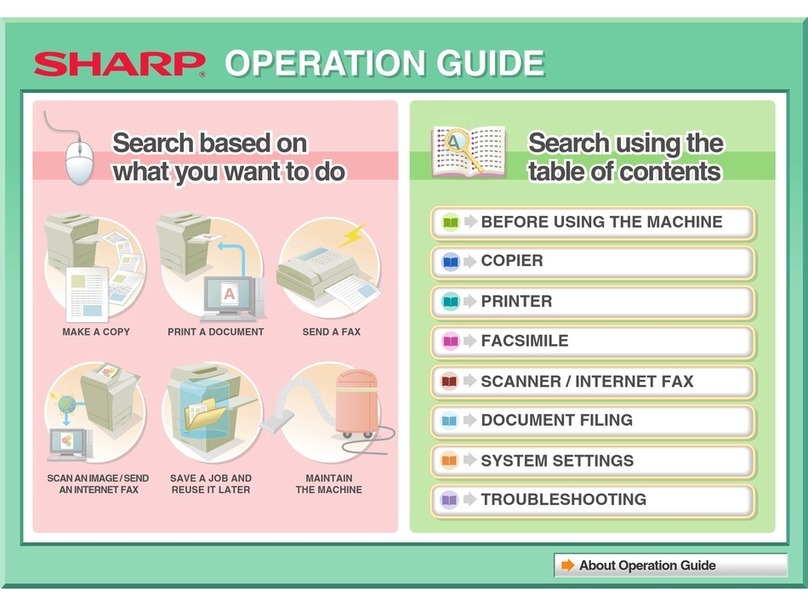

Sharp MX-C310 User manual

Other Sharp All In One Printer manuals

Sharp

Sharp DM-2000 User manual

Sharp

Sharp MX-M1204 User manual

Sharp

Sharp AR-FX9 - Fax Interface Card User manual

Sharp

Sharp MX-B382 User manual

Sharp

Sharp FO-4450 User manual

Sharp

Sharp MX-B427W User manual

Sharp

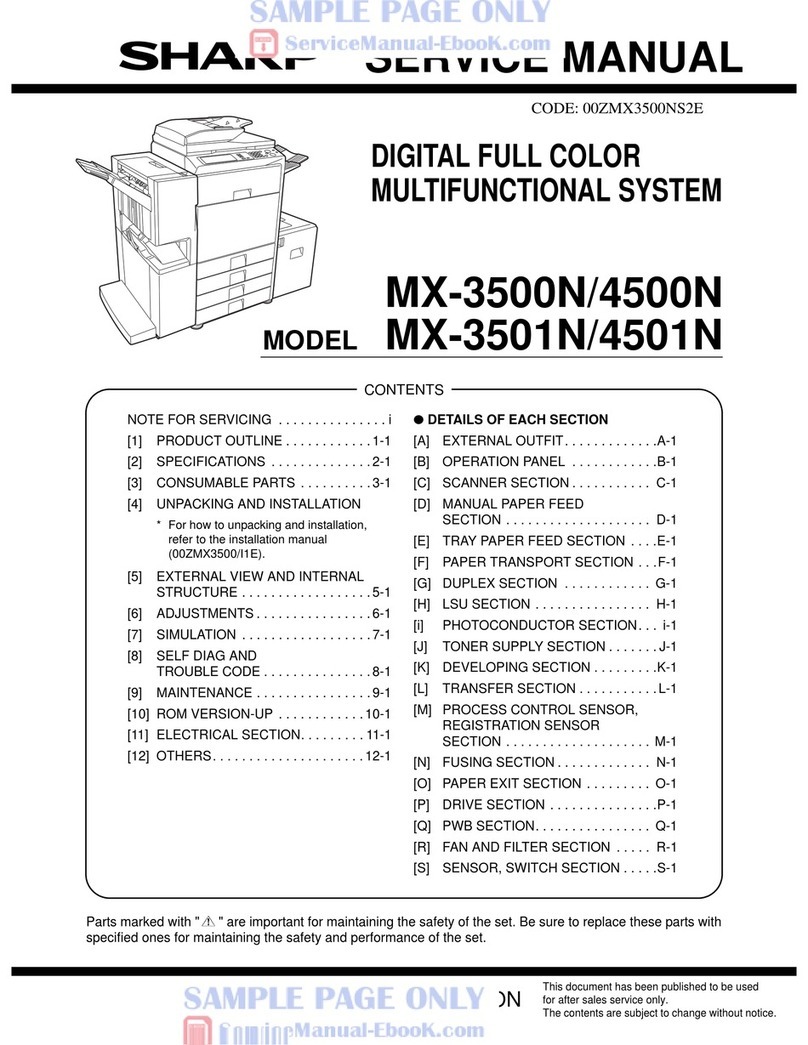

Sharp MX-3500N User manual

Sharp

Sharp AJ-5030 User manual

Sharp

Sharp B750 - UX B/W Inkjet User manual

