3. BEFORE ~STALLING OPTIONS

2.

3.

4.

5.

6.

If you install any option in the ER-31OO register already in use,

you must have a Z reading performedby its user before performing

the installation.

If the register is not reset, sales data stored in the register

may be destroyed.

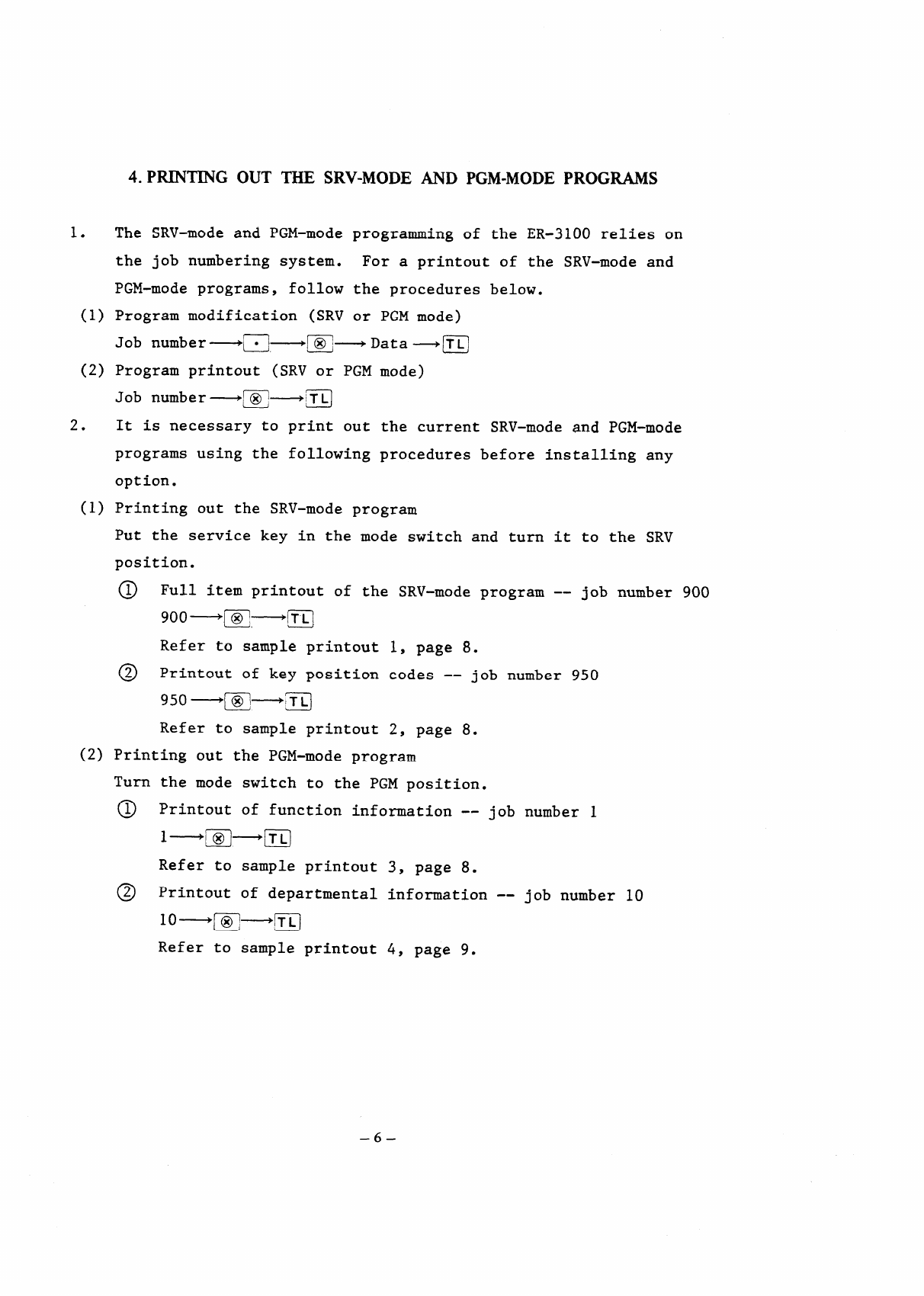

Print out the SRV-mode and PGM-modeprograms before installing

any option. It may be necessary to modify each program after

installation.

