2

Contents

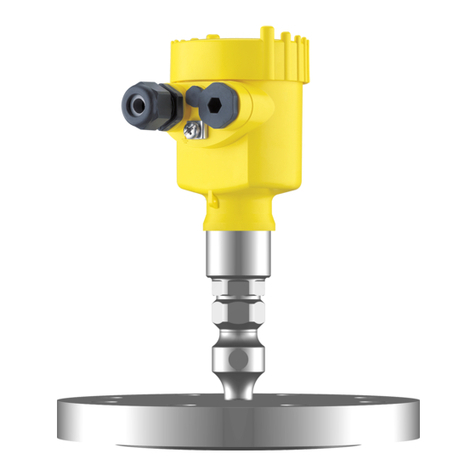

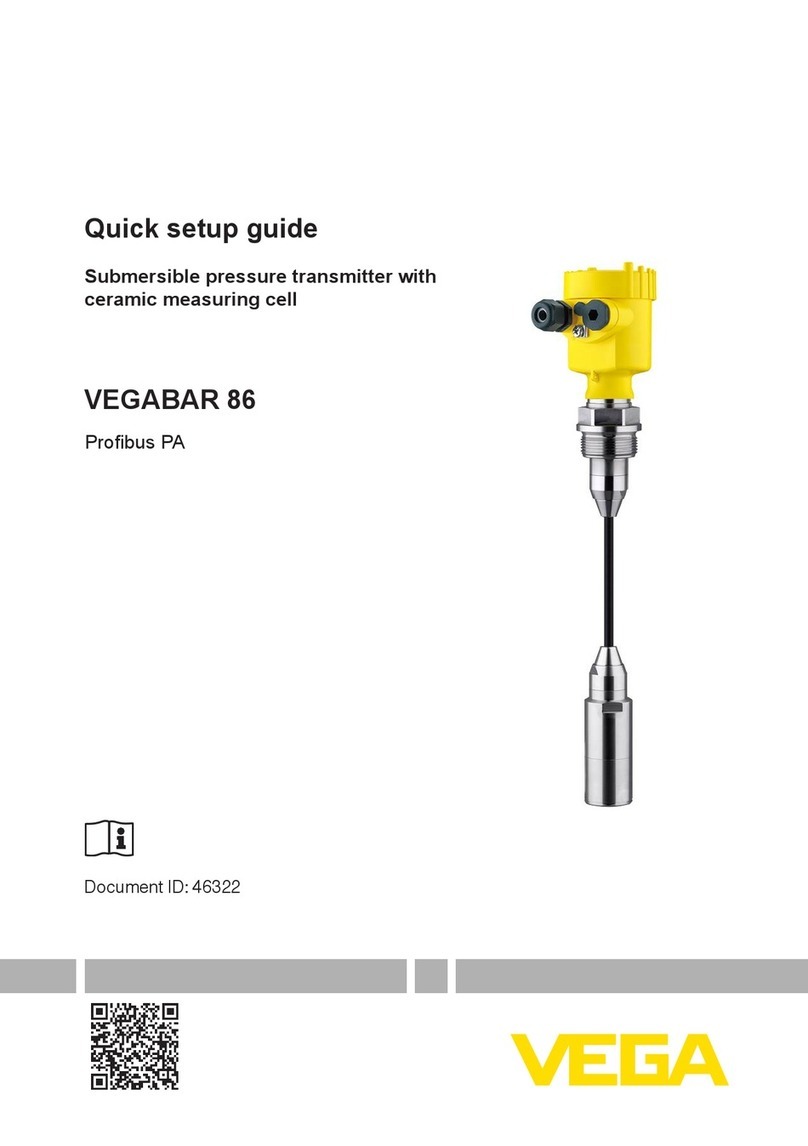

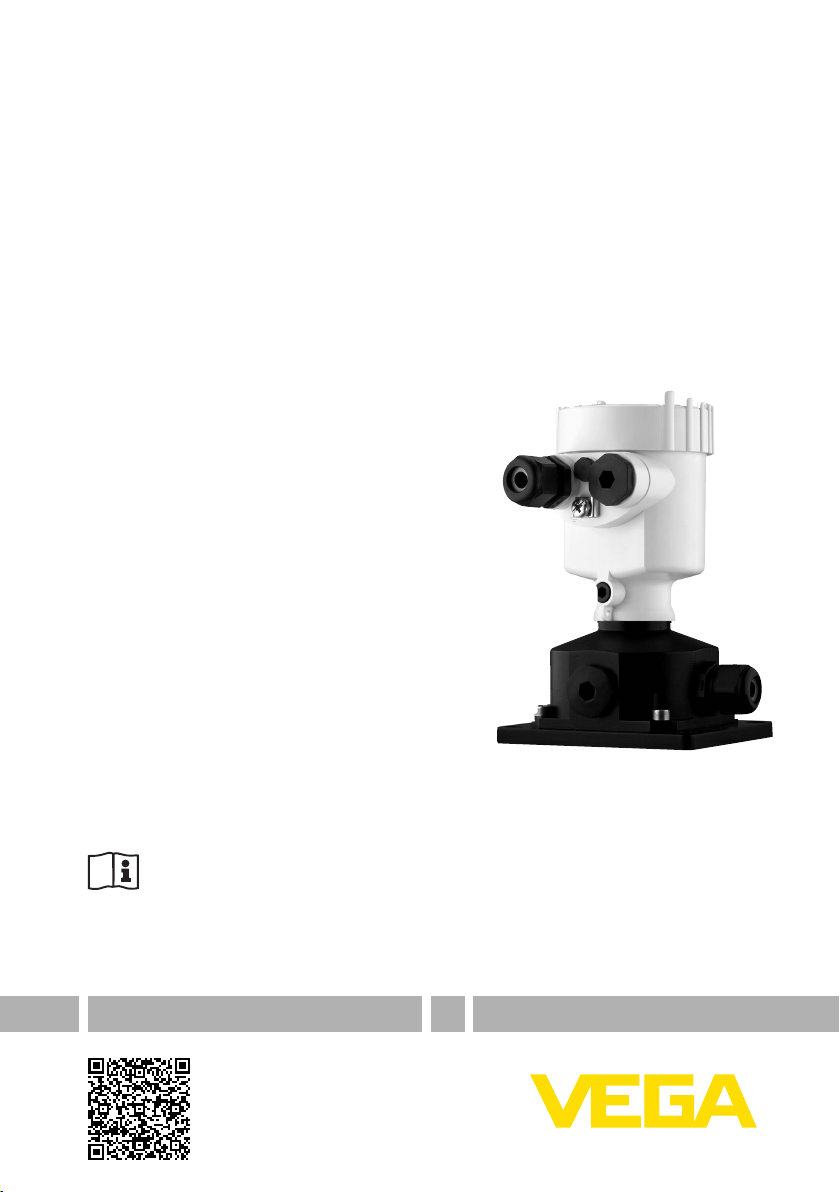

External housing • For pressure transmitter VEGABAR series 80

45081-EN-180104

Contents

1 About this document ............................................................................................................... 3

1.1 Function ........................................................................................................................... 3

1.2 Target group ..................................................................................................................... 3

1.3 Symbols used................................................................................................................... 3

2 For your safety ......................................................................................................................... 4

2.1 Authorised personnel ....................................................................................................... 4

2.2 Appropriate use................................................................................................................ 4

2.3 Environmental instructions ............................................................................................... 4

3 Product description ................................................................................................................. 5

3.1 Conguration.................................................................................................................... 5

3.2 Principle of operation........................................................................................................ 5

3.3 Storage and transport....................................................................................................... 5

4 Mounting................................................................................................................................... 7

4.1 Mounting preparations ..................................................................................................... 7

4.2 Exchange of the electronics module................................................................................. 7