Sharp

Sharp UX-5000 User manual

Sharp

Sharp MX-M354U N User manual

Sharp

Sharp AR 168S - Digital Imager B/W Laser User manual

Sharp

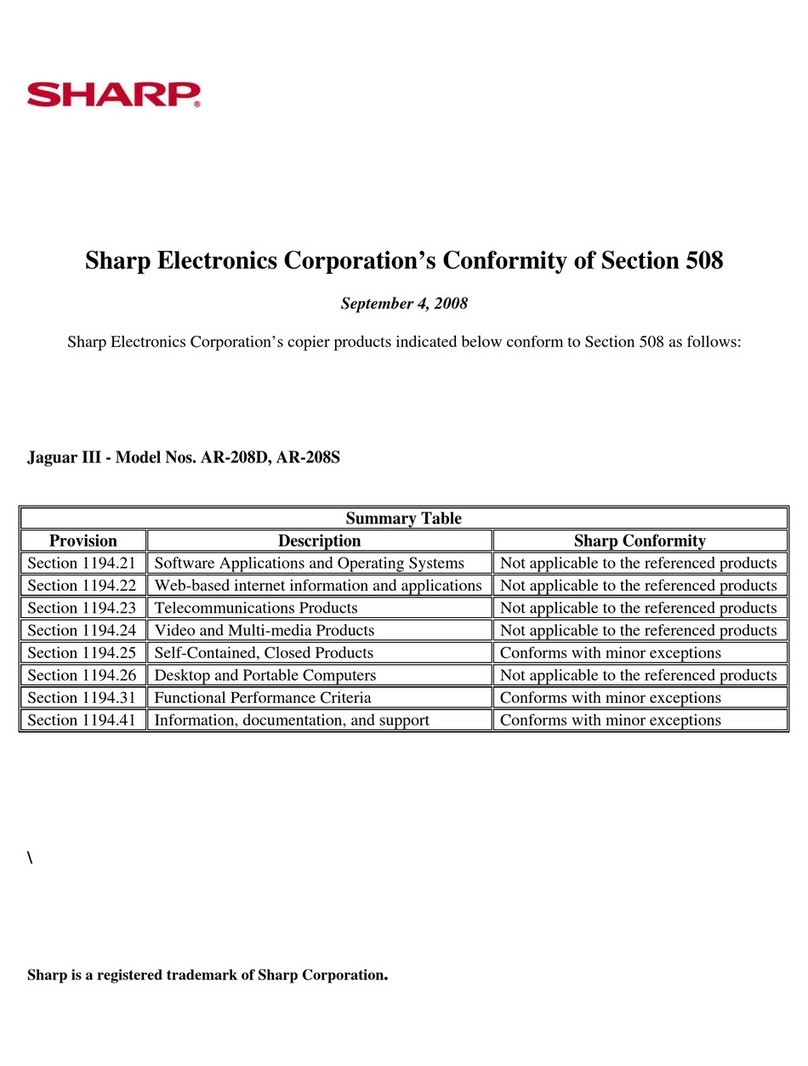

Sharp AR-208S User manual

Sharp

Sharp AL-1651CS User manual

Sharp

Sharp MX-B355W User manual

Sharp

Sharp MX-2610N User manual

Sharp

Sharp MX-7090N Guide

Sharp

Sharp AR-BC320 Assembly instructions

Sharp

Sharp AR 168D - Digital Imager B/W Laser User manual

Sharp

Sharp MX-6240N User manual