Select Engineered Systems TEC Series User manual

TEC Series v 3.2X

Page First

TEC Series

Telephone Access

Select

Engineered

Systems, Inc.

600TECMANUAL

Mar. 2015

TEC2

TEC4

TEC10

TEC Series v 3.2X

Page i

1 INTRODUCTION TEC SERIES 1

STANDARD FEATURES 1

CUSTOMIZING FEATURES 2

OPTIONS 3

ENVIRONMENT CONSIDERATIONS 4

ELECTRICAL REQUIREMENTS 4

TECHNICAL DATA 4

2 INSTALLATION 5

GENERAL 5

WIRE SPECIFICATIONS 5

TERMINAL WIRING HOOKUP CONNECTIONS 6

TERMINAL BARRIER STRIP CONNECTION DESCRIPTION 7

DIP SWITCH SETTINGS 8

SPEAKER SETTINGS 8

MICROPHONE SETTINGS 8

POWER SWITCH 9

3 ACCESSORY INSTALLATION 10

GENERAL 10

AVAILABLE OPTIONS 10

TWO (2) INPUT WIEGAND INPUT MODULE - VOLTAGE SELECT 11

FOUR (4) INPUT WIEGAND INPUT MODULE - VOLTAGE SELECT 11

WIRE SPECIFICATIONS 12

CARD READER WIRING 13

CARD READER SETTINGS 13

WIEGAND FORMAT 13

NIC CARD INSTALLATION 14

K2 RELAY FOR ENTRANCE 3 AND 4 15

K3 RELAY 16

ALARM AND CAMERA 16

TAMPER INPUTS 16

SHUNT USE FOR 4 WIEGAND INPUT MODULES 16

SERIAL PORT 17

PRINTER CONNECTION 17

MESSAGES 18

COMPUTER CONNECTION 18

TERMINAL CONNECTIONS 19

CURRENT LOOP WIRING 20

MODEM INSTALLATION 21

BOARD PLACEMENT 21

CONNECTIONS 21

SOFTWARE CONSIDERATIONS 21

MULTIPLE UNIT INTERFACE (MUI) 23

BOARD PLACEMENT 23

TWO MINUTE LOCKOUT 23

TECLITE 24

WIRING CONSIDERATIONS 24

LAMP CHANGING 24

TEC Series v 3.2X

Page ii

4 PROGRAMMING 25 - 68

QUICK KEYPAD EXAMPLE 25

TOUCH TONE 26

INITIALIZATION 27 - 49

MANAGER PASSCODE 50 - 68

PROGRAMMING CHOICES 50

KEYPAD 28

CODES / NAMES 30

ADD / FIND NAME 30

DELETING A CODE 30

DELETING A CODE FIELD 30

CODES USED 32

SHOW ALL CODES 32

SHOW ALL NAMES 32

ENABLE ACCESS GROUPS 32

ENTRY CONTROL 32

ENTRANCE X UNLOCK TIME 32

ENTRANCE X UNLOCK TONE 33

ENTRANCE X AUTO GROUP 33

ENTRANCE X LATCH TONE 33

ENTRANCE X SPECIAL RELAY ENABLE 33

SYSTEM PARAMETERS 34

TALK TIME 34

ALARM TIME 34

CODE LENGTH 34

PIN LENGTH 34

BACK BEEP 34

TONE DIAL 35

UNIT ID. OR RING COUNT 35

STRIKE OUTS 35

TITLE PAGE 35 - 36

COMMUNICATIONS SETUP 36

TERMINAL TYPE

36

RS 232 BAUD

37

PROGRAM PASSWORD 37

CONTROL PASSWORD

37

PIN ON ENTRANCE

37

SITE CODE

37

DIRECTORY ON / OFF

38

KEYPAD ON / OFF

38

SPEAKER TONE

38

TEC Series v 3.2X

Page iii

PROGRAMMING continued

CLOCK SETUP

38

SETTING TIME/DATE

39

SETTING TIME ZONES 39

SETTING HOLIDAYS

41

ACCESS LEVELS 42

SELECTING AN ACCESS GROUP 42

SELECTING AN ACCESS LEVEL

43

PROGRAMMING AN ACCESS LEVEL - TABLE

44

AUTOMATIC UNLOCK AND RELOCK BY TIME ZONE

44

EXAMPLE OF AN AUTOMATIC UNLOCK APPLICATION 44 - 45

TRANSACTION BUFFER INFORMATION

45 - 46

VIEW LOG

46

SEND LOG

46

BUFFER FREE

46

CLEAR BUFFER

46

CLEAR DATA

46

SET PARAMETERS 46

CLEAR TIME ZONES

46

CLEAR HOLIDAYS

46

CLEAR ACCESS LEVELS

47

CLEAR ACCESS GROUPS 47

CLEAR CORRUPT DATA

47

DISPLAY DATA

47

PRINT INFO

47

PRINT HOLIDAYS 48

PRINT ACCESS LEVELS 48

PRINT ACCESS GROUPS 48

DISPLAY TIME ZONE 49

DISPLAY HOLIDAYS 49

DISPLAY ACCESS LEVELS 49

DISPLAY ACCESS GROUPS 49

TERMINAL PROGRAMMING 50

