SSG579-585•9.801-193.0•Rev.3/143

PRESSUREWASHER OPERATOR’S MANUAL

INTRODUCTION & IMPORTANT SAFETY INFORMATION

ThankyouforpurchasingaSharkPressureWasher.We

reserve the right to make changes at any time without

incurring any obligation.

Owner/User Responsibility:

The owner and/or user must have an understanding of

themanufacturer’s operating instructionsandwarnings

before using thispressurewasher.Warning information

should be emphasized and understood.If the operator

is not fluent in English, the manufacturer’s instructions

and warnings shall be read to and discussed with

the operator in the operator’s native language by the

purchaser/owner, making sure that the operator com-

prehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’instructions.

The operator must know how to stop the machine

quickly and understand the operation of all controls.

Never permit anyone to operate the engine without

proper instructions.

SAVETHESE INSTRUCTIONS

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

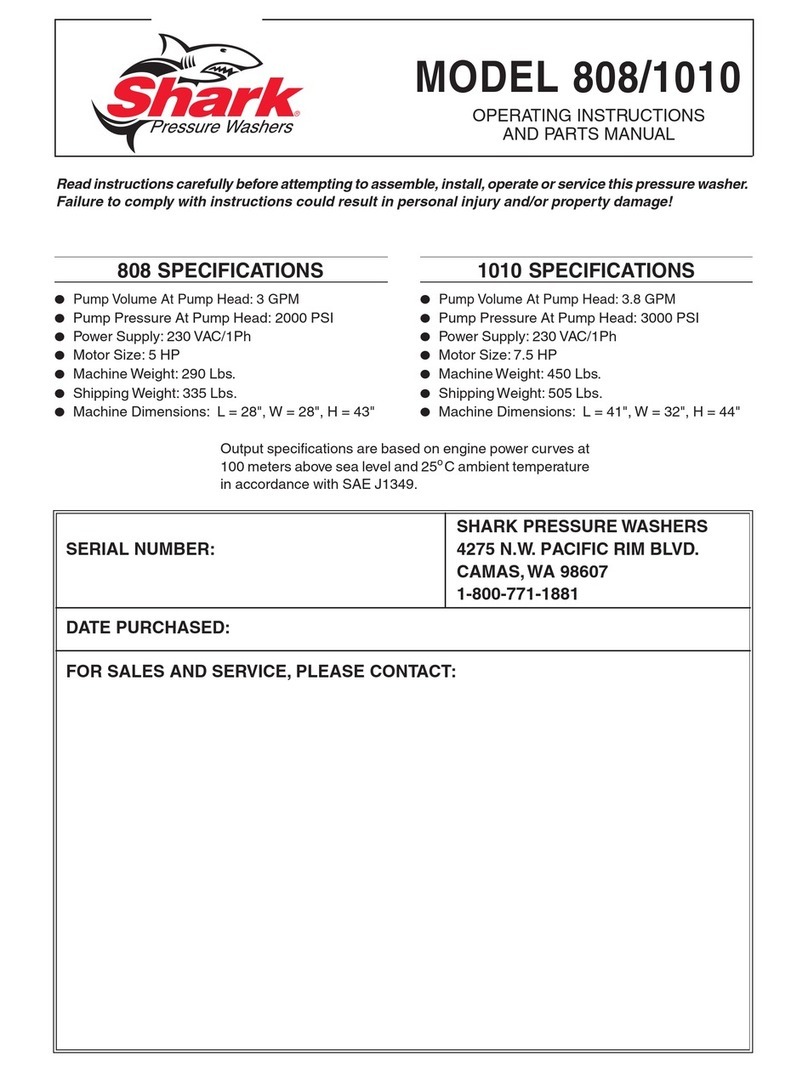

When ordering parts,please specify model and se-

rial number. Use only identical replacement parts.

This machine is to be used only by trained operators.

IMPORTANT SAFETY

INFORMATION

READ OPERATOR’S

MANUALTHOROUGHLY

PRIORTO USE.

WARNING:To reduce the risk of

injury, read operating instruc-

tions carefully before using.

1. Read the owner's manual

thoroughly. Failure to fol-

low instructions could cause

malfunction of machine and

result in death, serious bodily

injuryand/orpropertydamage.

2. Knowhow to stopthe machine and bleedpressure

quickly. Be thoroughly familiar with the controls.

3. Stay alert — watch what you are doing.

KEEPWATER

SPRAY AWAY FROM

ELECTRICALWIRING.

WARNING: Keep wand, hose, and

water spray away from electric wir-

ingorfatalelectricshockmayresult.

4. All installations must comply

with local codes. Contact

your electrician, plumber,

utility company or the selling

distributor for specific details.

EAR PROTECTION

MUST BEWORN

WARNING:Thismachineexceeds

85 db appropriate ear protection

must be worn.

USE PROTECTIVE

EYEWEAR

AND CLOTHING

WHEN OPERATING

THIS EQUIPMENT.

WARNING: High pressure spray

can cause paint chips or other

particles tobecome airborne and

fly at high speeds.To avoid per-

sonal injury, eye, hand and foot

safety devices must be worn.

5. Eye, hand, and foot pro-

tection must be worn when

using this equipment.

6. Keep operating area clear of all persons.

RISK OF EXPLOSION:

OPERATE ONLY

WHERE OPEN

FLAME ORTORCH IS

PERMITTED

WARNING: Flammable liquids

can create fumes which can ig-

nite, causing property damage

or severe injury.

WARNING: Risk of explosion —

Operate only where open flame

or torch is permitted.

RISK OF FIRE.

DO NOT ADD FUEL

WHEN OPERATING

MACHINE.

WARNING: Risk of fire — Do not

add fuel when the product is

operating or still hot.

WARNING: Do not use gaso-

line crankcase draining or oil

containing gasoline, solvents

or alcohol. Doing so will re-

sult in fire and/or explosion.

WARNING: Risk of fire — Do not spray flammable

liquids.

7. Allow engine to cool for 1-2 minutes before refuel-

ing.If any fuel is spilled, make sure the area is dry

before testingthe sparkplugor starting theengine.

(Fireand/orexplosionmayoccur if this isnotdone.)

Gasolineengines on mobileor portableequipment

shall be refueled:

a. outdoors;

b. with the engine on the equipment stopped;

c. with no source of ignition within 10 feet of

the dispensing point; and

d. with an allowance made for expansion of the

fuel should the equipment be exposed to a

higher ambient temperature.