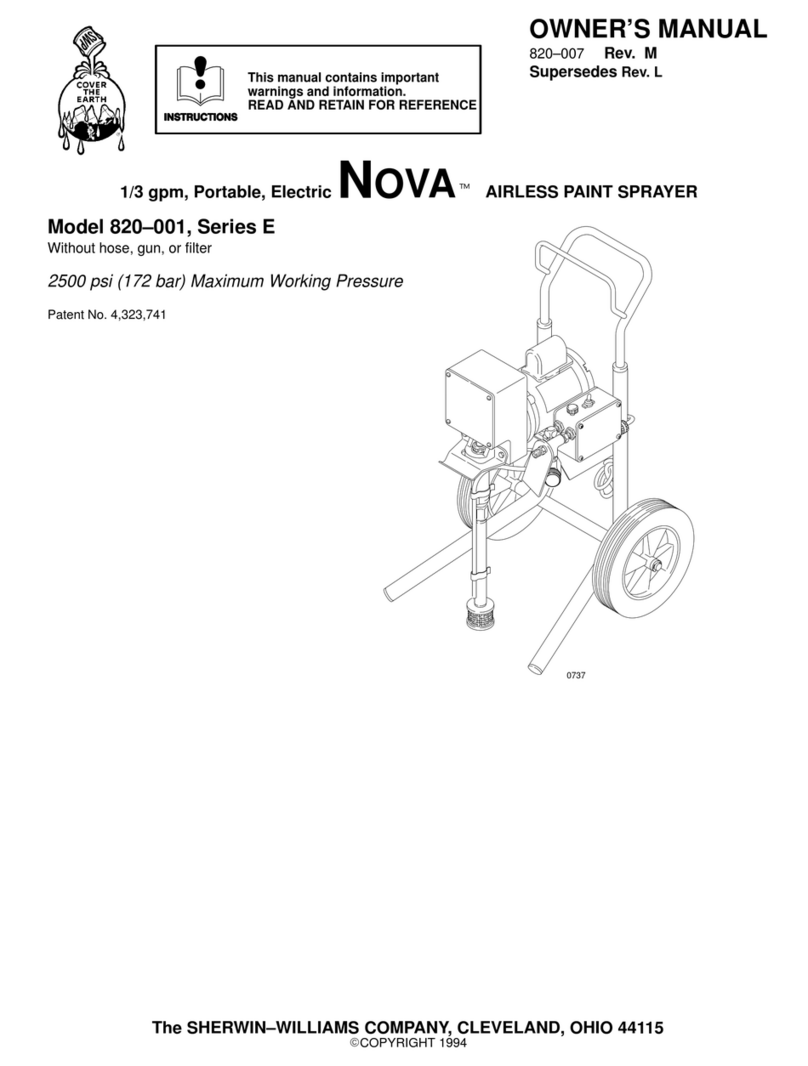

Sherwin-Williams ULTIMATE NOVA 1000 User manual

820"

Rev.

B

SUPERSEDES

Rw.A

Thii

manualcontainsimportantWarnings

and

Insuuctions.

Read

the

rnanua! and

keep

it

for

rsference.

1

HP, Portable, Electric

..

LTIMATE

AIRLESS

PAINT

SPRAYER

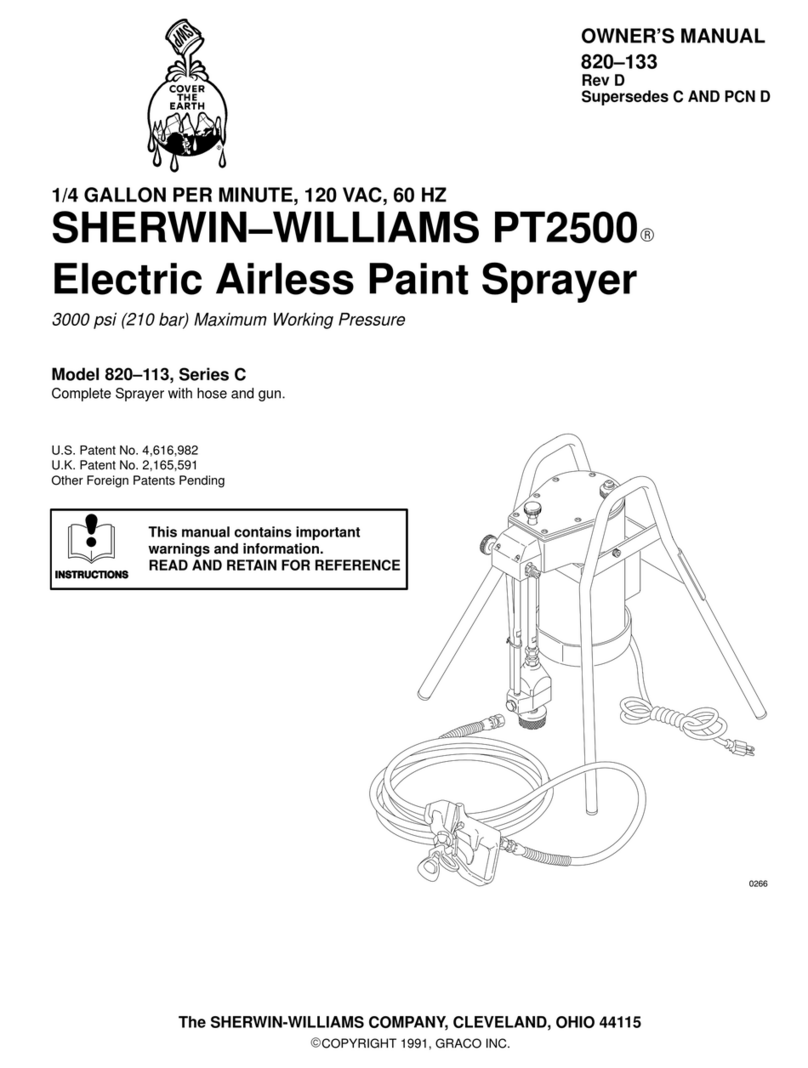

Model

W,

Series

A

Less

hdse,.gun. and filter

SzW

psi

(210

bad

MAXIMUM

WORKING PRESSURE

Index

.Warnings...

.........................

.2

Avertissarnent

.......................

4

Advertencih

.........................

.6

Set

UptOperation

..................

8

Rushing

.............................

10

Tmubleshooting

..................

11

Repair index

.......................

.lS

-How

To

Order

Replacement

Parts

Lists

8

Drawings

32

Shutdown and Care.;

.............

9

..........

Parts

................................

.37

Technical

Data

.........

Back Cover

PATENT NO.

4,323,741

PATENTED

1984,Canada

Brevete

1985

_.*.

i

.I

,,

.

:,

....

....

,:.

.A

-

..

Consult your fluid suppliers

to

ensure that the fluids being

used

are compatible with aluminum and zinc

parts.

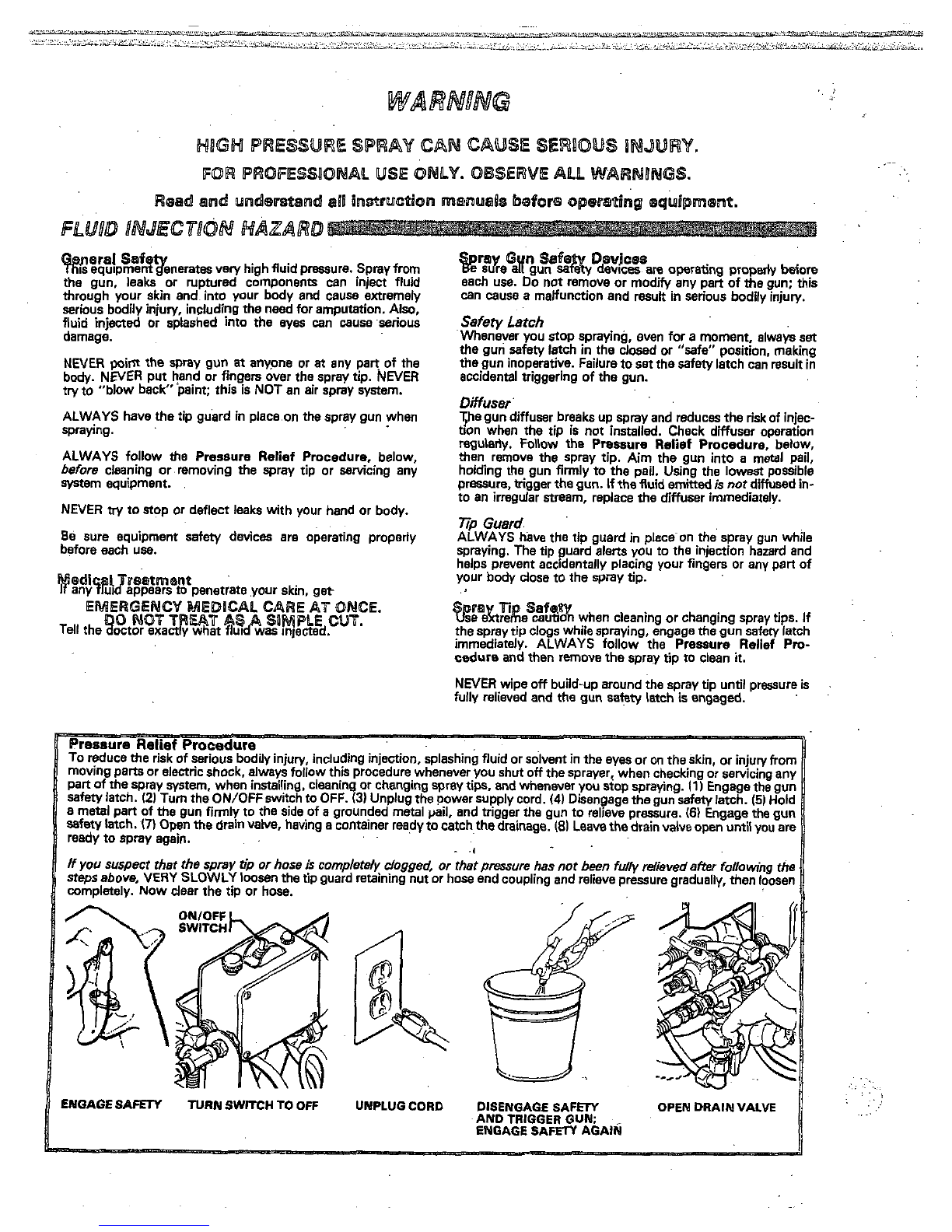

%IS

equlpment%nerates very highfluidpressure. Sprayfrom

thegun,leaksorrupturedcomponents

can

inject fluid

through yourskinand into your body and

cause

extremely

serious bodily injury,includingthe need for amputation. Also,

fluid injectedorsplashed into the

eyes

can

cause'serious

damage.

NEVER

poim

the

spray

gun

at anyone

or

at

any paq

of

the

body.

NEVER

put hand or fingers over the spray tip.

NEVER

try

to "blow back" paint; this is NOT an air spray system.

nerd

Safe

ALWAYS have thetip guard in place.on thespray

gun

when

spraying.

beforecleaning or removing

the

spray tip orservicingany

ALWAYS follow

the

Pressure Relief Procedure,

below,

systemequipment.

NNER

try

to

stop or deflect leakswith your hand or body.

before each

use.

Be

sureaquipmentsafetydevicesareoperatingproperly

?!

TB

edi

I

rmtmetnt

any

UI

amears

to

Denetrate vour skin.

aet

B

sJe

JI

gun

s%*E2Zare operating prop& before

each

use.

Do

not remove or modifv anv

Dan

of

the

wn:

this

ra

G

n

8af

can

cause

a

malfunction and result'in

&Nous

bodilykju.ry.

Safety

Latch

the

gun

safety latchin the closed or

"safe"

position. making

'Whenever youstop spraying, even for

a

moment, always

set

the

gun

inoperative. Failure

to

set

thesafety latchcan resultin

accidental triggering of the gun.

Diffuser'

Te

gun

diffuser breaks up spray and reduces

the

risk of injec-

hon

when the tip

is

not installed.Checkdiffuseroperation

regularly.Followthe Pressure

Relief

Procedure, below,

then

remove the spray tip. Aim the

gun

into

a

metalpail,

pmsure. trigger thegun.

If

thefluid emitted

is

not

diffused in-

holding the

gun

firmly to the pail. Using the

lowest

possible

to an irregular stream, replace the diffuser immediately.

nip

Guard.

ALWAYS have the tip guard in place~onthe spray

gun

while

spraying. The tip guard alerts youto the injection hazard and

helps prevent accidentally placing your fingers or anypanof

your body dose

to

the spray tip.

a

Ti

Safe81

e&&

cautio when cleaning or changing spray tips.

If

thespray tip clogs whilespraying, engage thegunsafety latch

immediately.ALWAYS follow the Pressure

Relief

Pro-

cedure

and

then removethe spray tip toclean

it.

NEVER

wipe

off

build-up around the spraytip

until

pressure

is

fully relieved and the gun

sa+ty

latchis engaged.

e

thegun safetylatch.

(51

Hold

prensura.

(61

Engage

the

gun

If

YOU

suspect

that the

spray

tip

or

hose

is

completely dogged,

or

that

pressure

has

not

been

fully relieved

after

following

the

Steps above.

VERY

SLOWLY loosen

the

tipguard retainingnutor hose end coupling and relieve pressure gradually,then

loosen

completely.

Now

dear the tip or hose.

pi

ENGAGE

SAFETY

TURN

SWITCH

TO

OFF

UMPLUG

CORD

DISENGAGE

SAFEW

AND

TRIGGER GUN;

ENGAGE

SAFEW

AGAI~~

OPEN

DRAIN

VALVE

..

