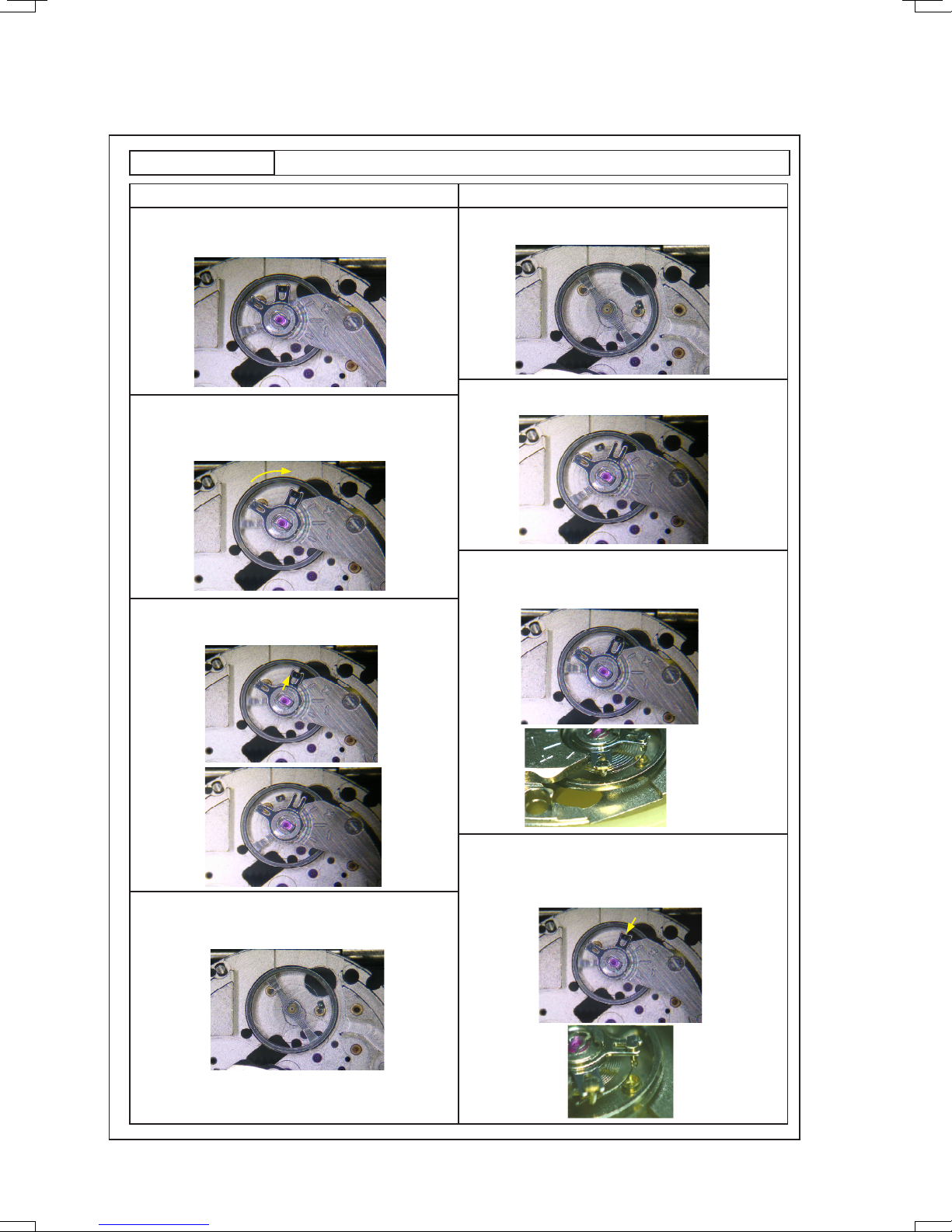

How to remove How to install

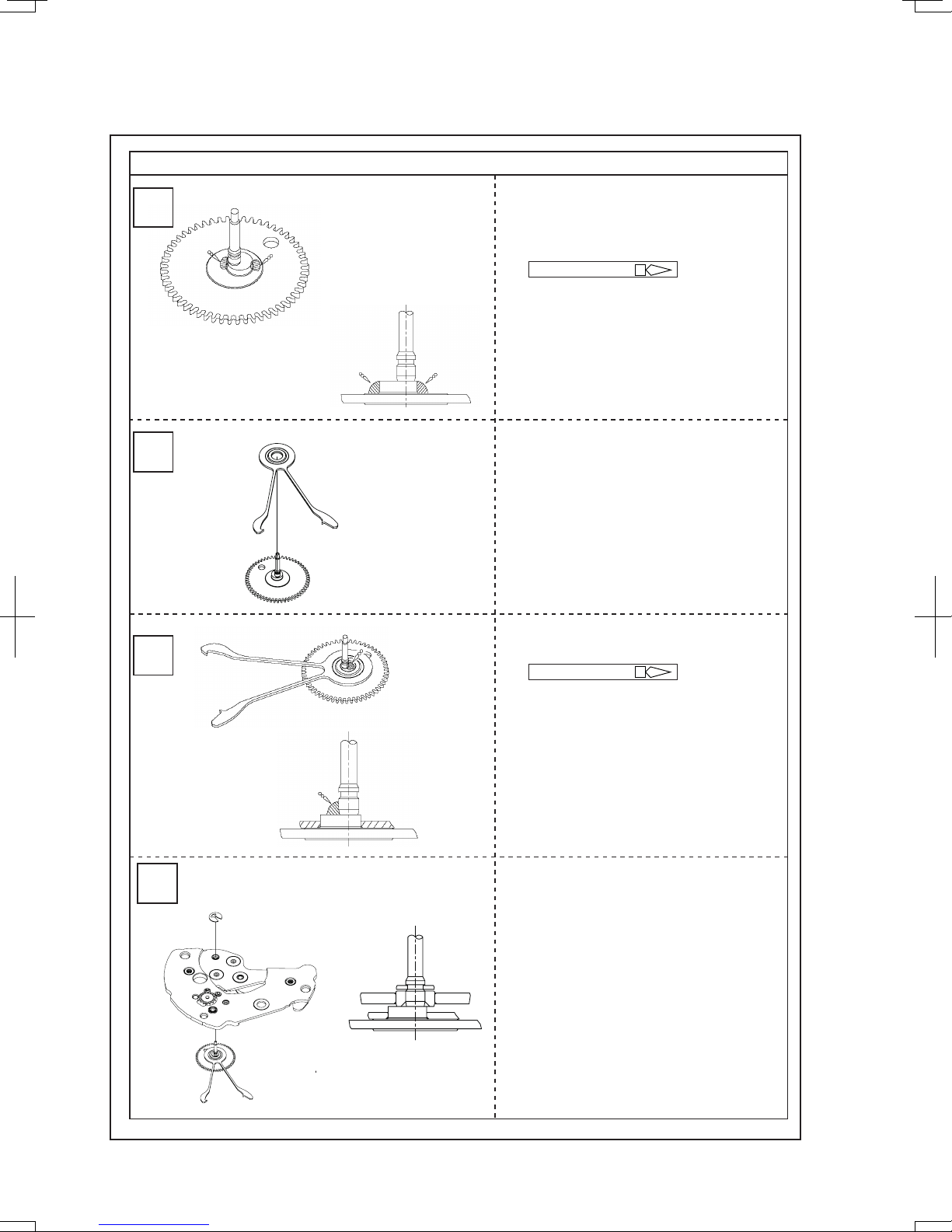

1. Initial phase

Set the balance complete with stud and balance bridge

to the main plate.