For the printout procedure refer to Section 4 “PRINTING OUT THE

SRV-MODEAND PGM-MODE PROGRAMS”on page 6.

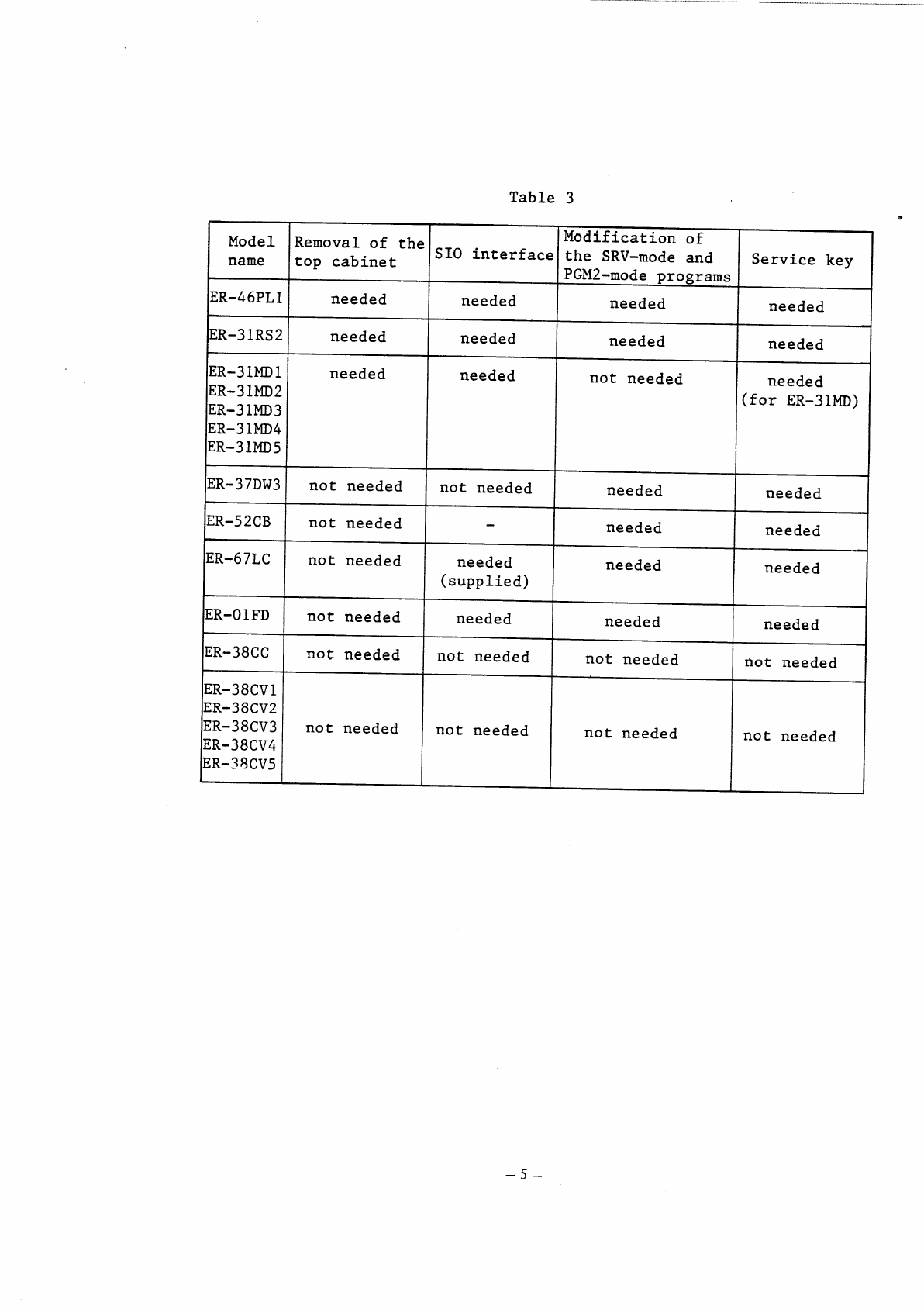

If you install optional expansionRAMs and/or ROM (for the

ER-31RS2) in the ER-31OO register already in use, perform data

saving for memory protectionby using the S10 interface in

advance. After the option(s)has been installed,perform data

loading for restoringmemory contents. See Section 8 “PRESETS

LOADER” for the data saving/loadingprocedure. It is advisable

to perform the above data savingwhen installingother options.

