z–w

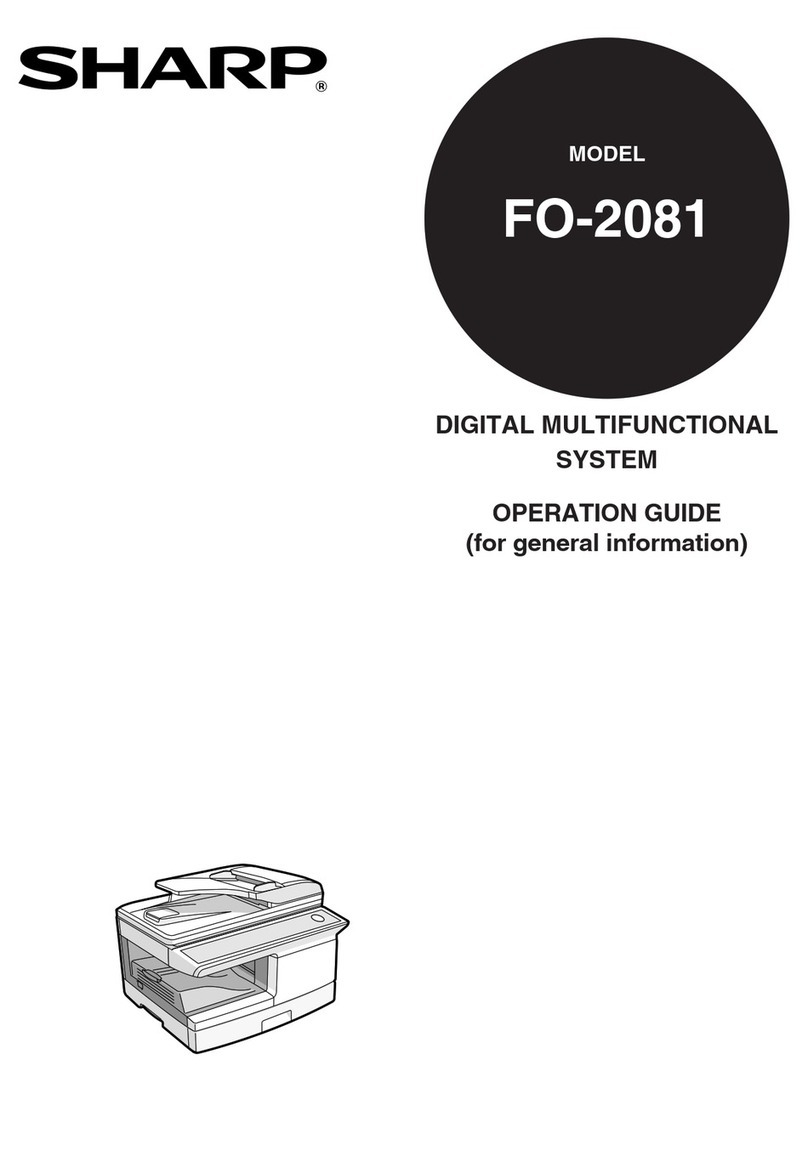

[2] OPERATION PANEL AND INDICATOR

FUNCTIONAL DESCRIPTION

y

I

1

Power switch and power ~upply cord

Power is turned on and off using the power lever.

Upper frame release button

Used to release the frame lock when amisfeed occurs

or the drum cartridge hasto be replaced.

Doorswitch

Used to check the front door position.

If the front cover is opened, the misfeed and multicopy

indicator wi II be reset.

Auto exposure control

Selects appropriate exposure rate depending on the

contrast and background color of the original.

Exposure control lever

It has three set positions.

For most originals, set at the center position.

To make the copy darker, move to DARK.

To make the copy lighter, move to LIGHT.

Misfeed indicator

When amisfeed occurrs, this lamp turns ON. .

TD cartridge replacement indicator

The lamp flashes when the TD cartridge needs replace-

ment.

Drum cartridge replacement indicator

Afier 8,000 copies, the indicator will start to flash.

An additional 1,000 copies can be made. At this time

the indicator will stop flashing and stay ON. No

additional copies can be made until the Drum canridge

is replaced.

Multicopy

Copy numbers between 1and 19 mn be entered

using the (–) or (+) key. Depression of the (–) key

while “O” is displayed brings “19” into the display,

and continued depression of the key reduces the

number. When the (+) is depressed after “19”, the

number is returned to, ::0”. Every time acopy is

produced in the multicopy mode, the number in the

display coun~ down. When the (–) isdepressed in the

middle of multicopy operation, the number of copies

already made is displayed.

Auto repeat ,j,.,, ~<.<.., ,,,, (

Upon completion of copying in the multicopy mode,

the copy number previously set returns to the copy

numberset.display.Use of the CLEAR key resets the

number. One minute after completion of copying,

the number @the auto repeat functions are auto-

matically cleared.

Paper feed alarm (P indication)

If ash~t of paper is not transferred to the paper stop.

par after depre~ion of the PRINT switch, or the cas-

sette is empty,“P” is “displayed in the copy number

wind~~. :If the COPY. NUMBER key or the CLEAR

key is depressed or the MANUAL FEED switch is

Wb:’ti ‘~~ief”ti b~ned, the “P” indication is also

cancalled.

@Clear !~,+: [

Multimpy and auto repeat modes are cleared with the

‘) ‘CLEAR key.~~ne rnlnuti after completion of copy

.-..-

‘;’:? fifi@;ati6nJ~&~~Qt n~rnbar and the repeat functions

are automatically *-tid.” i‘ “

@PRINTswitch

~,; ~~ ~ saconds:aftar-powar isturned on, the READY lamp

turns ON indicating ”-tit” the copier is ready for

cOPying. if left unoparatad for go ~conds, the

copier$tha ~into the power save mode and the {

READY lamp changes from ON to flashing. When

the PRINT switch is pressed while the READY lamp

is on, the machine immediately starts to copy. When

the PRINT ~itch is pressedwhile the READY lamp is

fkshin~ thepower~va mode is cancalled, the original

table rn&’’”to:’~+@py -~fi position, and it starts the

armup cycle.

is dependent

it will be less t

the PRINT

,.

–2–

....---- ‘... . ..

;. .... ~.......