[1] GENERAL

1. General

This model is a digital personal copier produced with key words

of “Comfort able copy, Clear copy, Easy copy” providing high

copy performances and copy productivity.

2. Target User Copy Volume: Monthly Average

Copies: 400 ∼800 (Max. 800)

Prints: 400 ∼800 (Max. 800)

3. Main features

A. High-speed laser copying

●Since warm-up time is zero, copying can be started imme-

diately after the power switch is turned on.

●First-copy time is only 9.6 seconds (normal mode).

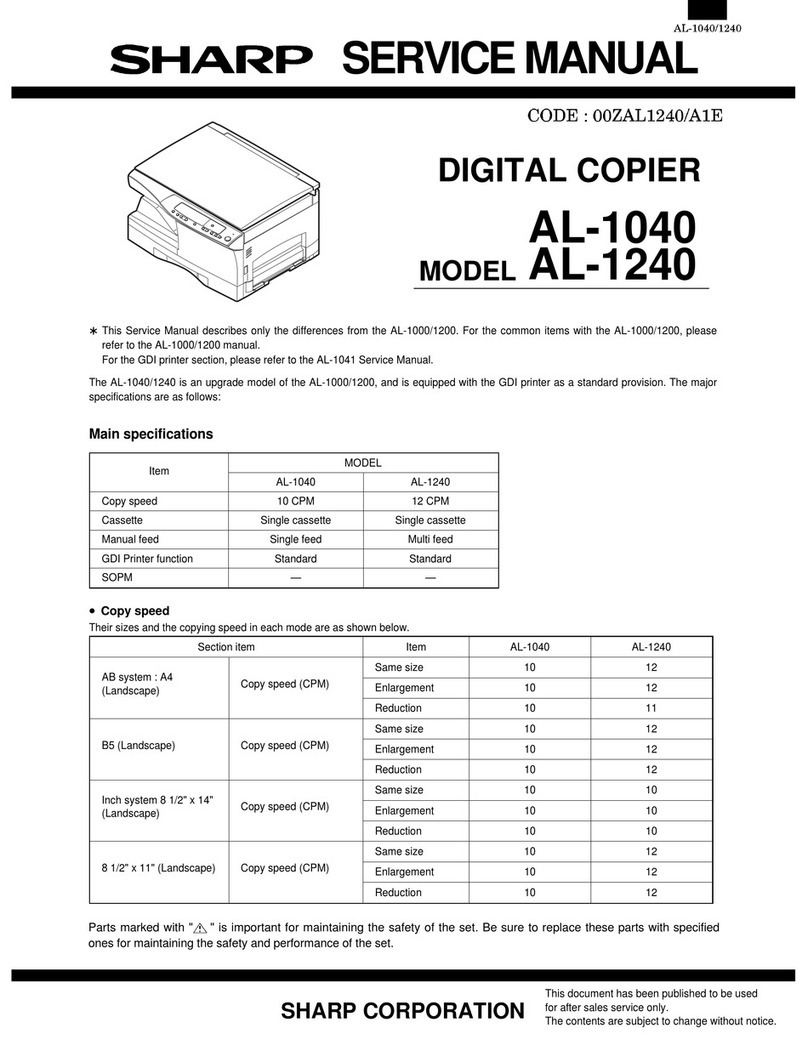

●Copying speed is 10 copies/min. (AL-1020) or 12

copies/min. (AL-1220/AL-1250), which adapts to business

use, allowing improvement of working efficiency.

B. High-quality digital image

●High-quality image copying at 600 dpi can be performed.

●In addition to the automatic exposure mode, the manual ex-

posure can be adjusted in five steps.

●The photo mode copying function allows clear copying of

delicate halftone original images such as monochrome

photos and color photos.

C. Substantial copying functions

●Zoom copying from 50% to 200% in 1% increments can be

performed.

●Continuous copying of maximum 99 sheets can also be per-

formed.

●Automatic document feeding through the single pass feeder

(SPF) can be performed.

●Toner save mode reduces toner consumption by ap-

proximately 10%.

●User programs allow setting/modification of functions for

customer’s needs.