As a safety measure, be sure to turn the mode switch to the OFF

position and unplug the registerbefore installingany option.

If you do not unplug the register, the transformerPm will

remain on.

The ER-31OO is equippedwith various SRV-mode functions to aid

you in installingthe options. Never enter any job numbers other

than those shown in each of the followingsections, so that data

stored is not destroyed.

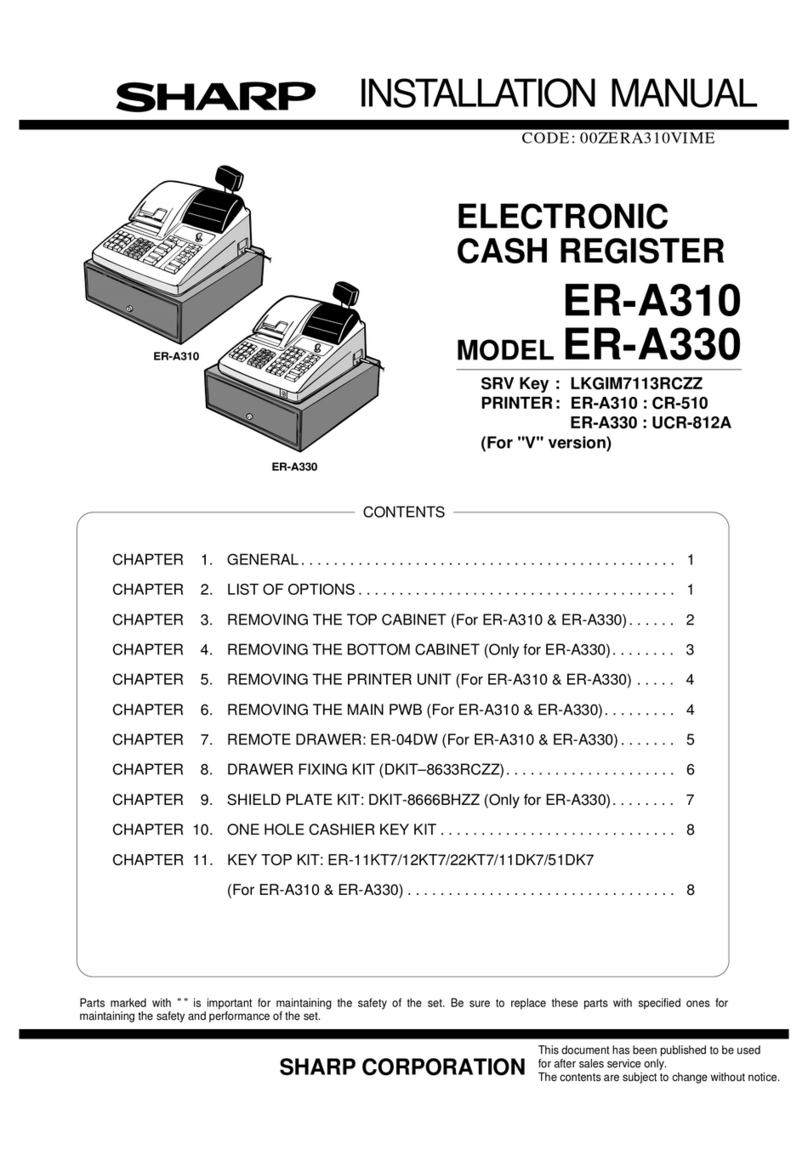

To install any options other than the remote drawer and presets

loader, you need to remove the top cabinet. Please read 5.1

“Removing the top cabinet”under Section 5 “REMOVING~E TOP

CABINET AND MAIN DRAWER~ on page 10. To install the remote

drawer or ER-31RS2 interfacecable, you need to remove the main

drawer. Please read 5.3 “Removingthe main drawer” on page 11.

–4–