12

THE WORK DISPLAY

After the startup process, the work display will be shown. This is the main working screen of the

instrument, and what will be used most of the time when detecting gas. The live gas reading is

shown on screen.

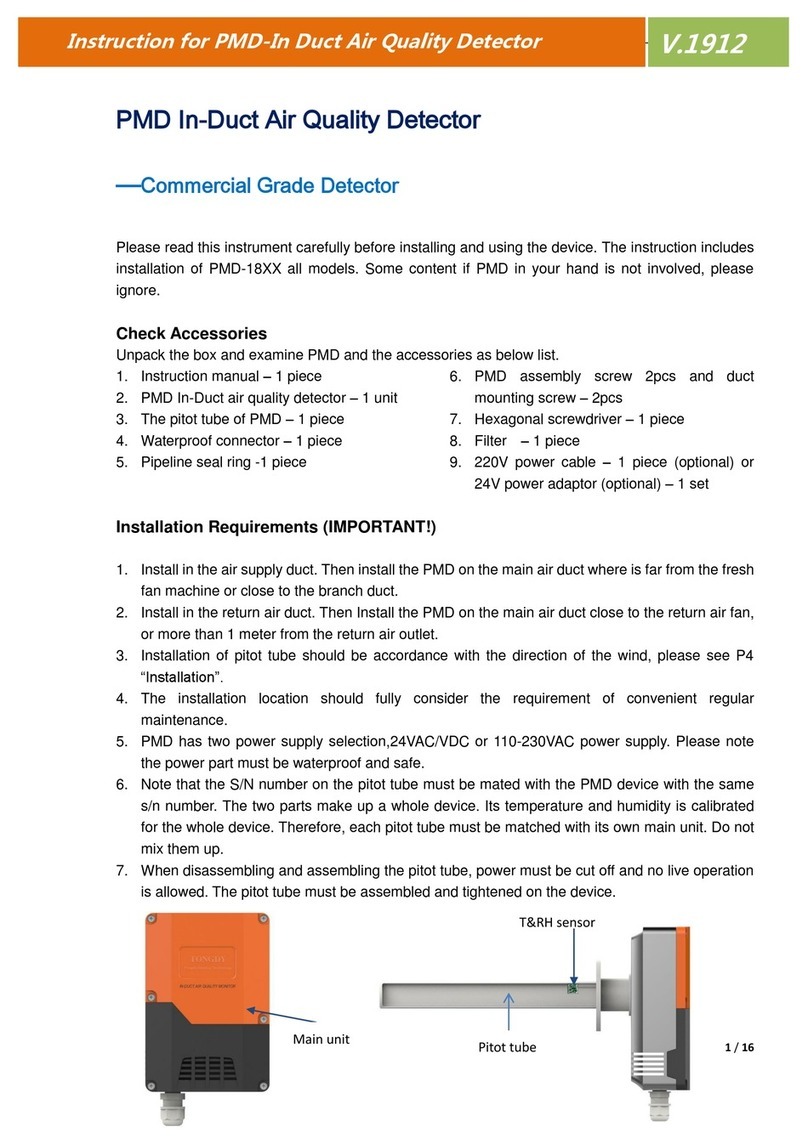

FILTER INTEGRITY AND FLOW BLOCK CHECK

Prior to use, a flow block check needs to be performed to test the integrity of the filter and

internal tubing. Block the inlet of the instrument or attached probe. Within a few seconds,

FLOW

BLOCKED

should be shown on the display. This ensures all seals are intact and there are no air

leaks in the probe or instrument. Press and release the Cbutton to restart the pump and return to

the previous screen. If flow block is not detected, check the integrity of the filter and connections

on the probe and instrument. If flow block cannot be achieved, contact the factory for assistance.

An airtight system is crucial for accurate readings.

READY FOR USE

After the startup process and Autozero are complete, and a successful flow block check has

been done, the instrument is ready for use. The “work display”, which is shown, will show live

gas readings. The operator does not need to leave this screen for most general-purpose use.

However, there are a few specialized test modes for specific applications, such as bar hole testing

and tick. See the Quick Menu section for more information on these.

To use the SENSIT PMD2 for gas detection, always follow federal, state, municipal, and/or

company procedures, then follow these generalized steps below for using the SENSIT PMD2.

1. It may be necessary to manually zero the instrument based on company practices and

environmental conditions. To do so, press & hold the Cbutton until

AUTOZERO

appears at

the top of the screen. Always zero the instrument in a clean air environment. If the instrument

is setup to display absolute readings, an Autozero will not set the instrument to 0ppm.

2. Alwaysperformaowblockcheckwhenusinganyprobeorattachment.

3. When sampling the sensor will cause the display to update when methane is encountered.

A combination of LED patterns and messages on the work display will occur when the

preset concentrations are reached. If any alarm condition exists, based on the preset alarm

points,theredLEDwillash,andthealarmwillsoundunlessitismuted.Additionally,the

readingwillashonscreen.ThestandardalarmsandLEDpatternscanbefoundinthe

features section.

4. To mute the alarm, quickly press and release the Abutton. To unmute the alarm press and

releasethesamebuttonagain.Duringanalarm,thereadingwillashonthedisplay,and

theredLEDwillashindicatingapotentiallyunsafecondition.Whenmethanereadings

exceed the alarm range UEL, the audible alarm will turn off. If the alarm condition no longer

exists or was muted, the alarm sound will activate if a new alarm condition is encountered.

5. To assist in locating small leaks, utilize the

TICK

feature. See the Quick Menu section for

more information.

6. Following Federal, State, Municipal and/or Company procedures move to the areas where

gas readings are suspected or must be tested. Use the proper accessories to draw samples

into the instrument. During sampling, the respective readings may change. Audible and

visual alarms will activate when the preset limits are reached.