CONTENTS

Transit, Installation (using) environment, Note

1. Installing (use) conditions . . . . . . . . . . . . . . . . . . .. . . . . . i

2. Transit and delivery. . . . . . . . . . . . . . . . . . . . . . . .. . . . . iii

[1] CONFIGURATION

1. System diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 1- 1

2. Option list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1- 2

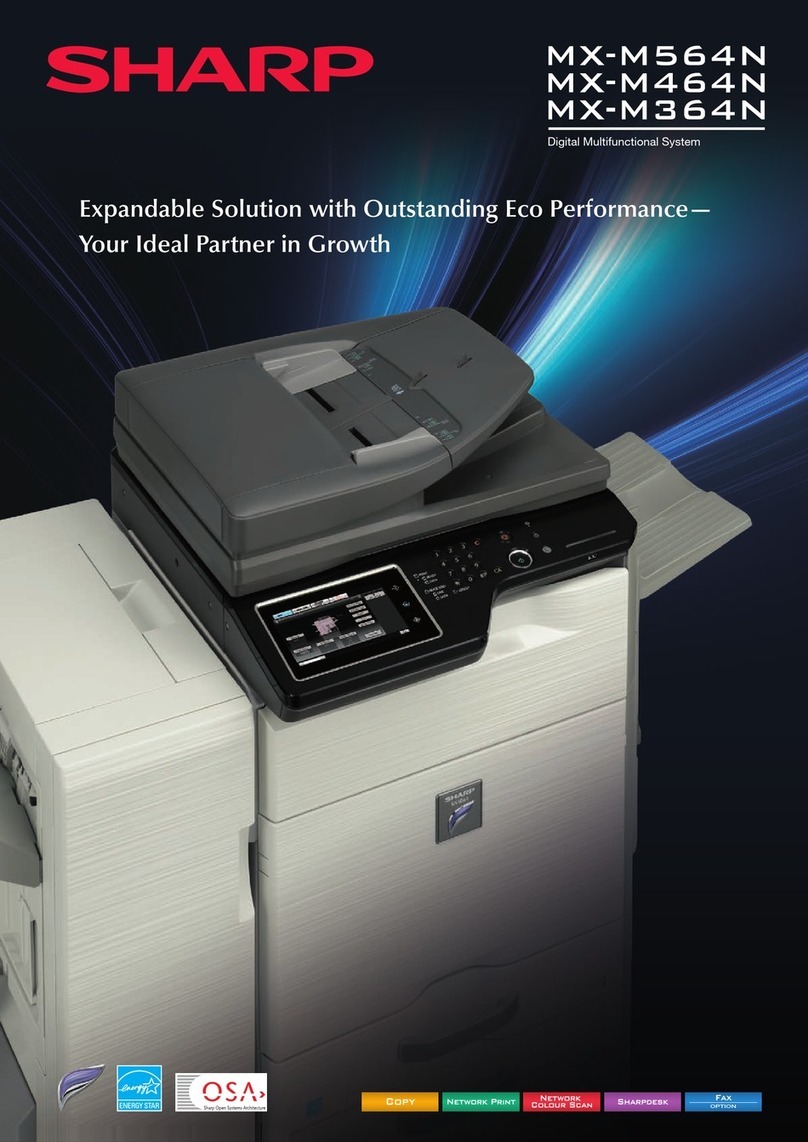

[2] MX-M264U/M314U/M354U/M264N/M314N/M354N

(MAIN UNIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 2

[3] MX-RP15 (REVERSING SINGLE PASS FEEDER)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 1

[4] MX-VR11 (DOCUMENT COVER)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 1

[5] MX-DE17/DE18 (500/2x500 SHEET PAPER DRAWER)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5- 1

[6] MX-DS16/DS17 (LOW STAND/HIGH STAND)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6- 1

[7] MX-FN23 (FINISHER)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7- 1

[8] MX-TE10 (EXIT TRAY UNIT)

1. Parts included . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8- 1

[9] MX-TR11 (JOB SEPARATOR)

1. Parts included . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9- 1

[10] MX-PB15 (PRINTER EXPANSION KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10- 1

[11] MX-PK11 (PS3 EXPANSION KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11- 1

[12] MX-PF10 (BARCODE FONT KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12- 1

[13] MX-NSX1 (NETWORK SCANNER EXPANSION KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13- 1

[14] MX-FX11 (FACSIMILE EXPANSION KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14- 1

[15] MX-FWX1 (INTERNET FAX EXPANSION KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15- 1

[16] AR-SU1 (STAMP UNIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16- 1

[17] MX-FR37U (DATA SECURITY KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17- 1

2. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17- 1

[18] MX-AMX1 (APPLICATION INTEGRATION MODULE)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18- 1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18- 1

[19] MX-AMX2 (APPLICATION COMMUNICATION MODULE)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19- 1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19- 1

[20] MX-AMX3 (EXTERNAL ACCOUNT MODULE)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20- 1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20- 1

[21] MX-HD12 (HARD DISK EXPANSION KIT)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21- 1

2. User data backup . . . . . . . . . . . . . . . . . . . . . . . . . 21- 1

3. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21- 1

4. User data restore . . . . . . . . . . . . . . . . . . . . . . . . . . 21- 3

5. Operation check . . . . . . . . . . . . . . . . . . . . . . . . . . 21- 3

[22] MX-KB14 (KEYBOARD)

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22- 1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22- 1

[23] Dehumidifying heater kit

1. Parts list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23- 1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23- 2

[24] IC card reader

1. Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24- 1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24- 1

3. Setting file for HID card reading . . . . . . . . . . . . . . 24- 5

[25] Remote operation panel function Enable setting

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25- 1

2. Remote operation panel function password setting

procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25- 1

[26] Setting, Adjustments, Operation check

1. Firmware version check and version up . . . . . . . . 26- 1

2. Function and operation check . . . . . . . . . . . . . . . . 26- 1

[27] Setup and adjustment data recording . . . . . . . . . . . 27- 1

[28] Necessary works before moving the machine . . . . 28- 1