sewerin SePem 351 User manual

10.07.2023 a – 108964 – en

SePem® 351 / 351HY

Operating instructions

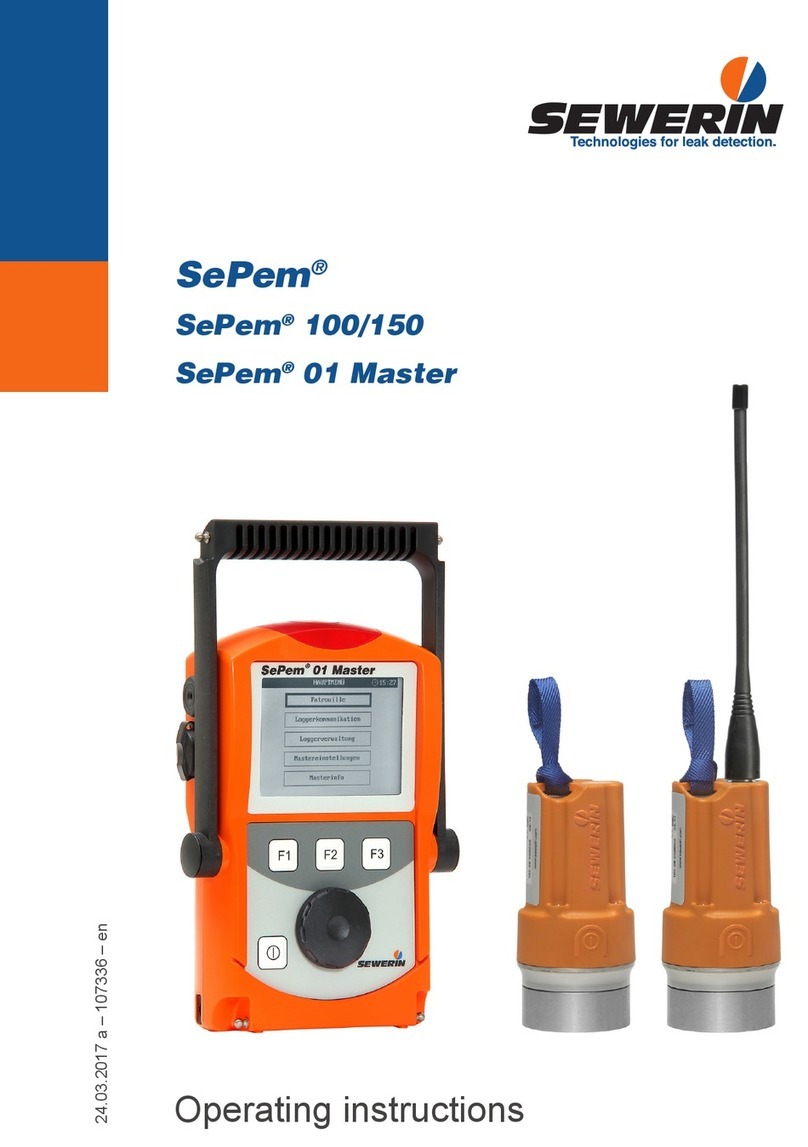

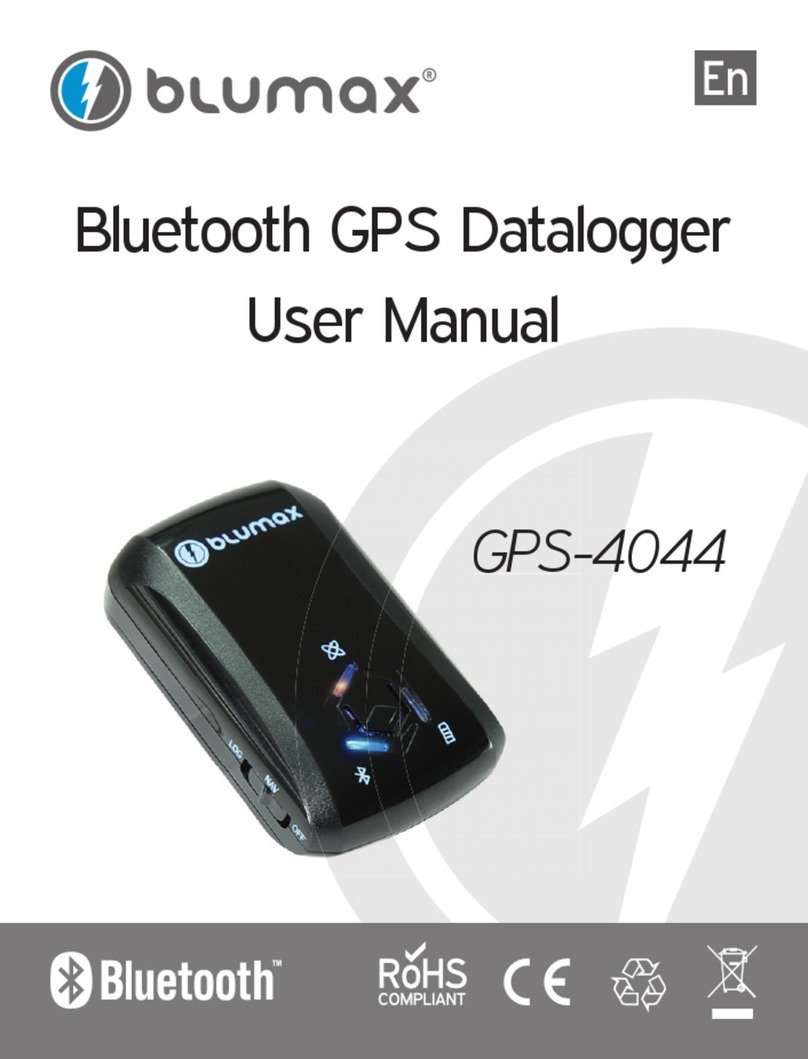

SePem®351

Fig. 1: SePem 351 logger

LED (internal)

