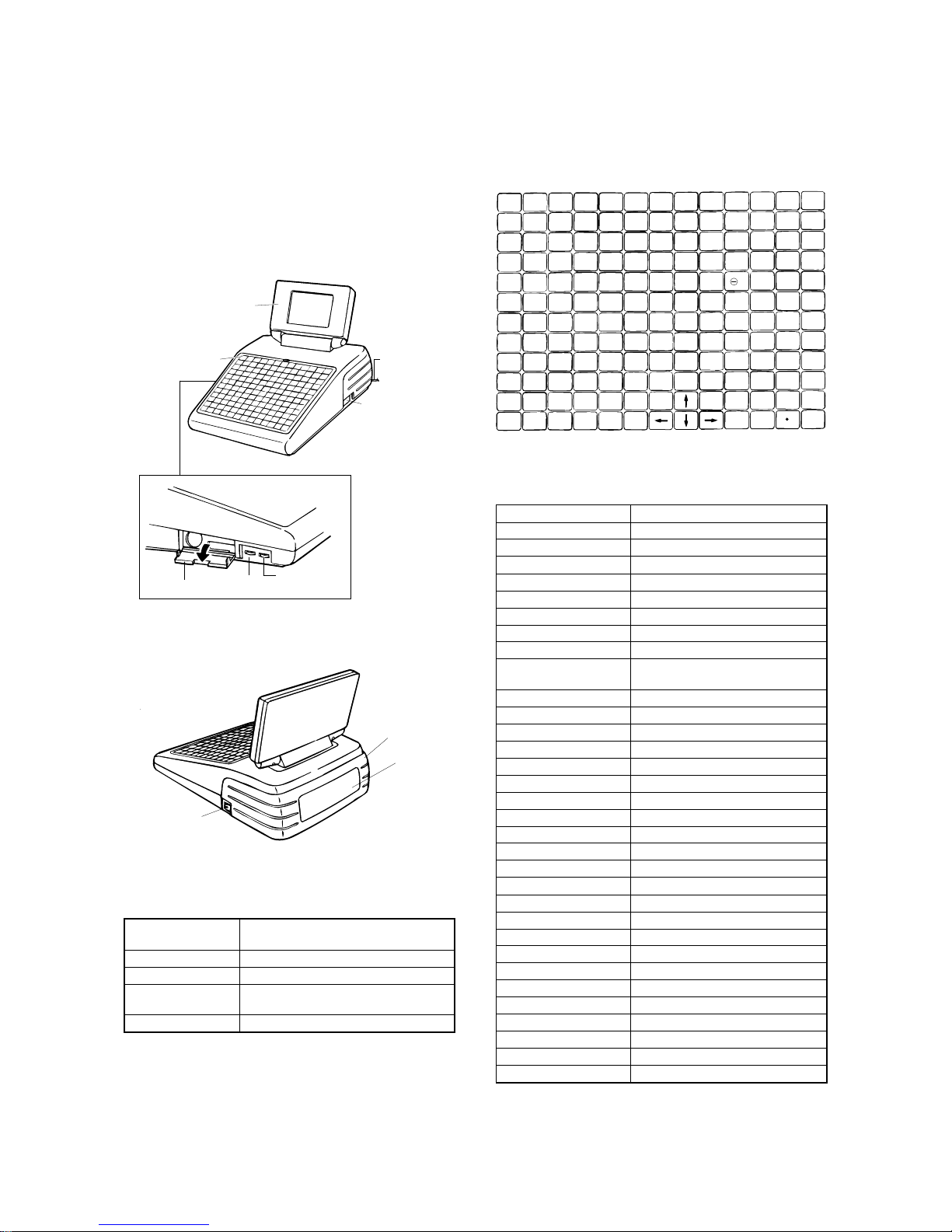

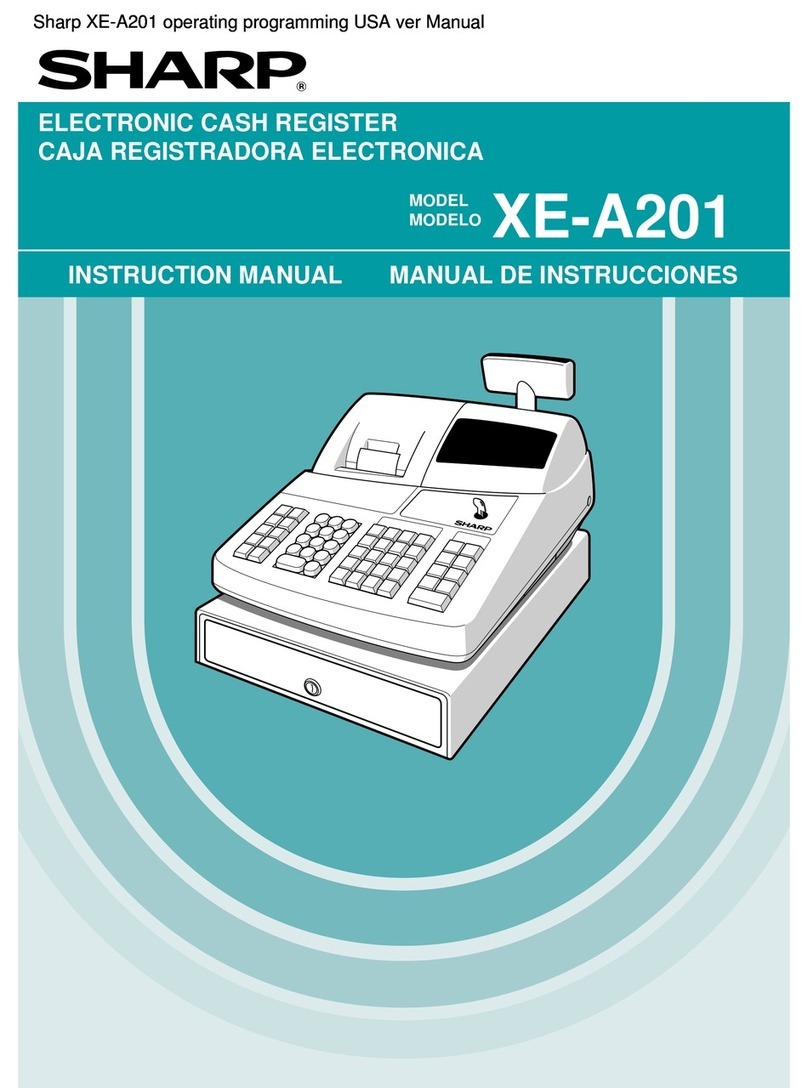

Sharp ER-A750 User manual

Other Sharp Cash Register manuals

Sharp

Sharp XE-A201 User manual

Sharp

Sharp XE-A202 - Electronic Cash Register User manual

Sharp

Sharp UP-3301 User manual

