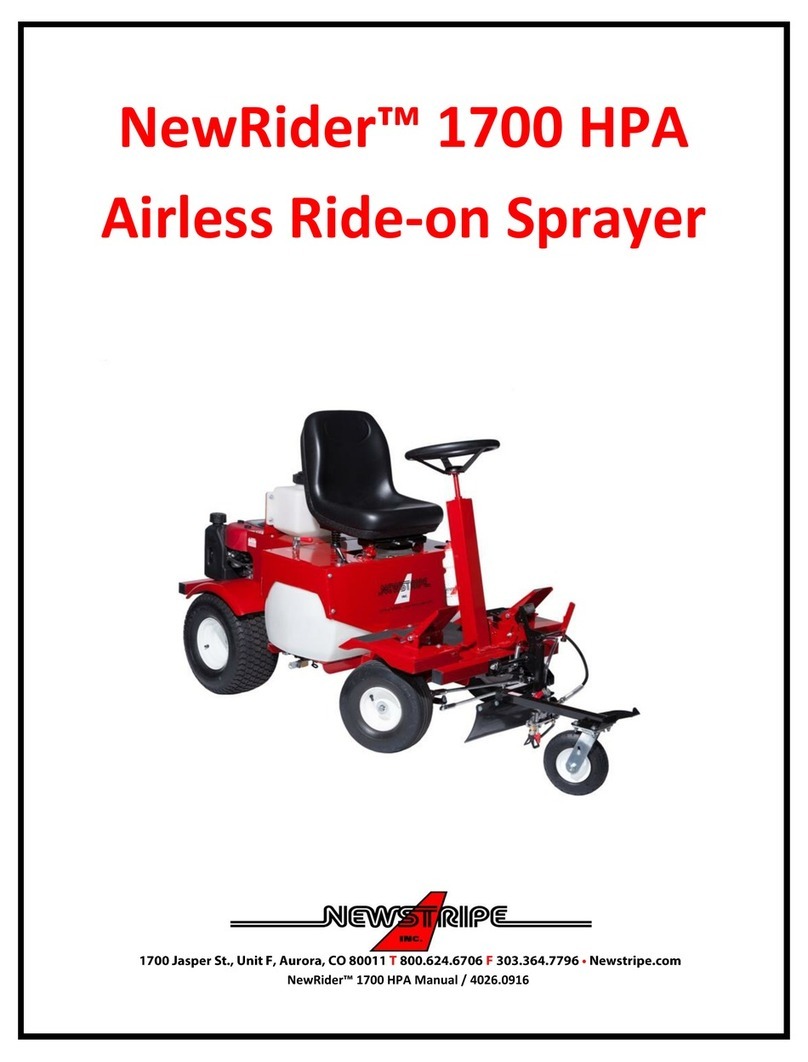

NewRider™ 1700 HPA Airless Ride-on Sprayer

ALWAYS wear safety goggles or protective eye-wear when operating the unit!

NewRider™ 1700 HPA Manual / 4026.0123

Page 5 of 23

DRIVING OPERATIONS

1. Before starting, set the brake with the hand lever

nearest the seat.

2. Place throttle lever in FULL FORWARD position. This

will set the choke.

3. Start the engine, when warmed up, move the

throttle to ¾ open. (where engine runs smoothly)

Engine does not need to run at full speed to run the

spray pump.

4. To move forward, release the parking brake and

press on the top of the right hand foot pedal.

5. Pushing the base of the pedal will move the machine

in reverse.

6. To stop, release foot pedal.

NOTE: If machine does not move set parking brake

and move to the rear of the machine. Pull the

Transaxle release lever up and back to lock into slot.

Enter the machine and release the parking brake. It

should now move.

7. To travel long distances when not spraying, or to

load the machine onto a trailer, lift the spray head

using the lift lever on the left hand side of the

steering column. The spray head will lock in position

when fully lifted. This also locks the spray gun so

that it may not be activated when the spray head is

lifted.

8. When loading on a trailer approach the ramp slowly

to assure the gun will clear the ramp. You may have

to raise the gun or possibly remove it if the ramp is

too steep.

SPRAY OPERATIONS

First time use or after extended periods of not using the machine use water to test operations and

settings. The NewRider 1700 is designed to be used with water based athletic field marking paints.

ALWAYS STRAIN THE PAINT BEFORE USE!

1. Add 5-25 gallons of water or paint to the spray tank

and 1-2 gallons of water to the purge tank

2. Push outlet button 3 times to ensure the outlet

valve is moving. The push button is located on the

left back side of the pump opposite the spray hose.

3. Turn pressure control valve to high pressure (fully

clockwise). DO NOT OVER TIGHTEN.

4. Turn prime/spray valve to prime position. (Circular

arrow symbol in-line with arrow on the side of the

pump.)

5. Ensure the spray gun trigger lock is disengaged.

6. Ensure the spray gun tip is in the spray position.

(The arrow on the spray tip points toward the

ground.)

7. Check that the tank feed valve (located under the

left side of the tank by the white filter housing) is in

the open position (handle in-line with hoses) and

the purge feed valve is in the closed position

(handle crosswise to hose).

8. Start engine as indicated in steps 1-3 in Driving

Operations.

9. Engage the pump by moving the engaging lever to

the “On” position. Lift and place in upper notch.

10. With the prime/spray valve in the prime position,

fluid should flow through the bypass hose into the

paint tank.

11. Let the pump run in the prime position for one

minute or until air bubbles are not seen from the

bypass hose.

12. Turn prime/spray valve to the spray position.

(Spray gun symbol in line with the arrow on the

side of the pump housing.) NOTE: A knocking

sound should be present at the pump, indicating

the pump is reaching its hydraulic relief pressure.

13. Activate foot pedal trigger and paint will spray

from the gun. Releasing pedal will stop spray.

14. Adjust the pressure by turning the pressure valve

counter clockwise until spray pattern deceases,

then increase pressure by turning clockwise just to

where you get a good even spray pattern.

Operating the pump at the lowest pressure while

still producing a quality line can increase the life of

the pump.

15. Adjust spray gun height for the proper line width.

16. When finished spraying or if machine will be left

unattended for any amount of time, turn the

prime/spray valve to prime position, and pull

spray trigger to release pressure from the

system.