ENGLISH - 1/8MI00035 -E9

EN

FREQUENCY => CURRENT / VOLTAGE CONVERTER

Z111

GENERAL FEATURES

TECHNICAL SPECIFICATIONS

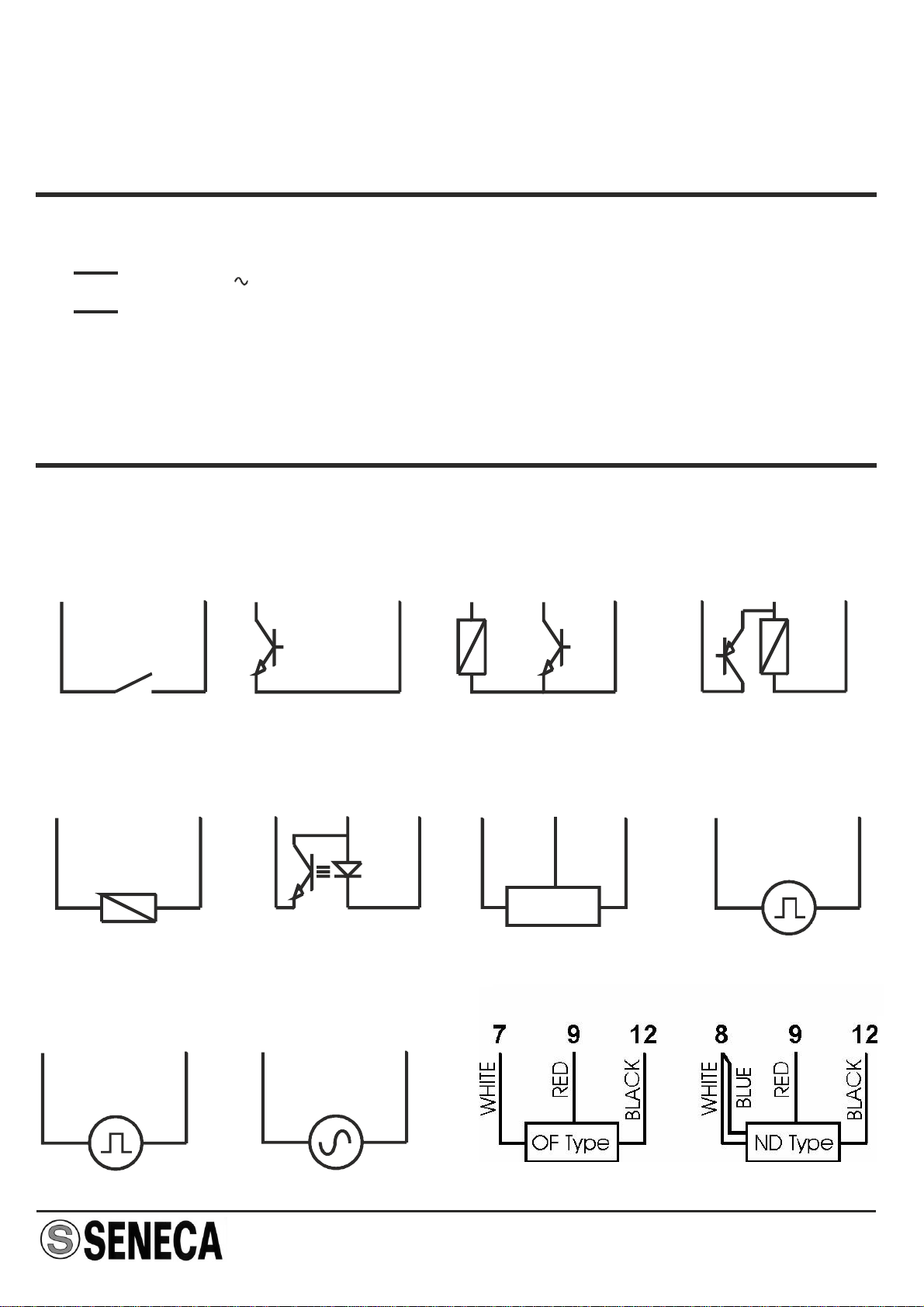

Pulse input for all the most commonly-used sensors: mechanical contact, reed, npn