GENERAL 50

MANAGER PASSCODE 51

PROGRAMMING CHOICES 51

CODES / NAMES 53

ADD / FIND NAME 53

DELETING A CODE 53

DELETING A CODE FIELD 53

CODES USED 54

SHOW ALL CODES 54

SHOW ALL NAMES 54

ENABLE ACCESS GROUPS 55

ENTRY CONTROL 55

TEC Series v 3.2X

Page iv

TERMINAL PROGRAMMING continued

ENTRANCE X UNLOCK TIME 55

ENTRANCE X UNLOCK TONE 55

ENTRANCE X AUTO GROUP 56

ENTRANCE X LATCH TONE 56

ENTRANCE X SPECIAL RELAY ENABLE 56

SYSTEM PARAMETERS 57

TALK TIME 57

ALARM TIME 57

CODE LENGTH 57

PIN LENGTH 57

BACK BEEP 57

TONE DIAL 57

UNIT ID. OR RING COUNT 58

STRIKE OUTS 58

TITLE PAGE 58

COMMUNICATIONS SETUP 59

TERMINAL TYPE

59

RS 232 BAUD

59

PROGRAM PASSWORD

59

CONTROL PASSWORD

59

PIN ON ENTRANCE

59

SITE CODE

60

DIRECTORY ON / OFF

60

KEYPAD ON / OFF

60

SPEAKER TONE

60

UPDATE LCD (TECVISION ONLY) 60

CLOCK SETUP

60

SETTING TIME/DATE

60

SETTING TIME ZONES

61

SETTING HOLIDAYS

62

ACCESS LEVELS 63

SELECTING AN ACCESS GROUP

63

SELECTING AN ACCESS LEVEL

64

PROGRAMMING AN ACCESS LEVEL - TABLE

65

AUTOMATIC UNLOCK AND RELOCK BY TIME ZONE 65

EXAMPLE OF AN AUTOMATIC UNLOCK APPLICATION 65 - 66

TRANSACTION BUFFER INFORMATION 66

VIEW LOG

66

SEND LOG

66

BUFFER FREE

67

CLEAR BUFFER

67

CLEAR DATA

67

TEC Series v 3.2X

Page v

TERMINAL PROGRAMMING continued

SET PARAMETERS 67

CLEAR TIME ZONES

67

CLEAR HOLIDAYS

67

CLEAR ACCESS LEVELS

67

CLEAR ACCESS GROUPS 67

CLEAR CORRUPT DATA

67

DISPLAY DATA 68

PRINT INFO

68

PRINT HOLIDAYS 68

PRINT ACCESS LEVELS 68

PRINT ACCESS GROUPS 68

DISPLAY TIME ZONE 68

DISPLAY HOLIDAYS 68

DISPLAY ACCESS LEVELS 68

DISPLAY ACCESS GROUPS 68

TEC Series v 3.2X

Page 1

The TECHF/50, through TECHF/2000, are automatic call , entry and card reader control

systems.

The TEC units operate and program identically. In this manual, the term "TEC" will be used

interchangeably to refer to any type of unit. The TEC series line includes a 2 line display LCD display

called the TEC2, a 4 line LCD display called the TEC4, and a 10 name LCD display called the TEC10.

Except for the display size or housing, the electronics are identical. This programming manual is valid

for any model TEC system. Where there are differences, a table will show those differences like this:

1 INTRODUCTION to the TEC SERIES

TEC10

The TEC 2 display message is: The TEC 10 display message is:

PRESS # TO VIEW

DIRECTORY PRESS # TO VIEW

DIRECTORY

PRESS # TO SEE NAMES

ON THE DIRECTORY

THEN DIAL THE CODE

TO THE RIGHT OF NAME

The TEC 4 display message is:

PRESS # TO VIEW

DIRECTORY

PRESS # TO SEE NAMES

THEN DIAL THE CODE

PRESS AND HOLD # FOR

FAST SCROLLING > Z

PRESS AND HOLD * FOR

FAST SCROLLING A <

TEC2

TEC4

TEC Series v 3.2X

Page 2

• 1 - 6 digit directory codes field programmable.

• 0 - 6 digit entry codes Personal Identification Number (PIN) field programmable.

• One card per Directory code.

• Up to 2,000 cards may be used

• Card reader control module for either 2 or 4 entrances using these technologies:

1) Wiegand, swipe, insert, or keypad.