Contact adapter

Aerial port

Aerial

Magnetic switch

Lug with loop

Communication

cable port

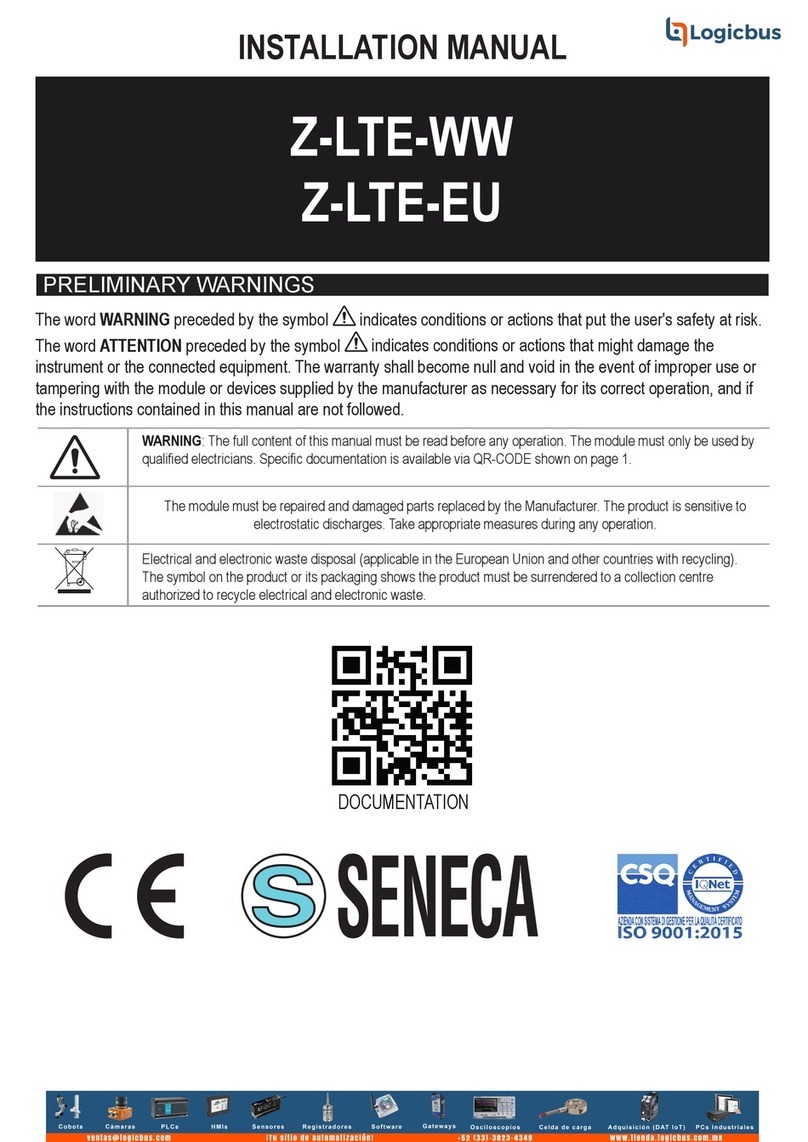

SePem®351 HY

Vent valve

Protective cap

Fig. 2: SePem 351 HY logger

Aerial

Lug with loop

Magnetic switch

Illustration of warnings in this document

ACAUTION!

Risk of personal injury. Could result in injury or pose a risk

to health.

NOTICE!

Risk of damage to property.

Contents│ I

1 Introduction .............................................................................1

1.1 Information about this document...............................................1

1.2 Purpose.....................................................................................1

1.3 Intended use .............................................................................2

1.4 Safety information .....................................................................2

2 Product description ................................................................4

2.1 Operating principle ....................................................................4

2.2 Product variants ........................................................................4

2.3 Setup and features....................................................................4

2.4 LoRaWAN .................................................................................5

3 Preparing the logger ...............................................................6

3.1 Commissioning (overview) ........................................................6

3.2 Other requirements ...................................................................6

3.2.1 Registering the loggers with the LoRaWAN provider.............6

3.2.2 Availability check....................................................................6

3.2.3 Network information system for evaluating measurement

data ........................................................................................6

3.3 Screwing on the aerial...............................................................7

4 Installing the loggers at the measurement location ............8

4.1 General information on installation............................................8

4.2 Installing the SePem 351 ..........................................................8

4.3 Installing the SePem 351 HY ....................................................9

4.4 Using the installation adapter for SePem 351.........................10

4.5 Using a built-in aerial...............................................................10

5 Information for loggers in operation ...................................12

5.1 Unstable radio connection.......................................................12

5.2 Erroneously suspected leak ....................................................12

5.3 Reprogramming loggers..........................................................12

6 Appendix................................................................................13

6.1 Technical data .........................................................................13

6.1.1 SePem 351 ..........................................................................13

6.1.2 SePem 351 HY ....................................................................14

6.2 Accessories.............................................................................16

6.3 Declaration of conformity ........................................................16

6.4 Advice on disposal ..................................................................16

1 Introduction│ 1

1 Introduction

1.1 Information about this document

This document is a component part of the product.

●Read the document before putting the product into operation.

●Keep the document within easy reach.

●Pass this document on to any subsequent owners.

● Unlessotherwisespecied,theinformationinthisdocument

refers to the product as delivered (factory settings) and applies

to all product variants.

●Contradictory national legal regulations take precedence over

the information in this document.

Right of reproduction

Nopartofthisdocumentmaybeedited,duplicatedorcirculatedin

any form without the express consent of Hermann Sewerin GmbH.

Translations

Translations are produced to the best of our knowledge. The

original German version is authoritative.

Registered trademarks

LoRaWAN®(Long Range Wide Area Network) is a brand used

under the LoRa Alliance®licence. SePem®is a registered trade-

mark of Hermann Sewerin GmbH. Registered trademarks are not

indicated in this document.

1.2 Purpose

SePem is a system for recording and evaluating measurements.