with 2 and 4 wires, pnp with 3 wires and 24V DC power supply, Namur,

photoelectric, variable reluctance, 24V and TTL pulses

Maximum frequency from 1 mHz to 9.99 KHz, selectable fullscale from 10 mHz to

9.99 KHz;

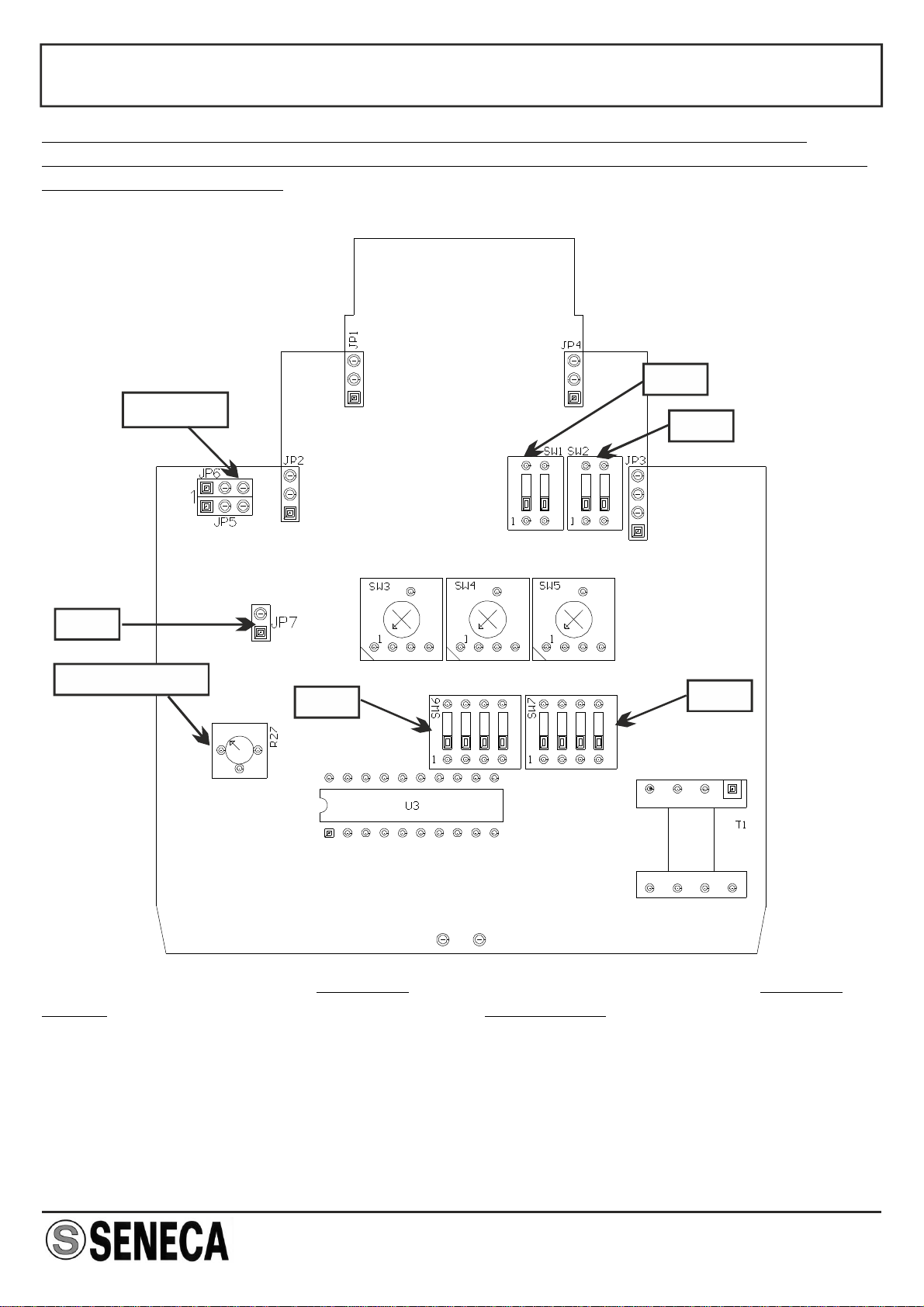

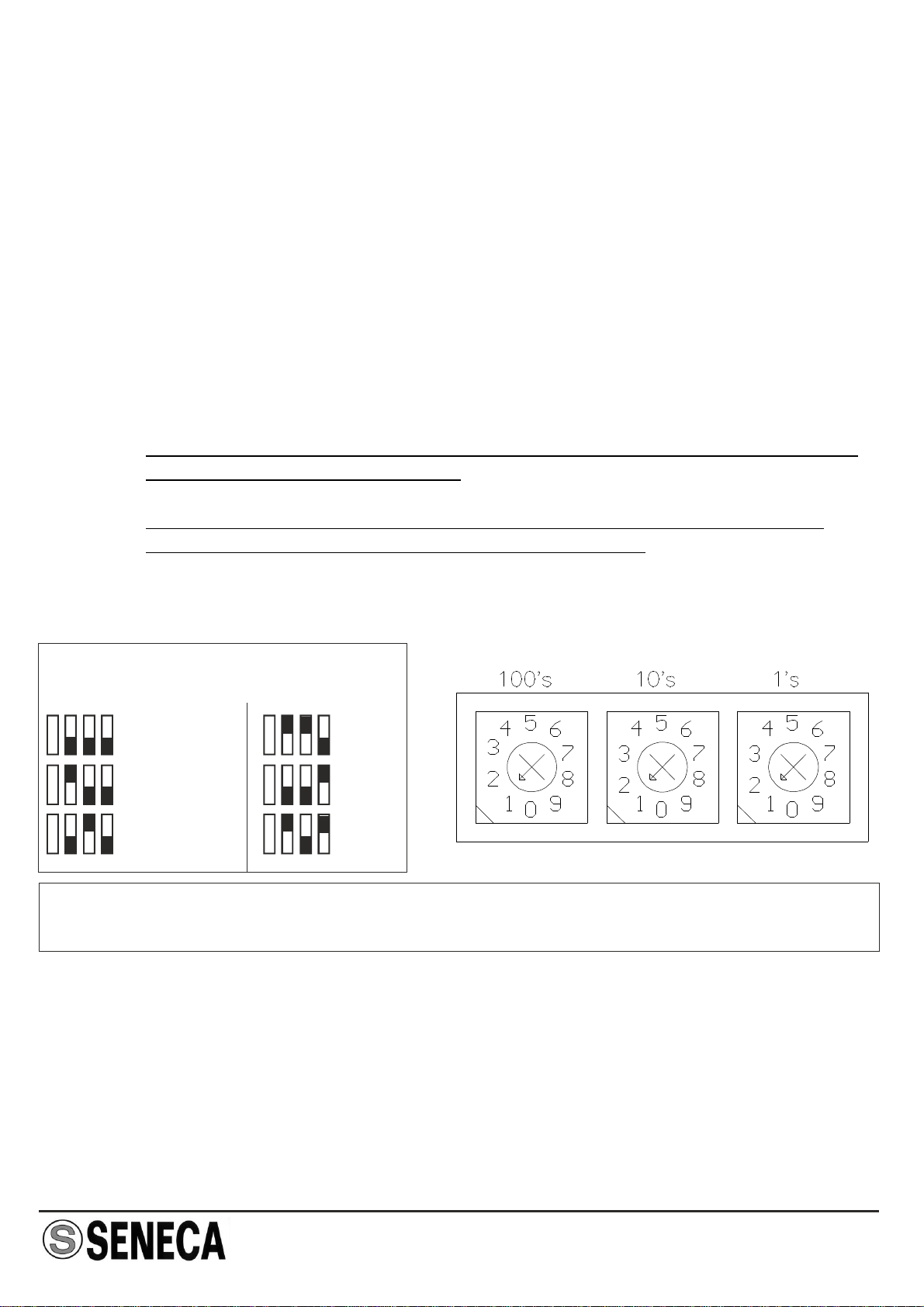

Full-scale can be easily set using rotating switches;

Selection of the output mode (0/4.20 mA, 0/1..5V , 0/2..10V) using dip-switches;