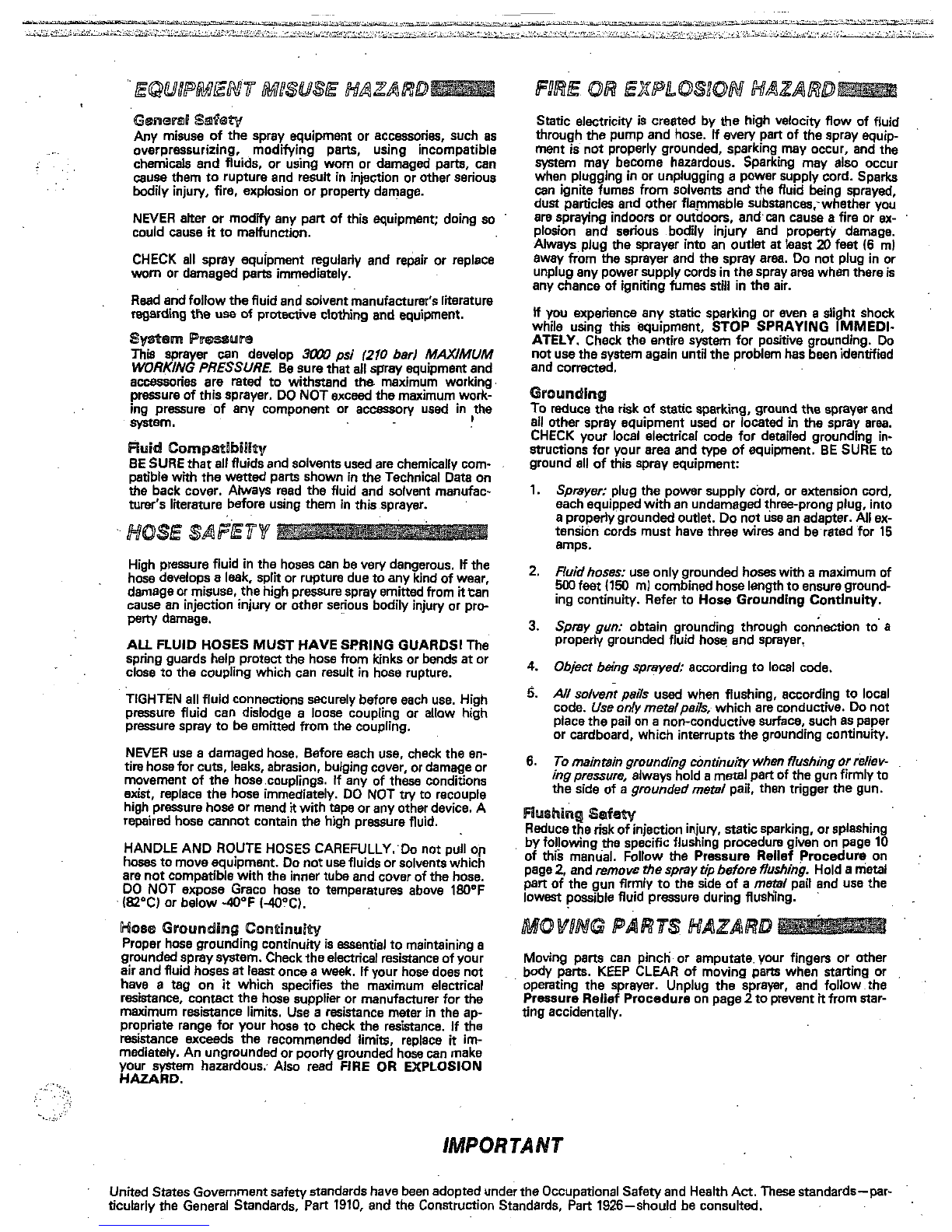

GEtPed

$Pf&Y

Anymisuse of the sprayequipmentoraccessories,such

as

overpressurizing, modifying parts, using incompatible

.

.,

chemicals end fluids, or usingworn ordamagedparts,can

cause them to ruptureand result in injection or other serious

..

bodilyinjury,fire.explosionorpropertydamage.

could cause

it

to malfunction.

NEVER alter or modify any part of this equipment; doing

so

worn or damaged

parts

immediately.

CHECK

all

sprayequipmentregularlyandrepairorreplace

Read

andfollow thefluidand solvent manufacturer's literature

regardingthe

use

of protectiveclothingand equipment.

$WEm

h@SSMU@

Thb

sprayercandevelop

3aW

psi

(210

b8rJ

MAXJMUM

accessoriesarerated to withstand the maximum working

WORKING

PR€SSURE

Be

sure that all

spray

equipment and

pressure

of

thissprayer. DO NOT exceedthe maximum work-

system.

ingpressure of anycomponentoraccessoryused in the

Wuid

Compatibility

BE SUREthat

all

fluids and solvents used are chemically com-

patible

with

the wetted parts showninthe Technical Data

on

the backcover.Alwaysread the fluid andsolvent manufac-

turer's

literature before usina themin this spraver.

h

Static electricity

is

created by the high velocity flow of fluid

throughthe pump and hose. If every partof the spray equip-

ment is not properly grounded, sparking myoccur, and the

when plugginginor unplugging

a

power supply cord. Sparks

systemmaybecomehazardous.Sparkingmayalsooccur

dust panicles and other flammable wbstances;whether you

can ignite fumes from solvents endthe fluid being sprayed,

are spraying indoors or outdoors, and.cancause

a

fire or

ex-

plosionandseriousbodily injury and property damage.

Always plug the sprayer inM an outlet

at

leest

20

feet

I6

ml

away from

the

sprayer and the spray area. Do not plug in or

unplug any powersupplycords inthespray area when there

is

any chance of ignitingfumes

still

in the air.

while using this equipment, STOP SPRAYING IMMEDI-

If

you experience any static sparking oreven

a

slight shock

ATELY.Check the entiresystem for positive grounding. Do

not

us8

thesystem againuntilthe problem has been identified

and corrected.

Grounding

To

reduce

the risk

of

staticsparking, groundthe sprayer and

all

other spmy equipment used or located

in

the sprayarea.

CHECK yourlocalelectrical defor detailed groundingin-

structiom foryour area and type of equipment. BE SURE to

ground

all

of this spray equipment:

1.

Sprayer: plugthepowersupplycord,orextensioncord,

each equippedwithan undamaged three-orona ulug.into

-

..

tension cords must have three wires and be rated for

15

a

properly grounded outlet.

Do

not

use

anadapter.ex-

amps.

HighPressurefluid in the hoses

can

be

very d~KIerous.

If

the

2,

F/ujdhoses:

use

only

groundedhoses with

a

maximum

of

hose develops a leak, split or rupturedue

to

any kindof wear.

damageormisuse, thehighpressuresprayemitted from

it

tan

5M)

feet

I150

ml combinedhoselength toensureground-

causaan iniectioniniurvorotherseriousbodilviniurvornrc-ingcontinuity.Refer to

Hose

Grounding Contlnulty.

perty

dam&

.

,~~~

3.

Sorev

nun:

obtainoroundinothrouahconnection to

a

ALL

FLUID

HOSES

MUSTHAVE SPRINGGUARDS1The pioper6grounded fhidhe-and spkyer.

springguardshelp protectthe hosefrom

kinks

orbends

at

or

4.

obieecr

being

sprayed:

according

to

local

code.

close to the couplingwhich can result in hose rupture.

TIGHTEN

811

fluid connections murelybeforeeach use, High

5.

A//

so1V&7r

Pat7swhenflushing,according to local

pressure fluid candislodge

a

loose coupling

or

allow high code. Useonly metalpails,which

are

conductive. Do not

pressure sprayto

be

emitted from the coupling. placethe pail on

a

non-conductive

surface,

such as paper

or cardboard, which interruptsthe grounding continuity.

NEVER

use

a

damaged hose. Before each use. checkthe en-

tirehoseforcuts,leaks,abrasion, bulgingcover,ordamageor

&

To

m8intah

groundins

COntinuiV

Whenflushing

OrdkV-

exist, replace the hose immediately. DONOT try to recouple

movementof the hose.couplings.If anyoftheseconditionsingpressure,always hold

a

metalpart of thegunfirmly

to

the side of

a

groundedmetalpail, then trigger the gun.

highpressurehoseormend

it

with tape oranyotherdevice. A

~~Ms&p

s,fey

repaired hose cannot contain the high pressure fluid.

HANDLE

AND

ROUTE

HOSES

CAREFULLY

.D~

not

pull

o~

.

byfo!owing

.the

specificflushingproceduregiven

on

page

10

Reducethe

risk

of injectioninjury, staticsparking, or splashing

hasas

toequipment.

Do

not

use

fluids

o;

which

ofthismanual. Follow

the

Pressure Rellef Procedure on

are not compatible with the inner tubeandcover ofthe hose.

''

and

the

'pray

tip

before

flu*in6"

Hold

a

metal

(82°C) or below

-4OOF

I4!'C).

DO

NOT

expose

G~~~

hose

temperinures

above 1m-F pa*of thegunfirmly to the side of

a

m-1

pail anduse the

lowest

possiblefluid pressure duringflustiing.

