PAGE 9

PAGE 8

OPERATION

BEFORE USE

1. Make sure the jack and vehicle are on a hard level surface.

2. Always set the vehicle handbrake and chock the wheels.

3. Consult the vehicle owner’s manual to ascertain the location

of jacking points and position the jack beneath the lifting

point.

4. Place jack stands beneath the vehicle at locations recom-

mended by the vehicle manufacturer. Do not work under the

vehicle without the use of jack stands. Jacks are not designed

to maintain heavy loads for long periods of time.

5. Incorporate a filter, regulator with pressure gauge, oiler, in-line

shutoff valve, and quick coupler for best service. An in-line

shutoff ball valve is an important safety device because it con-

trols the air supply even if the air hose is ruptured. The shutoff

valve should be a ball valve because it can be closed quickly.

6. Note: If an automatic oiler system is not used, add a few

drops of Pneumatic Tool Oil to the airline connection before

operation. Add a few more drops after each hour of continual

use.

OPERATION

LIFTING

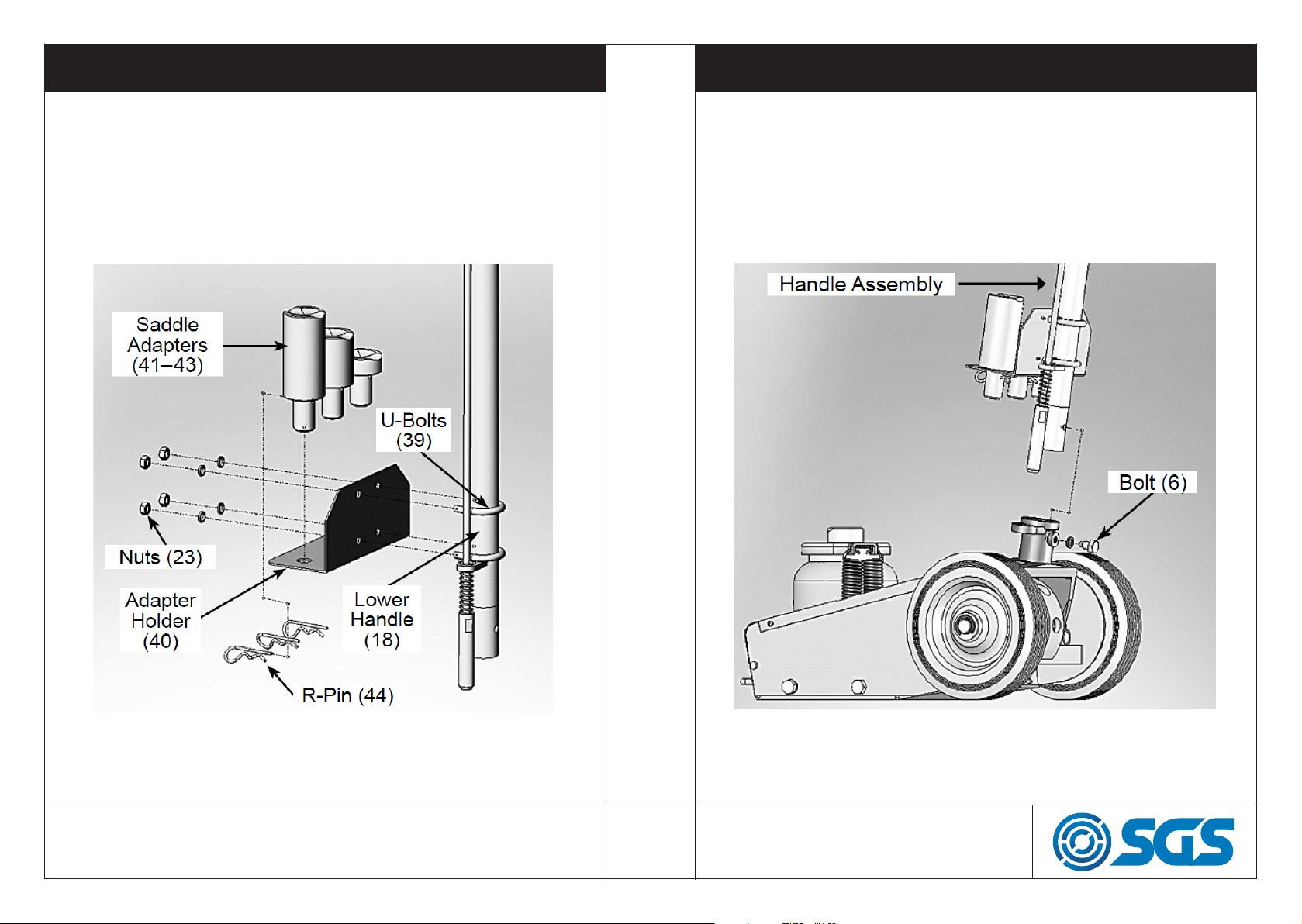

1. Install the handle assembly and turn the handwheel until snug.

2. Adjust the hand angle degree as needed to place the jack in

position under the load.

3. Adjust the extension screw as required. Turn counter clock-

wise to raise and clockwise to lower.

4. Connect the air supply hose lock fitting into the air fitting. The

lever should be off (not in the locked position)

6. Press the lever to the on position and lock using the lock lever.

This provides continuous air to the air motor.

7. Raise the jack by alternately lifting and lowering the handle

assembly.

LOWERING

1. Turn the handle knob clockwise to close the release valve.

2. Pump the handle to lift the vehicle off the jack stands.

3. Remove the jack stands. Do not get under the vehicle while

the vehicle is being lowered.

4. Turn the handle knob slowly counter clockwise to lower the

vehicle onto the ground.

WWW.SGS-ENGINEERING.COM