The system's loggers are used for the early detection of leaks in

waterdistributionnetworks.Theyaredesignedforstationaryuse,

i.e.forongoingmonitoringatxedmeasurementlocationsover

long periods (several years). Many loggers are usually deployed

at the same time in order to be able to monitor a large area.

SEWERIN recommends: The water distribution network should

be free from leaks before commissioing the system.

2 │1Introduction

1.3 Intended use

The product is suitable for the following uses:

●Professional

●Industrial

●Commercial

Theproductmustonlybeusedfortheapplicationsspeciedin

section 1.2.

Note:

The appropriate specialist knowledge is required for using this

product.

The logger may only be installed in shafts and stop tap boxes.

1.4 Safety information

This product was manufactured in accordance with all binding

legal and safety regulations.

The product is safe to operate when used in accordance with the

instructionsprovided.However,whenhandlingtheproduct,there

mayberiskstopersonsandproperty.Forthisreason,observe

the following safety information without fail.

●Observe all the applicable safety standards and accident pre-

vention regulations.

●Use the product only as intended.

● Handletheproductcarefullyandsafely,bothduringtransport

and when working.

● Donotmakeanychangesormodicationstotheproductun-

less these have been expressly approved by Hermann Sewerin

GmbH.

●Do not use the product if it is damaged or faulty.

●Observe the permitted operating conditions.

● Alwaysadequatelycordonotheworkarea.

●Never open the housing.

1 Introduction│ 3

●Keep the contact adapter away from magnetic storage media

(e.g.harddrives,creditcards)andmedicaldevices(e.g.pace-

makers,insulinpumps).

If the lithium metal battery is faulty:

●Observe the applicable regulations on the transport of hazard-

ous goods when transporting the product commercially.

4 │2Productdescription

2 Product description

2.1 Operating principle

SePem 351 and SePem 351 HY are noise loggers for the prelim-

inary detection of leaks in water distribution networks.

The loggers measure the noises in the pipe network at set times.

The measurement data is then prepared for transfer to a receiver

(e.g. water utility).

The measurement data receiver can display and evaluate the

measurement data in its network information system.

2.2 Product variants

SePem 351

●for distribution networks

● recordsnoisesacrossthepipeline/ttingbymicrophone

● attachestopipesorttings

SePem 351 HY

●for trunk mains

●records noises directly from the water by hydrophone

● attachestottingswithdirectaccesstothewatercolumn

2.3 Setup and features

Youwillndoverviewswiththenamesofthepartsoftheloggers

insidethefrontcover(g.1andg.2).

Loggers with a built-in aerial can be used as an alternative to the

aerialshowning.1/g.2.

Theloggersarettedwitharadiomodule(LoRaWAN)fordata

transmission. The radio module sends the measurement data

recordedandbueredbytheloggeratsettimeintervals.

2 Product description│ 5

2.4 LoRaWAN

LoRaWAN is a radio standard based on a special network pro-

tocol. Each logger must be registered wit the provider to use

LoRaWAN.

6 │3Preparingthelogger

3 Preparing the logger

3.1 Commissioning (overview)

Commissioning a logger involves the following steps:

1. Screwing the aerial onto the logger (section 3.3)

2.

Registering the loggers with the LoRaWAN provider (sec-

tion 3.2.1)

3.

Installing the loggers at the measurement location (sec-

tion 3.2.2 and section 4)

3.2 Other requirements

3.2.1 Registering the loggers with the LoRaWAN provider

Each logger must be registered with the LoRaWAN provider

before commissioning. Registration cannot be done by the user.

−Contact the service provider who will register the loggers for

you.

Suitable service providers might be external companies or your

company'sownqualiedstaforexample.

3.2.2 Availability check

Theinstallationofeachloggermust nishwithanavailability

check. This makes sure that the logger can connect to the radio

network.

Howavailabilityischeckeddependsonthespecicationsofthe

radio network.

−Contact the service provider who will explain how availability

is checked.