Hose

G~~nding

Continuity

~~~~~~

PARTS

HAZARD

Proper hosegroundingcontinuity

is

essentialto maintaining

a

air and fluid hoses

at

least

once

a

week. Ifyourhosedoes not

~ .

body parts. KEEPCLEAR of moving parts when starting or

groundedspraysystem.Checktheelectricalresistanceof your Movingpans can pincii oramputate.yourfingersorother

have a tag

on

it

which specifiesthemaximumelectrical operating the sprayer.Unplug

the

sprayer,and follow

.the

mau'rnum resistance limits. Use

a

resistance meter in the ap- tingaccidentally.

resiaence, contact the hosesupplierormanufacturer for the PressureRelief Procedure

on

page

2

toprevent

it

from star-

propriate range for your hose to check the resistance.

If

the

resistanceexceeds the recommendedlimits,replace

it

im-

mediately. An ungroundedor poorly groundedhose can make

yoursystemhazardous;Alsoread

FIRE

OR

EXPLOSION

HAZARD.

.

....

.I

...

..i

.,

..

.

..:

IMPORTANT

ticutariy the General Standards, Part 1910, and the Construction Standards,

Part

1926-should be consulted.

United States Government safety standardshave been adopted undertheOccupational Safetyand HealthAct.

Thee

standards-par.

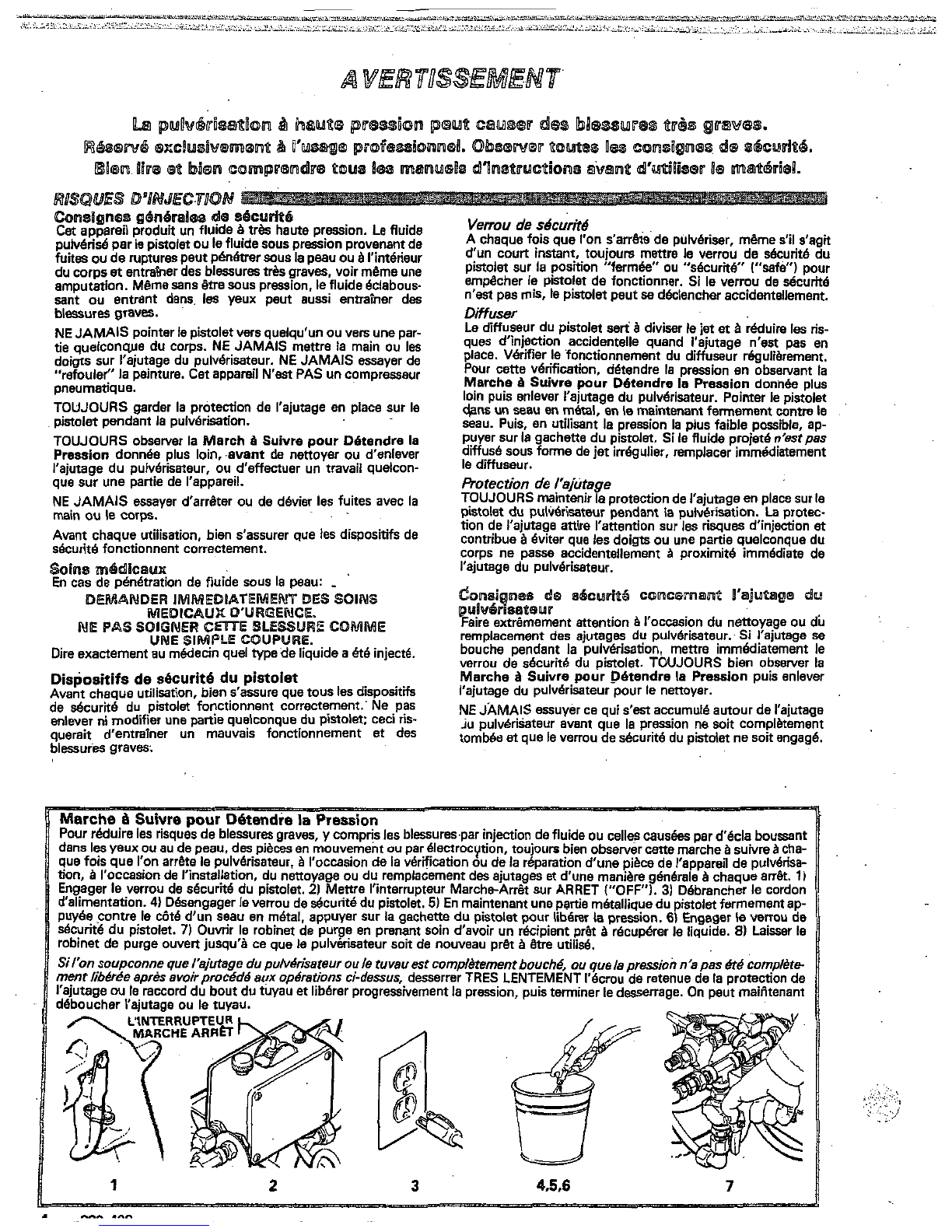

Coutsignes

g6n6ralm

de

securite

pulv4risti par

le

pistoiet

ou

iefluidesous pression pmvenant de

Cet

appareii produit un fluida

B

trh

haute pression.

LB

fluide

fuiies

ou

de ruptures peutpBnhrsous ia peau ou

B

I'intBrieur

du corpset entraher des blessurestdsgraves, voir

mBme

une

sant ou entrant dans.

les

yauxpautaussientrainerdes

amputation. MCma sans

We

sous

pression. ie fluide Bclabous-

blessures graves.

NE

JAMAIS pointer

ie

pistoietvars quelqu'un ou vers une par-

tie

quelconque du corps.

NE

JAMAIS menre

ia

main

ou

les

doigts sur I'ajutage du pulvdrisateur.

NE

JAMAIS essayarde

meumatique.

"refouiar"

ia

peinture.

Cet

appareil Nest PAS uncompresseur

TOUJOURSgarder

la

protectionda I'ajutage en piace sur

le

pistolatpendant

la

puivbrisation.

TOUJOURS observer la March

B

Suivre pour DBtendre la

Pression donnbaplusloin. .avant de nettoyer ou d'aniaver

que sur una partie de I'appareil.

I'ajutage du puivdrisataur,oud'effactueruntravailquaicon-

NE

JAMAIS essayerd'arrCtar oude dbvierles fuites avec

la

main

ou

ie corps.

Avant chaque utilisation, bian s'assurer que ies dispositifs de

sBcuritB fonctionnent correctement.

Boins

~mBdic~X

En

cas de pbnbtratlon de fluide sous

la

peau:

DEMANDER

IMMEDIATEMAENIT

DES

SQIMS

MEDICAUX

D'URQERICE.

Dire axacternent au medecin qual type

ae

iiquida

a

Bt6

inject&

UME

SIMPLE

CQUPURE.

Dispositifs

de

sbcurit6

du

pistolet

de &curit6 du pistoietfonctionnent corractament:Nepas

Avant chaque utiiisation, bien s'assure que tous ies dispositifs

enlevar

ni

modifier une partiaquelconque du pistoiet: ceci

ris-

queraitd'antrainerunmauvais fonctionnement

et

des

blessures graves:

NE

PAS

memm

cm~

BLESSURE

COW"

A chaque fois que I'on s'arr6ta de puhrdriser, mCme

s'il

s'agit

Verrou

de sdcuritd

d'un courtinstant,toujoursmettre

le

verroude skuritb du

empschar ie pistolat de fonctionnar. Si la varrou deSeCuritB

pistoletsur

la

position"fermbe" ou"sBcurit6"

l"safe"1

pour

n'est pas rnis,

le

pistolatpeut

se

dkiencher accidanteiiement.

Diffuser

Le diffusaur du pistolet

seti

B

diviser lejet

et

B

r&uire

les

ris-

quesd'injectionaccidantellequandI'ajutagen'estpasen

place.VBrifier

le

fonctionnament du diffuseur r6guiihramant.

Marche

B

Suivre pour DBtendre la Pression donn6eplus

Pour cettevBrification,dhtendre

la

pressionanobservant

ia

+ns

un

seau en mhi,

en

le

maintenant fermementwntre

le

loin puis enlever I'ajutage du pulvBrisateur. Pointer

ie

pistolet

seau.Puis,en utiiisant ia pression

la

plus faible possible, ap-

puyer

sur

la

gachette du pistolet. Si le fluida projet4

n'estpas

diffuse sous

forme

de jet irrdguiier. remplacer immediatement

le

diffusaur.

TOUJOURS maintenir laprotectionde I'ajutage an place sur

le

Rotection de I'ajutage

pistolet du pulvbrisateur pendant

la

puldrisation.

La

protec-

tion de I'ajutage attire I'attention sur ias risques d'injection

et

contribue

B

Bviter que lasdoigts ouune partie quelconque du

I'ajutage du pulv6risateur.

corpsnepasseaccidenteilement

B

proKimit6immediatede

@Mk6PISs'WN

bmsiqnes

de

a6curit6

concwnmt

1'@,4tagB

du

Faire extr&nemant attention

B

I'occasion du nettoyage ou du

rempiacementdesajutagesdupulv6risateur: Si I'ajutage

se

verroudesBcurit6dupistolat.TOUJOURS bian Observer

la

bouchependant

ia

pulv6risation.

mettre

imrn4diaternant

ie

Marche

B

Suivre pour DBtendrela Pression puis enlever

I'ajutage du pulvdrisateur pour ie nettoyer.

NE

JAMAISassuyer ce qui

s'est

accumulhautourde I'ajutage

jupulvbrisateuravantque

la

pression

ne

soit

completement

tombee

et

qua le vermu de&curite du pistolat ne

soit

engag6.

ies blessures-par injection de fluide ou cell@ causeeS pard'kla boussant

ou par 6lectrocytion,toujounbien observer cena marche

B

suNre

B

cha-

emplacement des ajutages

et

d'una manihre gBnBrale

B

chaque

an&.

11

la

vdrification oude

la

r6paration d'unepikade I'appareil de puivbrisa-

nterrupteur Marche-Arrit sur ARRET

("OFF").

31

DBbrancherle cordon

pistolet.

51

En maintenant une partie metalliqua du pistolet fermement ap-

r

le gachettedu pistoietpour iibBrer la pression.

6)

Engager leverrou de

ur soit de nouveau pr8t

B

&re

utilis6.

prenant Soin d'avoir un recipient prdt

B

r6cup6rer ie liquide.

81

Laisser la

Sil'onsoupconneque

menr

Jib&e

apr& emir

I'ajutage ou

ie

raccordd

3

4.5.6

7

R!SWfES

EN

CAS

DE

~AU~~n$E

UUULUSAUOON

DU

MAUERjEk

Cmsignes

g6n6uales

$0

sQcuritpB

Toute utiiisation,anormale de I'appareil de pulvBrisation ou des

Puessi

n

aaessoires

domrne,

per example, ia mise sous une pression

Ce

pulvfrisateur peut produire unePRESSION

MAXIMUM

DE

excessive.Ies modificationsdepieces,I'utilisationde produits Bl6mentsduPulv6risateUr

et

ses

accessoiressontconcuspour

TRAVAIL

210

bar

f3cX7V

Ib/po.2).

Sassurerque tous

les

chimiqum et dematieresincompatibles

et

I'utilisation de rbister

B

la

pressionmaximum detravail dece pulvbrisateur.

pi& udesou abim6es peut causer des dBg8ts

B

I'appareil ou

des ruptures de piket entrainer une injection deliquideou NE PAS d6passer

la

pression maximum de travail d'aucun dss

46ments ou accewires

utili&

avec cet appareil.

d'autresblessures drieuses, un incendie,uneexplosionou

bm

slet

cAi~ni~~

88

cou

d'autrm

d6gAts.

BlEN!'A&URERqueTous

fes

corpfdessolvantsutilishs

NE JAMAIS alt6rer ou mod#ier une piece de cet appareil; ceci sont chimiquement compatibles avec

les

Parties mouillbas

in-

risquerait d'enuainer

son

mauvais fonctionnement. diqubes dans ies

"Donn6es

techniques", au

dos

de

la

couver-

VERIFIER r6gulihrementtout I'appareil de pulv6risation et

ses

du

fabricant desfluides

a

utilisb

avant

de

Sfen

servir

ture. Toujours lire soigneusement

18s

documents

et

brochures

6quipements

et

r6parer ou remplacerimmddiatement

Ies

dans

~

pulvBrisateur,

,

pihsus& ou abim6es.

MEWRES

DE

SEWROUE

CONCERNANU

LE$

TUYAUX

FBEXIBLES

Le

fluide

B

hautepressioncirculantdans

les

tuyauxpeut&repar tout autrem'oyen.

trk

dmgereux.

En

cas defuitesur letuyau, mame minuscule,

de fissure,dbchirureourupture

B

la

suitedeI'usure,ded6gats

MANIPULER

LES

TUYAUX

ET

fluide sous pression.

oud'unernauvaise utilisation,

les

projectionsde fluide haute

.

CHOISIR

solGNEUsEMENT

LEUR

Ne

pas

d6placer

PreFSion qui en proviennentpauvententrainerdesbl-ur-

le

fluide

en

rent

sur

le

Ne

ws

utiliser

defluides

ou

de

gravespar pendtratbnsous

la

pew

oupar contactt.ainSique

qui

ne

pas

compatibles

aYBC

I~enVeloppe~in.

des d6ghmat6riels.

TOUS

LES

TUYAUX

FLEXIBLES

'DOIWENT AVOlR

DES

destempdraturessuphrieures

B

82°C(169°F)ouinfbrieures

B

!

tBrieureou endrieure dutuyau.NEPASexpcser

le

tuyau

B

RESSORTS SPIRALE

DE

PROTECTIONI

Lesspiralesde

4'C

(4°F).

boucles ou de nosuds sur

18s

tuyaux quipourraient entrainer

la

'

Une

benne

cont,nu#

Je

la

JTa

wrre

&

tuyeux

protection contniuent

B

biter

la

formation depliures,de

Gonainuiite

dQ,la,

,a,ter

dss

vu

8ux

SERRERFERMEMENTtousIes racmrdsavantchaqueutilisz-vaporisation.VBrifiez

ia

rkistance 6iectriquedevos Waux

h

rupturedu tuyau

B

I'endroitduraccordou

B

sonvoisinag6.essentiellepourmaintenir

la

mise

B

laterredeI'ensamblede

tion. Le fluide souspression peutfairesauterunraccord

desserr6 ouproduireunjet

B

haute pression s'6chappant par

le

fluides

et

B

air, a.u moins une fois par semaine. Sivotre tuyau

raccord.quemaximum,prenez contact avecle foumimur detuyaux

ne comporte pes d'etiquene qui prBcise

ia

rbistance Blectri-

NE

JAMA~S

utiliser un tuvau endommagb. Avant chaw Utiliser

un

metre

de

r6sistence

de

la

gammeappropride

pour

ou la fabricant pour avoir

les

limitesde Aistance maximum.

coupur-. fuitm. abrasions.boursouflur= de renveloppdou

limiteS

recornmand6es,

remplacez

le

tuyau

immwiaternent.

utiliiation, verifierentihrementchaquetuyaupourdeceler

les

~tretuyau

et

v6rifiaz

dshnce,

si

ceile-G

dBpasse

ies

route

am

dBt6riorationoujeudesraccords. Si I'on constate

Un

tuyau

san~

Fisc

a

terre

ou

avec

une

la

twre

incor.

rune de

cas

detBriorations,

iJ

fautremplacer le tuvauim-

reae

peut

dm

~sques

pour

VOtre

systeme.

,jsez

mbdiatement. NEPASessayerderefaire

le

raccordd'un tuyau

LES

RISQUES

D,INCENDIE

ou

DzmPLOSION

ci-dwus,

haute pressionnide rbparer le tuyau avec duNbanadhbifou

RISQUES

~1~~~~~~E

OU

WEXPLO$lON

De I'6lectricitB statique

est

produitepar le passage du f1uide.B

grande vitesse dans

la

pompe

et

dans

ies

tuyaux. Sitoutes

Ies

2.

Tuyaux flexibles: Afin d'assurer

la

continuit6 de

la

mise

B

la

pikes de I'appamil de pulv6risation ne sont pas convenable term, n'utiliser que des tuyaux comportant une mise

B

la terre

etavantunelongueurmaximumcornbin&de

1%

m

ment reli6es

B

la

masse ou

a

la

terre, des Mrncelles peuvent se

produire

et

I'appareilrisque &&re dangereux.Des hinceiles tinuit6ducircuit de mlse

B

la

terre des tuyaux".

(1500pieds).Sereporter6galementauparagraphs

"Con-

Peuvent balement seProduire

i

I'occasiondubranchemem

3.

mstolet:

~~~li~~~

la

&

la

terre

en

le

raccordant

un

sontsuffisantespourallumerles vapeun de wlvants

et

le

oududbbranchemantducordond'alimentation.LesBtincelies

tuvau

fle~ble

et

+,

un

pulv6risateurdeja

convena~ment

reli&

fluidepulvdris6,

les

finesparticulesdepoussihreainsique

B

ia

terre.

d'autres substances inflammables, quend on pulv6rise

B

I'in-

t6rieur ou

B

I'extBrieur. et elles oeuvent causer un incendie ou

4.

Objets, mat.4rid

ou

surfacesrecevant

la

puldrisation:

observer

le

code ou les dalementations

locales.

..

..

..

..

...

..

..

~.

uneexplosion.

ainsi

quedesblessures gra~ketdes db@ts

trouvant

B

au moins

6

m

(20

piedslde I'appareil

et

de I'endroit

matbriels. Toujoun brencher

le

pulvdrisateur dans une prise

se

oh

se

fait

la

pulv6risation. Ne pas brancher ou d6brancher un

cordon

d'alimentation quei qu'il

soit

dans

la

zone

oh

se fait

la

pulv6risation quand

il

y

a

lemolndrerisquequedesvapeurs

encore prbsentes dans I'air prennent feu.

ressentez lamoindredbcharge, ARRETR IMMEDIATEMENT

S'il

se produit des 6tincelles d'6lectricitB statique, ou si vous

LA

PULVERISATION. VBrifiez aue

le

sWheentier

est

bien

mis

B

la terre. Ne vous servezpaidu syaiheavant que

le

pro-

bldme soit identifie

et

corrigd.

fiWh

la

tWPe

QU

&

la

lllaS88

Pour r6duire iesrkquesde productiond'Btincelles d'BlectricitB

statique,

le

pulvbrisateureitous

les

6quipementsutilidsou

se

tmuvent dans

la

zone de pulvbrisation doivent&re relis

B

la

termou

B

la

masse. Pour connaitre le detail des instructions de

mise

B

la

terredans

la

rdgion et

le

type

particulier d'Bquipe

ment, CONSULTER le code ou

les

rdglementations Blectriques

tion suivants sont bien rell6s

B

la

terre:

locales.

