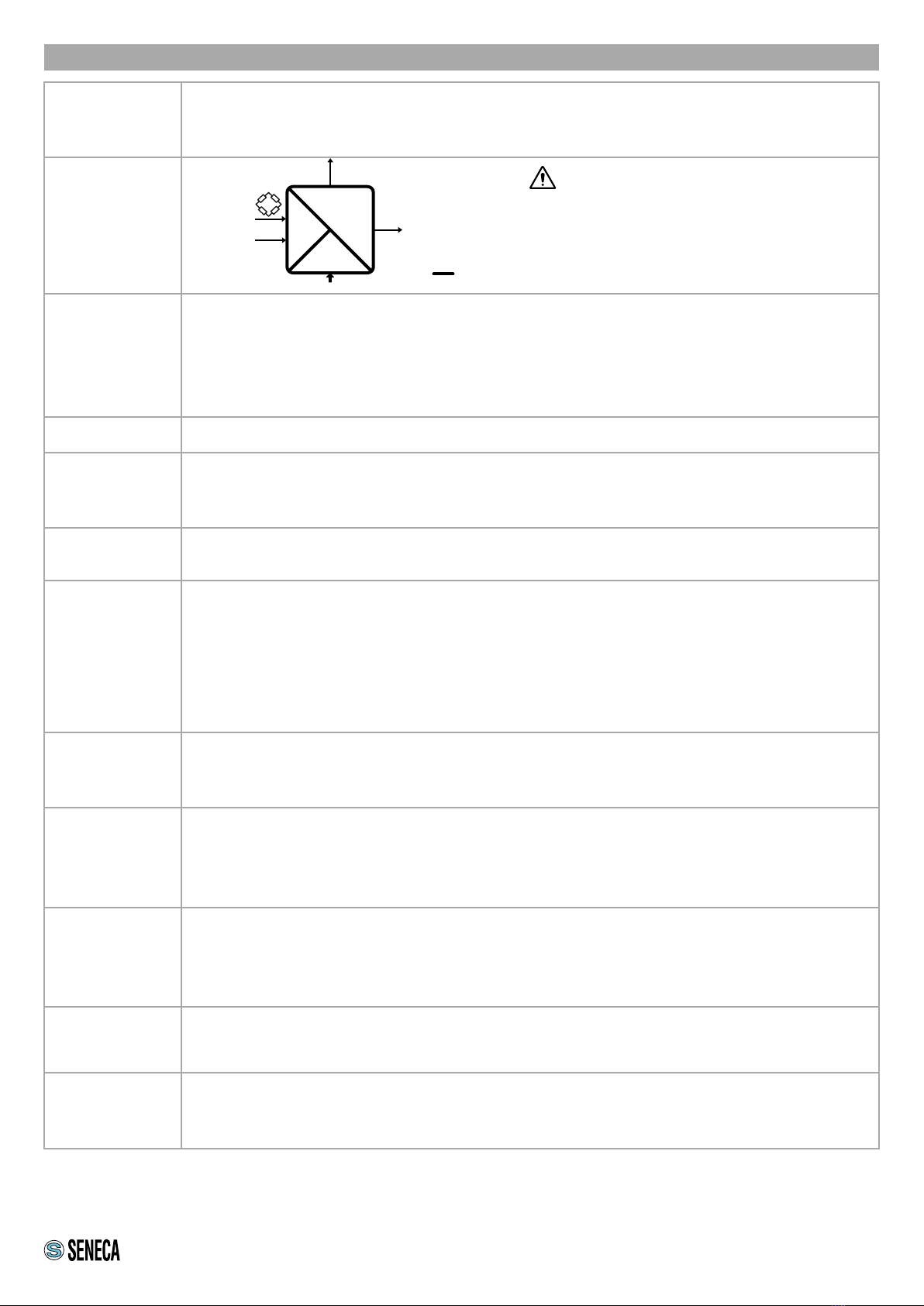

SETTING THE SW1 DIP-SWITCHES: Z-SG / Z-SG2 VERSION

DESCRIPTION OF COMMON FUNCTIONS

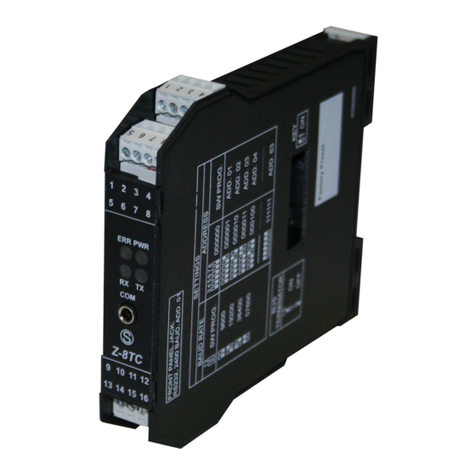

• Power supply and serial connection wiring facilitated by means of a bus housed in the DIN rail.

• Communication can be congured by DIP-switch or software.

• RS485 serial communication or via USB with MODBUS-RTU protocol.

• Protection against ESD discharges up to 4 kV.