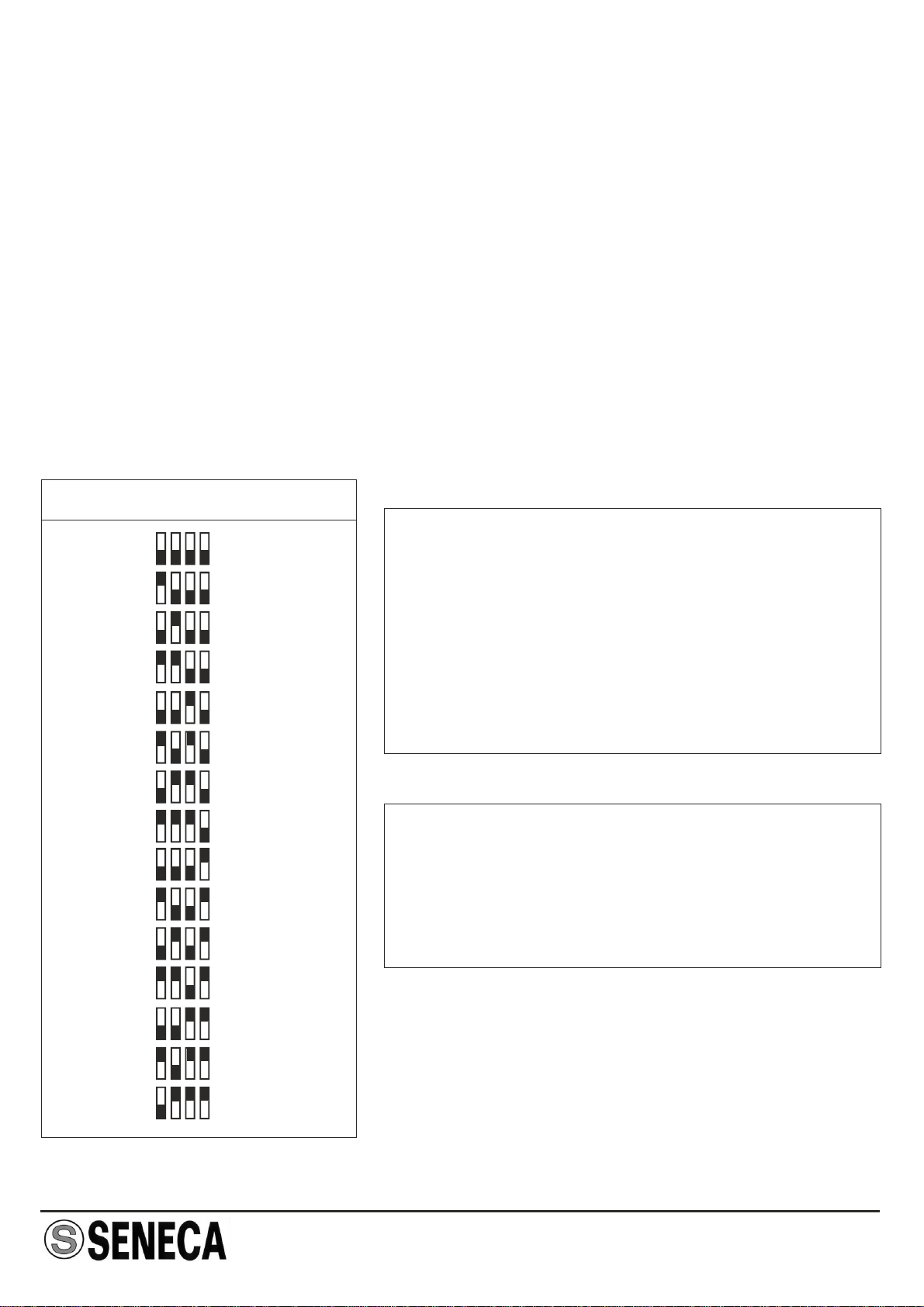

Possibility to set the number of pulses for the calculation of the pulse average;

Indication of power supply presence and out-of-scale errors provided on front panel;

3-point insulation: 1500V AC.

Power supply:

Input:

Output:

Work conditions:

Standards:

19..40 Vdc, 19..28 Vac 50..60 Hz, max 2,5 W

Pulses: mechanical contact, reed , npn with 2 and 3 wires ,

pnp with 3 wires and 24V DC power supply, Namur,

photoelectric, “HALL” sensor, and variable reluctance.

Maximum frequency 9.99 KHz

Active current 0..20 mA / 4..20 mA, max. load resistance: 600

ohm

Voltage 0..5 V / 0..10 V / 1..5 V / 2..10 V , min. load resistance:

2500 ohm

Error : < 0.3% of F.S.

Temperature: 0 - 50°C , Min. humidity: 30% , Max. humidity:

90% at 40°C (non condensing)

The instrument conforms to the following standards:

EN50081-2 (electromagnetic emission, industrial environments)

EN50082-2 (electromagnetic immunity, industrial environments)

EN61010-1 (safety)

Notes:

-Usewithcopperconductor.

-UseinPollutionDegree2Environment.

-PowerSupplymustbeClass2.

-WhensuppliedbyanIsolatedLimitedVoltage/Limited

Currentpowersupplyafuseratedmax2.5Ashallbe

installedinthefield.