Sharp

Sharp ER-A460 Owner's manual

Sharp

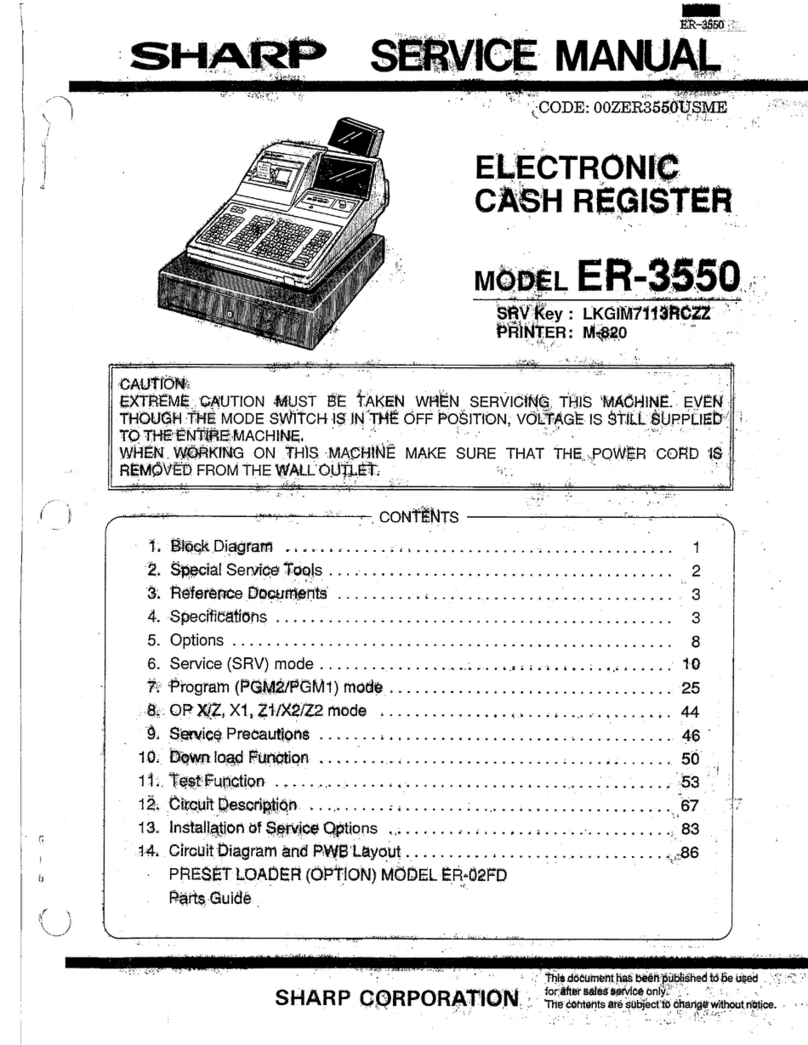

Sharp ER-3550 User manual

Sharp

Sharp ER-2386S User manual

Sharp

Sharp XE-A147-BK Instruction Manual

Sharp

Sharp XE-A407 User manual

Sharp

Sharp ER-A410 User manual

Sharp

