SGS SSB400 User manual

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

OWNER’S MANUAL

SSB400

SANDBLASTING CABINET

NoNoNo

PAGE 3

PAGE 2

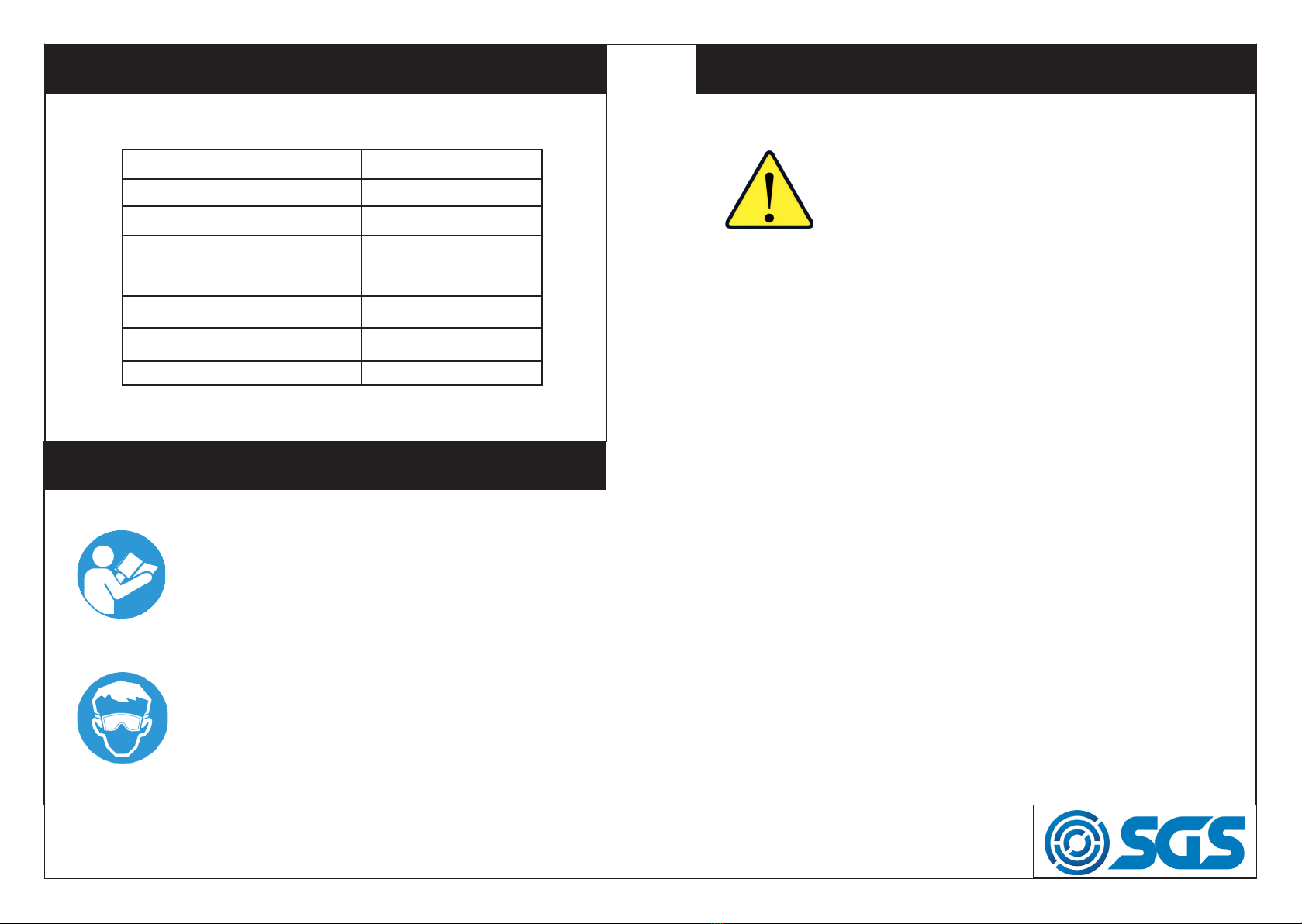

SPECIFICATION

MODEL No SSB400

MAX WORK PRESSURE 125 PSI / 8.6 BAR

WEIGHT 160kg

LENGTH

WIDTH

HEIGHT

1240mm

1330mm

1770mm

MOTOR 120V, 60Hz, 1100W

AIR CONSUMPTION 680L/min

AIR REQUIREMENT 24 CFM @ 125PSI

WARNING

Read and understand instructions before use.

