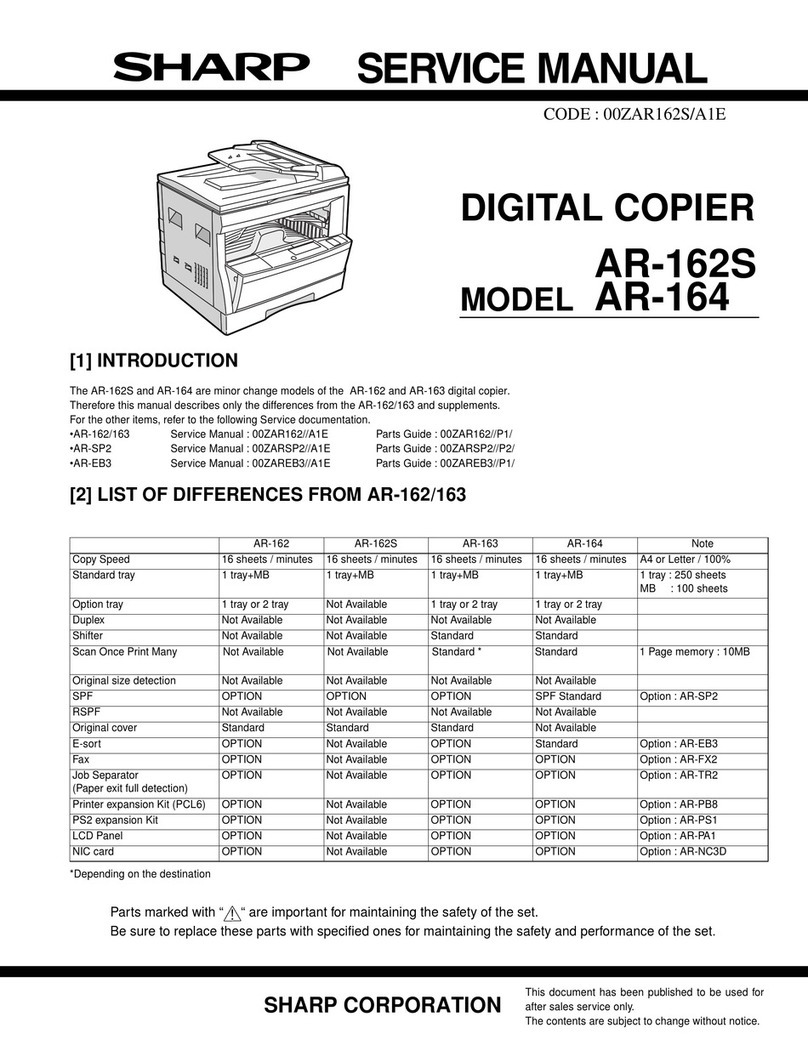

[2] PRODUCT SPECIFICATIONS

1. Basic specifications

(1) Type: Console

(2) Copying system: Dry, electrostatic transfer system

(3) Original Kinds: Sheet, book, cubic

Max. original size A3, 11 ×17

Original reference position Center left

Detection Japan, YES; outside Japan, NO

Detection size A3, B4, A4, A4R, B5, B5R

Option RADF (Standard except for

Japan/SEEG/SUK)

Original load capacity 50 sheets

Original size A3 ∼A5, 11 ×17 ∼5.5 ×8.5

Original replacement

speed 50 sheets/min (A4, 8.5 ×11)

Original weight

(Excluding special

paper)

Signal

mode

(Japan) 35 ∼128 g/cm2

(Outside Japan) 50 ∼

128 g/cm2

Duplex

mode

(Japan) 50 ∼110 g/cm2

(Outside Japan) 50 ∼

110 g/cm2

Mixed original feed Possible

(4) Copying speed

Normal Reduction

(50%) Enlargement

(200%)

A3 28 28 27

B4 32 30 31

A4 (Portrait) 50 43 36

A4 (Landscape) 39 37 36

B5 (Portrait) 50 48 36

B5 (Landscape) 39 37 36

11 ×17 28 28 27

8.5 ×14 32 30 31

8.5 ×11 (Portrait) 50 43 36

8.5 ×11 (Landscape) 39 37 36

(Note) The speeds at enlargement/reduction are at the mag-

nification ratio of the lowest speed.

