AR-1118 SIMULATIONS 7-3

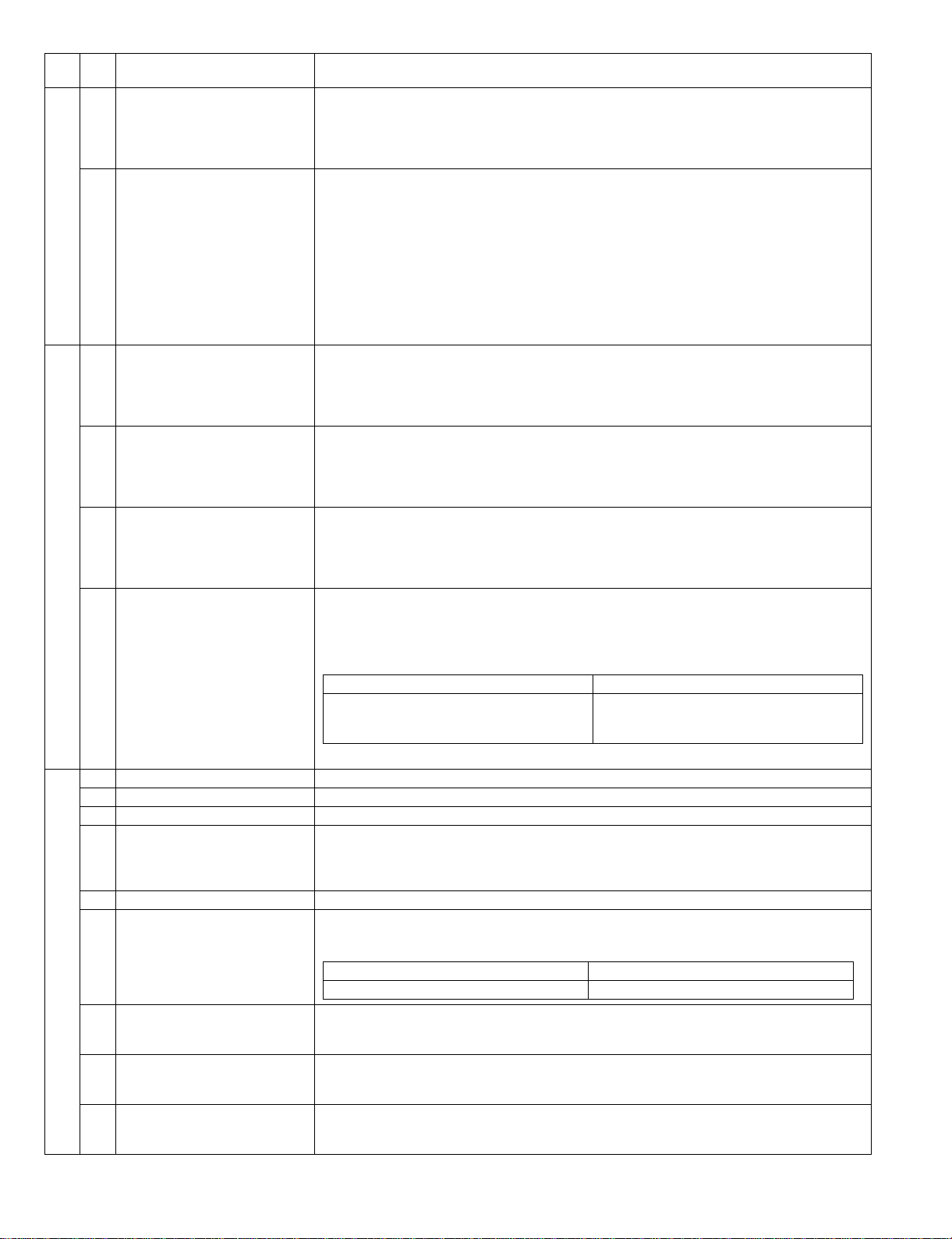

06 02 Resist roller solenoid operation

check

When the [START] key is pressed in the sub code input state, the resist solenoid (RRS) turns ON for

500ms and OFF for 500ms. This operation is repeated 20 times.