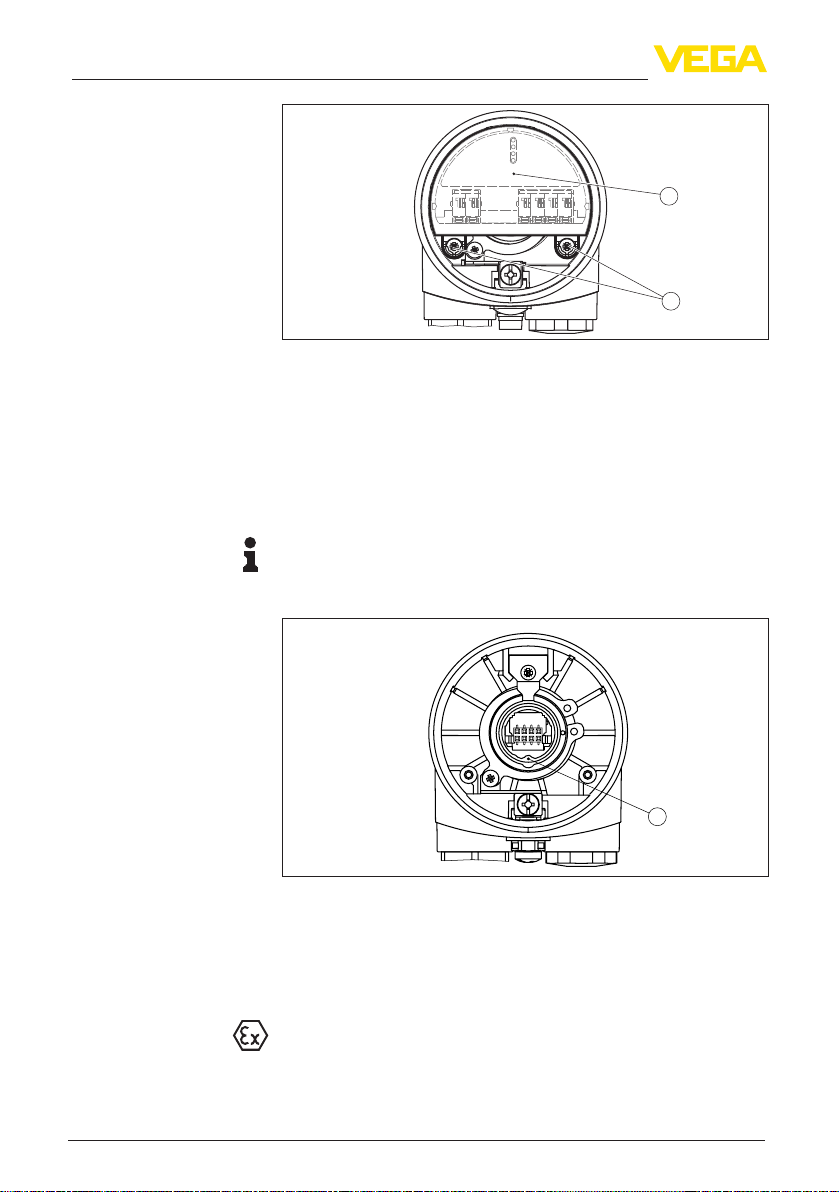

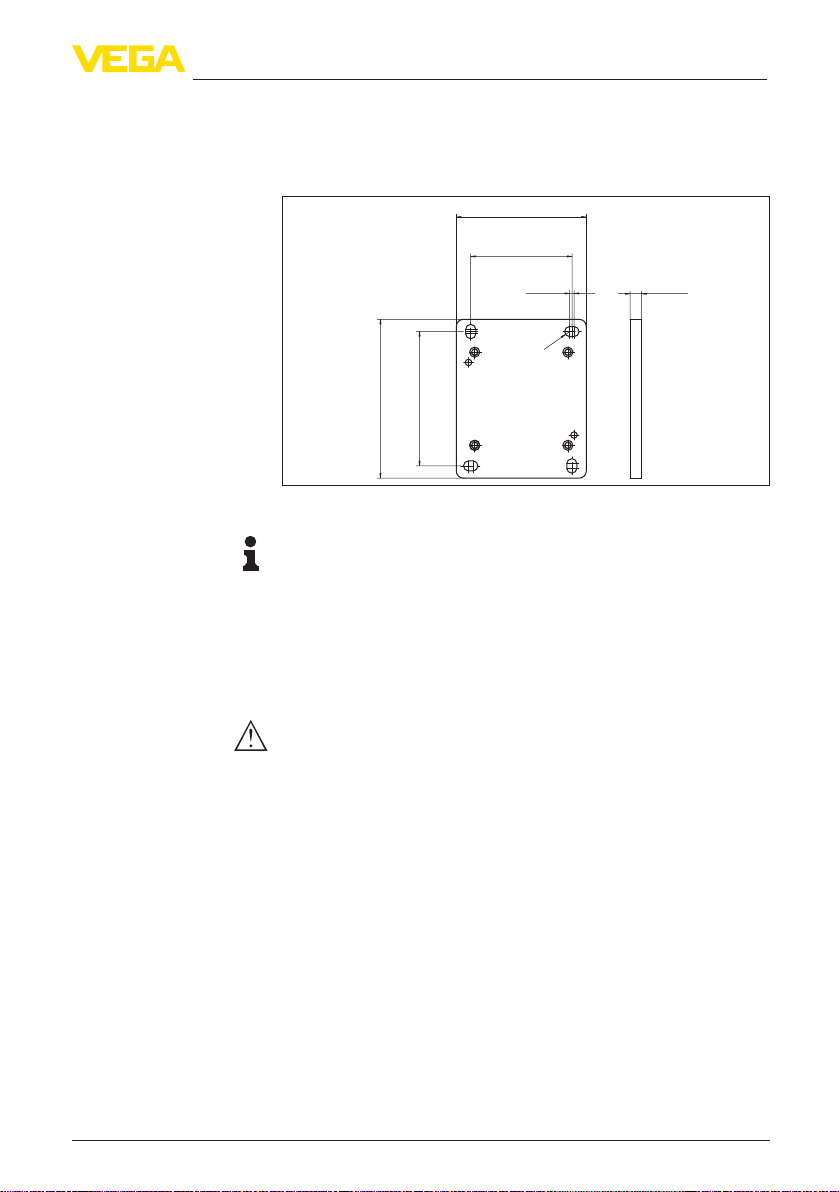

4.3 Mounting steps, external housing..................................................................................... 9

5 Connect the sensor to the external housing....................................................................... 10

5.1 Preparing the connection ............................................................................................... 10

5.2 Connection procedure.................................................................................................... 10

5.3 Wiring plan ..................................................................................................................... 11

6 Setup ....................................................................................................................................... 14

6.1 Setup.............................................................................................................................. 14

7 Maintenance ........................................................................................................................... 15

7.1 How to proceed if a repair is necessary.......................................................................... 15

8 Dismount................................................................................................................................. 16

8.1 Dismounting steps.......................................................................................................... 16

8.2 Disposal ......................................................................................................................... 16

9 Supplement ............................................................................................................................ 17

9.1 Technical data ................................................................................................................ 17

9.2 Dimensions .................................................................................................................... 18

Safety instructions for Ex areas

TakenoteoftheExspecicsafetyinstructionsforExapplications.

These instructions are attached as documents to each instrument

with Ex approval and are part of the operating instructions manual.

Editing status: 2018-01-04