Q / ! W / " E / # R / $ T / % Y / & U / ' I / ( O / ) P / =

SYMBOL

A / |S D F G / { H / } J / [ K / ] L / +

Caps Lock

Z / < X / > C V B N / * M / ? @ .com

SHIFT / ^ / / \ ; / : Space _- . / , DEL

Q / ! W / " E / # R / $ T / % Y / & U / ' I / ( O / ) P / =

SYMBOL

A / |S D F G / { H / } J / [ K / ] L / +

Caps Lock

PAGE COUNTER

CONFIDENTIAL

TIMER

COVER SHEET

LIFE

MEM.STATUS

REPORT

DOCUMENT

Z / < X / > C V B N / * M / ? @ .com

SHIFT / ^ / / \ ; / : Space _- . / , DEL

01 02 03 04 05 06 07 08 09 10

11 12 13 14 15 16 17 18 19 20

40 41 42 43 44 45 46 47 48 49

50 51 52 53 54 55 56 57 58 59

21 22 23 24 25 26 27 28 29 30

31 32 33 34 35 36 37 38 39

7

7

810 11 12 13 14 15 16

PLAIN PAPER LASER FACSIMILE

HALF TONE

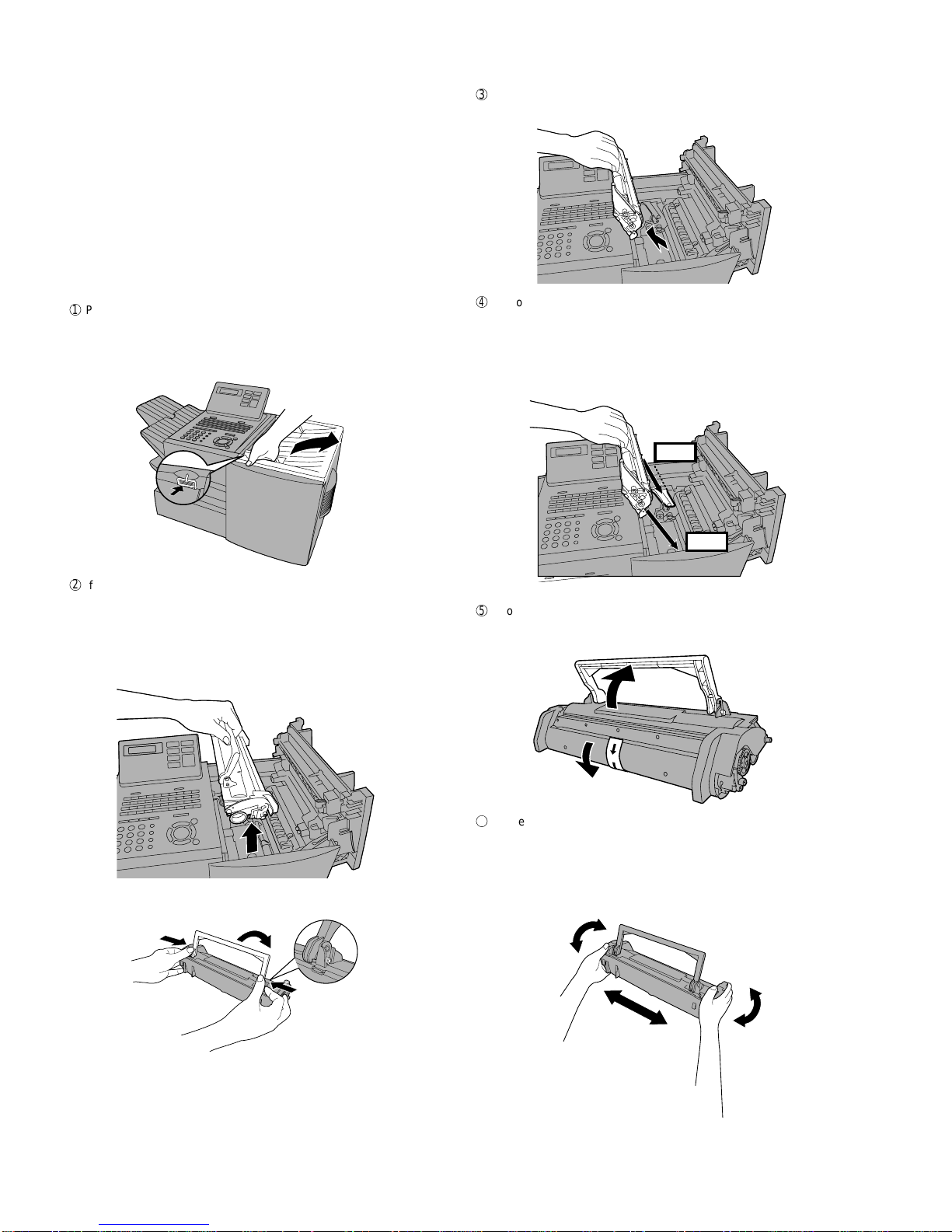

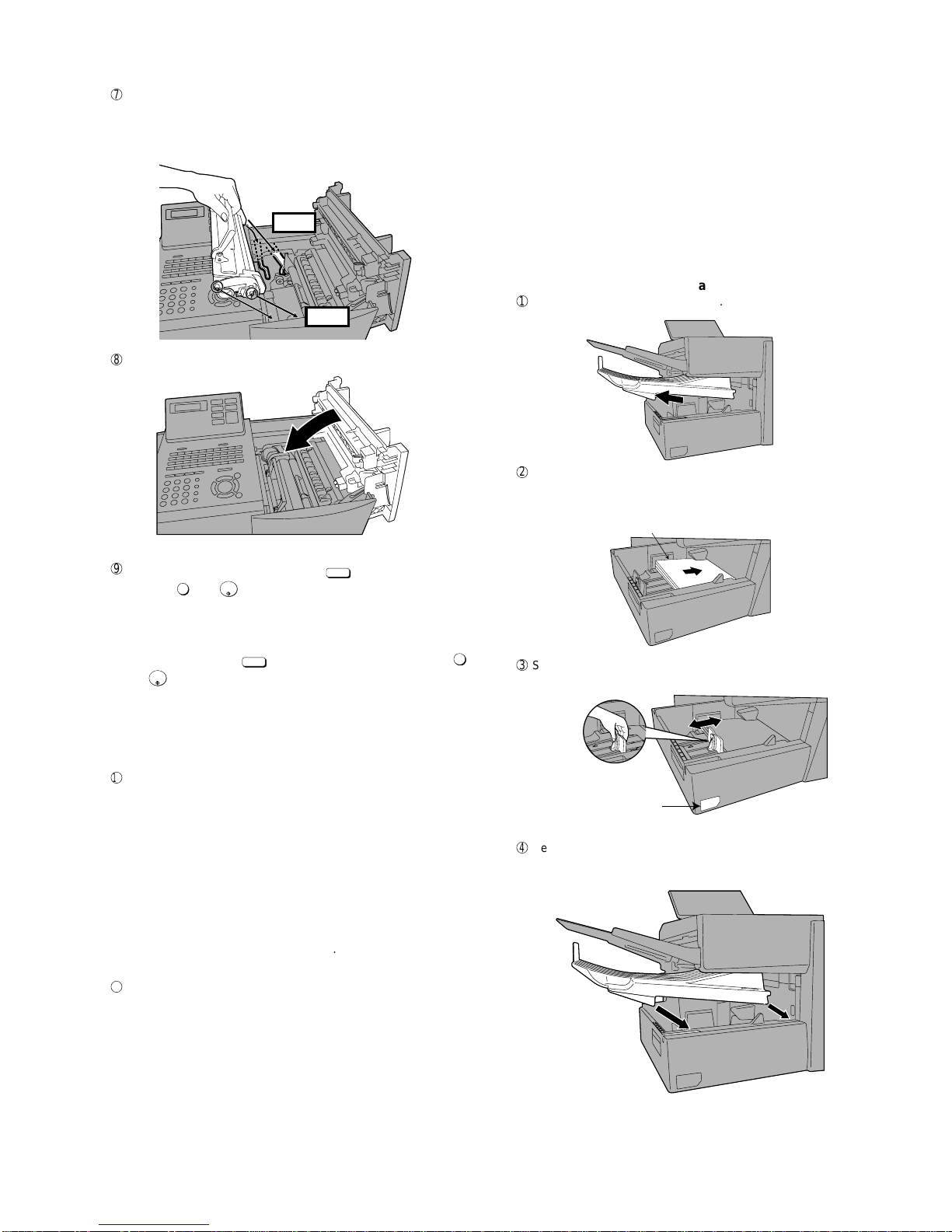

Toner Cartridge

Drum Cartridge

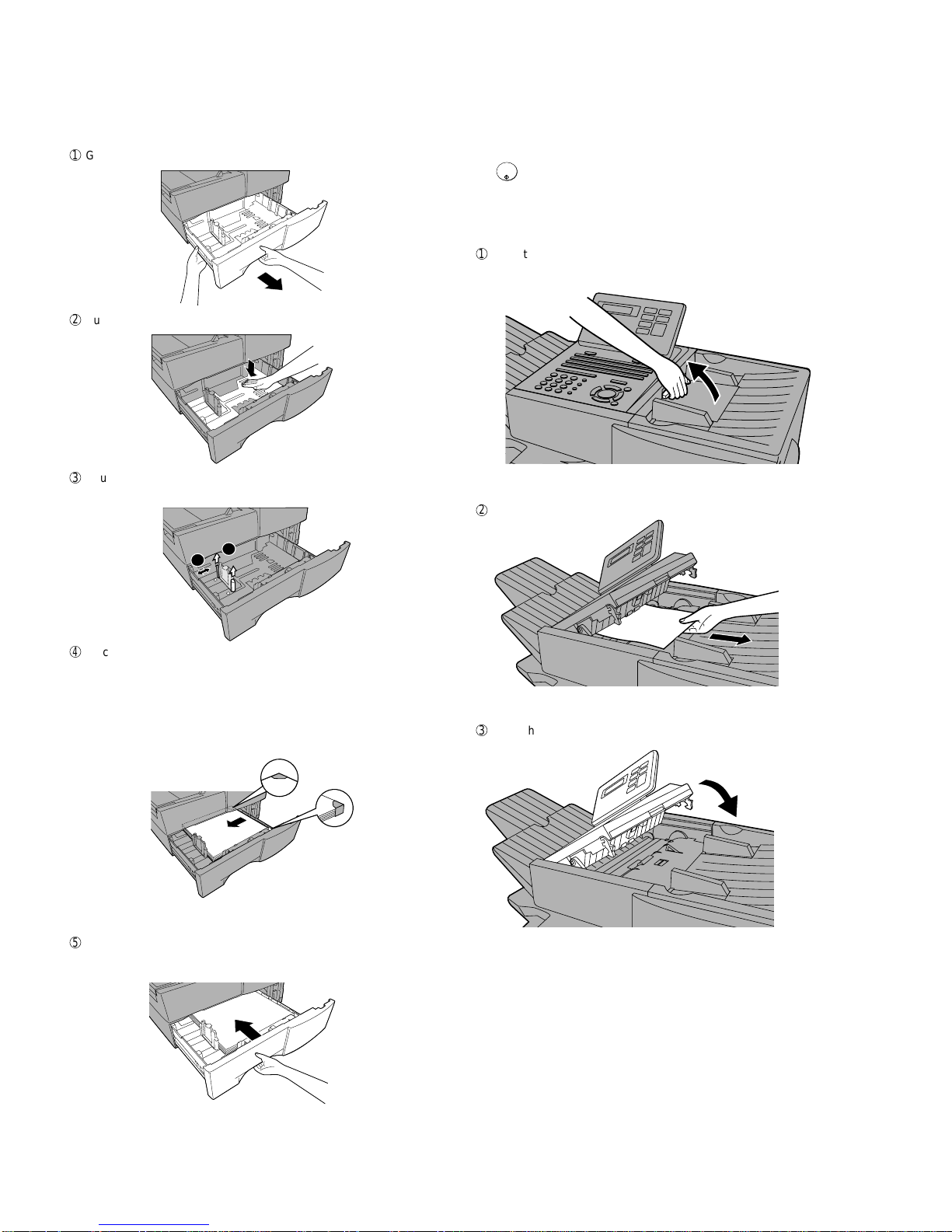

Paper Supply

Paper Jam

Paper Size Error

Printer Cover Open

Out Put Tray Error

ALARM Guide

ALARM

TONER

LINE IN USE

CONTRAST RESOLUTION

STANDARD

FINE

SUPER FINE

1

5

2 3 4

6

JKL

ABC

1

DEF

WXYZ

9

GHI

45

MNO

6

PQRS

7

TUV

8

0

2 3

OPER

PERSONAL

BOOK

SPEED DIAL

REDIAL

SPEAKER

JOB STATUS

DUPLEX SCAN

PRIORITY

BROADCAST

MENU

UP

ZA

DOWN

START/

ENTER

COPY/HELP

STOP

1717 24241818 1919 2020 2525

2626 3030 31312727 2929

2323

2828

22222121

PAGE COUNTER key

Press this key to include a slash and the total number of pages after each

page number on the pages of a transmitted document.