• 1500 Vac insulation: between input and all other circuits, between communication and power supply and

between retransmitted output and power supply.

• Analogue output in voltage or current, with programmable limits.

• Cell calibration with sample weight, not required in case of known cell sensitivity.

• Congurable digital I/O.

• Rejection at 50 Hz and 60 Hz.

• Stable weighing signal via digital output/Modbus register.

• Remote tare writing in volatile and/or non-volatile memory via digital input/Modbus register

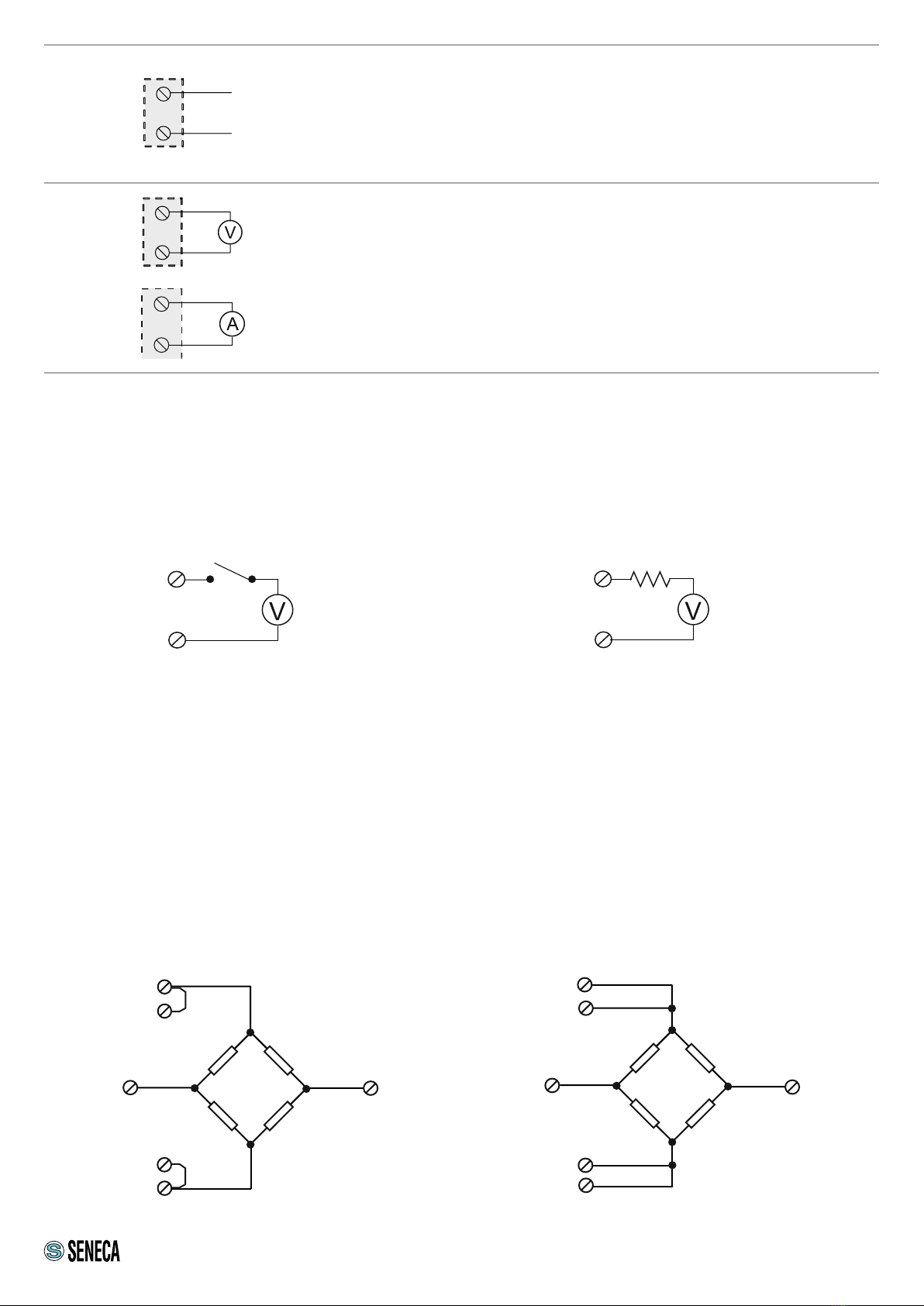

• Strain gauge directly powered by the instrument.

• Ratiometric measurement.

• Sensitivity from ± 1 to ± 64 mV/V.

• Complete congurability with dedicated EASY SETUP software.

• Cell calibration and conguration using Easy Setup software.

• Congurable resolution (max, auto, customized).

• Sampling frequency can be set from 5.4 Hz to 1365.3 Hz.

• Alarm can be activated when a set threshold is exceeded.

• Measurement that can be stabilized by means of a special noise lter.

• Available sizes in both integer and oating point.

• Piece counting function

• Upgradeable rmware.