Suitable service providers might be external companies or your

company'sownqualiedstaforexample.

3.2.3 Network information system for evaluating measurement

data

Measurement data can only be evaluated if a network information

system is installed.

3 Preparing the logger│ 7

The network information system must be adapted once before

commissioning of the loggers so that the measurement data can

be evaluated.

−Contact the service provider who will adapt the network infor-

mation system for you.

Suitable service providers might be external companies or your

company'sownqualiedstaforexample.

3.3 Screwing on the aerial

The aerial must be screwed on with great care.

NOTICE! Risk of damage to device

Aerial contacts can get damaged if too much force is used when

screwing on the aerial.

● Alwaysscrewontheaerialbyhand,i.e.donotuseanytools.

●Tighten the aerial just enough to ensure that there is a good

contact and seal in the joint.

1. If necessary:

−Clean and dry the aerial port of the logger and the thread

of the aerial.

2. Screw the aerial onto the logger so that it is hand-tight.

8 │4Installingtheloggersatthemeasurementlocation

4 Installing the loggers at the measurement

location

4.1 General information on installation

●The logger must only be installed if an aerial is screwed on.

●Installation must be carried out with great care. This applies in

particular to positioning of the aerial.

●The aerial must not come into contact with metal parts at the

measurement location.

Thisdoesnotapplytothebuilt-inaerial,asitisfedthrougha

hole in the stop tap box.

●The aerial must stay straight when the stop tap box is closed

with the cover.

●Information about the availability check can be found in sec-

tion 3.2.2.

4.2 Installing the SePem 351

The logger can be installed on:

●pipelines

● ttings(slidegates,undergroundhydrants)

Inplasticpipes,theloggercannotbeattachedtothepipe,but

mustbemountedonthettings.

The logger is attached using a contact adapter. The contact adap-

ter comes protected by a short circuit disc.

−Remove the short circuit disc from the contact adapter before

installing the logger.

1. Install the logger.

−Install the logger as upright as possible.

Otherwise use an installation adapter (section 4.4).

4 Installing the loggers at the measurement location│ 9

−Use a safety rope if the contact point is so deep that you

cannot position the logger by hand. The safety rope is at-

tached to the loop.

The safety rope is available to buy as an accessory.

−

Make sure that there is a good connection between the

contact point and the contact adapter.

− Thesoundtransmissionmustnotbemutedbydirt,sludge

or rust. Clean the contact point if necessary before attaching

the contact adapter.

2. Check that the logger is available.

4.3 Installing the SePem 351 HY

The logger is installed in the water column. Any points in the wa-

ter distribution networks that are already a designated measuring

location or where a measuring location can be set up.

ACAUTION! Risk of drinking water contamination

Water in drinking water networks are subject to special

quality standards.

●Make sure that no contamination ends up in the pipe

network during assembly.

●

Only use disinfectants approved for drinking water to

disinfect the logger.

The hydrophone comes covered by a protective cap.

−Unscrew the protective cap before installing the logger.

1. Rinse the pipe until the water is free from dirt.

2. Disinfect all parts of the logger that could come into contact

with drinking water.

3. Attach the logger to the measuring location.

−Carefully seal the connection when screwing in the logger.

4. Openthettingfully.

10 │4Installingtheloggersatthemeasurementlocation

5.

Vent the measuring location using the vent valve on the logger.

6. Check that the logger is available.

4.4 Using the installation adapter for SePem 351

Atsome measurementlocationsitis dicult orimpossibleto

attach the SePem 351 logger upright using the contact adapter.

An installation adapter can help here. The installation adapter is

ideal for installing the logger horizontally.

Note:

The installation adapter cannot be used for SePem 351 HY.

The installation adapter consists of an angled stainless steel

sheet with slotted hole and a contact adapter. The contact adapter

can be pushed into the slot until the optimal position has been

found for the measurement location. The contact adapter is then

fastened with a nut. The logger is attached to the short part of

the sheet.

Fig. 3: Logger on installation adapter

The installation adapter is available to buy as an accessory.

