FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

CE MARK

SGS Engineering is committed to designing, manufacturing, and market-

ing products that meet or exceed the needs of the customers we serve.

SGS engineering can supply a letter of incorporation or a declaration of

conformity and CE marking for products that conform with European com-

munity directives.

ISO 9001

SGS engineering’s commitment to quality is evident in everything we do,

from raw material receipt to how we support our customers years after

they purchase our products. SGS engineering is registered to ISO 9001:

2000 international quality standard. ISO 9001: 2000 requires compliance

with standards for management, administration, product development,

manufacturing and continual improvement.

Our registration verifies that SGS engineering has adopted and maintains

documentation for processes ranging from suppliers to customers, inspec-

tion, handling, and training. ISO 9001 also requires periodic internal and

external audits to ensure all aspects of w ork affecting quality control are

monitored. This always has been, and will continue to be, our philosophy.

That’s our guarantee to you.

For more products please browse our website: www.sgs-engineering.com

• Gas struts for cars, domestic & industrial applications

• Hydraulic bottle jacks, trolley jacks, axle stands, farm jacks

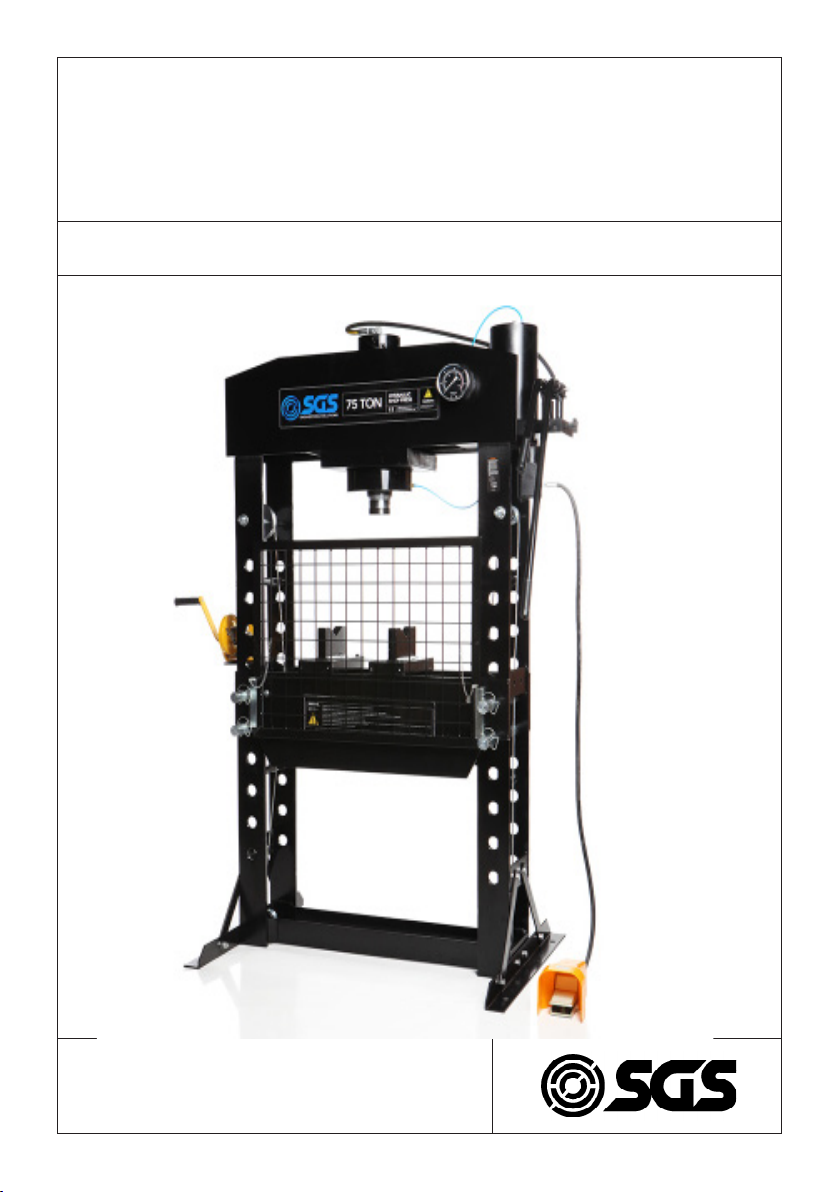

• Workshop and industrial hydraulic presses

• Hydraulic cylinders, pumps, tools & equipment