S'ASSURER que tous Ies 6quipements de pulvbrisa-

rallongequidoivent &reBquipBs d'une prise

B

3

fiches en bon

1.Pulvdrisateur:Brancher

le

cordond'alimentation

ou

la

&at,

.dam uneprisede murant convenablementmise

B

la

terre. Ne pasutiliserd'adaptateur. Toutes

les

rallongesdoivent

avoir

3

fils

et &re pr6vues pour 15 amp8res.

5.

Tousles

saaux

de

solvantsutilis& pour

le

rincage: observer

mdtalliques conducteurs de I'Blectricite.Ne pas mettre leseau

le code ou ies rbglemenmtions locales.N'uMserque des

seaux

sur une surface non conductricecomme.sur du papier ou du

carton

carcela interrompreit

ia

continuit6

le

lemise laterre.

6.

Pour

conserver la continuit.4 de

la

mise

B

la

terre quand on

rince le

mat6riaI

ou

quand on

lib*

la

pression, toujours

contre

le

cbt4 d'unseau en

m.4td

puis appuyer sur

la

d6tente

maintenir une partle metaliique dupistoietfermement appuy6e

du pisfolet.

ou d'autres parties du corps.

SE

TENlR

A

L'ECART des pieces

Les pieces en mouvement peuventpincerou couper

185

doi

enmouvamentpendant

la

miseen route

et

la

marchedu

pulv6risateur.Pour Bviter un d6marrageaccidentel,,debran-

cher

le

pulvBrisateur

et

IibBrer

la

pression avant d'effectuer des

MPORTAWT

arations.

&B

adoptBes en vertu de

la

Loi sur

la

SBcurit6 et

la

Sam6 au

Lees

nomes de s6curitB du Gouvernement des Ems-Unisont

Travail.

Ces

normes

et,

particulidrement, ia Section 1910des

Normes

GBn6rales ainsi que

la

Section 1926 des Normes de la

Construction, doivent atre consult&.

Rnswm

DUS

AUX

PECES

EM

~~~~~~~~~

..

Fun43E5

Seeguridad

general

Este

equipogeneraunfluidoaunapresi6nmuy

alta.

0

rociado delapistola.

10s

escapesdefluido

o

roturasde

los

wmponentes pueden inyectar fluido

en

la piel

y

el

cuerpo

y

causar lesiones earemadamente graves, incluyendo a veces

la

necesidad de amputaci6n. Tambih.

el

fluidoinyectado

o

salpicado

en

10s

ojos

puede causar graves daflos.

NUNCAapuntarlapistolahaciaalguien

o

algunapartedel

quilla. NUNCA tratar de "hacer retornar la pintura";

este

NO

cuerpo. NUNCA colocar la mano

o

10s

dedos encima de

la

b-

es

un

sistema de rociado de aire.

SIEMPRE tenercolocado

el

protectordelaboquillaenla

pistola mientras

se

est6

pulverizando.

SlEMPREseguir elprocedimiento dedescarga depresi6n.

servicio a cualiquier equipo del sistema.

dado

m&

abjo.

antes

de limpiar

o

Sacar

la

boquilla

o

de dar

NUNCA tratar de parar

0

desviar los'escapes con la mano

o

ei

cuerpo.

edn

funcionando bien antes de cada uso.

Asegurarquetodos

10s

aparatosdeseguridaddel.equip0

Tratamiento

mddico

Si pareciera que un.poco de fluido.penar6 la piel, conseguir

TRATAMllENTO MEDICO

DE

UROENCIA

DE

INMEDIATO.

NO

TRATAR

LA

HERIDA

@DM0

UPJ

SIMPLE

CORTE.

Deciralmedicoexactamentecua fluido fue.

Aparatos

de seiuridad de

Ira

pi5tOl~3

pulverized&

Asegurar que todos

ios

aparatosprotectoresdelapistola

estsn

funcionandobienantesdecadauso. No scar

ni

modificarninaunaoiezadelaoistola Dues oodrla causar

el

malfuncionamlento

be

la misma

con

iasconsiguientes [miones

personalas.

Pestillodeseguridad

Cada vez que

se

deje de pulverizar, aunque

sa8

por

un

breve

momento.siemprecolocarel pest" deseguridaden

la

posici6n"cerrada".

Io

quedejala pistolainoperante. El

no

hacedo puede llevar

al

disparo imprevisto de la pistola.

Difusor

8

difusor de la pistola dispersa el chorro pulverizado

y

reduce

el

riesgo de inyeccidncuando

no

est6

instaiadalaboquilla.

el

procedimientode descaigadepresi6n. dado rnhsabajo.

Revisar con reguiaridad

e1

funcionamiento del difusor. Seguir

mat6lico.sosteni4ndolabien firm contra

61.

Utilizando

ia

y

despub sacarlaboquilla.Apuntarlapistola

a

unbalde

emitido

no

sale disperso

en

un

chorro irregular, reemplazar

de

presi6n

m6s

bajoposible,disparar ia pistola. Si

el

fluido

inmediato

el

difusor.

Rotactor de la boquilla

pistola mientras

se

est6

pulvenzando. Este protector llama

ia

SIEMPREtener

e1

protector

de

laboquillacolocado

en

la

atenci6n contra el peiigro de inyecci6n

y

ayuda a prevenir

la

colocaci6n accidental de

10s

dedos

o

cualquier otra partedel

cuerpo cerca de la boquilla.

Sagupidad

de

la

bcqullla

pulverizadcra

Tenermuchocuidado

al

limpiar

o

cambiarlasboquillas.

Si

pestiilo

de

la

pistoladeinmediato.SIEMPREseguir

el

pio-

llegara

a

obstruirse mientras est6 pulverizando; enganchar

el

quilla para limpiarla.

cedimiento de descarga de presl6n

y

despub Sacar

la

bo-

NUNCA limpiar

la

acumuiacibn

de

pintura alrededor

de

la

bo-

quiilaantes

i13

quesehayadescargado por cornpleto

la

..esidn

y

el

pmillo

est6

enganchado.

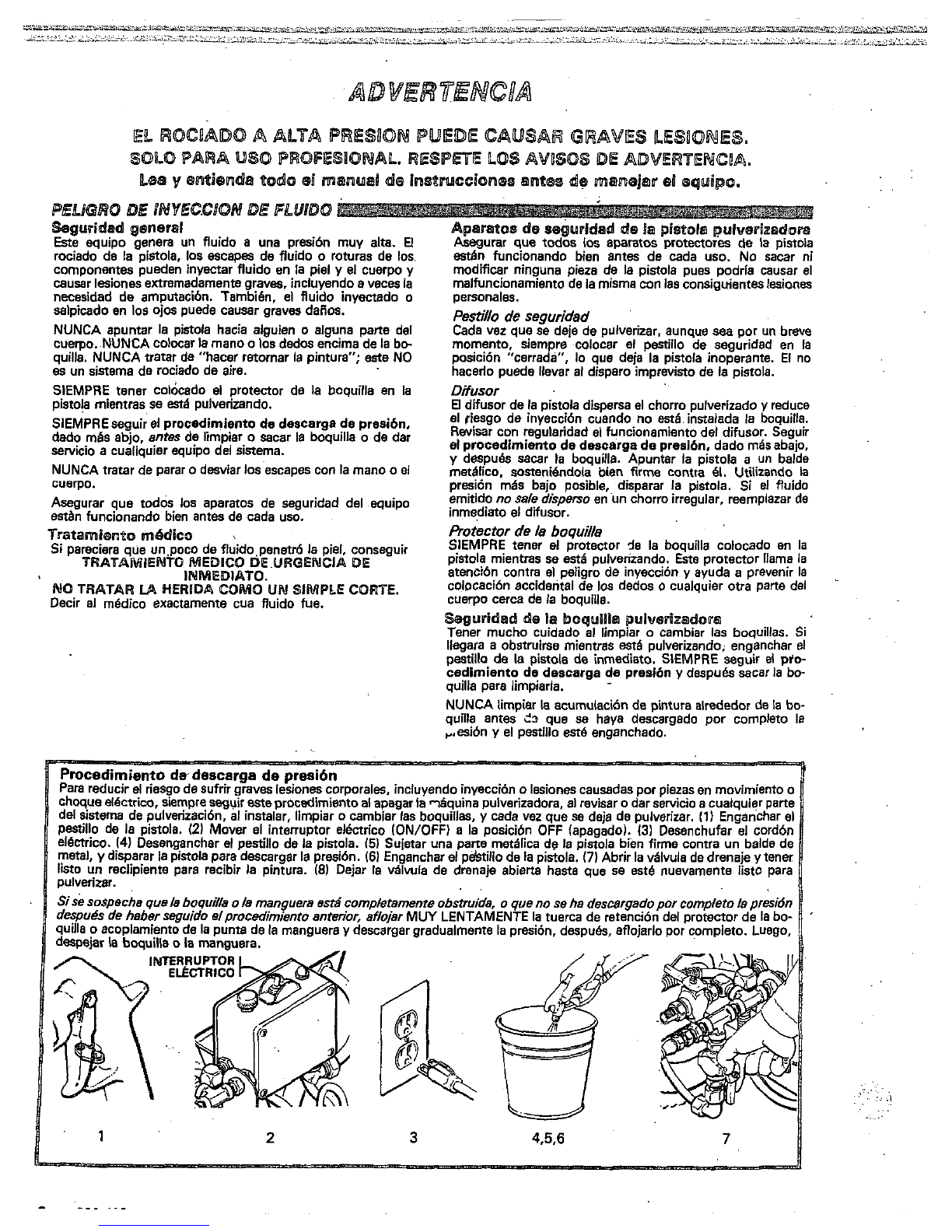

Procedimiento dedescarga de

presi6n

choqueel6ctriw, Siempreseguir esteprocadimiento al apagarla T6quina pulverizadora,

al

revisar

o

dar servicio a cualquier parte

Para reducir el riesgo desufrir graves iesiones corporales, incluyendo inyecci6n

o

lesiones causadasporpiezas

en

movimiento

o

del sistema de pulverizaci6n.

al

instalar, limpiar

o

cambiar Ias boquillas,

y

cada vez que

se

deja de pulverizar.

11)

Enganchar

e1

elhrico.

(4)

Desenganchar

el

pesu'llo

de

la pistola.

15)

Sujetar una parte mdlicade la pistola bien firme contra

un

balde de

Pestillodelapistola.

(21

Mover

e1

intenuptorelbctrico

ION/OFF)

a

laposicibn

OFF

(apagadol.

I31

Desenchufar

el

cord6n

metal,

y

disparar la pistola para descargar la presi6n.

161

Enganchar

e1

perstilio de lapistola.

17)

Abrir la vhlvula de drenaje

y

tener

pulverizar.

list0

un

reclipientepararecibirlapintura.

18)

Dejarlav6lvuladedrenajeabiertahastaque

se

est6nuevamente iisto para

SiSesospacha

que

la

boquila

o

la

mnguera estd

qutlla

o

acoplamiento de la pun- de la man

despuhs de haber seguidoelprocedimiento

despajar la boquilla

o

la manguera.

,..

. .

.. ..

.. .

'

.

:.

.,

..

..~.

"ERRUPTOR

2

PELhGRO

POR

MAL

US0

DEL

EQUPO

segws~ded

gpwasal

Cualquler mal

us0

de(

equipo pulverizador

o

10s

accesorios. tal

como ~brepresurizaci6n.modificaci6nde piezb,

UM

de

matenales

y

pmductos quimicosincompatibles,

o

utiliuaci6n

y

causenlainyecci6ndefluido

u

otraslesionescorporales

graves, incendio, explosi6n

o

daiion a

la

propiedad.

NUNCA alterar

o

modficar ninguna pieza de este equipo; el

hacerlo podria causar una averia.

REVISAR con regularidad el equipo pulverizador

y

reparar

o

reemplazar de inmediato las piezas daiiadas

o

desgastadas.

PwiOn

del

sietema

Esta

pulverizadora puede desarmllar

210

barlas

WM

psi) de

PRESION

DE

TRABAJOMAXIMA.Asegurarquetodoel

equip0 pulverizador

y

sus

accesorios tienen la capacidad para

aguantar ia presi6n maxima de trabajo de esta pulverizadora.

NOexcederla presi6n maximade trabajodeningrlncom-

ponente

o

acmoriode mesistema.

Cornpatibilldad

de

Fluid0

ASEGURARque todos

10s

fluidos

y

saiventesusadosson

en.la hoja de datos tbcnicos en la contratapa. Siempre lee las

quimicamente compatibles con

las

piezasmojadas ilustradas

instruccionesdelfabricantedelfiuido

y

sulvente antdde

usarlos

m

esta pulverizadora.

El

fluido

que pasa a aka presidn por18s mangueras puede ser

muy

peligroso. Sien la manguera se desarrolla unescape

pe-

desgaste. daiio

o

maitrato,

el

chorro a aka presi6n emitido por

queiio.unarotura

o

rajaduradebidoacualquier tip0 de

alli

puede causar una lesi6n por inyecci6n

u

otraslesionscor-

porales graves

o

deiion a la propiedad.

lTODAS

US

MAMGUERAS PARA FLUIDOSTIENEN

QUE TENER GUARDAS

DE

RESORTEI Estas protegen las

tos

o

cerca de ellos,

10s

que podrian traducirseen roturas de le

mangueras contra dobleces

0

retoreeduras en

10s

acopiamien-

manguera.

Antes de usarlas, APRETAR bien firmes todas las conexiones.

o

dejar que por

bt

escape un chorro a aka presi6n.

Elfluido

a

alta presi6n puede desalojar

un

acoplamiento sueito

NUNCAusarunamangueraque

e&

daflada.Siempre.

revisarlaen buscade cortaduras,escapes, abrasih, cubierta

abultada,

o

acoplamientos sueltos

o

datiados. Sillegara a en-

contrarse cualquiera de mascondiciones,reemplazar dein-

mediato la manguera. NO intentar reacoplar una manguera de

aha presibn

o

enmendarla con cinta adhesiva u otro material

Ruido a akapresi6n.

similar.Una manguera que ha sido remendada no aguante el

MANEJAR

Y

PASARCUIDADOSAMENTELAS

MANGUERAS.Notirardelasmanguerasparamoverel

equipo.

No

usarfluidos

o

solventesquaSean incompatibles

con ei tubo interno

y

la

cubierta dela manguera. NO exponer

4'C

(-4O'F).

lasmanguerasatemperaturassobre 82°C

(180OF)

o

bajo

Continuidad

de[

EIPCM~FO

ola.puesta

8

tierpa

de

la

manguara

esencialparamantenerconectadoatierraelsistema

La continuidaddelcircuit0depuestaatierraapropiado

es

pulverizador.

Es

indispensablerevisarlaresistencia elktrica

vsz a

la

semana. Si la manguera no tiene una etiqueta en la

maxima de Ias mangueras de aire

y

de fluidopar

lo

menos una

cual se especifica le resistencia eltktrica maxima, ponerse en

contact0 con el proveedor

o

fabricante de la manguera para la

resistencia en lagama apropiada para comprobar la resisten-

informaci6n sobre

10s

limites de resistencia. Usar un metro de

mediato.

Es

muy arriesgado tener una manguera sin puesta

a

cia; si excede 10s limitesrecomandados,reemplazarlade in-

tierra o'conla puesta a tierra en malas condiciones. Leer tam-

bi6n la informaci6n sobre RIESGO DE INCENDIO

0

EXPLO-

.~.

depiezasdaiiadas

o

desgastadas,puedehacenqueserompan

SEGUR!DAD

EN

EL

us0

DE

BAS

~~~~U~~~S

. ...

