3

25MR15J

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

1

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

1

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

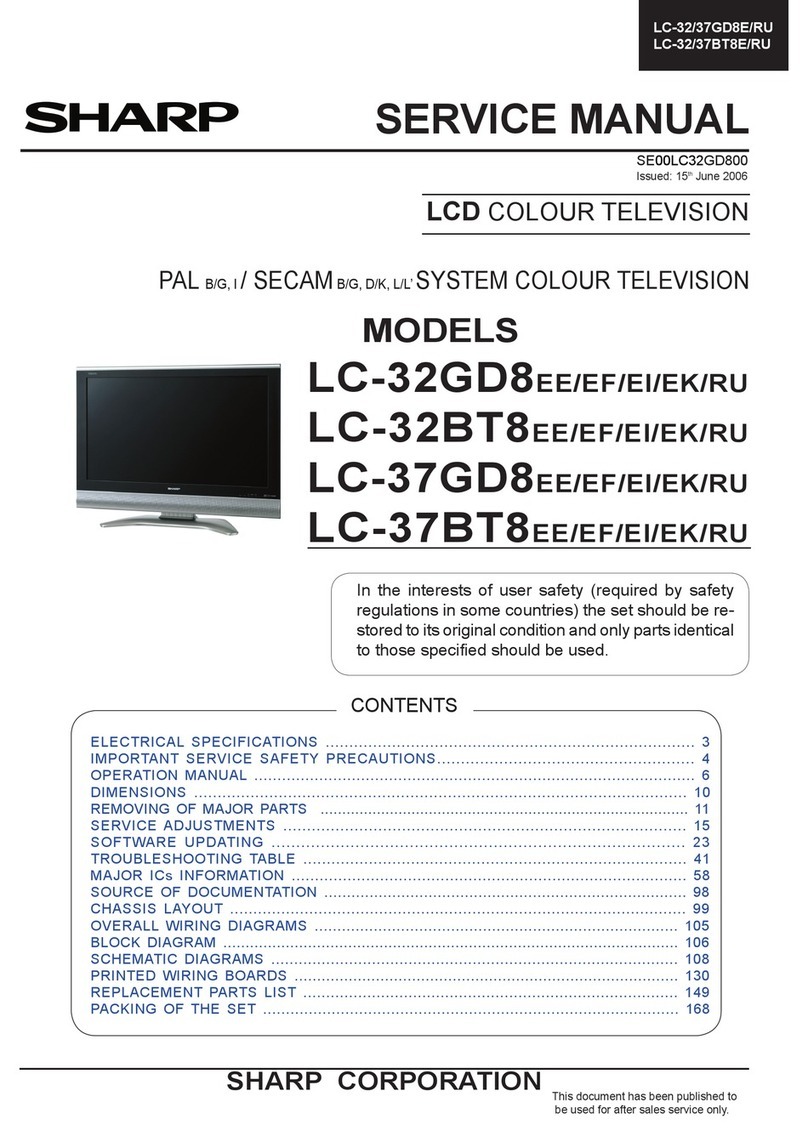

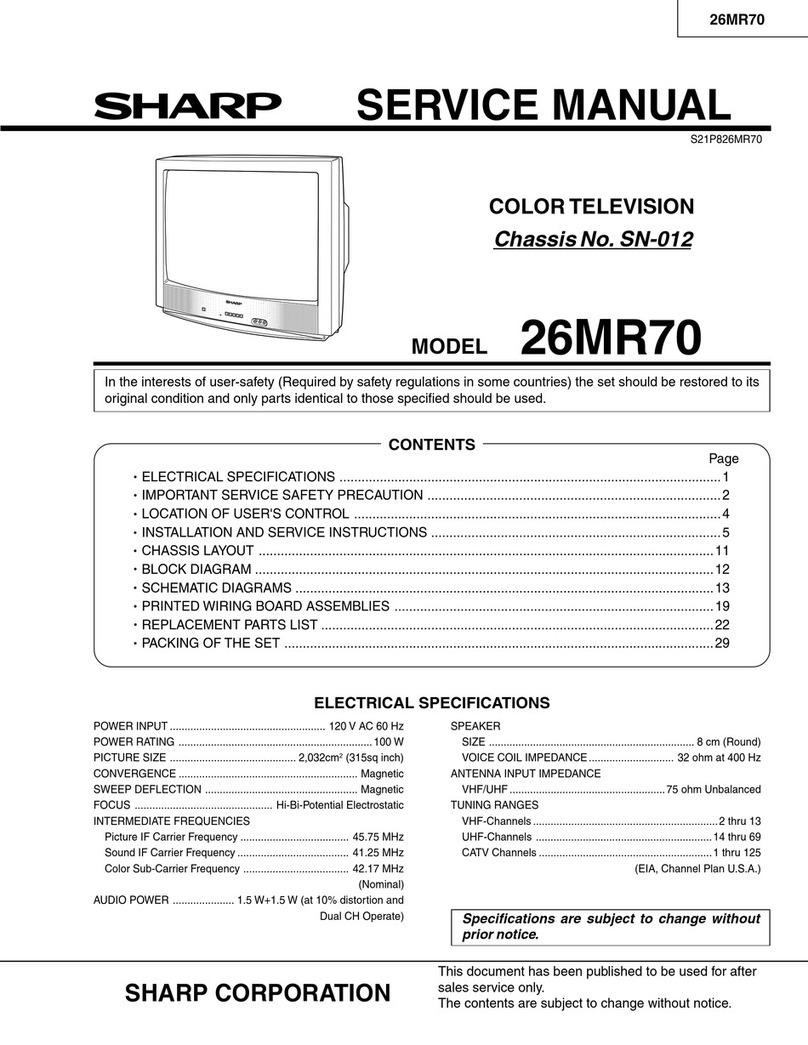

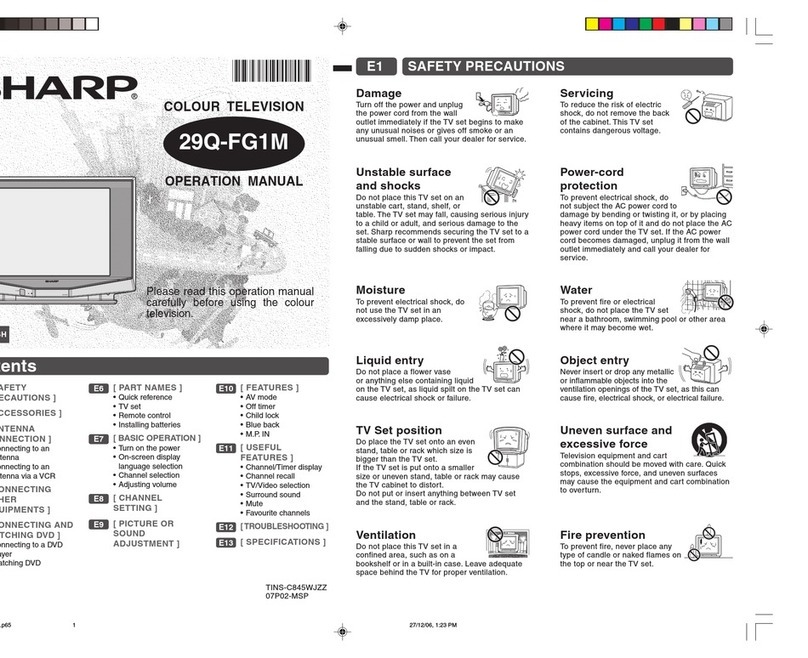

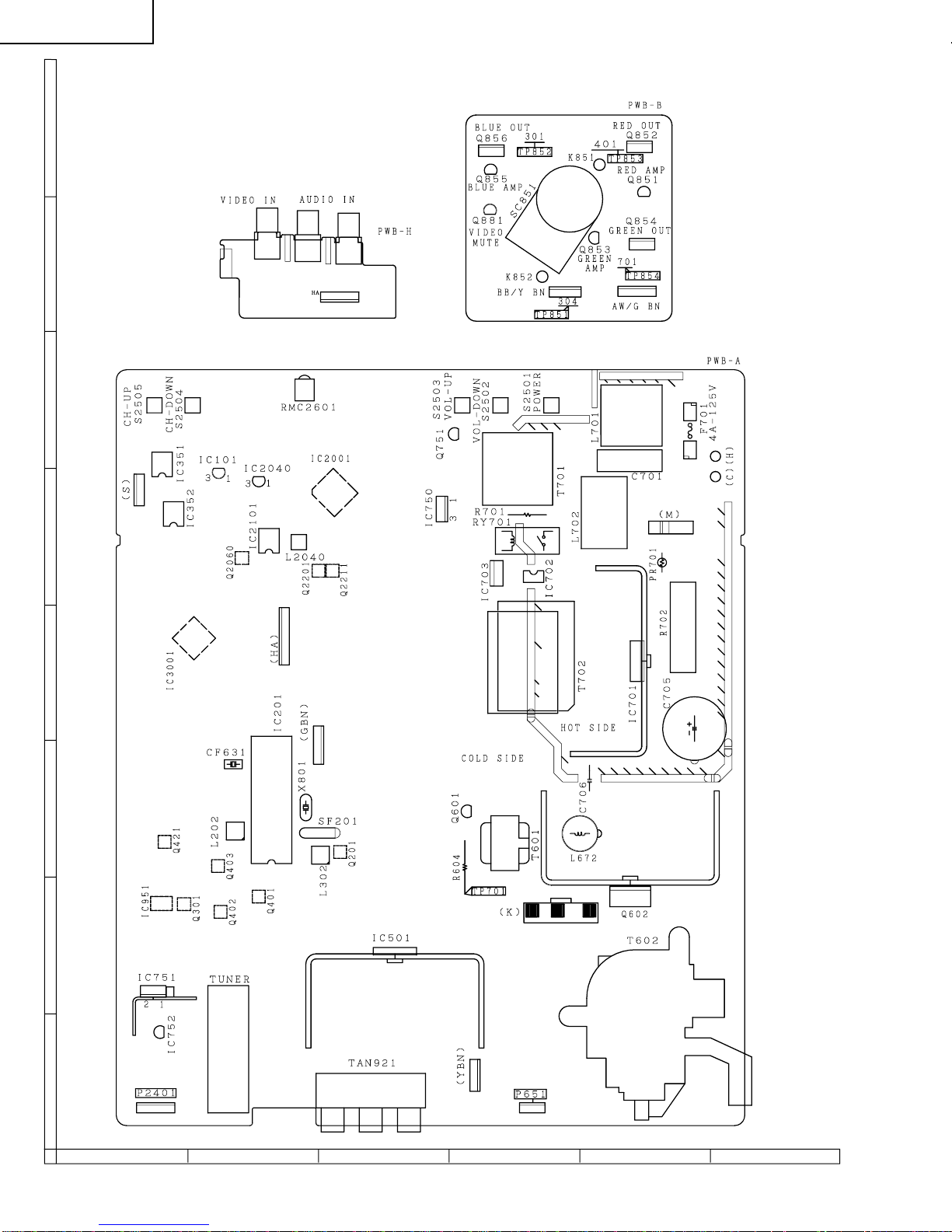

SAFETY NOTICE

Many electrical and mechanical parts in television

receivers have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by " S"

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams.

IMPORTANT SERVICE SAFETY PRECAUTION

(Continued)

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators and etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

»Plug the AC cord directly into a 120 volt AC outlet,

(Do not use an isolation transformer for this test).

»Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15mF capacitor in series

with all exposed metal cabinet parts and a known

earth ground, such as electrical conduit or electrical

ground connected to earth ground.

»Use an AC voltmeter having with 5000 ohm per volt,

or higher, sensitivity to measure the AC voltage drop

across the resistor.

For continued protection, replacement parts must be

identical to those used in the original circuit.The use of

substitute replacement parts which do not have the

samesafety characteristics asthefactory recommended

replacement parts shown in this service manual, may

create shock, fire, X-radiation or other hazards.

BEFORE RETURNINGTHE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks.

»Connecttheresistorconnectiontoallexposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon and etc.) and measure the AC voltage

drop across the resistor.

AII checks must be repeated with the AC line cord

plug connection reversed. (If necessary, a non-

polarized adapter plug must be used only for the

purpose of completing these check.)

Anycurrentmeasuredmust not exceed0.5milliamp.

Any measurements not within the limits outlined

above indicate of a potential shock hazard and

corrective action must be taken before returning the

instrument to the customer.

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

TO EXPOSED

METAL PARTS

AC

VOLTMETER