After completion of the process, the machine goes into the sub code input standby mode.

When [INTERRUPT] key is pressed during the process, the machine goes into the sub code input

standby mode. When [CA] key is pressed, the simulation is terminated.

10 Cassette semi-circular roller

cleaning

First of all, remove the developer unit.

Enter the simulation code, specify the cassette to be cleaned with the tray select key, and press

START button. The main motor rotates to move the cassette semi-circular roller by half circle and

make the roller face downward.

After completion of cleaning, when INTERRUPT key is pressed, the machine goes into the sub code

entry standby mode and the roller returns to the original positions.

To clean another roller continuously, press INTERRUPT key to return the roller to the original

position, and execute the simulation again.

During the operation, the sub code is displayed on the display.

* When CA key is pressed, the simulation mode is terminated.

However, the roller returns to the original position by the initial operation.

08 01 Developing bias output When the [START] key is pressed, the developing bias signal is turned ON for 30 sec.

However, to calculate the actual output value is calculated, execute SIM25-01.

After completion of the process, the machine goes into the sub code input standby mode.

When [INTERRUPT] key is pressed during the process, the machine goes into the sub code input

standby mode. When [CA] key is pressed, the simulation is terminated.

02 Main charger output (Grid = HIGH) When the [START] key is pressed, the main charger output is supplied for 30 sec in the grid voltage

HIGH mode. After completion of the process, the machine goes into the sub code input standby

mode.

When [INTERRUPT] key is pressed during the process, the machine goes into the sub code input

standby mode. When [CA] key is pressed, the simulation is terminated.

03 Main charger output (Grid = LOW) When the [START] key is pressed, the main charger output is supplied for 30 sec in the grid voltage

LOW mode. After completion of the process, the machine goes into the sub code input standby

mode.

When [INTERRUPT] key is pressed during the process, the machine goes into the sub code input

standby mode. When [CA] key is pressed, the simulation is terminated.

06 Transfer charger output Select an output mode with the [Mode select] key and press the [START] key. The transfer charger

output is delivered for 30 sec in the selected mode.

After 30 sec of transfer charger output, the machine goes into the sub code entry standby mode.

When [INTERRUPT] key is pressed during the process, the machine goes into the sub code input

standby mode. When [CA] key is pressed, the simulation is terminated.

22 01 Maintenance counter display The maintenance counter value is displayed. (Alternate display by 3 digits)

04 Jam total counter display The jam total counter value is displayed. (Alternate display by 3 digits)

05 Total counter display The total counter value is displayed. (Alternate display by 3 digits)

06 Developing counter display The developing counter data is acquired and displayed on the 7-seg display. (Alternate display by 3

digits)

When the [Interrupt] key is pressed, the machine goes into the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

08 SPF counter display The SPF counter value is displayed. (Alternate display by 3 digits)

14 P-ROM version display The P-ROM version is displayed on the copy quantity display. The main code and the sub code are

alternatively displayed by 2 digits. The display interval is same as that of the counter display.

By pressing the fixed magnification ratio key, each version display is switched.

17 Copy counter display The copy counter value is displayed. (Alternate display by 3 digits) When the [Interrupt] key is

pressed, the machine goes into the sub code input standby mode. When the [CA] key is pressed, the

simulation is terminated.

18 Printer counter display The printer counter value is displayed. (Alternate display by 3 digits)When the [Interrupt] key is

pressed, the machine goes into the sub code input standby mode. When the [CA] key is pressed, the

simulation is terminated.

21 Scanner counter display The scanner counter value is displayed. (Alternate display by 3 digits)When the [Interrupt] key is

pressed, the machine goes into the sub code input standby mode. When the [CA] key is pressed, the

simulation is terminated.