SION.

ds

amba.

..

.i

:

PBBGW6

DE

8NCENDlO

8

EXPLO$lOM

El

flub a

alta

velocidaddelRuidoal .pasar

por

labomba

y

mangueracreaelectricidadest6tica.Sitodas 18s panesdel

equipopulverizador no tienenbuena tierra.puedenocurrir

chispas, convirtiendoai sistemaen algopeligmso. Tambibn,

d6nel6ctrico. €staschispas puedeninflamar

los

vaporesde

pueden producirse chispas a1 enchufar

o

desenchufar

el

cor-

10s

solventes

y

ei chorro de fluido puiverizado, panicuies de

polvo

y

otrassustancias infiamabies,

sea

alaire libre

o

bajo

techo;

Io

que podria causar una explosidn

o

incandio

y

graves

Iesiones corporales

y

dafios

a

la propiedad. Enchufar siempre

la pulverizadora a

un

tomacorriente quese encuentre a por io

rociar. No enchufar

o

desenchufar ningrln cord611 elbctrico en

menos

6

m

(20

pies)delamhquina

y

dd

Area

que

88

va

a

posibilidadde que queden vapor- inflamables en el aire.

ellugardondeseest6rociandocuandotodaviaexista

ia

Si se observa alguna chispa esthtica,

o

se siente

el

mas

leve

choqueelbctrico. APAGAR DE INMEDIATOLA

PULVERIZADORA. Revisar todo el sistema en busca de con-

exi6n

a

tierra positiva. No usarnuevamenteelsistemahasta

haber ubicado

y

corregido el problema.

Para reducir el riesgo de chispas esthticas. conectar a tierra la

se encuentre en el iugar que se va a rociar. CONSULTAR el

pulverizadora

y

todo el otro equipo de pulverizar que se use

o

c6digo elbctrico de la localidadpara las instrucciones sobre

IBS

conexionesatierraexigidasparalazona

y

tip0 deequipo.

pulverizador:

ASEGURARdeconectara tierratodo esteequipo

1.

Pulverizadora: enchufar el cord6n elbctrico,

o

cable exten-

sor, cada uno con unenchuf de tres patas en buen estado,

a

un tomacorriente con puesta a tierra apropiado. No usar un

adaptador. Totos

10s

cables extensores tienen que tener tres

hilos

y

una capacidad de

15

amperios.

,

2.

Mangueraspara

fluidos:

usarsolamentemanguerascon

puestaatierradeuna longitud combinadade

150

m

tambiknalphrrafosobre continuidad a tierrade.la

(500

pies), para asegurar buena continuidad

a

tierra. Referirse

3.

pistola:hacerlapuesta

a

ti.erraconecthndola

a

una

manguera.

manguera de fluido

y

puiverizadora bien conectadas

a

tiena.

4.

Objeto

que

$e estd rociando: de conformidad con el cddigo

local.

5.

Todos

10s

baldes de solvente usados durante el lavado, de

meta4 que,sesnconductivos.

No

coiocarelbaldeenuna

conformidedconelc6digolocal.Usarsolamentebeldes.de

superficienoconductiva,comopapei

o

cartbn,queinter-

rumpe

la

continuidad

a

tierra.

6.

Para

mentener la continuidada tierra duranre

el

lavado

o

descarga de presidn, siempre apoyar una parte metelica de la

pistoiabien firme contra eicostadodelbeldedemetal,

despuk apretar el gatillo.

Syqldaq

.durante

el

Ba\rgd~

R

uclr el rlesgo de lesiones por inyeccibn, chispas elbctricas

o

salpicaduras.siguiendoelprocedimientodelavado

especffico dado en la phgina

10

de este manual. Seguir

81

pro-

cedlmlento dedescarga de prasi6nen

ia

phgina

6,

v

quitar

la boquilla rociadora antes

de

law. Apoyar una pane metblica

de la pistola bien firme contra ei costadode un balde de metal

y

usar

la

presi6n

mhs

baja posible de fluido durante el !avado.

Pu@sta

61

tierm

Las

piezas en mowmiento pueden pinchar

o

amputar dedos

u

otraspartesdelcuerpo.MANTENERSEALEJADOdelas

piezasen movimientodurante elarranque

o

funcionamiento

de la pulverizadora. Desenchufar la pulverizadora

y

descargar

arranque inesperadamente.

la presi6n antes de revisarla

o

darle servicio, para impedir que

IMPORTANT

Se han adoptado las normas de seguridad del gobierno de

10s

Estados Unidos de Noneambrica bajo el Acta de Seguridad

y

especial Ias Generales, Parte

1910;

y

las Normas de Construc-

SaludOcupacionai.Deberhn consultam

estas

normas,en

ci6n.Pane

1926.

Connect Hose end.

Gun

Connect

at

least

50

.ft

(15

m)

hose

to

thefluid outlet

of

thepressurecontrol. See

Fig

1.

Connect

a

spray

gun

to

the other end

of

the hose. Don't use thread sealant, and

don't install thespray

tip

yet!

For

two

gun hookup, remove the plastic cap plugfrom

the secondary hose

ball

valve and connect

an

accessory

hoseand spray gun.

See

Fig

1.

CAUTION

To

avoiddamaging the pressurecontrol, which

may

result

in

poor equipmentperformanceand

componentdamage, follow these precautions:

1.

Always

use

at

least

50

f-t

(15

m)

of

nylon

spray hose.

2.

Never

use

ewire

braidhose as

it

istoo rigidto

act as apulsationdampener.

3:

Never installany shutoff device beVe6n the

fluid outlet of the pressure control and the

first

50

ft

(15

m) of spray hose.

4.

Alwaysuse the main fluid outlet for one-gun

operation. Never plug this outlet.

II

Fill

Packing

NutlWdt

Cup

Pour throat seal liquid, supplied with the sprayer, into

wet-cupfilled'to helpprotect and prolong thelife

of

the

thepacking nut/wet-cup until

it

is

1/3

full.

Keep

the

pump throat packings. See Fig

2.

Check Electrical Service

Be

sure

theelectrical service

is

120

V,

60

HzAc,

perly grounded.

15

amp (minimum) andthat.the outlet

you

use is pro-

Use

an

extension cordwhich has3wires

of

minimum

12

gaugesize, rated for

15

Amps, andamaximum

of

150

h

(45

m) long. Longer lengths may affect sprayer

performance.

Be surethe ON/OFFswitchisOFF. Plug

the

power sup-

Plug

In

Sprayer

20

ft

(6

rn)

away from thespray area to reduce the

ply cordinto

a

grounded electricaloutletthat is

at

least

chance of

a

spark igniting the spray vapors.

See

Fig

3.

Do

notremovethe thirdprong

of

thepower supplycord

plug, which is the grounding prong,and do not use an

adapter.

Flushthe Pump

flush the pump to remove he

No.

10

motor oil which

was

left

in to protect pump

parts

after

factory testing.

Refar to page

10

for

WHEN

and

HOW

to flush.

Prepare

the

Paint

Prepare the paint according.to themanufacturer's

formed,and stirthe paint to

dissolve

hardpigments.

recommendations.Removeanyskin

that

mayhave

Strain the paint through

a

finenylon meshbag

[available

at

mostpaintdealers) toremove particlesthat

could clog the spray tip. This is probably themost im-

portant step toward trouble-free spray painting.

SECONDARY

Fig

2

Fig

3

..

;.:

.

:,::

,

1,

.

.

,

.

..

,

.; ...

... ... .

..

..

,

. ....

,

.

Priming theSprayer

Close the main drainvalve and the secondary ball valve.

See

Fig

2.

Plug

in

the sprayer. Don't install thespray tip

in

the gun yet1

-

-.

Placethesuctiontubeintothe paintcontainer.Turnthe

..

lowerthe pressure setting. SeeFig

3.

Disengagethe

pressure control knob allthe way counterclockwise to

gun

safety

latch.

grounded metal pail, and trigger the gun into the pail.

Hold

a

metalpartof the gunfirmly against the sideof

a

increase the pressure setting until thesprayer

starts.

Hold thetrigger open, turn

the

sprayer

ON,

and slowly

ed

outofthesystem, andthepaint

ROWS

freely fromthe

Refer

to

Fig

4.

Keepthe guntriggereduntil

all

air isforc-

gun. Release the trigger

and

engage the safety latch.

/

....

...

~

.

.

..._

.

..

.._.

METALTO

METL

CONTACT BETWEEN

GUN AND CONTAINER

Fig

4

MOTE:

If

the paint ishard to prime,openthedrain

valve. When fluid comes from the valve,

close

it.

Then disengagethe gun safety latch

and follow the paragraph above.

Check

all

fluid connections for leaks. If any are found,

follow

the

PressureReliefProcedureWarnlng on

page

2

or

11,

beforetighteningconnections,

Be

sure the gun safety latch

is

engaged. Install the tip

Install

the

Spray Tlp and TipGuard

andtipguardas instructedin the separate gun ortip

iv-

struction manual.

Adjusting

the Spray Pattern

spray

from

the gun is completely atomized. To avoid

ex-

Increase the pressure adjusting knob setting just until

andextendthe

lie

ofthe sprayer, always use thelowest

cessive overspray and fogging, andtodecreasetipwear

possible pressure neededto get thedesired

results.

If

more coverage is needed,

use

a

larger tip rather than

increasingthe pressure.

Test the spray pattern. To adjust the direction of the

spray pattern, engage the gun safety latch and loosen

horizontalfor

a

horizontalpattern or vertical for

a

ver-

tical pattern. Then tighten the retaining nut.

.~

theretainingnut.Positionthe tip

so

the grooveis

I

.:;

,,

..~

',?

..,

..

:.

.. .

,.

. ...

:

..i.

.

..

'L..s

____

._....

~,,~..~.

,..,

~~

,,...

~,,,

...*i,~~,"~-,.L.

.....

._.

.ll.,..,)

...~~-~~~~!~,~~"~

".LX&&

......................................................

~

'.~.