(5) First copy time about 2.7sec (paper feed port: tray 1)

First copy time at each paper feed port (sec)

Paper feed

port First copy

time Paper feed

port First copy

time

Tray 1 2.7 Tray 4

(Japan only) 3.3

Tray 2 2.9 Manual feed 2.9

Tray 3 3.1 LCC 2.8

(6) Warm-up time

Japan About 4 min

Outside Japan About 3 min

Pre-heat YES (Selected by the key operator

program (P31).)

Jam recovery

time 4 sec or less (Jam outside the fusing

section)

(7) Multi copy: max. 999 sheets

(8) Copy magnification ratio

Fixed

magnification

ratio

AB series: 4R+4E: 200, 141, 122, 115,

100, 86, 81, 70, 50 %

Inch series:4R+4E: 200, 141, 129, 121,

100, 95, 77, 64, 50 %

Zoom range 50 ∼200% (151 steps in 1% increment)

(9) Exposure

(9)-1 Exposure system: Slit exposure by moving the optical

system (Fixed original table)

(9)-2 Exposure mode: Auto/Manual/Photo

(9)-3 Manual steps: 9 steps (Manual/Photo)

(10) Paper feed

(10)-1 Paper feed system: (Japan) 4 trays + multi manual feed

(Outside Japan) 3 trays + multi

manual feed

(For SEC/SECL, LCC is a standard

provision.)

(10)-2 Paper feed

capacity: (Japan) 550 ×4 + 50

(Outside Japan) 500 ×3 + 50

(10)-3 Details of the paper feed section

AB series

Paper feed

port

Paper feed

capacity Paper size Paper

weight

Size

selection Side/front

Tray 2

500 sheets

(500 sheet

in Japan)

A4, A4R,

B5, B5R,

B4, A3,

(*A5)

52 ∼

80g/m2,

14-21 lbs

Guide

change is

made by a

serviceman.

Front/

drawer

integrated

Tray 1

Tray 3

Tray 4

(Japan only)

500 sheets

(550

sheets in

Japan)

A4, A4R,

B5, B5R,

B4, A3

52 ∼80

g/m2, 14 ∼

21 lbs

Guide

change is

made by a

serviceman.

Front-

drawer

integrated

Inch series

Paper feed

port

Paper feed

capacity Paper size Paper

weight

Size

selection Side/front

Tray 2 500 sheets

8.5 ×11

8.5 ×11R

8.5 ×14

11 ×17

(*8.5 ×

5.5)

52-80g/m2

14-21 lbs

Guide

change is

made by a

serviceman.

Front/

drawer

integrated

Tray 1

Tray 3 500 sheets

8.5 ×11

8.5 ×11R

8.5 ×14

11 ×17

52-80g/m2

14-21 lbs

Guide

change is

made by a

serviceman.

Front/

drawer

integrated

*For A5 (8.5" ×5.5"), the rear edge guide is required.

8.8" ×13" is feedable.

Manual feed section

Paper size AB series: A3 ∼A6R

Inch series: 11 ×17 ∼5.5 ×8.5

Paper weight

Multi paper feed: 56 ∼80 g/m2,

15 ∼21 lbs

Single paper feed:52 ∼128 g/m2,

15 ∼21 lbs

(When exceeding

104 g/m2,

A4 or smaller.)

Paper kinds Standard paper, specified paper, special

paper, OHP film, Postcard, etc,

Detection size

(Japan) A3, A4, A4R, B4, B5, B5R

(Outside Japan AB series)

A3, B4, A4, A4R, A5

(Outside Japan inch series)

11 ×17, 8.5 ×12, 8.5 ×11,

8.5 ×11R, 8.5 ×5.5

2 – 1