2) Proximity, RF Transmitter, Bar Code (Wiegand code only), Long Range Proximity.

• Transaction Buffer (up to 1580 transactions depending on code size and options).

• Clock & Calendar, timed lock and unlock.

• Time Zones, Access Levels, and Holidays.

Resident activated door/gate release via Touch-Tone™ number (1-9), field programmable on all

entrances.

• Voice mail response capability. (Keypad active after unit calls out, programmed from TEC).

• Crystal controlled tone detection for short burst 50 MS tone.

• Speaker Listen-in.

• Memory Capacities:

50/125/250/500/1000/2000 for residents telephone numbers and names in directory.

• Dials out either Touch-Tone™ or rotary - field programmable.

• Dials up to 14 digit phone numbers.

• Unit will mute tones in speaker during dialing.

• Unit will not accept Touch-Tone™ signals through the microphone.

• Two line 16 character per line LCD display. (TEC 2 Series) Displays one name.

• Four line 20 character per line LCD display. (TEC 4 Series) Displays 4 names.

• Four line 40 character per line LCD display. (TEC 8 & Advantec Series) Displays 8 names.

• Programmable without opening cabinet, via keypad, RS-232, or Modem with Selcom 7 Software

• Talk time field programmable from 1 - 99 min.

• Postal lock capability included.

• Request to exit input for all entrance control relays.

• Entry code attempts (strike out) programmable from 0 - 9.

• Non-volatile memory, retains data even when power is removed.

• Surface or semi-flush mounting.

• Remote Entrance relay activation.

• Latching Entrance relays (with Remote Control Password).

• Programmable background "beep" to indicate call placed from telephone entry unit.

• Personal Identification Number (PIN code). Extra PIN codes above unit capacity.

• Remote Touch-Tone™ Entrance Relay Control.

• Manager Password (First three digits of Program Password).

• Battery charging circuitry.

STANDARD FEATURES:

STANDARD CUSTOMIZING FEATURES

1 INTRODUCTION

TEC Series v 3.2X

Page 3

• Hide Name Feature. Allows people to dial a code without displaying name on directory.

• Two minute modem lockout time.

• Dynamic scrolling, based on number of phone numbers programmed (See table below).

(Scrolls after key is held more than 4 seconds).

STANDARD CUSTOMIZING FEATURES continued

BASIC OPERATION:The TEC is a microprocessor based device that allows entering from 1 - 6

digits on the front keypad. It then automatically dials the phone number programmed into memory.

The TEC provides a relay output for controlling doors, gates, elevators or any device actuated by a

contact closure or contact opening. The TEC has a programmable 1 to 99 minute talk-time limit. It

provides warning tones near the end of talk time.

The TEC will dial out either pulse (rotary) or Touch-Tone™ via programming selection. While

the TEC dials, the speaker disconnects, keeping the dialed phone number confidential.

The TEC has an (optional) relay (OPTK3R). This can (depending on the options ordered and

the programming) be configured as either: a third door control, an alarm and off-hook control relay, or

Door 1 & 2 shunt relay and door sense. Calling the TEC from a Touch-Tone™ telephone will allow

the user to control the output relays by pressing a Touch-Tone™ number. (Factory default is 6 to

actuate relay 1.) When the user calls the TEC, the TEC will ring, go off hook and send a ¼ second

tone. Entering the proper control password will allow access to the output relays. This also allows

relay latching functions.

The (Optional) 12 volt DC .8 A/hr internal battery (B12V) is recommended for line stability. The

battery is NOT required for memory storage. SES supplies the TEC with a 16.5 vac transformer that

will operate the TEC and recharge the optional internal battery.

DO NOT CONNECT ANY OTHER DEVICES TO THE BATTERY.

TEC 2 TEC 4 TEC 10

1 to 30 Names scrolls by 2's scrolls by 4's scrolls by 8's

33 to 100 Names scrolls by 5's scrolls by 8’s scrolls by 16’s

101 to 260 Names scrolls by 10's Scrolls by 16’s scrolls by 32’s

261 or more Names scrolls by 15’s scrolls by 48's scrolls by 96's

Dynamic Scrolling Table,

• Card reader control module for either 2 or 4 entrances using these technologies

•

56.6K Baud modem

• Wiegand, swipe, insert or keypad

• Proximity, RF Transmitter, Bar Code (Wiegand Code Only), Long Range Proximity

• Clock & Calendar, timed lock and unlock with Time Zones Access Levels and Holidays

• Printer capability (RS-232 port) , Current Loop or NIC Interface to printer, terminal or computer

• (Baud rates to printer and/or remote terminal (CRT)) 300, 600, 1200, 2400, 4800, 9600, 19200

• Current loop 300, 600, 1200, 2400, 4800, 9600 to 2000 feet.

