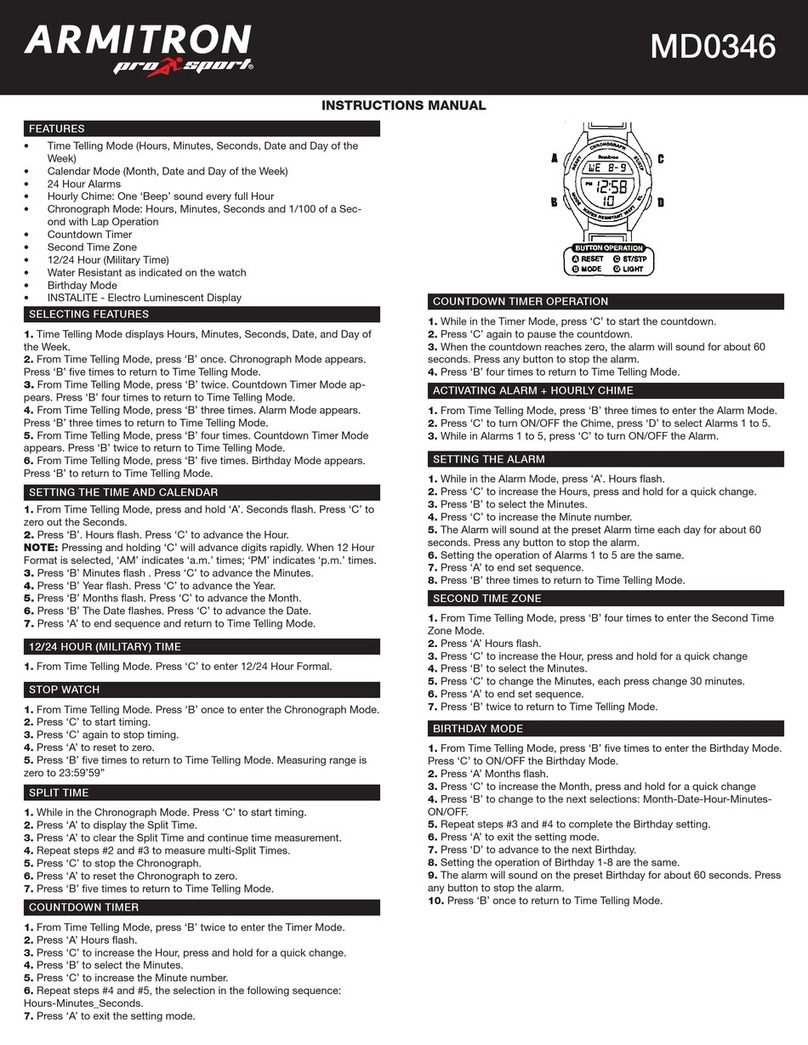

Armitron

Armitron pro sport MD0346 instruction manual

West Marine

West Marine BlackTip 13411293 Instruction Booklet and Care Guide

Jaeger-leCoultre

Jaeger-leCoultre HYBRIS MECHANICA CALIBRE 184 manual

FOREVER

FOREVER iGO PRO JW-200 user manual