4.5 Using a built-in aerial

A built-in aerial can considerably improve the reception quality of

the radio signals of a logger.

Whenusingabuilt-inaerial,aholeneedstobedrilledintothewall

ofthestoptapbox,throughwhichtheaerialcanbefed.

4 Installing the loggers at the measurement location│ 11

Drill hole requirements

Whenclosingthestoptapboxwiththecover,thebuilt-inaerial

mustnotbepinchedorkinked.Thisalsoappliestotheexible

part of the aerial (aerial cable).

Minimum dimensions:

−Diameter: 15 mm

−Drill depth: approx. 160 mm

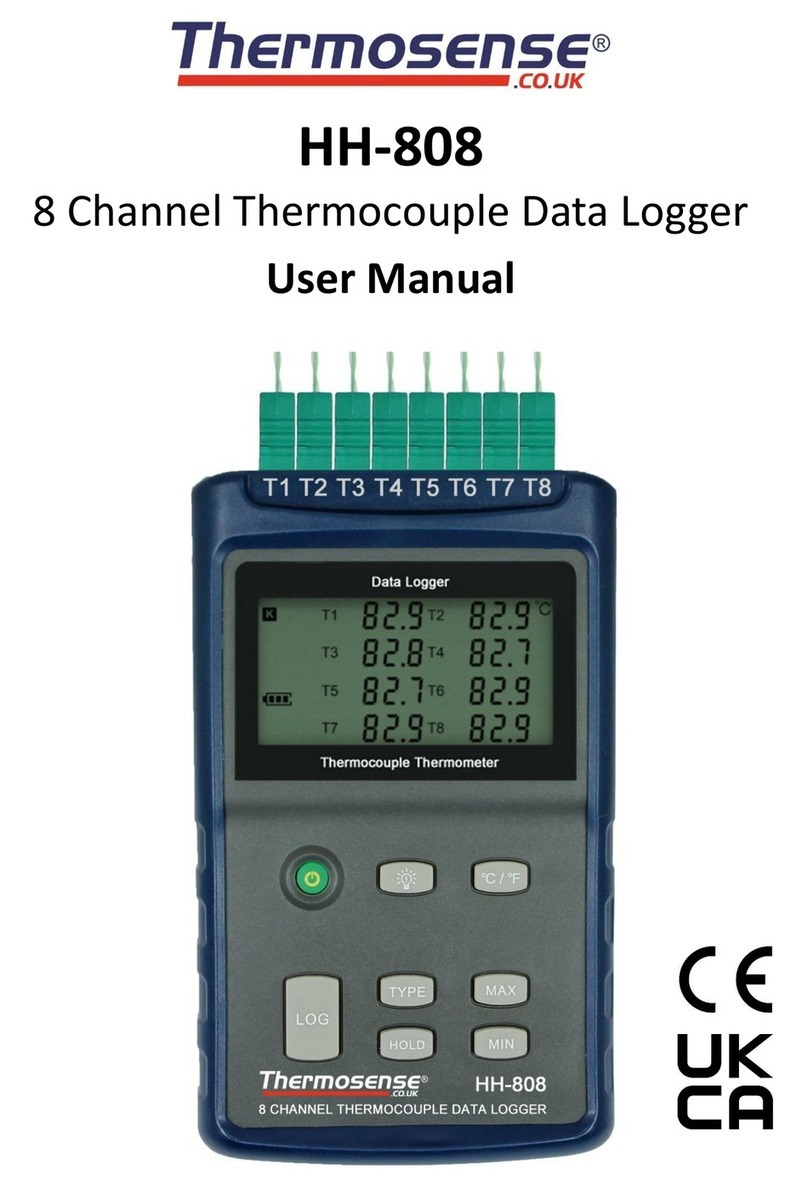

Fig. 4: Built-in aerial in stop

tapbox(simplieddiagram)

1 Built-in aerial

2 Wall of stop tap box

12 │5Informationforloggersinoperation

5 Information for loggers in operation

5.1 Unstable radio connection

Iftheradioconnectionisunstable,theloggermaynotsendany

measurementdata, eveniftheavailability testhasbeen suc-

cessful.