CONFIDENTIAL key

Press this key to send or print out a confidential document.

TIMER key

Press this key to set an operation to be performed automatically at a later

time.

11

COVER SHEET key

Press this key to include a cover sheet when sending a fax.

LIFE key

Press this key, followed by , to check the total number of pages printed

by the fax machine.

MEM. STATUS key

Press this key to check the status of fax transmission jobs, copy jobs, and

receptions.

fax This key can also be used to cancel a job.

REPORT key

Press this key to print out a report on the most recently completed

transmission or reception.

DOCUMENT key

Press this key to transmit a document directly from the feeder without

it into memory.

1

15

16

13

12

14

JOB STATUS key

Two types of information appear in the display: prompts related to

operations you are performing, and information about how the fax machine

is using the telephone line (transmitting, receiving, etc.). Press this key to

between the two types of information.

DUPLEX SCAN key

Press this key to transmit or copy a two-sided document.

PRIORITY key

Press this key when you need to transmit a document ahead of other

documents waiting in memory for transmission.

BROADCAST key

Press this key to send a fax to a group of receiving fax machines.

17

19

20

18

PERSONAL BOOK

Press this key to use or store an auto-dial number in a personal book. If

book has a passcode, enter the passcode; otherwise, select the book

with or and press .

SPEED DIAL key

Press this key to dial a Speed Dial number.

MENU key

Press this key to select special functions and settings.

UP and DOWN arrow keys

Volume setting: Press these keys to change the speaker volume when the

SPEAKER key has been pressed, or the ringer volume at any other time.

COPY/HELP key

When a document is in the feeder, press this key to make a copy of a

document. At any other time, press this key to print out the Help List, a

reference guide to the operation of your fax machine.

Dial keypad (numeric keys)

Use these keys to dial and program fax numbers.

REDIAL key

Press this key to automatically redial the lastnumber dialed.

SPEAKER key

Press this key when transmitting adocumentby NormalDialing to listen to

the line and verify the response of the receiving fax machine.

START/ENTER key

Press this key to begin fax transmission when using Speed Dialing, Direct

Keypad Dialing,or Normal Dialing. This key is also used to select settings

and complete entries when storing names and numbers.

Left and right arrow keys

Auto-dial numbers: Press these keys to search for an auto-dial number

when sending a fax.

MENU key settings: Press these keys after pressing the MENU key to

scroll through the MENU key settings.

STOP key

Press this key to cancel an operation before it is completed.

START/

ENTER

24

25

26

27

28

29

30

31

23

21

22

Display

This displays messages and prompts to help you operate the machine.

ALARM indicator

This blinks when one of the paper sources is empty or the drum cartridge is

near the end of its life (printing is still possible). This lights steadily when the

drum cartridge has reached the endof its life, all papersources areempty, the

print compartment cover is open, or a paper jam has occurred (printing is not

possible). A message will appear in the display to indicate the problem.

TONER indicator

This blinks when the toner cartridge nears empty, and lights steadily when the

toner cartridge needs replacement.

LINE IN USE light

This lights when the fax machine is using the telephone line.

CONTRAST key

Press this key to adjust the contrast before sending or copying a document.

RESOLUTION key

Press this key to adjust the resolution before sending or copying a document.

An indicator will light next to the selected setting (HALFTONE, STANDARD,

FINE or SUPER FINE).

1

2

3

4

5

6

reading

change

the

quick

9

Rapid Dial Keys

Press one of these keys to dial a fax number automatically. (Note that you

must attach the Rapid Key labels.) When navigating through the display

menu, a Rapid Key can also be pressed in place of the numeric keys to

enter a two-digit number (for example, you can press Rapid Key 01 to enter

the number “01”).

7

10

9

SYMBOL key

When entering a name, press this key to enter the symbol on a letter key

(the character to the right of the slash). Press the key again to turn off

symbol entry mode.

8