D. Scan once/Print many

This copier is equipped with a 1-page memory buffer. This

Memory allows the copier to scan an original 1 time only and

make up to 99 copies. This feature allows for improved

workflow, reduced operating noise from the copier and reduced

wear and tear on the scanning mechanism. This feature

provides for a higher reliability.

E. Printer feature

The AL-1250 copier can be used as a laser printer. The AL-

1020 and AL-1220 copiers can be used as a laser printer by in-

stalling an optional printer upgrade kit.

F. Environmentally friendly design

Paper output tray is housed in the copier for space saving.

Preheat mode and auto power shut-off mode are provided to

reduce power consumption in standby mode.

4. Environmental

The environmental conditions for assuring the copy quality and

the machine operations are as follows:

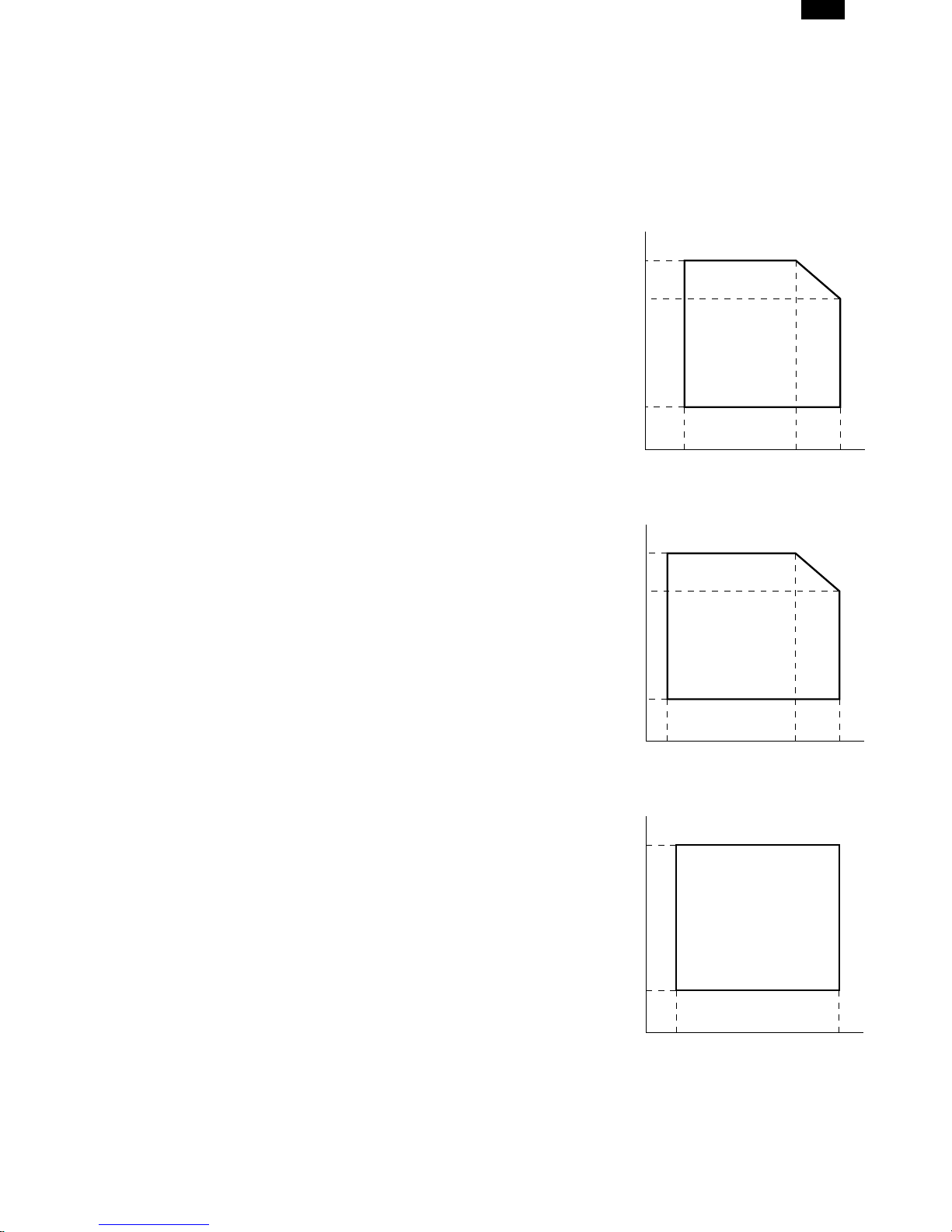

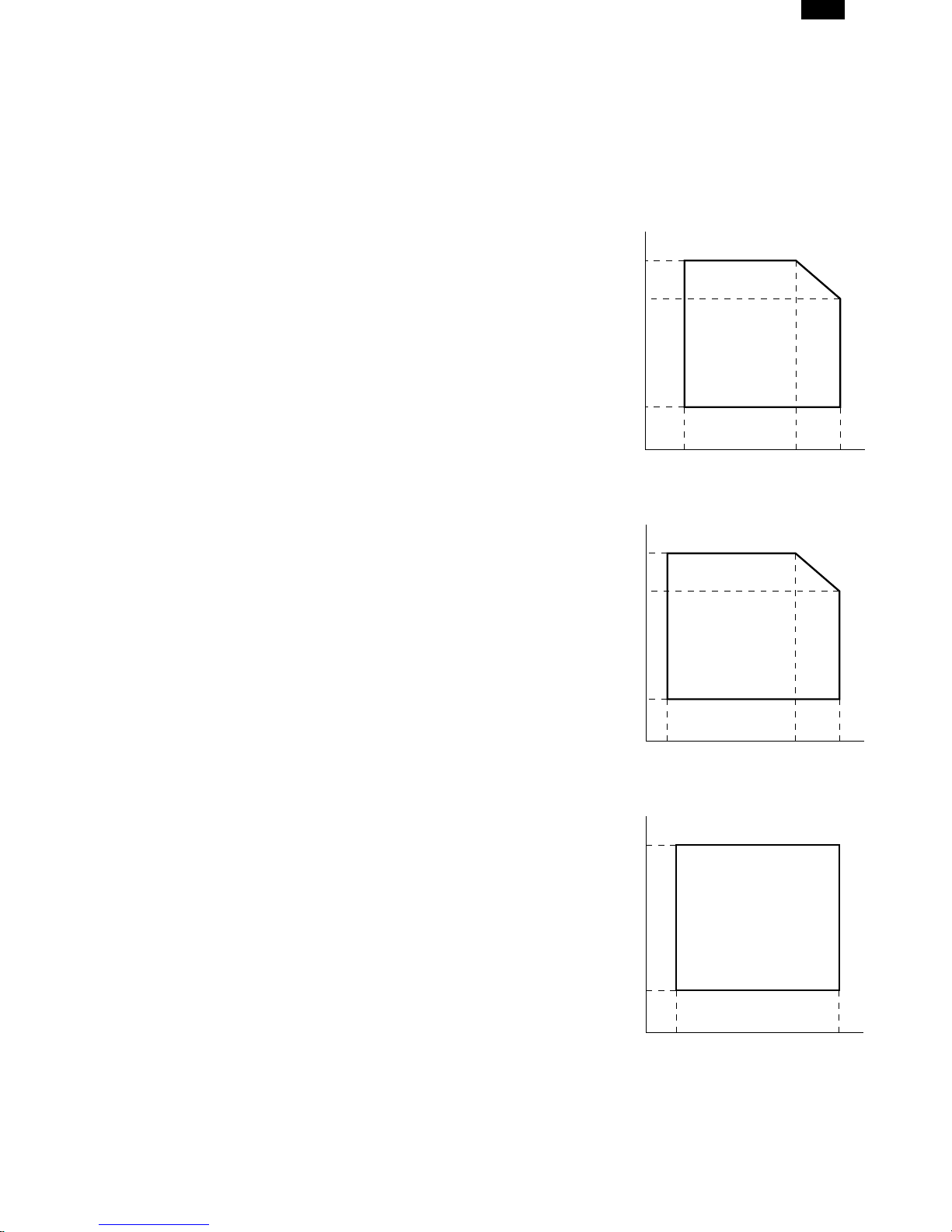

A. Normal operating condition

Temperature:20˚C~25