Always wear eye/face and hand protection.

WARNING

Do not use any silica based abrasives with this cabinet.

Silica based abrasives have been linked to severe res-

piratory disease. Always use recommended abrasives.

Abrasives used in this unit may be covered by COSHH.

• All hoses sould be rated at least 125 PSI.

• Supplied air should be dry and clean from oil and other contaminants.

• Before operating the cabinet check seals on the doors, and make sure

dust collection system is running.

• This tank is NOT suitable for paint thinners, gun wash, or air drying.

• DO NOT operate the cleaning tank when you are tired, under the

influence of alcohol, drugs, or intoxication.

• When not in use switch the cleaning tank off and remove plug from

power supply.

• DO NOT operate the cleaning tank if any parts are missing or

damaged. Use original parts and do not sybstitute or modify original

supplied items.

WWW.SGS-ENGINEERING.COM

PAGE 5

PAGE 4

ELECTRICAL CONNECTIONS

WARNING! READ THESE ELECTRICAL SAFETY IN-

STRUCTIONS THOROUGHLY BEFORE CONNECTING

THE PRODUCT TO THE MAINS SUPPLY.

Before switching the product on, make sure that the voltage of your elec-

tricity supply is the same as that indicated on the rating plate. This product

is designed to operate on 230VAC 50Hz. Connecting it to any other power

source may cause damage.

This product may be fitted with a non-rewireable plug. If it is necessary to

change the fuse in the plug, the fuse cover must be refitted. If the fuse

cover becomes lost or damaged, the plug must not be used until a suitable

replacement is obtained.

If the plug has to be changed because it is not suitable for your socket, or

due to damage, it should be cut off and a replacement fitted, following the

wiring instructions shown below. The old plug must be disposed of safely,

as insertion into a mains socket could cause an electrical hazard.

We strongly recommend that this machine is connected to the mains sup-

ply via a Residual Current Device (RCD). If in doubt, consult a qualified

electrician. DO NOT attempt repairs yourself.

Plug must be BS1363/A

approved

Always fit a 3amp fuse

Live

(Brown)

Earth

(Green & Yellow)

Blue

(Neutral)

1. Upend the base and use M8x20 hex bolts to attach leg A and leg B,

then mount on the bracket.

2. Use M8x20 hex bolt and spring washers to attach the leg reinforcement

bars.

3. Place the assembled parts upright, then put the funnel in the centre.

Please note: The front of the funnel should be facing leg B.

4. Place the upper cabinet on the assembled stand. The front of upper

cabinet should be facing leg B.

5. Open the double folded door and attach the upper cabinet, big funnel &

bracket together with 22pcs M6x16 round head screws and faced washers.

6. Use 4pcs M6x12 bolts & M6 flange nuts to mount the dust collector at

the backboard of the upper cabinet. Plug the dust collector plug into the

switch box through the slot on the right of the upper cabinet.

ASSEMBLY

WWW.SGS-ENGINEERING.COM

PAGE 7

PAGE 6

ASSEMBLY

7. Mount pressure regulating valve on the leg B, and connect the orange

air hose to the side hole of funnel, then connect it to the sandblast gun.

8. Place the left / right grid in the upper cabinet.

9. Move the sandblaster to its final position by forklift, then remove the

reinforcing front leg.