Sharp ER-A247 User manual

Sharp

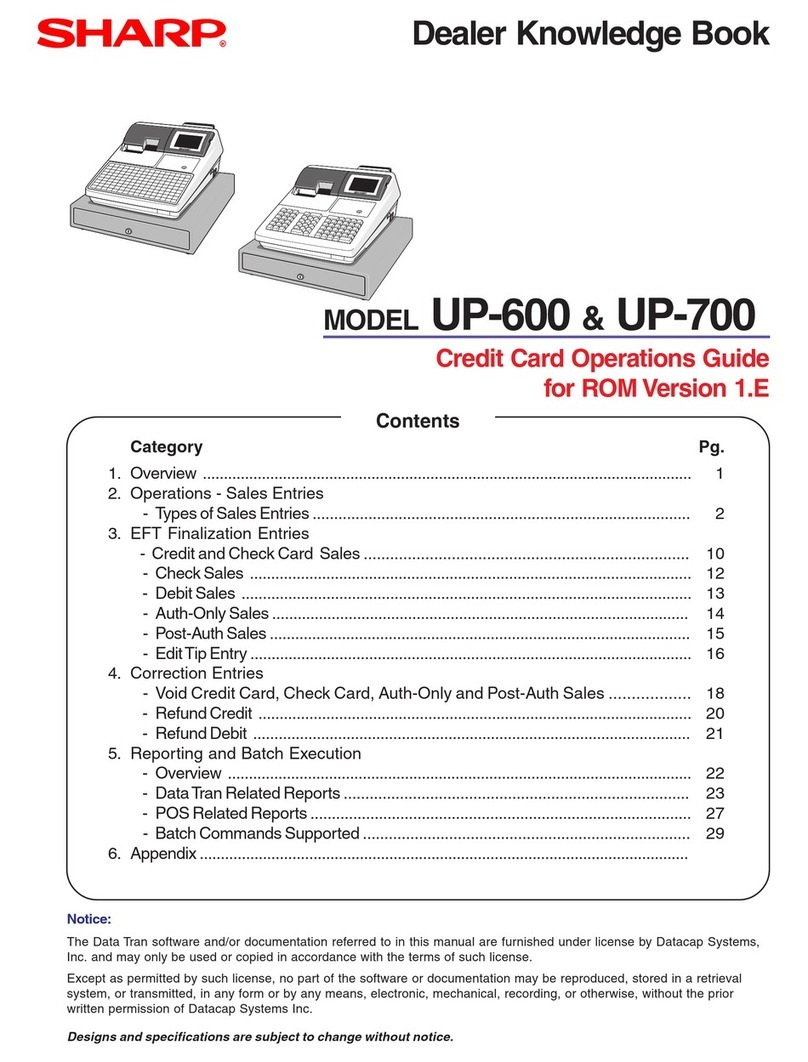

Sharp UP-600 User manual

Sharp

Sharp XE-A152 User manual

Sharp

Sharp UP-600 User manual

Sharp

Sharp XE-A177 Quick manual

Sharp

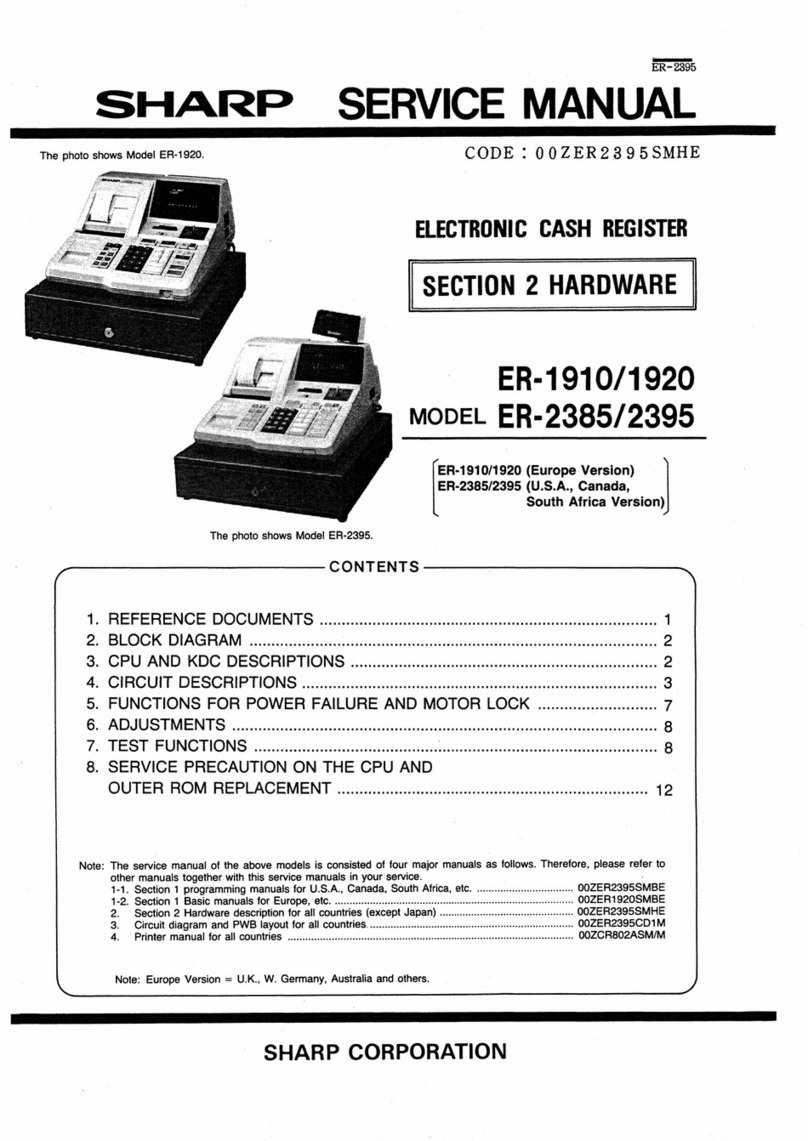

Sharp ER-1910 User manual