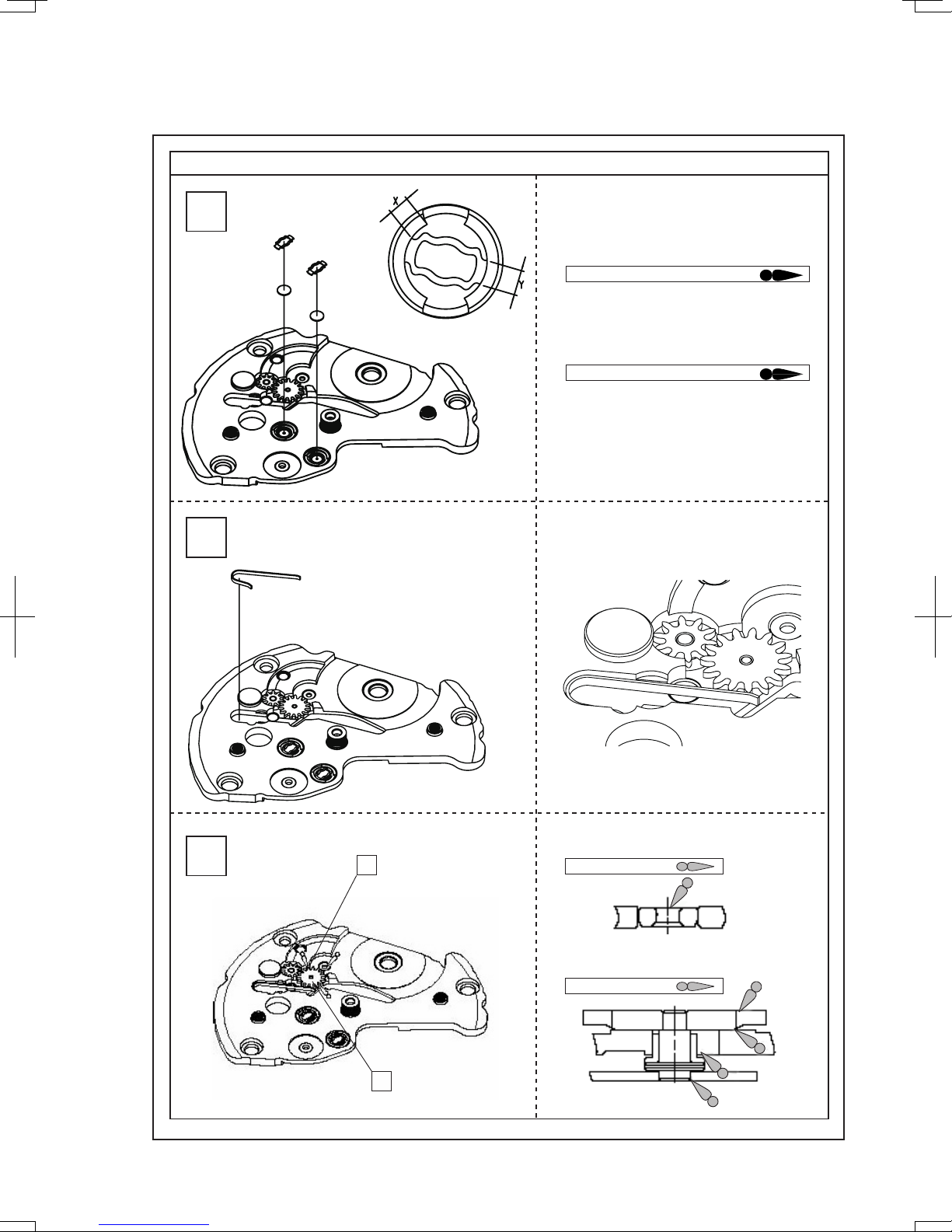

PREPARATION

HOW TO REMOVE AND INSTALL THE BALANCE STAFF

2. Move the stud support toward the balance bridge until it

is attached to the balance bridge.

* When doing so, make sure that the outer end of the

hairspring is not removed from the regulator arm.

4. Remove the balance bridge and replace the balance

complete with stud with a new one.

3. Temporarily set the stud to the stud support.

Make sure that the hairspring passes outside the pin of

the regulator arm.

* Be careful not to damage the hairspring.

1. Initial phase

Set a new balance complete with stud to the main plate.