• Third signal relay with two modes of operation:

1.) for CCTV activation, alarm output, tamper input)

2.) or for control of a third door (timed and latched functions).

• Multiple TEC's (2 - 8 depending on programming mode) can share same telephone line, via

multiple unit interfaces (OPTKMUI).

• Local ringer capability.

OPTIONS:

TEC Series v 3.2X

Page 4

Indoor or Outdoor: The standard TEC housing is suitable for indoor or outdoor installations. For

semi-flush installations, contact SES about the optional flush ring (OPTFLR). For surface mount

installations, contact SES for the optional trim ring (OPTSL-2). Optional pedestal mounts for curb

(PST236), or street (PST242).

ENVIRONMENTAL CONSIDERATIONS

ELECTRICAL REQUIREMENTS

• POWER INPUT: 16.5 VAC 20 VA UL LISTED TRANSFORMER (PROVIDED).

• EMERGENCY BATTERY: 12V .8 A/HR GEL CELL ON CONSTANT CHARGE (OPTIONAL).

• TELEPHONE LINE: VOICE GRADE RJ-11C JACK.

• SHIPPING WEIGHT: APPROXIMATELY 15 LBS. (TEC 2 & 4 only)

• CONSTRUCTION: FRONT PANEL: 16 GA. STAINLESS STEEL (TEC 2, 4 & 8 only).

• BACK BOX: PAINTED CHEMICALLY TREATED ALLOY

ALUMINUM.

• OPERATING ENVIRONMENT: TEMPERATURE: -20º F (-6ºC) TO +160ºF (70ºC)

• RELATIVE HUMIDITY: 5% - 95% NON-CONDENSING.

• ` VISION TEMPERATURE: -32º F (-0ºC) TO +122ºF (50ºC)

• RELATIVE HUMIDITY: 5% - 95% NON-CONDENSING.

•

• RELAY OUTPUT: FORM C DRY CONTACTS 24V @ 3 AMP.

• MOUNTING: SURFACE OR SEMI-FLUSH.

• MEMORY TYPE: NON-VOLATILE.

• TONE DETECTION: CRYSTAL CONTROLLED, WILL DETECT SHORT BURST 50

MILLISECOND TONE.

Power: The TEC uses 16.5 volt ac 50/60 Hz. SES supplies a 16.5 vac transformer with each

purchase in the U.S. only. The installer may choose to provide their own 12 volt 300 - 600 ma. DC

supply (for TEC only depending on model type, will not also power card readers). YOU CAN NOT

USE AC TRANSFORMER AND DC SUPPLY AT THE SAME TIME.

Ground: The TEC must be connected to a good earth ground with at least # 16 ga. stranded wire.

This wire MUST be a minimum of 16 ga. connected to a ground rod or cold water pipe at one end,

and to the provided ¼-20 bolt at the TEC end. The maximum wire length is 50 feet. Surge damage

protection built into TEC diminishes if you do not provide an adequate earth ground.

Relay capabilities: 24 volts AC or DC at 3 amp. Form "A" (N/O) OR Form “B” (N/C) contacts are

present for all relays.

Gate controllers: Some solid-state gate controllers react to the over-voltage protection devices used

on all SES products. This is a gate controller dependent problem. The symptom is an intermittent

gate open, or gate stuck open condition, sometimes occurring after using the latching function. If this

occurs, add an external relay controlled by the TEC output relay contacts to your gate system

(OPTKFRMC) . This will help isolate the contacts going to your solid state gate controller from the

over-voltage protection devices.

Pedestal Mounting: For installations where the TEC will be mounted on a pedestal, a ground rod

MUST be installed immediately adjacent to the TEC. In addition, a ground wire of at least # 14

gauge wire must be used from the ¼-20 ground lug mounted in the back of the TEC back-box to the

ground rod clamp. This ground wire is to be no more than 25 feet in length, and should have no

sharp bends in the wiring.

TECHNICAL DATA

1 INTRODUCTION

TEC Series v 3.2X

Page 5

1. Never install telephone wiring during a lightning storm.

2. Never install telephone jacks in wet locations unless the jack is specifically designed for wet

locations.

3. Never touch un-insulated telephone wires or terminals unless the telephone line has been

disconnected at the network interface.

4. Use caution when installing or modifying telephone lines.

Installation of TEC requires coordination with your telephone company. SES recommends that a

Touch-Tone™ line be installed to allow much faster dialing. If a Touch-Tone™ line is not

available, the TEC can be reprogrammed to dial out pulse (rotary) signals.

The phone company may require the following information:

The ringer equivalence number.

The FCC registration number.

These numbers are on the label on the inside door of the TEC.

The desired location of the telephone jack must be given to the phone company at the

time you order the phone line.

