USER MANUAL – Z-SG

5

- short-circuit screw terminal 10 to screw terminal 11.

Use shielded cables for connections.

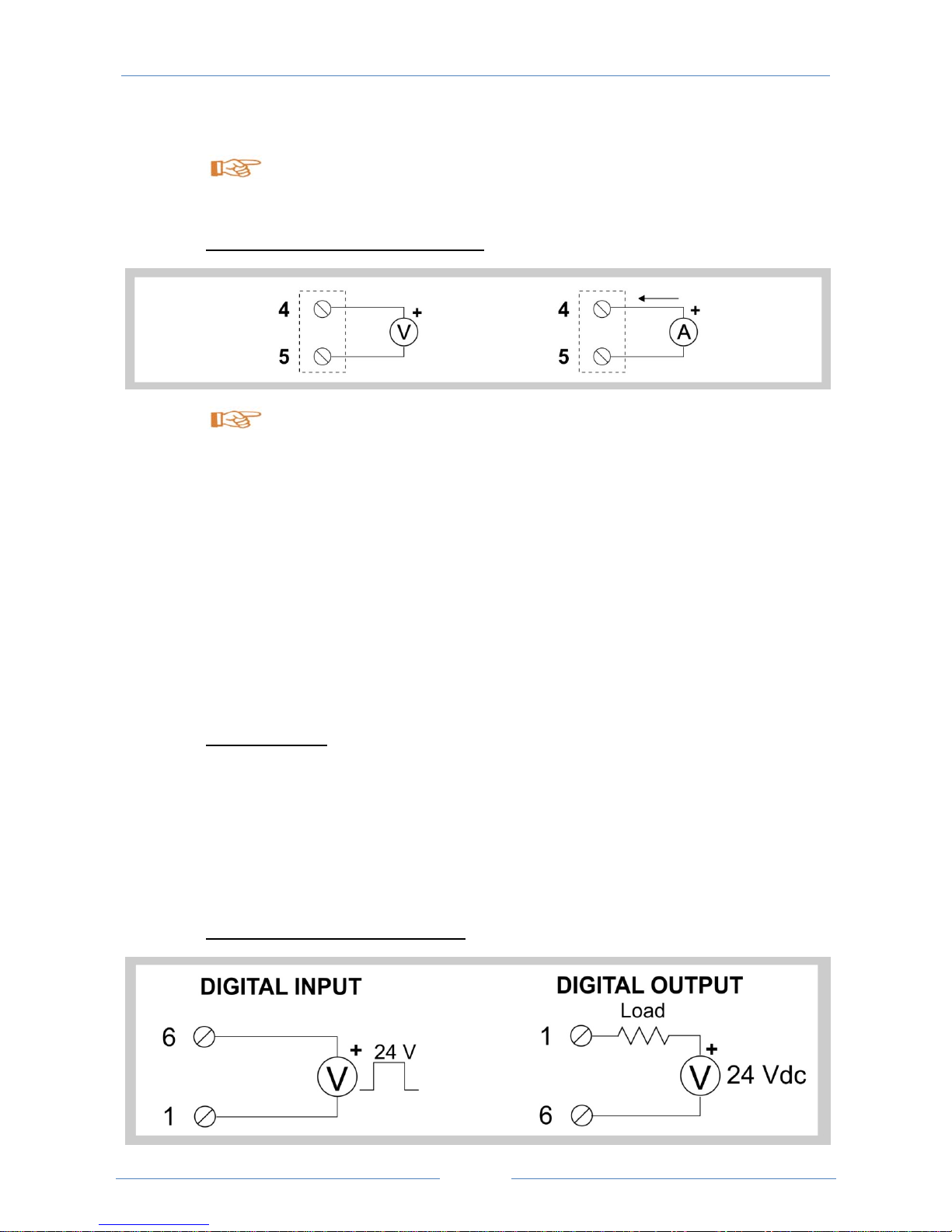

ANALOG OUTPUT (ONLY Z-SG MODEL)

”V” means voltmeter, “A” means amperemeter.

Z-SG module allows to associate net weight to the analog output value (and normalized net-

weight measure), as described in the following points:

- if technical net weight measure (reg.40064, 40065 FP) is less than min tech net-weight

(reg.40050, 40051 FP): normalized net-weight measure (reg.40063) is equal to 0 and analog

output is 0% (0V, 0mA, 4mA), available through screw terminals 4 and 5;

- if technical net weight measure (reg.40064, 40065 FP) is greater than max tech net-weight

(reg.40052, 40053 FP): normalized net-weight measure (reg. 40063) is equal to 30000 and

analog output is 100% (5V, 10V, 20mA), available through screw terminals 4 and 5;

- if technical net weight measure (reg.40064, 40065 FP) is between min tech net-weight and

max tech net-weight, analog output (current/voltage) is directly proportional to the net weight

measure and it is available through screw terminals 4 and 5.