..~~

.-.-

1_..L

~~~~~ ~ ~

,_","-mid

-..,,

Cleaning a Clogged Tip

DO NOT

try

to "blow back" paint; this

is

NOT

an

Follow the instructions given

in

yourseparategunor

spray tip instructionmanual for cleaning a spray tip.

SHUTDOWN

AND

CARE

Check the packing nut/wet-cup

daily.

First

follow the

Pressure

Rellef

ProcedureWarningon page

2

or

11.

timestohelp preventfluidbuildupon thepistonrodand

Keep the wet-cup

113

full

of throat seal liquid

at

all

prematurepackingwear.Thepacking nut shouldbe

tight enough

to

stop leakage, but no tighter. Over-

tightening maycause binding andexcessivepacking

wear.

Use

a screwdriver and

light

hammer toadjust

the

nut.

See

Fig

5.

enadjustingthe packingnut, be carefulnot

to

nickthe cylinder threadswhich may beprotruding

above the bearing housing.Nickstothese threads

maystripthe threadsinthe bearing housing when

the displacement pump is removed

or

installed.

Fig

5

Flush the sprayer

at

the endof each work day and

fill

it

freezing.

See

"Flushing Guidelines" on page

10.

withmineral spirits

to

help prevent pump corrosionand

ious 'sprayer damage.

pints for

the

final

flush,

ave the mineral spiritsin

For very shortshutoff periods, leave thesuction tubein

thepaint, follow the Pressure

Relief

Procedure

:

Warning, and clean the spray

tip.

Coil the hose and hang

it

on the hose rack whenstoring

thesprayer, evenfor overnight,

to

help

protectthe hose

from kinking, abrasion, coupling.darnage, etc.

When to Flush

1.

New Sprayer. YournewUltimateNovaTM

lo00

Sprayerwas factow. tested

in

No.

10

motor oil

which was

left

in

to protectpump parts.

Before

using

wafer-base palnt,flush

with

mineral

spirits, followed by

soapy

water, and then a clean

water flush.

Before

uslng

oibbase palnt, flushwithmineral

spirits

only.

2.

Changing Colors. flush

with

a compatible solvent

such

as

mineralspiritsor water.

3.

Changingfrom water-base to oll-basepaint.

flush withsoapy.water, then mineral spirits.

5.

Storage.

Water-base

paint

flush with water, then mineral

spiritsand leavethepump, hose andgun filled

with

mineralspirits. Shutoff and unplug the sprayer,

open the drain valve to relieve pressure and leave

open.

Oll-bese paint: flush

with

mineral spirits. Shutoff

andunplugthe sprayer,open thedrain valve to

relieve pressure and

leave

open.

Before

using

water-base

paint,

flush out mineral

spirits

with

soapy water andthenacleanwater

6.

Stenupafter storage.

Rt

mh

4.

Changing from oil-base

to

water-basepaint. When using

011-base

paint,

flush out the mineral

Flushwith mineral spirits, followedbysoapy water,

then

a

aean water flush. spirits

with

the material to besprayedand the

sprayer is readyto use.

..I"...

How

to

Flush

1.

Engage the gunsafetylatch, turn the ON/OFF

switch to OFF,release the gun

safety,

trigger the

gun to relieve pressure, engagethe gun safety and

open the drain valve.

2.

Pour one-half gallon

(2

liters)

of compatible solvent

into

a

bare metal pail. Put the suctiolrtube in the

pail.

3.

4.

5.

6.

7.

Close the drain valve.

Remove the spray tip

from

the gun.

Point the spray gun into a metalwastecontainer

and

with a

mepl

part

of

the gun

firmly

touchingthe

metal

container,squeeze the gun trigger.

'See

and splashing. With the guntriggered, turn the

Fig

6.

Thk

procedure helpsawoid

stetlc

sparking

ONIOFF

switch

to

ON

and

slowly

turn the pressure

starts.

Keep the gun triggered until clean solvent

adjusting knob clockwise

lust

untll

the sprayer

engage the gun safety latch.

comes

from

thenozzle.Release

tha

triggerand

Check

all

fluid

connections for leaks.

If

anyleak,

first turnthe ON/OFFswitch to OFF, then open the

drain valve slowly

to

relievepressure.

Now

tighten

fig

6

the connections, start the sprayer, and recheck the

connectionsfor leaks;

1

fromthe ho&.bo nG-let

thspump.

run

dry

ior

sprayeragain.

pump

packingslThenturn

ON/OFF

switchtoOFF

more

then

30

seconds

to

avoid damaging the

9.

If

you

flushed

with

mineralspiritsandaregoing to

and engage the gun saftey. use

a

water-base paint, flush with soapy waterfol-

lowed

by

a

clean water flush. Then repeat Step

1.

.,

. .....

..

. ...

I

~.

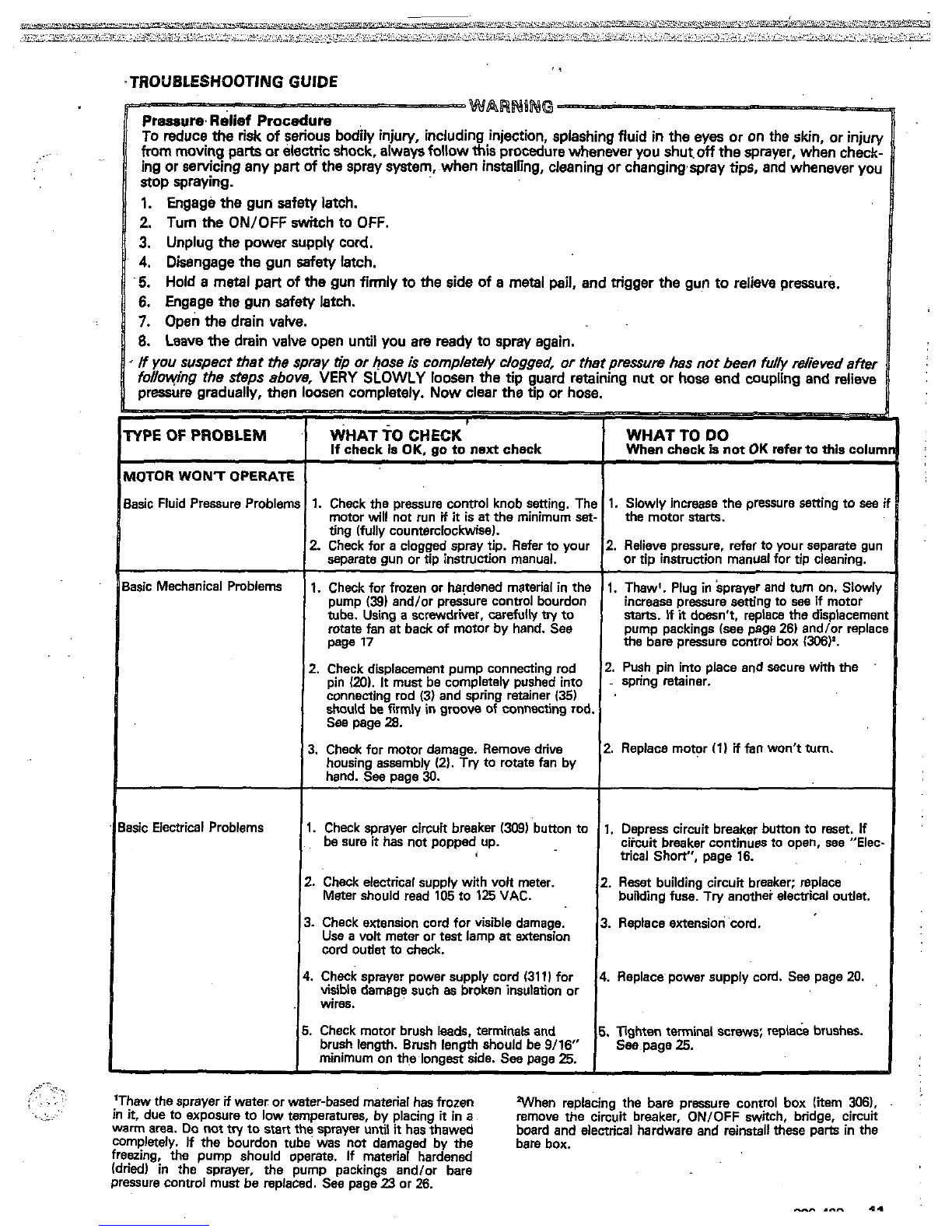

,TROUBLESHOOTING

GUIDE

~.

~~~~U~~

-

...

1.

Engage the gunsafetylatch.

2.

Turn

the

ONIOFF

switchto

OFF.

3.

Unplug

the

powersupplycord.

4.

Disengagethegunsafetylatch.

5.

Hold

a

metal

part

of

the

gun

firmly

to

the

side

of

a

metalpail, and trigger the

gun

to relievepressure.

6.

Engagethegunsafetylatch.

8.

Leave the drain

valve

openuntilyou

are

readytosprayagain.

BasicMechanicalProblems

1.

Check for fmzenor hadened material in the

1.

Thaw'.Plug in sprayerand turn on.Slowi)

pump

(39)

and/or pressurecontrolbourdonincreasepressure setting

to

see

if

motor

tube. Using

a

screwdriver, carefully try to

rotate fan

at

back

of

motor by hand. See

stam.

If

it

doesn't, replace the displacemei

page

77

the

barepressure controlbox

(306)'.

pump packings (see page

26)

andlor replac

2.

Checkdisplacement pumpconnecting rod

2.

Push

pin into placeandsecure with

the

connecting md

(3)

and spring retainer

135)

'

pin

1201.

It

must be completelypushed into

-

springretainer.

should

be

firmly

in

grmw

of

connecting rod.

See page

28.

3.

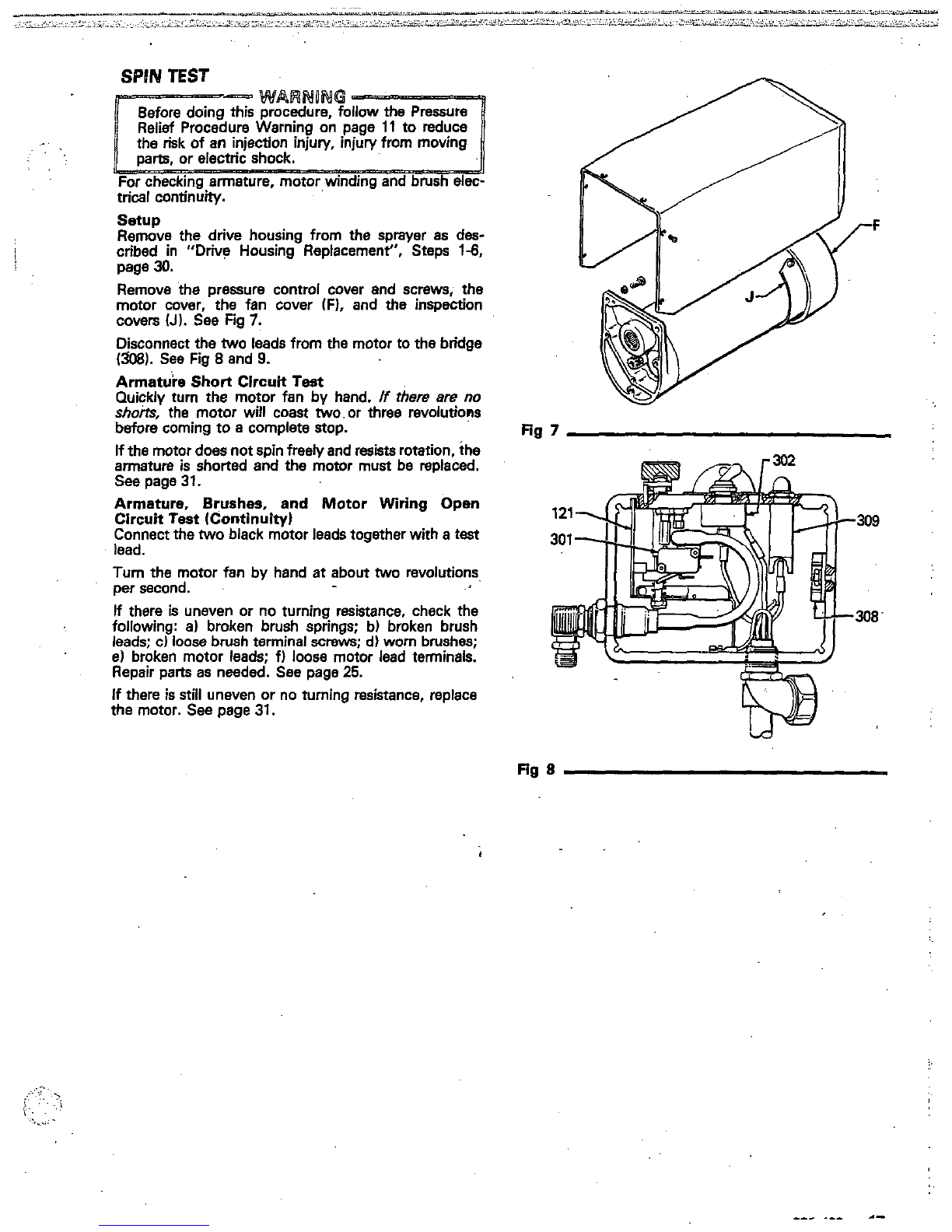

Cheok for motor damage. Remove driw

2.

Replace motor

(1)

if

fan

won't turn.

housing assembly

(2).

Try to rotate fan by

hand.

See

uaae

30.

lsicElectricalProblems

1.

Checksprayer circuitbreaker 1309'buttonto

1.

Depress circuit breaker buttonto reset. If

besure

it

has not poppedup. ciicuit breaker continuesto open,

see

"Elec

3

tricalShort",page

16.

2.

Checkelectricalsupply with volt meter.

2.

Reset

building circuit breaker;replace

Metershouldread

105

to

125

VAC. building

fuse.

Try

anotherelectricaloutlet.

3.

Checkextensioncord for visibledamage.

3.

Replaceaxtension cord.

Use

a

volt meter or test lamp

at

extension

cord outletto check.

4.

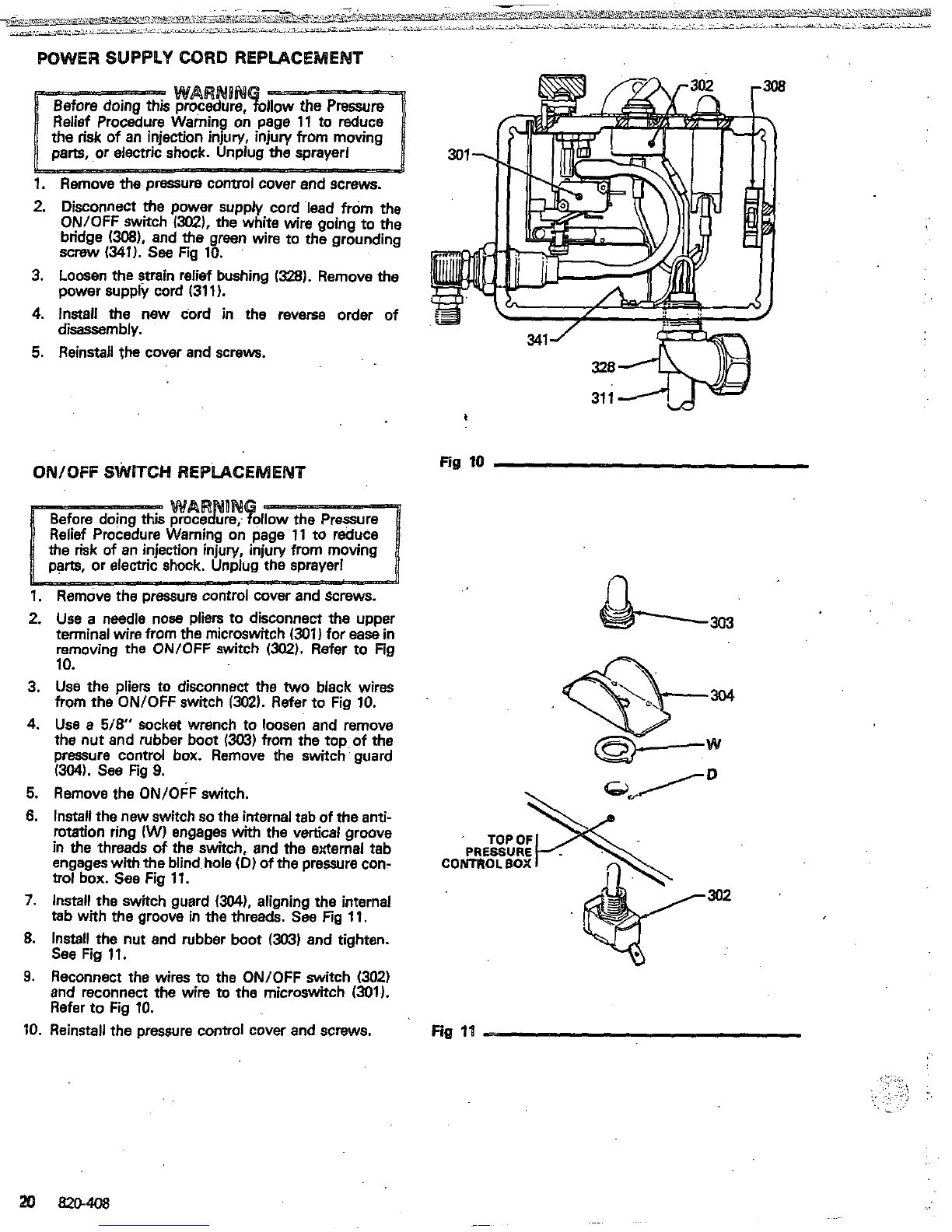

Ch,ecksprayerpower supplycord

(31

1)

for

4.