INSTALLATION INSTRUCTIONS

INSTALLATION PROCEDURE

1) The TEC should be mounted approximately 52 inches above finished floor to the center of the

TEC. For drive up applications, TEC should be mounted approximately 42" - 48" above finished

flooring to the center of TEC. Hand set units should be mounted 40" - 46" above finished floor to

help comply with the Americans with Disabilities Act (ADA).

2) To surface mount the TEC, mount the back-box using the holes provided.

3) To flush mount the TEC, cut a hole the size of the back box (9 ½" wide X 13 ½" high) in the wall.

Mount the TEC in the hole. LEAVE ½" CLEARANCE FROM THE REAR OF THE DOOR TO THE

WALL SO THE DOOR WILL OPEN.

4) We recommend an optional weather hood (WH) when mounting TEC in a stand-alone application,

to protect it from direct exposure to rain and snow.

5) The TEC MUST BE AT EARTH GROUND POTENTIAL. Connect a #16 stranded or larger wire

from the ground lug mounted on the back-box of the TEC to a cold water pipe or other suitable

ground. This wire should be less than 50 feet in length.

6) Connect the wires for the power connections to TBS-5 and TBS-6, as shown on Pg. 7. Connect

the other ends of the wires to the screws on the supplied transformer (16.5 vac).

NOTE THE FOLLOWING BEFORE ATTEMPTING ANY INSTALLATION:

Recommended wire gauge is as shown: 16 ga. up to 50 feet.

14 ga. up to 100 feet.

For unusual distances or requirements please consult factory.

7) The ouput contacts for entrances 1 & 2 are Form A or B. If you are using the N.O. contacts on the

entrance 1 relay, connect the wires from the controlled device to TBS-13 and TBS-14, as shown on

Pg. 6. To use the N.C. contacts, move the jumpers on J201-1&2 as shown on Pg 8. Wire

entrance 2 relay to TBS-15 and TBS-16 and J202-1&2 in the same manner. For Entrance 3 & 4

relay connections, see Entrance 3 & 4 control on Page 15.

NOTE: THE RELAY CONTACTS ARE RATED FOR 24 VOLTS AC OR DC AT 3 AMPS MAXIMUM.

8) Connect the modular plug for the telephone line to the RJ-11 jack provided by the phone company.

No other telephones or equipment should be on this line. If attaching multiple TEC's to a single

phone line, the optional OPTKMUI (Multiple Unit Interface) may be purchased. For further

information, see Section on Page 23.

9) All wire openings, or any penetration of the TEC enclosure should be sealed in accordance with

the National Electrical Code or local ordinances.

10)This completes the installation.

INSTALLATION INSTRUCTIONS

TEC Series v 3.2X

Page 6

WIRING HOOKUP CONNECTIONS

TBS = TERMINAL BARRIER STRIP

INSTALLATION INSTRUCTIONS

PHONE LINE

TBS-2

TBS-3

TBS-5

TBS-6

TBS-11

Entrance 1

TBS-16`

MODULAR PLUG

TO RJ-11 JACK

TBS-12

SES

TRANS-

FORMER

POWER 16 GA. TWIST

50 FEET MAX DIST.

ELECTRIC DOOR STRIKE

DOOR STRIKE

N.O. DRY CONTACT

FOR GATE CONTROLLER

OR ELEVATOR INPUT

TBS-11

TBS-12

N.C. DRY CONTACT FOR

FAIL SAFE STRIKE OR MAG LOCK

TO DEVICE

TBS-12

TBS-13

TRANS-

FORMER

AS

NEEDED

TRANS-

FORMER

AS

NEEDED

Entrance 2

TBS-14

TBS-14

TBS-15

TBS-15

TBS-15

16.5VAC

20VA

TEC Series v 3.2X

Page 7

TERMINAL BARRIER STRIP CONNECTIONS

USE 16 GA. OR LARGER

TEC UNIT MUST BE GROUNDED

SES SUPPLIED TRANSFORMER 16 GA. TO 50 FT.

SES SUPPLIED TRANSFORMER 16 GA. TO 50 FT.

ENTRANCE #1 N.O.

or (Jumper 201-1&2)

ENTRANCE #1 N.C.

COMMON TO BATTERY AND REX INPUTS

ENTRANCE #2 N.O.

or (Jumper 202-1&2)

ENTRANCE #2 N.C.

FOR ALL SHIELDS

Entrance 1 and 2 Relays can be reconfigured to Normally Closed

Contacts. See page 8 for details on jumper changes.