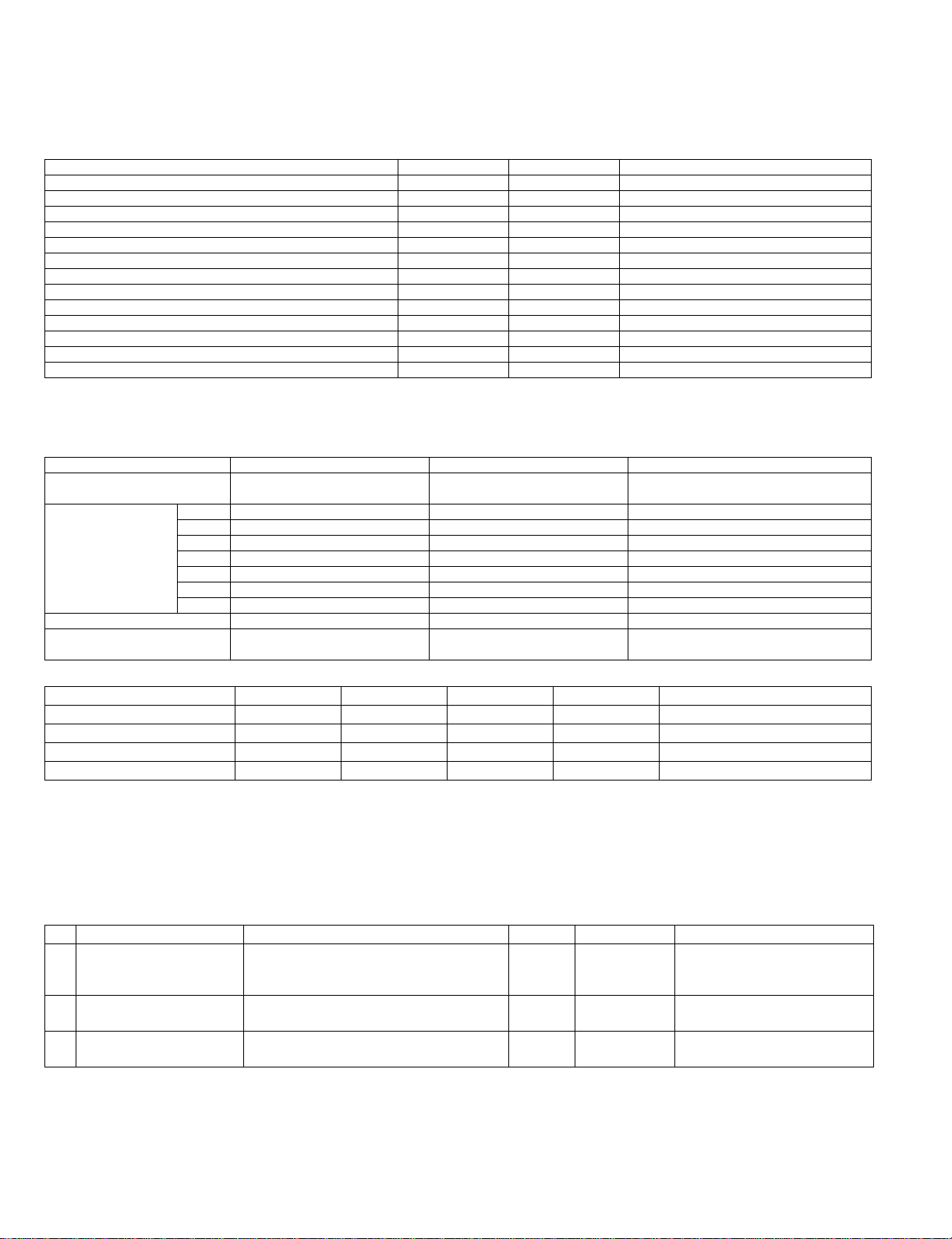

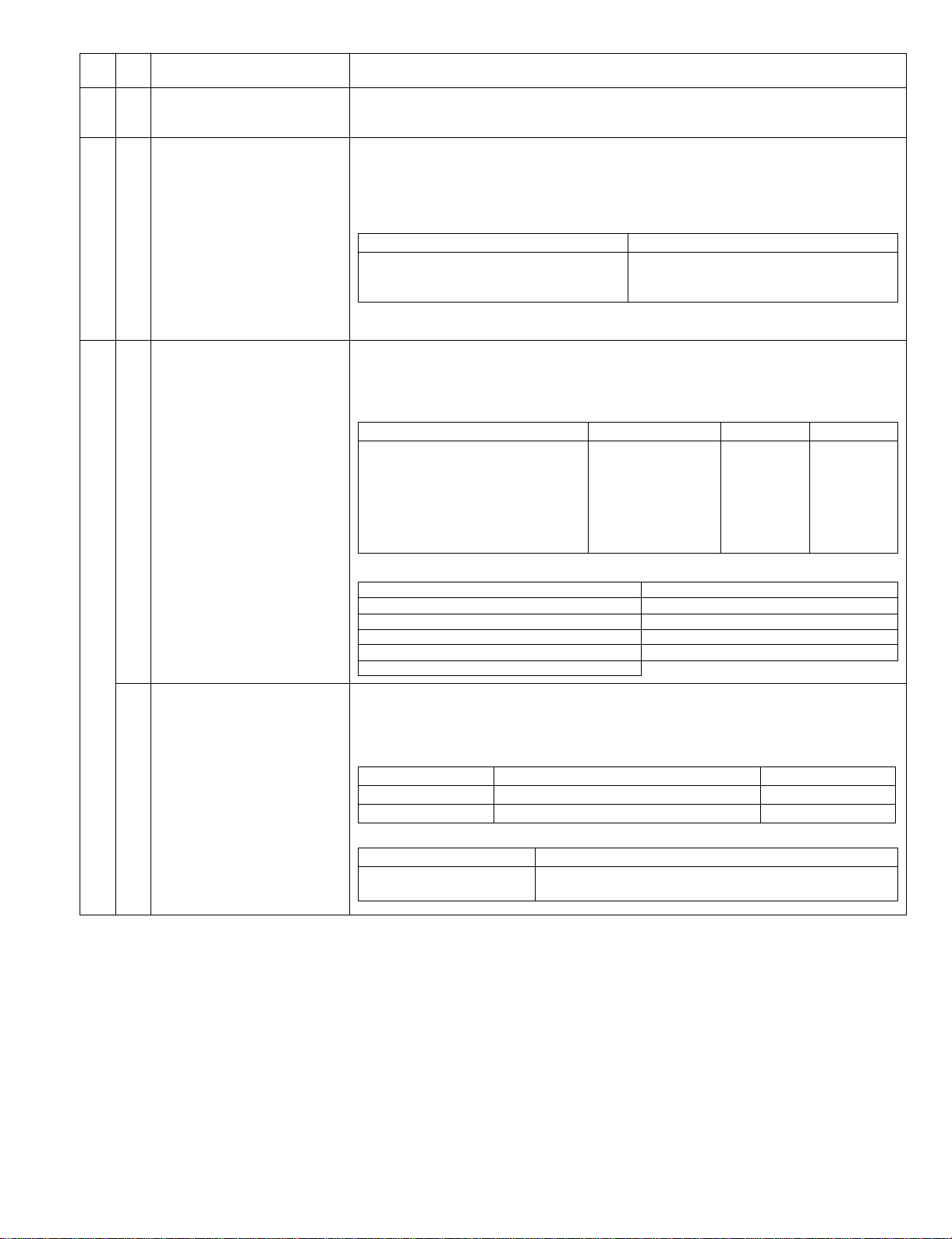

Main

code Sub

code Contents Details of operation

•Small size is A4R or smaller.

Display lamp Output mode

AE mode lamp

AE mode lamp & PHOTO mode lamp

AE & TEXT & PHOTO mode lamp

Normal size width: Front surface

Small size width: Front surface

Manual paper feed mode

Display lamp (AB series) Displayed version

141% Machine program

[07]SIMULATIONS.fm 3 ページ 2005年3月25日 金曜日 午後4時7分