Sharp

Sharp XE-A212 User manual

Sharp

Sharp UP-600 User manual

Sharp

Sharp XE-A202 - Electronic Cash Register User manual

Sharp

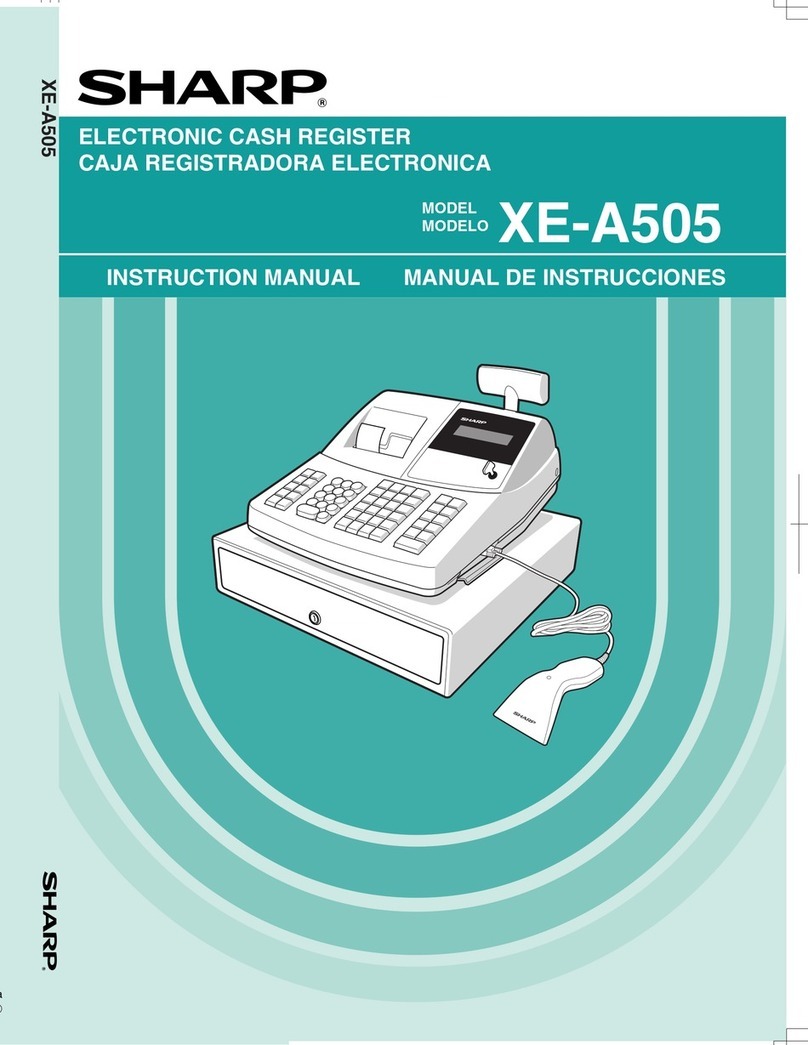

Sharp XE-A505 - Cash Register, Thermal Printing User manual

Sharp

Sharp ER-A220 User manual