BACKUP BATTERY + (POSITIVE)

INSTALLATION INSTRUCTIONS

TELEPHONE LINE CONNECTS HERE

TELEPHONE LINE CONNECTS HERE

N.O. REQUEST TO EXIT #1

N.O. REQUEST TO EXIT #2

COMMON TO BATTERY AND REX INPUTS

COMMON TO BATTERY AND REX INPUTS

Not Used

16.5 VAC

20 VA

TEC Series v 3.2X

Page 8

RESET

ALWAYS ON

2RDR=OFF / 4RDR=ON

SPKR ENABLE

PROGRAM ENABLE

CARD DIAG.

TecVision ENABLE

ALWAYS OFF FACTORY

SETTINGS

DO NOT

CHANGE

DIP SWITCH (SW1) SELECTION DESCRIPTIONS

— PROGRAM ENABLE

— SPKER ENABLE

— ALWAYS OFF

— ALWAYS OFF

— CARD DIAG.

— 2 RDR-OFF/ 4RDR-ON

— ALWAYS ON

— RESET

SPEAKER AND MICROPHONE ADJUSTMENTS

MORE

LESS

LESS

MIKE

SENS

SPEAKER

VOLUME

MORE

INSTALLATION.

Entrance 1

Shown N/O Move both

jumpers for each to

make N/O

Shown N/C Move both

jumpers for each relay

to make N/C

Entrance 2

Relay Jumper Selections

(J201-1&2 for Entrance 1)

(J202-1&2 for Entrance 2)

J201 1&2J202 1&2

NOTE:

MIKE SENSITIVITY AND

SPEAKER VOLUME

INTERACT WITH EACH

OTHER. IMPROPER

ADJUSTMENT WILL

ADVERSELY AFFECT

PERFORMANCE AND/OR

OPERATION.

TEC Series v 3.2X

Page 9

POWER SWITCH LOCATION

POWER SWITCH

TURN OFF BEFORE

INSTALLING OR

REMOVING

ACCESSORIES.

POWER

CONNECTOR

PHONE LINE

POLYSWITCHES

POWER LED

TEC Series v 3.2X

Page 10

ACCESSORIES OVERVIEW

Although some options are not shown, available options are:

• External Card reader(s) input (2 or 4 Readers)

• Wiegand, Proximity, RF Transmitter, Barcode (Wiegand output).

• Several reader technologies using Wiegand format signals are available, including Wiegand,

Proximity, RF Transmitter, and Long Range Proximity Readers. Wiegand output keypad

controllers also may be used in some situations. Contact the factory for particulars on Wiegand

output keypads.

• Second signal relay (OPTK2R) has functions for shunt activation and 2 REX inputs.

• Third signal relay (OPTK3R) has functions for CCTV activation, alarm output and 2 tamper inputs.

• Standby batteries (OPTB12V).

• 56k baud modem (OPTKMODEM56).

• RS-232 port or Current Loop for printer, terminal or computer connections (OPTKPRT)

• Serial Baud rates to printer and/or remote terminal (CRT) 300, 600, 1200, 2400, 4800, 9600,

19200

• Current Loop baud rates- 300, 600, 1200, 2400, 4800, 9600

• NIC Card for Networking connections for monitoring and programming

• Multiple units can share same telephone line, via MUIs (OPTKMUI).

• Two minute "sleep" function to allow programming up to 4 TECS with modems.

•Third signal relay (OPTK3R) has functions for CCTV activation, alarm output and 2 tamper inputs.

•

••

•Lighted Hood for greater night time visibility

To NIC2

TEC Series v 3.2X

Page 11

WIEGAND INPUT MODULES

The TEC OPTIONALLY can be equipped with two or

four internal card reader inputs. The card reader modules work

with 26 or 30 bit Wiegand format bit streams. There are no LED

drive indicator signals on the 4 door reader. Belden 9941 is

used to connect readers to the card reader modules.

There are jumpers on the card reader board to select 5 or

12 volts for various reader types. Many WIEGAND swipe,

insert or key readers are 5 volts. Many RF, PROXIMITY and INFRARED readers are 12 volts. If the

readers and the card option were purchased together, this has already been configured. If not, see the

diagram to select the appropriate card reader voltage setting. Check with the manufacturer of your

card reader for correct voltage selection.

Note that the card reader and relay assignments cannot be mixed. Card Reader 1 will

ALWAYS control the first relay. This is the relay on the terminal barrier strip to the left of the mother

board. Card Reader 2 will ALWAYS control the 2nd relay output on the terminal barrier strip to the left

of the mother board. The maximum distance for WIEGAND readers is 500 feet. Belden #9941 or

close equivalent must be used for card reader signals. The maximum distance for RF, PROXIMITY, or

INFRARED readers is 100 feet, using Belden #9941. For distances up to 500 feet use Belden #

83656, or close equivalent.

The maximum power consumption available for using on-board power supply is 125 ma. per

reader. For readers with greater power requirements, an external power supply MUST be used.