−Change the position of the logger at the installation site. Even

small adjustments to the alignment can help improve the radio

connection.

Then check the availability again.

5.2 Erroneously suspected leak

The loggers save all the noises they can technically record during

the measurement. These can include noises caused by unwanted

externalinuences,e. g. from prolonged rain or the proximity of

power cables.

−

Please allow for this when evaluating and interpreting the

measurement data.

5.3 Reprogramming loggers

Theloggerscomewithcertainsettingsforthemeasuringtime,

measuringduration,timeofdatatransmissionetc..Thesesettings

can be changed.

−

Contact your service provider if you want to reprogram the

loggers.

Suitable service providers might be external companies or your

company'sownqualiedstaforexample.

6 Appendix│ 13

6 Appendix

6.1 Technical data

6.1.1 SePem 351

Device data

Dimensions (H x Ø) 126 x 54 mm (without aerial)

Weight approx. 760 g (without aerial)

Certicates

Marking CE

Features

Signal light 1 LED

Memory 128 kB

Processor microcontroller 16 bit

Ports • TNC port

• 3-pin communication contact

Control Reed switch for testing the radio connection

Operating conditions

Operating temperature -20 – 55°C

Storage temperature -20 – 70 °C

Humidity 100% r.h.

Atmospheric pressure up to 16 bar

Protection rating IP68

Permitted operating

environments

submersible up to 1 m

Non-permitted operating

environments

• in liquids other than water

• in aggressive media

• in potentially explosive areas

Power supply

Power supply lithium metal battery [1355-0022]

Lithium mass per cell 2.8 g

Net weight of batteries 61 g

Operatingtime,typical 9 years when using the default settings

14 │6Appendix

Measurement data recording

Type noise sensor

Sampling rate 1 s – 1 h (adjustable)

Measuring range 0 – 3000

Data transmission

Communication • LoRaWAN

• cable

Frequency bands LoRaWANAS923,AU915,EU868,KR920,

IN865

Additional data

Attachment option magnetically to the measuring location

Shipping instructions contains:

• 1 lithium metal battery packed with

equipment (UN 3091)

• with 2.8 g lithium

transport as per ADR class 9 and VA 970 part I

IATA possible

6.1.2 SePem 351 HY

Device data

Dimensions (L × D × H) 55 × 65 × 170 mm (without aerial)

Weight approx. 820 g (without aerial)

Certicates

Marking CE

Features

Signal light 1 LED

Memory 128 kB

Processor microcontroller 16 bit

Ports • TNC port

• 3-pin communication contact

Control Reed switch for testing the radio connection

Threaded connection G1 Whitworth pipe thread DIN EN ISO 228-1

6 Appendix│ 15

Operating conditions

Operating temperature 0 – 55°C

Storage temperature -20 – 70 °C

Humidity 100% r.h.

Atmospheric pressure up to 16 bar

Protection rating IP68

Permitted operating

environments

submersible up to 1 m

Non-permitted operating

environments

• in liquids other than water

• in aggressive media

• in potentially explosive areas

Power supply

Power supply lithium metal battery [1355-0022]

Lithium mass per cell 2.8 g

Net weight of battery 61 g

Operatingtime,typical 9 years when using the default settings

Measurement data recording

Type hydrophone

Sampling rate 1 s – 1 h (adjustable)

Measuring range 0 – 3000

Data transmission

Communication • LoRaWAN

• cable

Frequency bands LoRaWANAS923,AU915,EU868,KR920,

IN865

Additional data

Attachment option 1" external thread

Shipping instructions contains:

• 1 lithium metal battery packed with

equipment (UN 3091)

• with 2.8 g lithium

transport as per ADR class 9 and VA 970 part I

IATA possible

This manual suits for next models

1

Table of contents

Other sewerin Data Logger manuals