Section 1- Introduction

General Information ................................................1-1

About This Manual..............................................1-1

Model Variations.................................................1-2

Technical Assistance .........................................1-2

Theory of Operation.................................................1-3

General...............................................................1-3

Faults..................................................................1-4

EZ-Bags® and Film Materials.............................1-5

Thermal Transfer Ribbon....................................1-5

Specifications...........................................................1-6

Machine Specifications.......................................1-6

Packaging Specifications....................................1-6

Machine Dimensions...........................................1-6

Section 2 – Maintenance & Adjustments

Maintenance Schedule ............................................2-1

Daily Maintenance.......................................... 2-1

Annual Maintenance...........................................2-1

Cleaning....................................................................2-2

General...............................................................2-2

Cleaning the Printhead and Film Feed Rollers....2-3

Machine Adjustments..............................................2-5

Adjusting the Pinch Roller...................................2-5

Checking Belt Tension........................................2-6

Checking Belt Tension........................................2-7

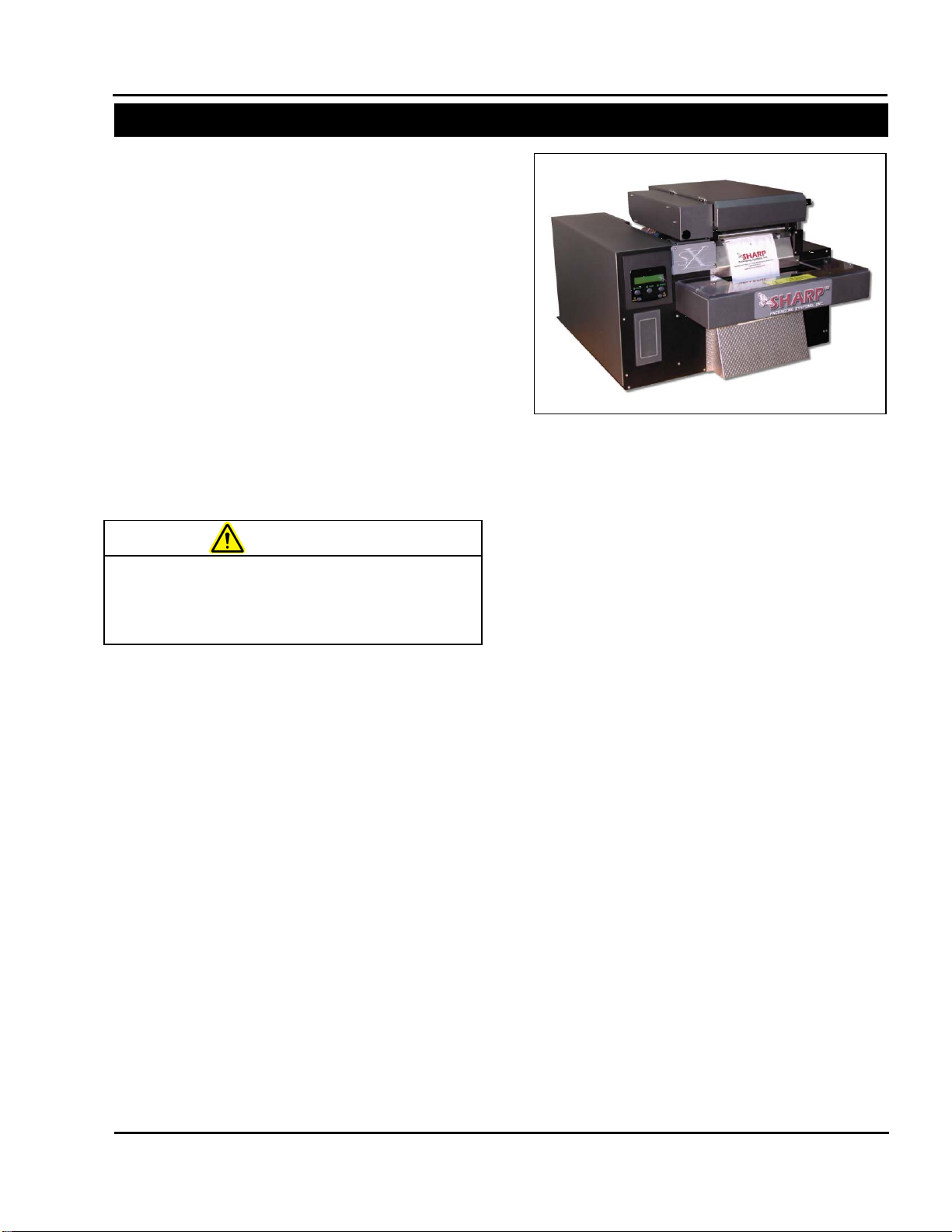

Sharp SX™ with Printer......................................2-8

Section 3 – Component Repair

Electrical Assembly................................................3-1

Pressure Jaw and Film Feed Motor Controllers...3-1

Fuses..................................................................3-6

24VDC Power Supply.........................................3-8

Line Filter..........................................................3-16

Main Power Switch (RED).................................3-20

Transformers.....................................................3-22

Aromat PLC ......................................................3-27

Aromat PLC Battery..........................................3-28

Color Touch Screen..........................................3-30

Cooling Fan.......................................................3-33

Solid State Relay.............................................. 3-35

Grey Relay 24V ................................................ 3-39

Red Relay 24V.................................................. 3-41

Printer GPIO Board........................................... 3-44

Printer Performance Logic Board...................... 3-45

Printer Power Supply Board.............................. 3-46

24 VDC Fan Assembly...................................... 3-48

Laminated White Ribbon Cable........................ 3-49

Datamax LCD Module....................................... 3-51

Printhead Stepper Drive.................................... 3-53

Film Feed Assembly.............................................. 3-56

Photoelectric Sensor......................................... 3-56

Film Feed Motor Drive Belt............................... 3-60

Film Feed Roller Drive Belt............................... 3-61

Platen Roller Drive Belt..................................... 3-63

Film Feed Roller ............................................... 3-67

Platen Roller..................................................... 3-69

Film Feed Drive Motor ...................................... 3-72

Cradle Lock Cams............................................ 3-74

Printhead Cradle Assembly .................................. 3-76

Ribbon Rewind Assembly................................. 3-76

Ribbon Rewind Motor ....................................... 3-76

Primary Ribbon Drive Belt................................. 3-79

DC Roller Clutch............................................... 3-81

Secondary Ribbon Drive Belt............................ 3-83

Adjustable Slip Clutch....................................... 3-87

Printhead Position Assembly ................................... 3-89

Printhead Position Motor................................... 3-89

Printhead Position Drive Belt............................ 3-92

Printhead Pressure Cams................................. 3-94

Printhead Position Sensor ...............................3-100

Thermal Printhead...........................................3-102

Ribbon Supply Assembly........................................3-103

Slip Clutch Spring ............................................3-103

Ribbon Motion Sensor .....................................3-104

Ribbon Clips ....................................................3-106

Gas Springs.....................................................3-107

Cross Flow Fan................................................3-108

Service and Maintenance Manual 960714-02B © 2007 I2407