READER1CONTROLSOUTPUTRELAY

ONTBS-13 &TBS-14ONLY

READER3CONTROLSK2 OUTPUTRELAYONLY

SEE SECTION12.0ENTRANCECONTROL

WIEGAND

BARIUM

FERRITE

OR

PROXIMITY

4

12 3

READER2CONTROLSOUTPUTRELAY

ONTBS-15 &TBS-16ONLY

READER4CONTROLSK2 OUTPUTRELAYONLY

SEE SECTION12.0ENTRANCECONTROL

Jumper selectionistypicalfor all4

reader modules

.

CARD READER VOLTAGE SELECT

READER 1 CONTROLS OUTPUT RELAY

ON TBS-13 & TBS-14 ONLY

WIEGAND

BARIUM

FERRITE

OR

PROXIMITY

1

2

READER 2 CONTROLS OUTPUT RELAY

ON TBS-15 & TBS-16 ONLY

Jumper selection is typical for both

reader modules

.

ACCESSORY INSTALLATION

Reader 1 Common (Black)

Reader 1 LED (Brown)

Reader 1 D0 (Green)

Reader 1 D1 (White)

Reader 1 Power (Red)

Reader 2 Common (Black)

Reader 2 LED (Brown)

Reader 2 D0 (Green)

Reader 2 D1 (White)

Reader 2 Common (Red)

For older style readers still in use, above are

the jumper settings for voltage select.

(OPTIONAL)

(OPTIONAL)

TEC Series v 3.2X

Page 12

GROUNDING CARD READER WIRING

NOTE: DO NOT WIRE ANY PORTION OF THE CARD READER "HOT." REMOVE

ALL POWER BEFORE WIRING ANYTHING TO THE CARD READER.

WIEGAND CARD

READER

BLACK COM

GREE N D0

WHITE D1

RED +5 VDC

OR +12 VDC

BELDEN9941 100 FEET MAX DISTANCE

BELDEN83656 500 FEET MAX DISTANCE

TAPE SHIELD

THIS END

BARIUM

FERRITE

READER

BELDEN9941

500 FEET MAX DISTANCE

CONNECT SHIELD

TO GROUND LUG

READER 1 2 3 4

IJACKET INSULATION

RED

BLK

GRN

WHT

BRN

SHIELD BRAID

Strip away 3 inches from the outer jacket, as

shown at left.

JACKET INSULATION RED

BLK

GRN

WHT

BRN

SHIELD BRAID

Attach an insulated #18 gauge stranded

wire to the shield with a wire nut. Allow

enough length for the insulated #18 wire to

reach the ground lug in the back of the TEC

back box.

Tape the shield from the cable to the wire

nut to prevent shorting to any components

on the TEC PC board.

Poke a hole in the braid as shown at left.

Spread the braid open, so the conductors

are visible. Peel the conductors out, taking

care not to damage the insulation on the

conductors.

JA CK ET IN S U L AT IO N

R E D

B LK

G RN

W H T

B RN

S HIE L D B RAID

W I R E N UT

BLACK COM

GREEN D0

WHITE D1

RED +5 VDC

OR +12 VDC

UNUSED

BROWN LED

READER 2 1

ACCESSORY INSTALLATION

(OPTIONAL)

TEC Series v 3.2X

Page 13

CONNECTING CARD READER WIRING

BLK

RED

GRN

WHT

WIRE

READER 1 2 3 4

Strip 3/16" insulation from the conductors. Fold the stripped portion of the conductor over the

insulated portion. Insert the wire in the clamps of the screw terminals on the card reader board and

clamp down by screwing the terminal screw tightly. This ensures a good mechanical connection and

an electrical connection that will keep the small wires from breaking.

SITE CODE

To keep a card (for example card number 12345) from being used from another facility, a Site Code is

set in the TEC. This is the same as a Facility Code would be in a commercial card reader installation.

Set the Site Facility Code using Pg. 37

If the Site code (of the cards) is not known, turn on #5 on the dip switch on the main PC board.

This will display card errors on the LCD screen on the front door. Swipe a card through a reader and

read the site code error information on the LCD display to determine the Site code. After the Site

code is entered turn switch 5 off, to keep swiped card numbers confidential.

To have the TEC unit ignore the site code completely, enter 255 as a site code. This

diminishes the security of the facility, as a card from some other facility that was coincidentally the

same number as a valid card, could operate the reader. This is sometimes necessary when mixing

card technologies on a site, but should only be done as a last resort.

SETTING WIEGAND FORMAT

While there are several Wiegand output formats, the two used by SES are 26 and 30 bit Wiegand

output. The factory default from SES is 30 bit output. To set the bits to 26, enter 260 as a site code

number (See Pg 37) To set the bits to 30, enter 300 as a site code number. Neither of these numbers

will change the existing Site code.