PARTS DIAGRAM

WWW.SGS-ENGINEERING.COM

PAGE 9

PAGE 8

PARTS DIAGRAM PARTS LIST

No Description Part No No Description Part No

1 Upper cabinet 903848 35 Support pole of air springs 903882

2 Round head cross screws 903849 36 Plastic slot board of wire 903883

3 Suction sand hose 903850 37 Front door latch 903884

4 Left grid 903851 38 Latch seats 903885

5 Right grid 903852 39 Rack board 903886

6 Sealing tape 903853 40 Grips 903887

7 Big funnel 903854 41 Elements of big hoops 903888

8 Bracket 903855 42 Mounting ring of gloves 903889

9 M8x20 Bolt 900393 43 Glove seats 903890

10 Leg B 903857 44 Gloves 903891

11 Permanent seat of pneumatic device 903858 45 Sand board 903892

12 Pressure gauge 903859 46 Front opening door 903893

12 Pressure regulating valve 903860 47 Cap of nozzle 903894

13 Assembled latches 903861 48 Nozzle 903895

14 Welded cover board for falling sand 903862 49 “O” seal ring 903896

15 Pneumatic device of foot pedal 903863 50 Gun body 903897

16 Leg reinforces 1 903864 51 Sheath of air jet pipe 903898

17 Leg reinforces 2 903865 52 Lock nut 903899

18 Legs A 903866 53 Air jet pipe 903900

19 Dust collector 903867 54 Straight-pass connector 903901

20 M6x32 round head screws 903856 55 Conversion connector 903902

21 Bracket of viewing window 903868 56 Air hose 903903

22 Glass board of viewing window 903869 57 Quick fitting 903904

23 Glass of viewing window 903870 58 Clamps 903905

24 PE film of viewing window 903871 59 1/2” Sand hose 903906

25 Sealing tape of viewing window 903872 60 Switches 903907

26 Rubber seal strip of front opening doorframe 903873 61 Power cord of daylight lamp 903908

27 Bracket of top light 903874 62 wire clips 903909

28 Seat of fluorescent lamp/ lamps 4pcs 903875 63 Socket 903910

29 Glass of light window 903876 64 Cover of E-box 903911

30 PE film of light window 903877 65 Self tapping screws 903912

31 Rubber seal strip of light window 903878 66 Fuse seat 903913

32 sand boards 903879 67 Power cord 903914

33 Main body of upper cabinet 903880 68 Body of E-box 903915

34 Main support poles 903881

WWW.SGS-ENGINEERING.COM

OPERATING AND MAINTAINING

1. All parts processed must be free of oil, grease and moisture. Make sure

parts are dry before putting into the cabinet for cleaning.

2. Set air pressure to 80 psi. For light gauge steel, aluminum, and other

more delicate parts, start at lower pressure and gradually increase the

pressure until the desired finish is achieved.

Warning: Do not connect to high pressure bottled gas.

3. Direct gun at parts at 45-60 degree angle with ricochet towards the back

of the cabinet. Hold gun approximately 6 inches form parts being blasted.

Warning: Gun must always be pointed away from the operator and towards

items being processed. Never blast with any of the cabinet doors open.

4. Media should be of good quality and dry. Moisture will cause the media

not to flow and will clog the metering valve and hopper.

5. After 10-12 hours of blasting time, the nozzle should be checked. If it

shows uneven wear it should be turned 1/4 turn every 10 hours of use.

6. Replace nozzle if it’s measured 1/16 over its original size or if it shows

uneven wear. Adjust as needed for different media and conditions.

A properly working gun will pull 15-17 inches of mercury on manometer.

7. Clean dust from dust collector and clean filter as needed.

8. Air line should be more than 8mm (0.3”). All hoses should be rated for

125 psi (8.6 bar). An isolation valve should be installed.

9. Electric extension cords should be three wire grounded (wire size can

not be smaller than 3x1.5mm2 ).

10. Before starting inspect fittings and hoses for damage and water.

EC Declaration of Conformity

This is an important document and should be retained

MANUFACTURER’S NAME:

TYPE OF EQUIPMENT:

PART NUMBER:

I, the undersigned, hereby declare that the equipment specied above

conforms to the above European Communities Directive(s) and

Standard(s).

PLACE:

DATE: (Signature)

Robert Wyatt

Company Secretary

Derby, UK

24th NOV 2018

SGS Engineering (UK) Ltd

SGS Engineering (UK) Ltd

West Side Park

Raynesway

Derby, DE21 7AZ

SHOT BLASTER CABINET

SSB400

2014/35/EU Low Voltage Directive

2014/30/EU EMC Directive

2012/19/EU WEEE Directive

2011/65/EU RoHS Directive

APPLICATION OF EC COUNCIL DIRECTIVES / STANDARD:

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

Table of contents

Other SGS Power Tools manuals