• Min/max values of the net weight

• Automatic tare reset

DESCRIPTION OF FUNCTIONS DEDICATED TO THE Z-SG2 INSTRUMENT

The position of the DIP-switches denes the Modbus communication parameters of the module: Address and Baud Rate

The following table shows the values of the Baud Rate and the Address according to the setting of the

DIP-switches:

DIP-Switch status

SW1 POSITION BAUD

RATE

SW1 POSITION ADDRESS

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

9600 #1

19200 #2

38400 #...

57600 #63

From

EEPROM

From

EEPROM

Note: When DIP switches 3 to 8 are

OFF, the communication settings

are taken from programming

(EEPROM).

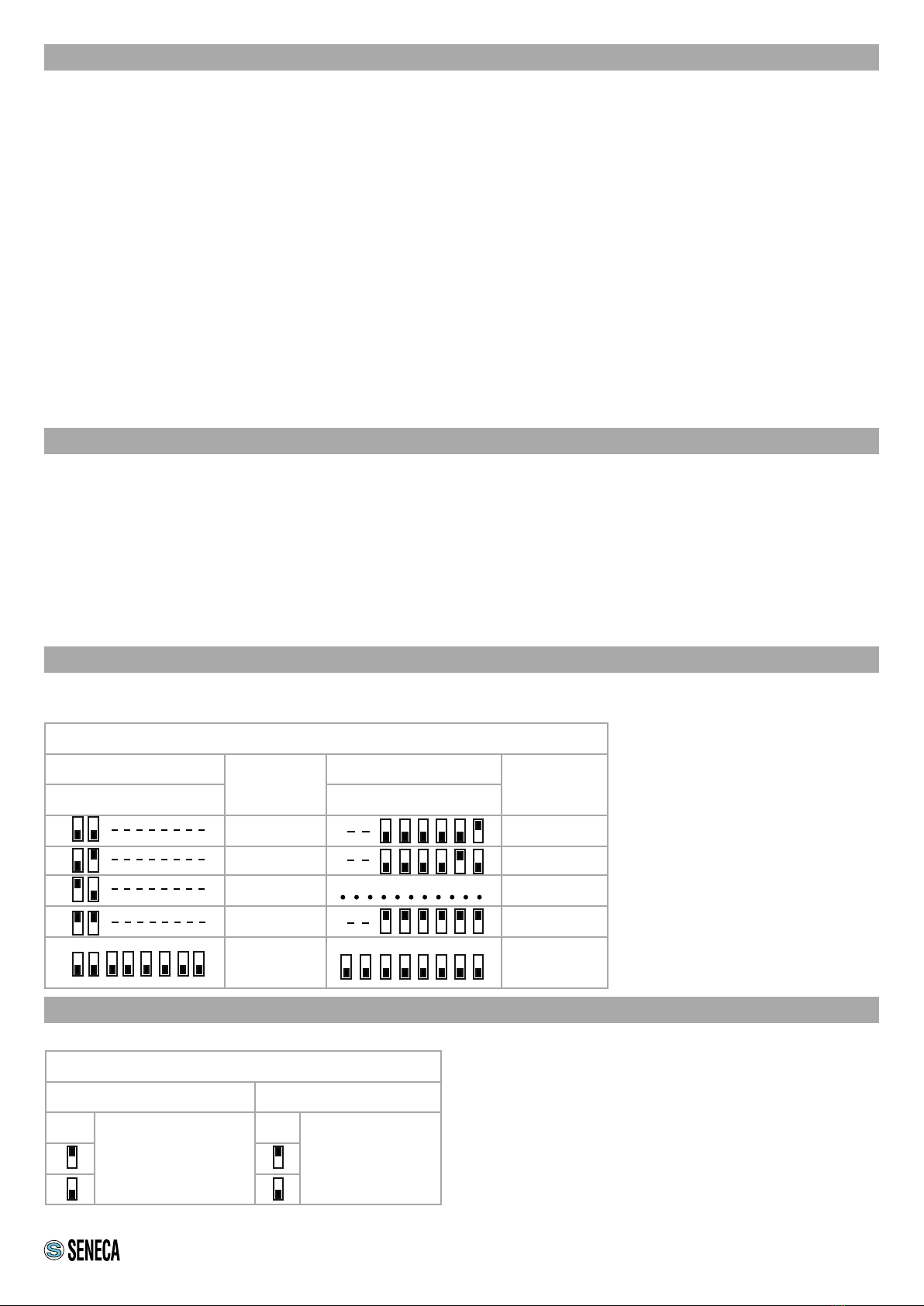

SETTING THE SW3 DIP-SWITCHES Z-SG / Z-SG2 VERSION

Status of the SW3 dip-switches

SW3 POSITION SW3 POSITION

1

RS485 terminator

2

GND interruption

Note 1:The RS485 line must be terminated only at the

ends of the communication line.

Note 2: Since the GND terminal of the RS485 port and the

negative terminal of the analogue output are not isolated

from each other, in order to use the analogue outputs

of several instruments simultaneously and connected

to each other via the RS485 port, it is necessary to

disconnect the GND terminal of the RS485 port via the

dedicated dip-switch (SW3). 4/8