ACCESSORY INSTALLATION

As the above drawing shows, grounding the card reader correctly is very important. Since the

ground lug for the TEC is near the top of the unit, take care to avoid shorting the card reader cable

shield to components on the mother board.

(OPTIONAL)

TEC Series v 3.2X

Page 14

NIC2 CARD

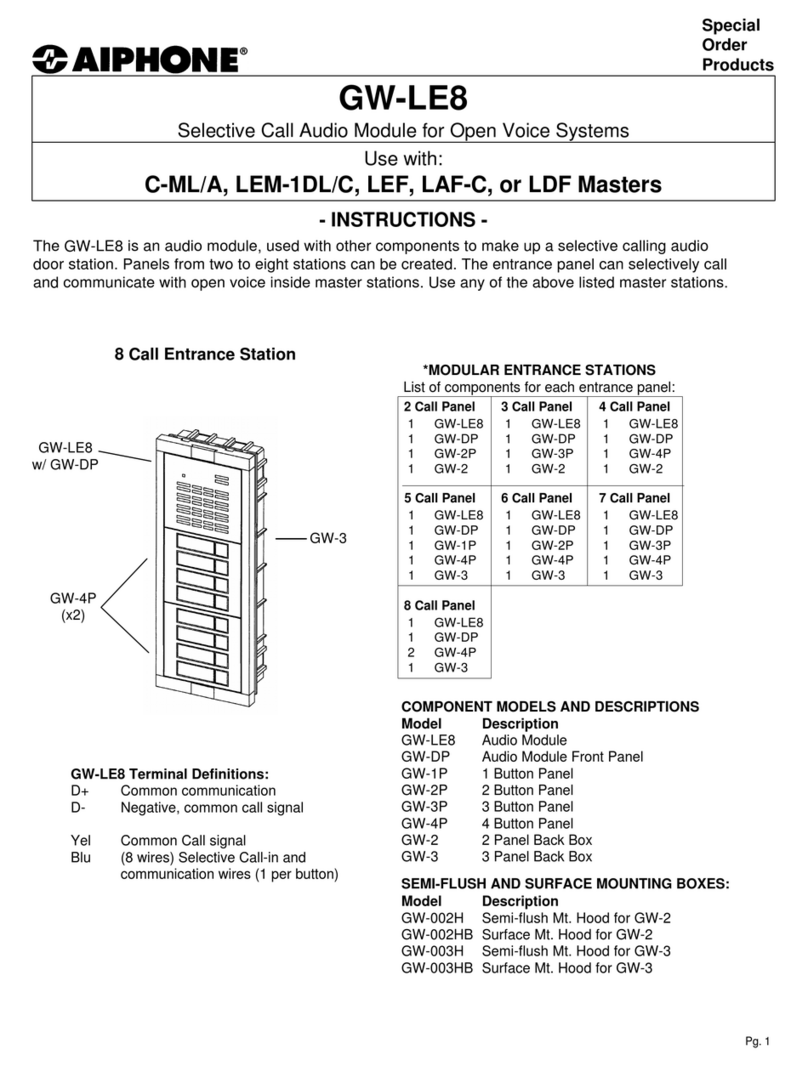

The NIC (Network Interface Card) provides a

plug-in TCP/IP interface for all CAT and TEC

products

• TCP/IP network compatible ONLY.

• Compatible with all CAT products.

• Compatible with TEC products

running Selcom 7 or newer *

•Compatible with TEC1.

• Requires the end user to have a

qualified network manager for setup.

The SES Network Interface is used to provide a Programming and Data connection to a SES CAT or

TEC Telephone Access Controller through a local area network. The SES Network Interface

provides for conversion of the standard serial interface in the SES CAT or TEC controller to a

TCP/IP connection. All portions of the connection must operate at the same speed and connectivity

settings. We are pre-setting the selections to 9600 baud, 8 bits, no parity, 1 stop bit.

Each interface is provided with a unique hardware address. The network system administrator

provides an IP address that is assigned to the unique hardware address. Each SES Network

Interface is then assigned a unique port address on the network. A standard range of port addresses

is provided, that are normally not used in most networks, but the actual address(es) used should be

cleared by and approved by the network system administrator.

The Com Port Re-Director provides a means of using the IP address as a directed serial com port.

An unused port number is chosen in the computer and assigned to the IP address of the SES CAT

or TEC unit. The actual address(es) used should be cleared by and approved by the network system

administrator. The redirected comm port is then selected in older versions of Selcom Software

(Selcom Secured 6 or older) for that SES CAT or TEC unit. Selcom Secured 7 and newer can

directly address TCP/IP addresses and a comm port redirector is not required.

See the NIC2 Card Instruction

for further Info.

(OPTIONAL)

This manual suits for next models

9

Other Select Engineered Systems Intercom System manuals