Humidity:65 ±5%RH

B. Acceptable operating condition

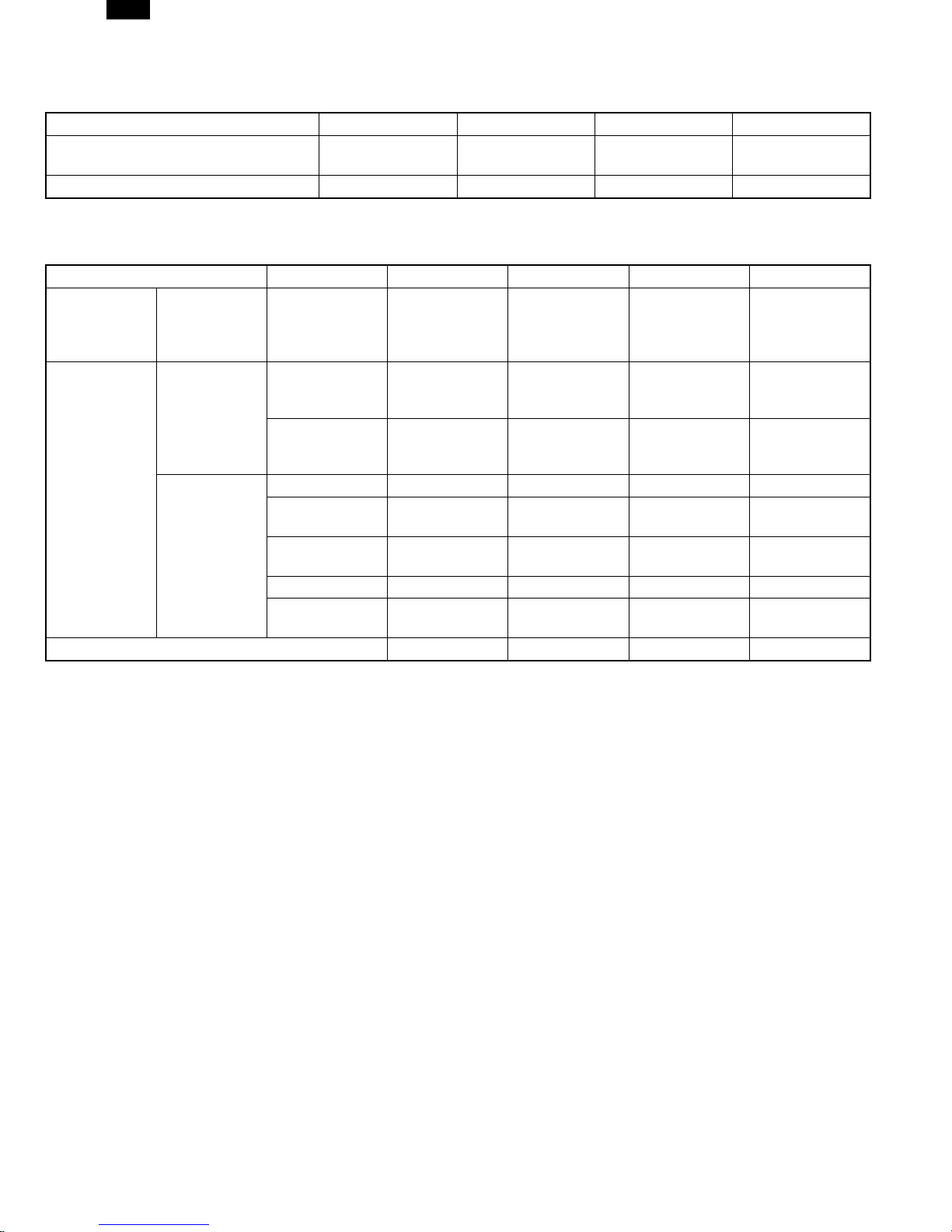

C. Optical condition

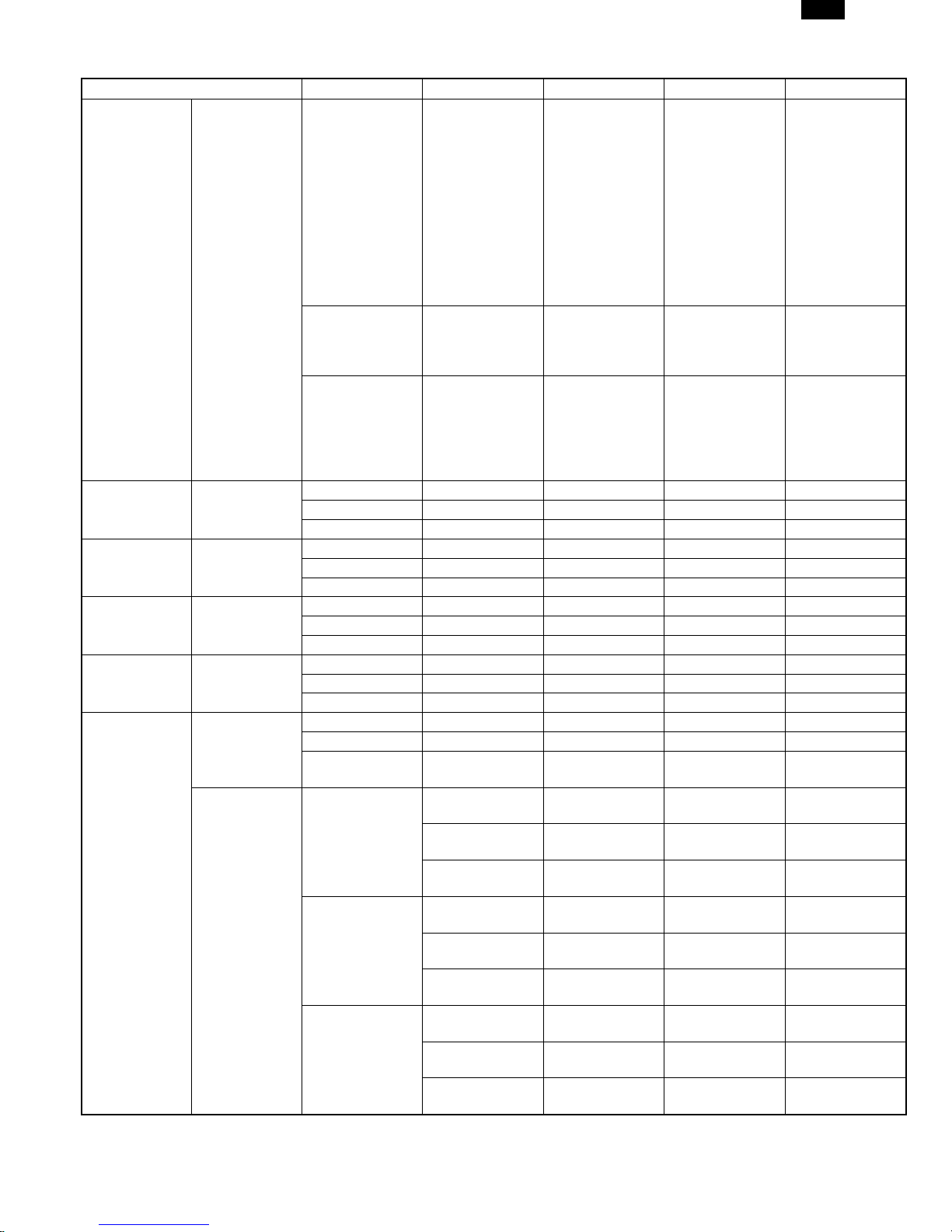

D. Supply storage condition

Humidity (RH)

85%

60%

20%

10˚C 30˚C 35˚C

Humidity (RH)

90%

60%

15%

–25˚C 30˚C 40˚C

Humidity (RH)

90%

20%

–5˚C 45˚C

AL-1250

1-1