STABLE WEIGHT

Z-SG / Z-SG-L module allows to detect when a weight is stable: weight stability information is

available through bit40066.4 or through digital output.

In particular, a weight measure is stable if the weight variation of net weight (reg.40064, 40065),

in a given time interval (“delta time”, reg.40058), is less than weight interval (“delta weight”,

reg.40056, 40057 floating point).

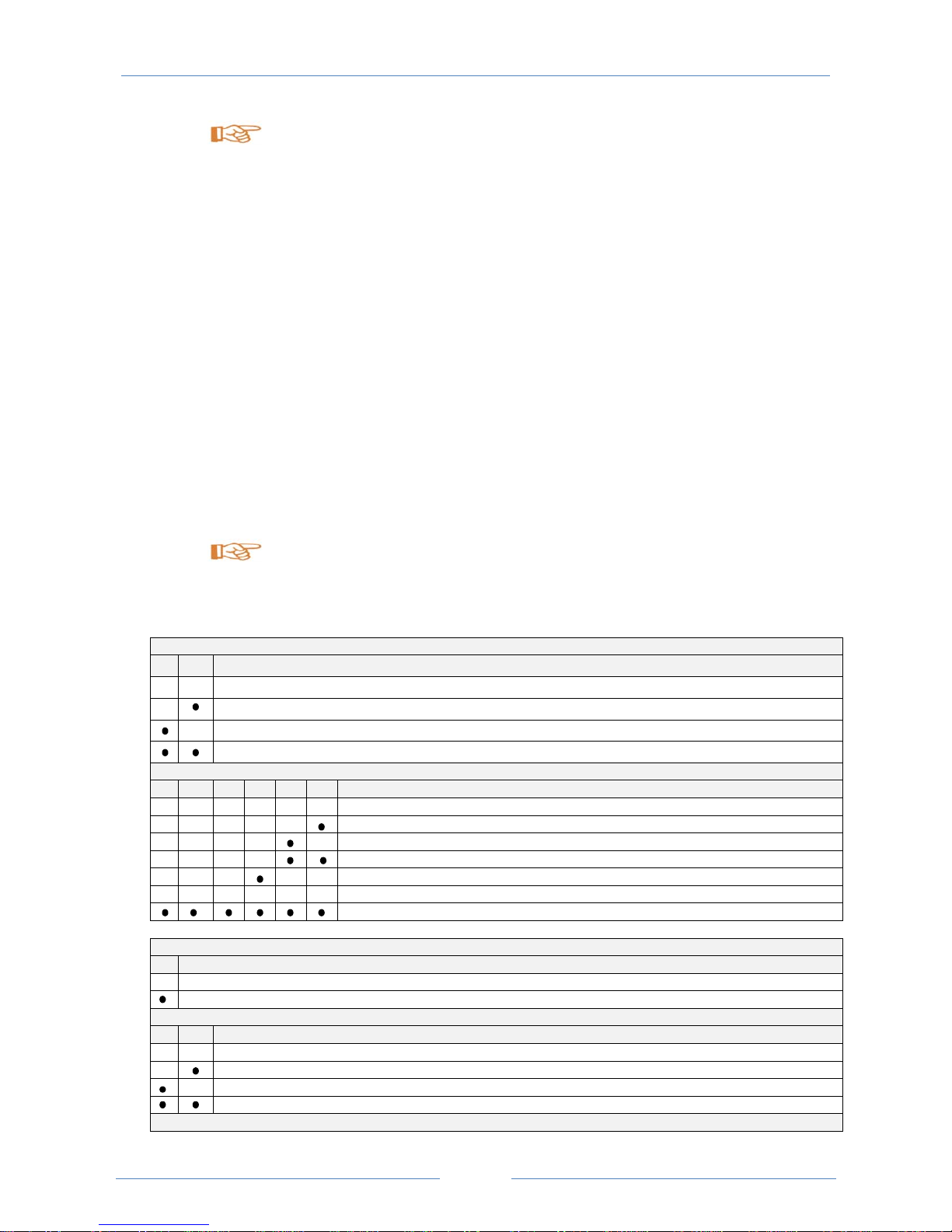

DIGITAL INPUT OR DIGITAL OUTPUT