(2) When storing the printer

Printer

•When storing the printer, make sure to raise the head up lever

in the : Head up position. Never store it with the : Close

position or : Cleaning position.

•Avoid storing the printer in areas with a lot of dust, direct sun-

light, or high humidity.

•If the printer is stored for an extended period, put it in a anti-

static bag and store it in a dry place.

•The thermal paper should not be left for an extended period

(more than two weeks at normal temperature) held between

the platen roller and the head ( : Close position).

•Do not leave the printer in the : Checking position for more

than 2 days.

Paper (thermal paper)

•Since thermal paper gradually darkens from about 70°C, pay

attention to heat, humidity, sun light, etc., regardless whether or

not the paper has been printed on.

•Avoid high temperature and high humidity areas.

•Avoid direct sun light.

(When thermal paper is left near the window in direct sun

light, the base color may change and discoloring may take

place.)

(3) When using the printer

Printer

•Since the printer contains a thermal head, permanent magnets

(motor) and micro switches, avoid using it in areas with a lot of

iron powder, dust, etc.

•Never operate with no paper loaded.

•Never pull out the paper (forward or backward) with the head

head against the platen rollers.

•Do not touch the head heating elements and driver Ics, espe-

cially with hard or metal objects.

•During printing and just after printing completes (for about 15

minutes), the area around the head and the motor surface are

very hot. Never directly touch them with your hand.

•Operate the head up lever only when required.

Never touch the surface of the head heating elements.

(Dirt may stick to the heating elements and affect the printing.)

•Never leave the printer with the platen rollers and the head

directly touching ( : Close position).

Do not leave the head-up lever in the : Cleaning position for

more than 2 days.

(When the printer is left for a while, make sure to raise the head

up lever in the ➡: direction in Fig. Loading paper.)

•Since electronic parts are used in the print head, never touch

the thermal head with your bare hand.

Before handling the printer, execute proper body grounding

procedures to avoid static electricity.

Paper (thermal paper)

•Use only the specified thermal paper.

(Thermal paper with a rough surface may result in poor printer

quality and shorten the print head life.)

(4) When mounting the printer

•Make sure the power is turned OFF before installing the printer to

an ECR.

•When attaching the printer to your product, avoid areas with a lot

of iron powder, dust, etc.

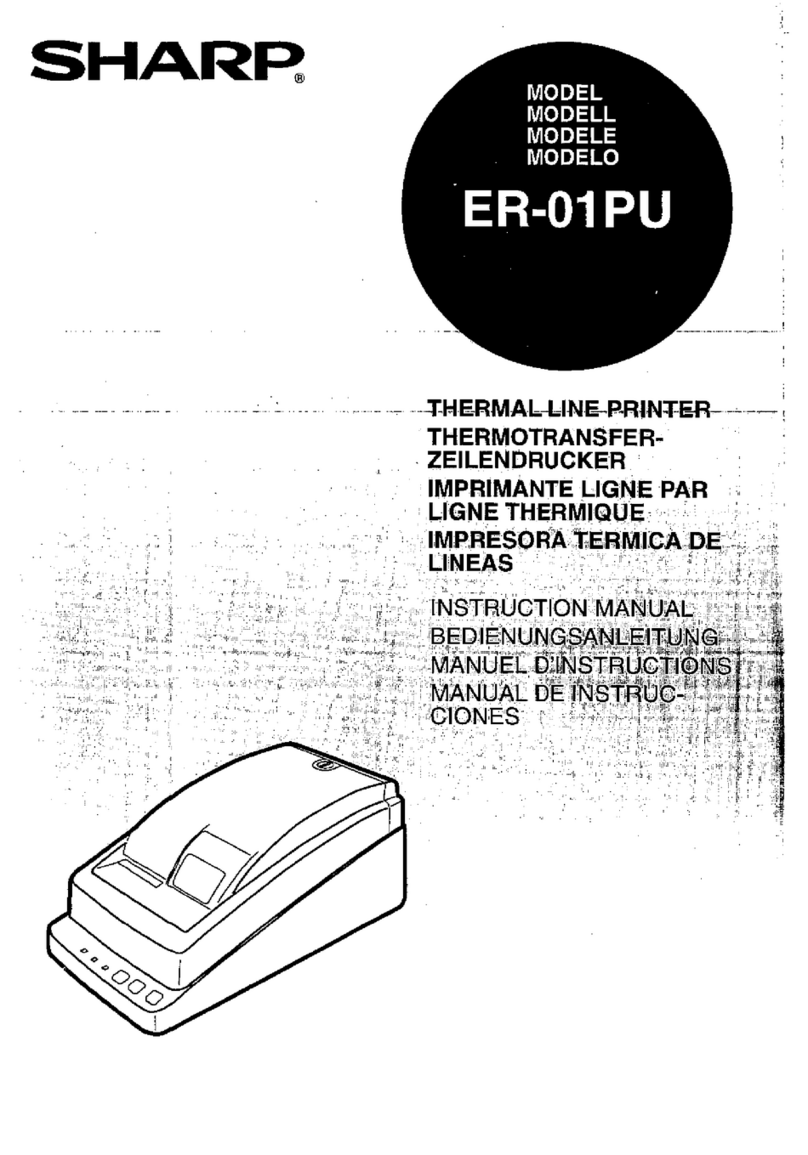

2. Loading the Paper (insertion and

removal)

Use only the paper specified in the specification sheet issued by our

company.

(1) Loading paper

Load paper following the procedure below.

Cut the edge of the paper as shown in the figure below.

Fig. Shape of the cut paper edge

Fig. Paper setting state

Fig. Loading paper

Turn the ECR ON.

Make sure the head-up lever in the (Close) position.

Insert the paper through the paper inlet.

The paper is automatically loaded into the printer by the auto

loading mechanism and the leading edge of the paper roll is deliv-

ered a little from the paper outlet.

If there is slackness in the paper or paper is loaded slantly, set the

head up lever in the head up position and adjust the paper

position.

If the length of the paper delivered from the outlet is insufficient,

feed the paper properly with the key board of the ECR.

(Notes) If paper is fed without following the above procedure, it

could cause improper paper feeding and jamming.

Good WrongGood Wrong

Good Bad

A

B

C

Recording paper Head up lever