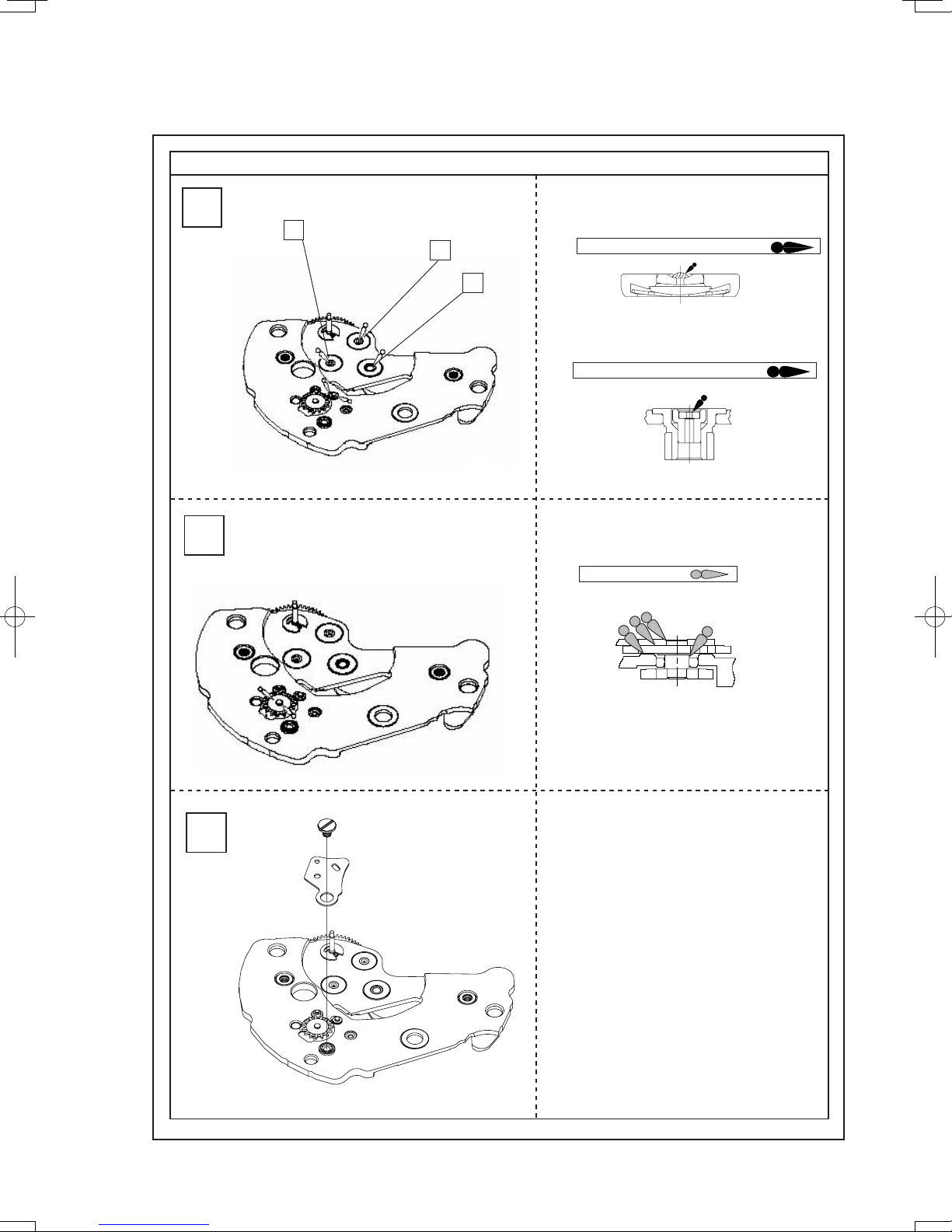

2. Set the balance bridge and tighten the balance bridge

screw.

4. Using sturdy tweezers, set the stud to the stud support

and press it down.

Make sure that the outer end of the hairspring passes

through the regulator slot of the regulator arm.