Replacepower supply cord.

See

page

20.

wlble damage such

as

broken insulation or

wires.

5.

Check motorbrush

leads,

terminalsand

5.

Tightenterminalscrews; replaw brushes.

brushlength.Brushlengthshouldbe

9/16"

See

page

25.

minimum onthe longest side.

Sea

page

25.

..:;

..

..

. . ..

,.

.

'~~

,.

'Thaw thesprayer

if

water orwater-basedmaterialhas frozen Wenreplacingthebare presure contml box litem

306).

."

in

it,

duetoexposure to low temperatures,byplacing

it

in

a

warm

area.

Do

not

try to start the sprayeruntil

it

has

thawed remove the circuit breaker,

ON/OFF

switch,bridge.circuit

board and electrical hardware and reinstall these parts in the

completely.

If

the bourdontubewas not damaged by the

freezing. thepumpshould operate. If materialhardened bare box.

pressure control must be replaced.

See

page

23

or

26.

(dried)

in

thesprayer, thepumppackings and/or bare

"

.^..

..

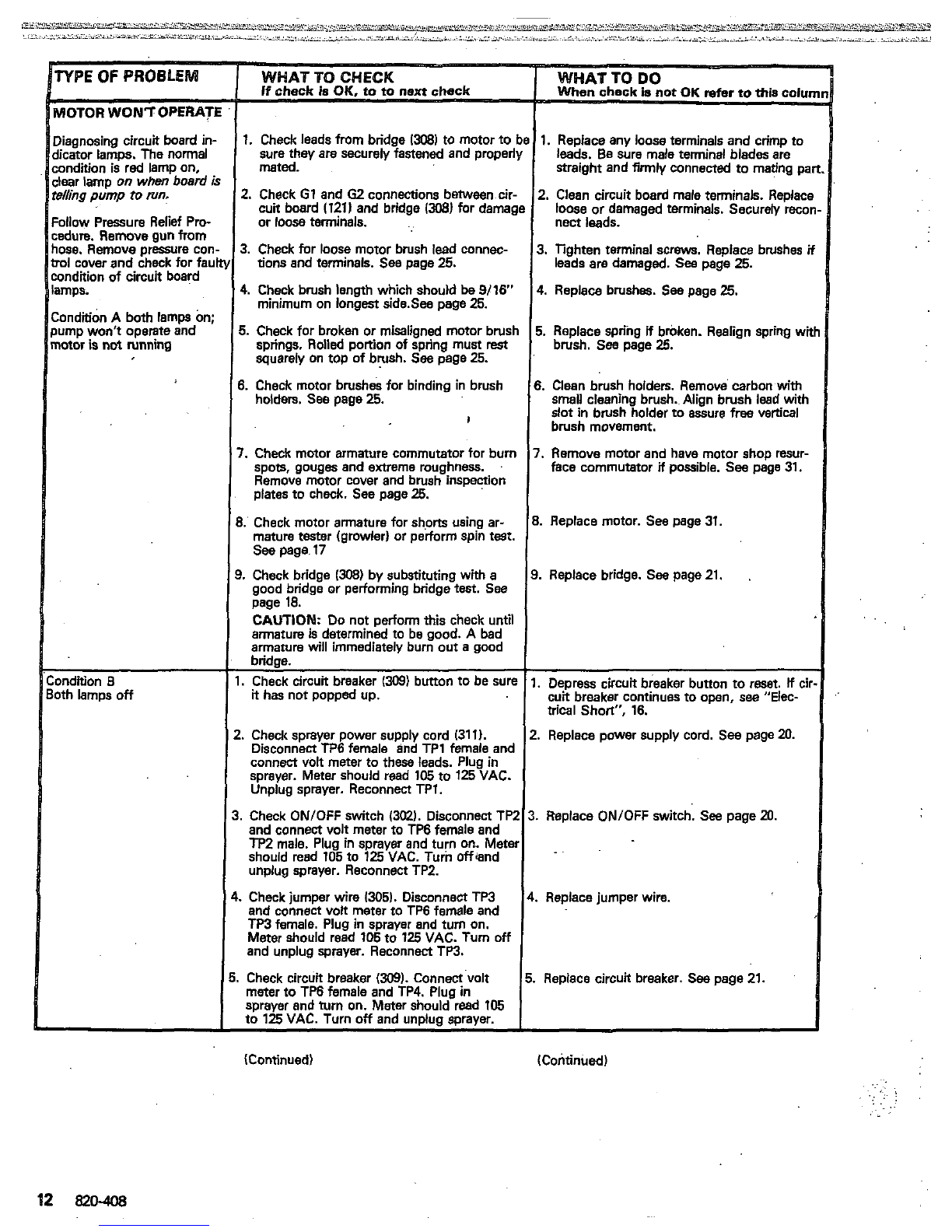

HOTOR

WONTOPERATE

Iiagnosingcircuit board

in-

Iicator lamps. The normal

andition is red lamp on,

$ear lamp

on

when

board

I

elling

pump

to

run.

:allow

Pressure Relief

Pro-

ndure. Remove gun from

lose. Remove pressure cor

rol

cover and check for fat

ondition

of

circuit board

mps.

:ondtion

A both lamps

On;

lump won't operate and

mor

is

not

running

Dndition

8

fh lamps

off

refer

to

*is colu~

sure they aresecurelyjastenedand properl)

mated.

1.

Checkleads from bridae

13081

to motor

to

be

1.

Replaceany

loose

terminals and crimp to

I

leads.Besuremaleterminalbladesare

straightand firmly connected to matingpa

2.

Check

G1

and

62

connections between cir-

or

loose

terminals.

cuit board

1121)

and bridge

1308)

for damagl

3.Check for loose motor brush lead wnnec-

tions

and terminals. See page

25.

4.

Check brush length which should

be

9/16"

minimum on longestside.Sea page

25.

5.

Check for broken or misaligned motor brush

squarely on top of brush. See page

25.

springs.

Rolled

portion

of

spring must

rest

6.

Check motor brush& for binding in brush

holders. See page

25.

I

7.

Check moior armature commutator for burn

spots, gouges and extreme roughness.

plates to check. See page

25.

Remove motor cover and brush inspenion

3.

Check motor armature for shorts using ar-

mature tester (growler) or perform spin test.

See page

17

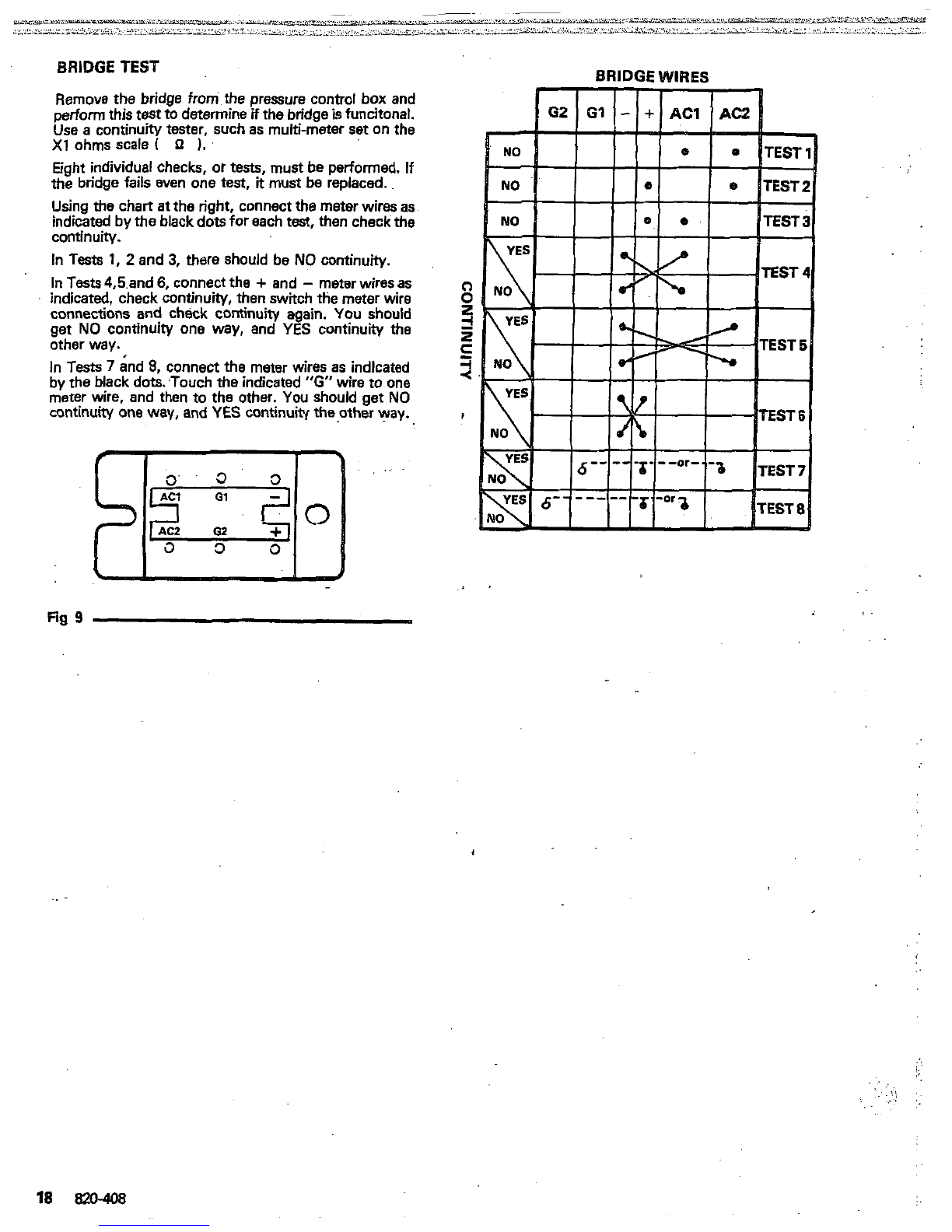

good bridge or performing bridge

test.

See

page

18.

CAUTION:

Do

not

perform this check until

armature

is

determined to be good. A bad

armature will immediately bum out

a

good

bridge.

I.

Check circuit breaker

(309)

buttonto be sure

it

has not popped up.

3.

Check bridge

(308)

by substituting with

a

!.

ChecA sprayer power supply cord (31

1).

DisconnectTP6femaleandTP1femaleand

sprayer. Meter should read

105

to

125

VAC.

connect volt meterto these leads. Plug in

Unplugsprayer.Reconnect

TPl.

.

Check

ON/OFF

switch

13MI.