* Be careful not to damage the hairspring.

3. Using sturdy tweezers, push the stud outward from the

direction of the arrow shown in the illustration until it is

removed from the stud support.

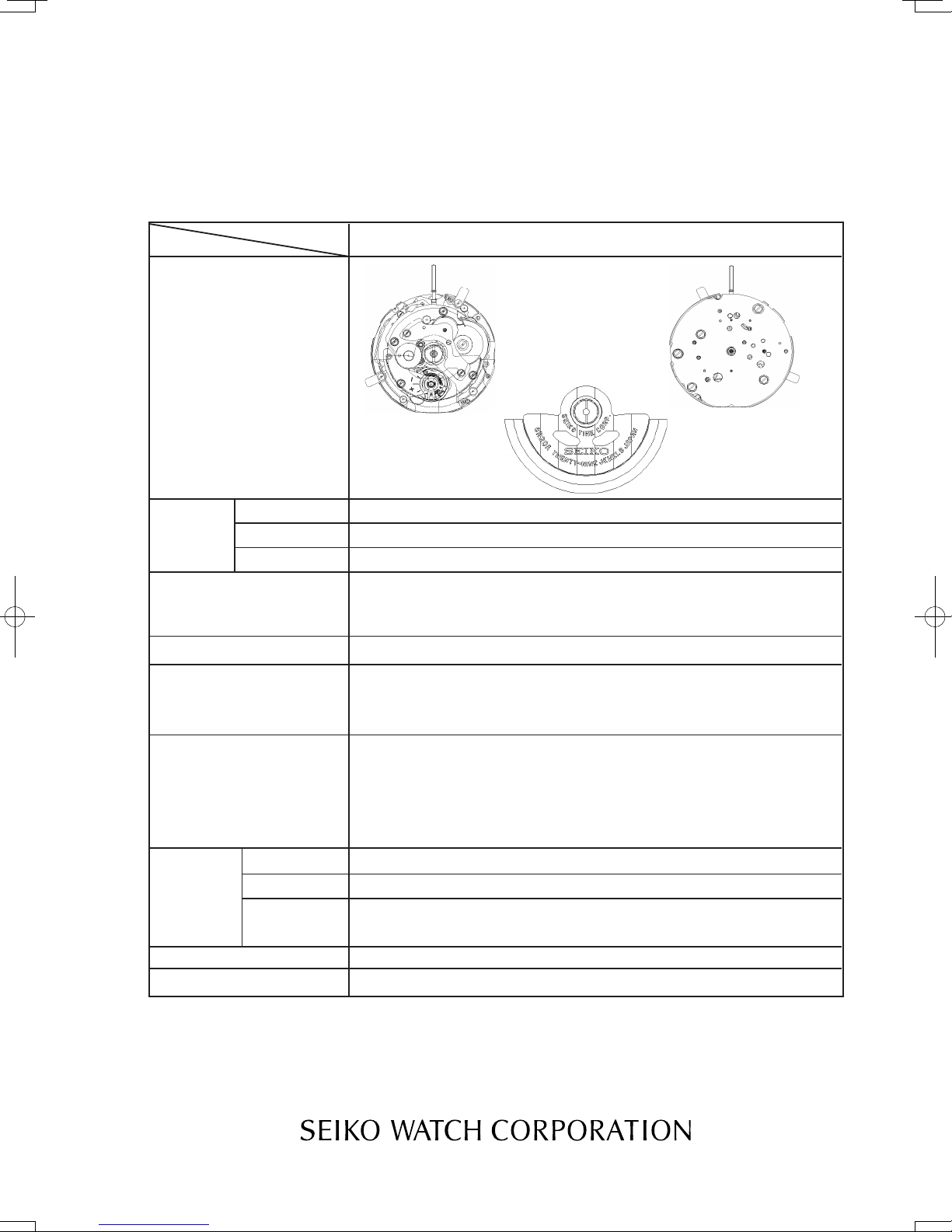

TECHNICAL GUIDE Cal. 6R20A

6/24