DisconnectTP2

~ ~~ ~

and connectvolt meter to TP6 female and

should read

105

to

125

VAC.Turin offand

TP2

male. Plug insprayer and turn on. Meter

,

~~~.

unplug sprayer. Reconnect TPZ.

.

Check jumper wire

1305).

DisconnectTP3

and connect volt meter to TP6 female and

TP3 female. Plug

In

sprayer and turn on.

and unplug sprayer. Reconnect TP3.

Meter should read

106

to

125

VAC. Turn

off

meter to TP6 female and TP4. Plug

in

Check circuit breaker

(309).

Connect volt

sprayer and turn on. Meter should read

105

to

125

VAC. Turn

off

andunoiuosoraver.

1

i

2.

Clean circuit boardmale terminals.Replacl

loose or damaged terminals. Securely reco

nect leads.

3. Tighten terminal

screws.

Replacebrushes

i

leads are damaged.

Sea

page

25.

4.

Replacebrushes.

Sea

page

25.

5.

Replace spring

if

broken. Realign spring

wi

brush. Seepage

25.

6.

Clean brush hoiders.Removecarbon

with

slot in brush holderto assure free vertical

SWall

cleaning brush..Alignbrush lead with

brush movement.

7.

Remove motor and have motor shop resur-

face commutator

if

possible. See page 31.

8.

Replace motor. Seepage31.

3.

Replacebridge.Seepage

21.

I.

Depress circuitbreaker bunon to reset.

If

cil

cuit breaker continuesto

open,

see

"Elec-

tricalShort",

16.

?.

Replace power supply cord.

See

page

20.

I.

Replace

ON/OFF

switch.

See

page

20.

..

..

Replace jumper wire.

.

Replace circuit breaker.

See

page

21.

Continued) (Continued)

.::

!

..

.. .

.,

..

:ontiition

B

Continued)

ondition

C

'nplug sprayed

ed

lamp

on,

clear lamp

oi

WHAT

TO

CHECK

If

check

is

OK,

go

to

next

check

6.

Check motor thermal cutout switch.

female. Plug in and turn

on

sprayer. Meter

Connect volt meter to TP6 female and

TP9

should read

105

to

125

VAC. Turn

off

and

unplugsprayer.

7.

Check microswitch

1301).

Reconnect

TP6

connectors. Connect volt meter to TP15

VAC.

male and TP4. Meter should read

50-125

8.

Visually inspect microswitch

1301)

button.

Adjustment stud

101

should

not

depress th

microswitchbunon when fluid pressure is

with small screwdriver; an audible click in-

zero.

Manually check by depressing button

dicates.micmswitch

is

in

normal position.

9.

Check microswitch

1301)

continuity with

oh

meter. Be

sure

sprayer

is

unplugged1

Mete!

should read zero ohmswith

no

fluid pressu

in the sprayer.

10.Check

all

terminals for damage or

loose

fit.

Reconnect

Tffi

connectors.

11.Check circuit board

l307)

by substituting

w'kh

a

good board.

See

page

22.

I.

Check circuit board

1121)

by removing from

box

without

disconnecting wires;

see

page

22

for removal procedure.

-

WARNING:

Removingthe circuit board

while

Su'll

wired over-rides the optical detec

tor which could

causa

the sprayer to ovar-

tion

properly. Turn the sprayer

on

ONLY

pressurize.

if

the microswitchdoes

not

func

long enough to check lamp condition, then

WARMING:

To reduce

the

risk of electric

shut

off

immediately.

shock, handle board by edges onbl

Do

not

with the board1

allow any metal objects to come in contact

Plug inand turn

on

sprayer. Clear lamp

should be

on

now

-

removing the circuit

off

and unplugsprayer.

board over-rides the optical detector.

Turn

.

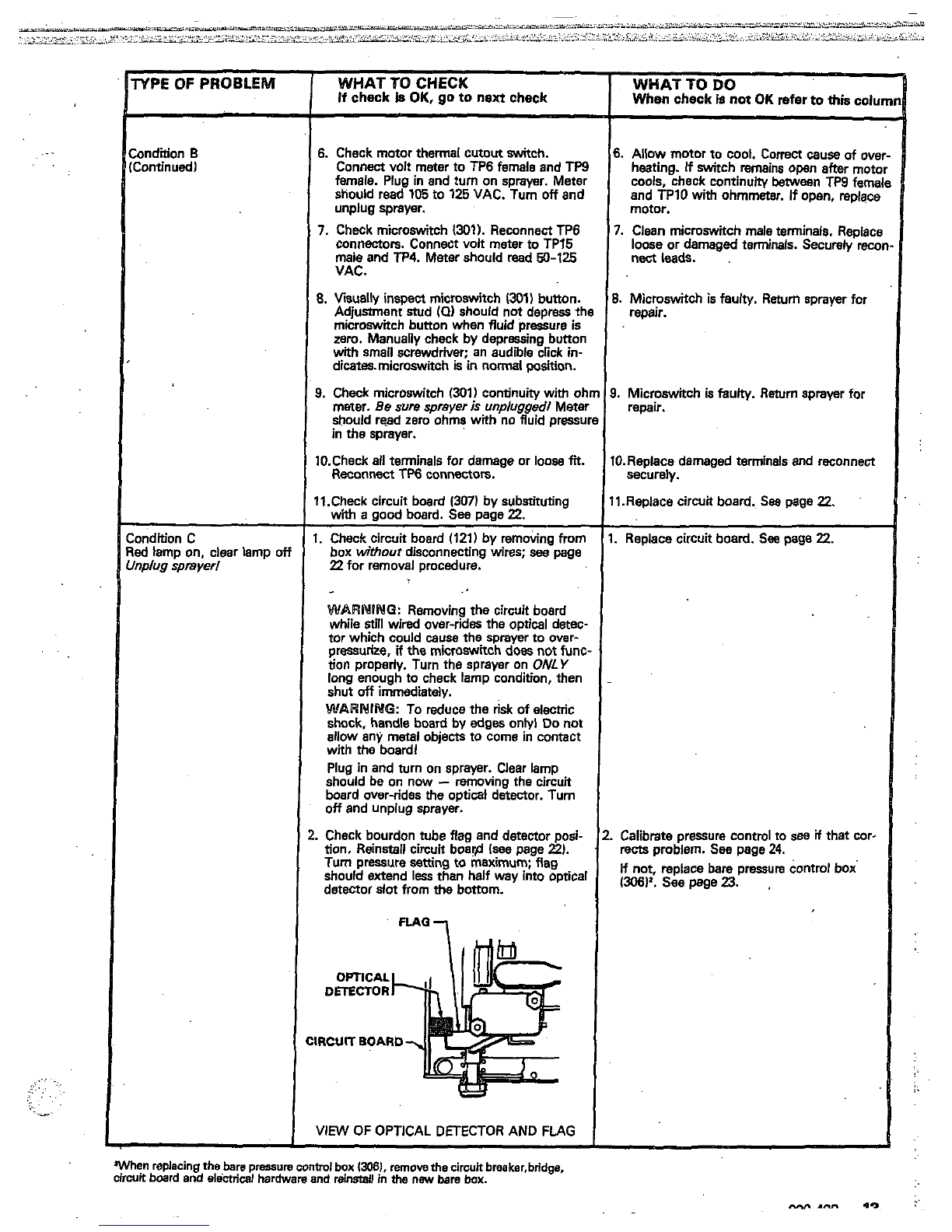

Check bourdon tube flag and detector posi-

tion. Reinstall circuit boar@ (see page

2).

Tum pressure

setting

to maximum; flag

detector slot from the bottom.

should extend

less

than half way into optical

DmCTOR

OPTICAL

IRCUIT

BOARD

VIEW

OF

OPTICAL DETECTOR AND

FLAG

When replacing

the

bare

pressure

control

box

13081.

remove

the

cirwtt

breaker,bridge.

circuit board and

electrical

hardware

and

reinstall

in

the

new

bare

box.

When

check

is

not

OK

refer

to

thk

colu

WHAT

TO

DO

6.

Allow

motor

to cool. Correct

cause

of ove

heating.

If

switch remains

open

after

motc

cools, check continuity

Ween

TW

fama

and

TPlO

with ohmmeter.

if

open, replacs

motor.

7.

Clean microswitchmaleterminals.Raolact

nect

leads.

loose or damaged terminals. Securely

rex

~~~-

~~

8.

Microswitch

is

faulty. Return sprayer for

repair.

3.

Microswitch

is

faulty.

Return

sprayerfor

remir.

I0.Replace damaged terminals and reconnect

I1.Replace circuitboard.

See

page

22.

securely.

.

Replace circuitboard.

See

page

22.

Calibrate pressurecontmlto

see

if

that cor-

rects

problem.

See

page

24.

(306)'.

see

page

23.

If not, replace bare pressure control box

WHAT

TO

CHECK

If

check is

OK.

go

to

next check

1.

Check for worn spray tip.

2.

to stroke

when

gun trigger is released. Plug

Check to

see

that

pump does not continue

inand turn onsprayer. Prime with material.

engage

safely

latch. Relieve pressure, turn

Trigger gun momentarily, then release

and

off

and unplug sprayer.

3.

Checkelectricalsupply with volt meter.

Meter should read 105

to

125VAC.

4.

Checkextensioncordsizeandlength;must

beet

least

12 gaugewire

and

no

longer thal

150

ft

(15.2.

m).

i.

Check

G1

and

62

leads

from bridge

(p81

to

circuit board

(3071

for damage or

loose

wire!

or connectors. Refer

to

page

22.

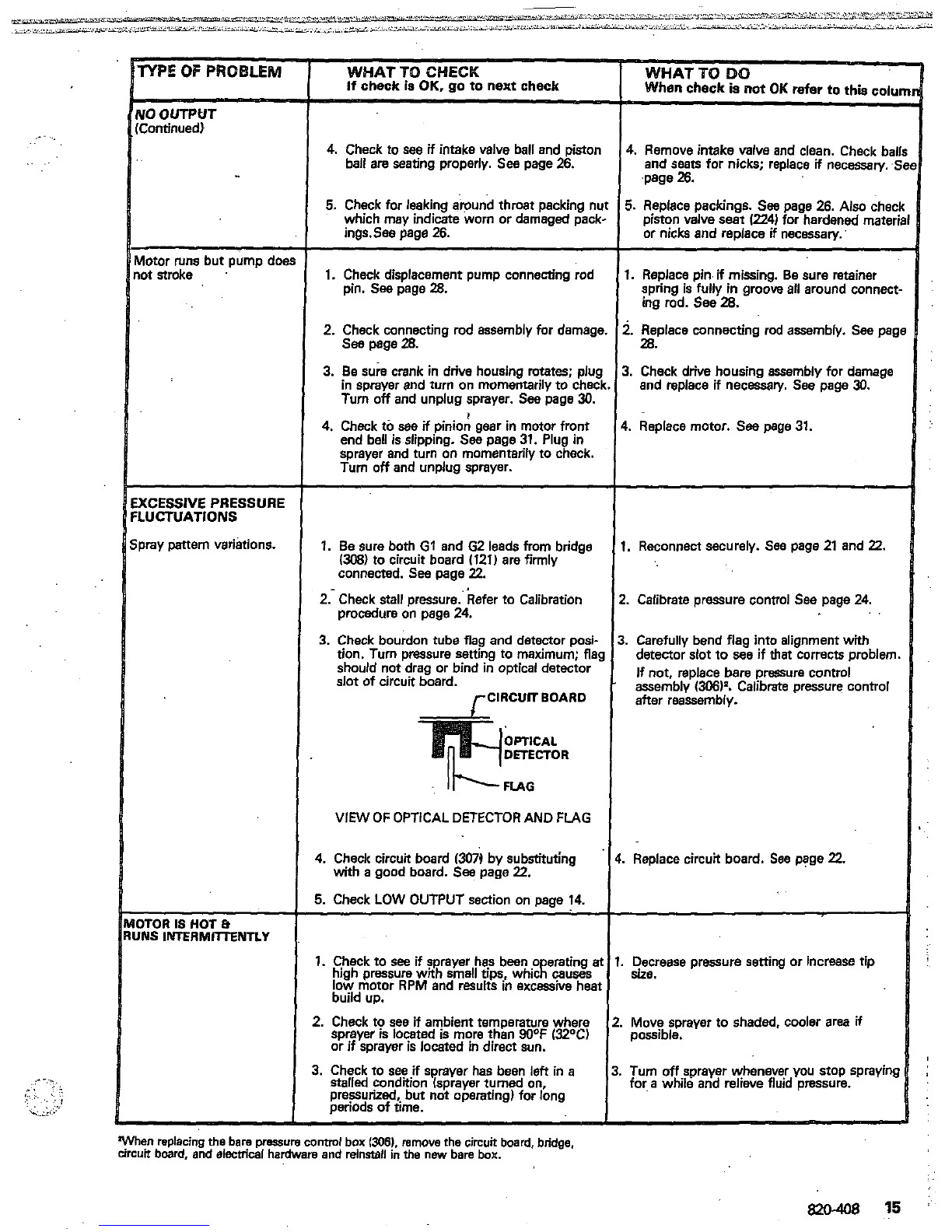

Procedure on page 24.

3.

Check

stall

pressure.Refer to Calibration

7.

Checkbridge

(3081.

+

and

-

leadsand ter-

and terminalsfor signs of overheating.

See

minals

to

motor. Inspect wiring insulation

page

18.

I.

Check for loose motor brush leads and ter-

minals.

See

page

25.

I.

Check for worn motor brushes which should

be 9/16 minimum length on longestside.

See

page

25.

0.Check for broken and misaligned motor

brush springs. Rolled portion of spring must

resf

squarely on top of brush.

1.Check motor brushes for binding

i:.

orush

holders. See page

25.

2.Check circuit board

(307)

by substituting

with

a

good circuit board.

See

page

22.

3.Check

motor

armature for shorts by.using an

armature tester (growler)or perform spin

test.

See

page

18.

3

4.Check bridge

(308)

by substituting with

a

test.

See

page

18.

good bridge or by performingthe bridge

CAUTION:

Do

not perform

this

check until

armature

is

determined

to

be good.

A

bad

armature will immediately bum

out

a

gcd

bridge.

Check material supply.

Check for clogged intake strainer.

See

page

26.

Check for loose suction tubeor fittings.

Sea

Page

26.

WHAT

ro

DO

When check

Is

not

OK

refer

to

this

colul

1.

FollowPressureReliefProcedurethen

replace tip.

See

your separate gun or tip

manual.

2.

Service pump. See page

26.

3.

Reset buildingcircuit breaker;replace

buildingfuse. Repair electrical outlet

01

another outlet.

1.

Replacewith

a

correct, grounded extension

cord.

i.

Clean circuit

board

mete terminals. Replace

lease

or defective lead terminals. Securely

reconnect

lead

terminals to board.

i.

Calibratepressure control.

See

page

24.

'.

Be sure male terminal blades are centered

and firmly connected to female terminals.

ing. Securely reconnect wires to bridge.

Replace any loose terminal or damaged wir-

i.

Tightenterminalscrews.Replacebrushes

if

.

Replacebrushes.Seepage

25.

leads are damaged. See page

25.

0.Replace spring if broken. Realign spring witt

brush.

See

page

25.

1.Clean brushholders. remove carbon

dust

with

slot

in brush holder to assure

free

ver-

with small cleaning brush. Align brush lead

tical

brushmovement.

Z.Repiace circuit board.

See

page

22.

Meplacemotor.

See

page

31.

1.Repiace bridge.

See

page 21.

Refill

and reprime pump.

Remove and clean, then reinstall.

Tighten;

use

thread sealant or sealing tape

on threads

if

necessary.

(Continuedl [Continued)

.-

-

.

.

..

YO

OUTPUT

Continued)

dotor

mns

but pump doe

ot stroke

KCESSIVE

PRESSURE

IUCTUATIONS

,ray pattern variations.

ITOR

IS

HOT

e

NS