Shimadzu DGU-405 CL User manual

Other Shimadzu Laboratory Equipment manuals

Shimadzu

Shimadzu FCV-S CL User manual

Shimadzu

Shimadzu Shim-pack GIST Series User manual

Shimadzu

Shimadzu GC17A User manual

Shimadzu

Shimadzu LC-40D X3 CL User manual

Shimadzu

Shimadzu AOC-20i User manual

Shimadzu

Shimadzu LC-10 User manual

Shimadzu

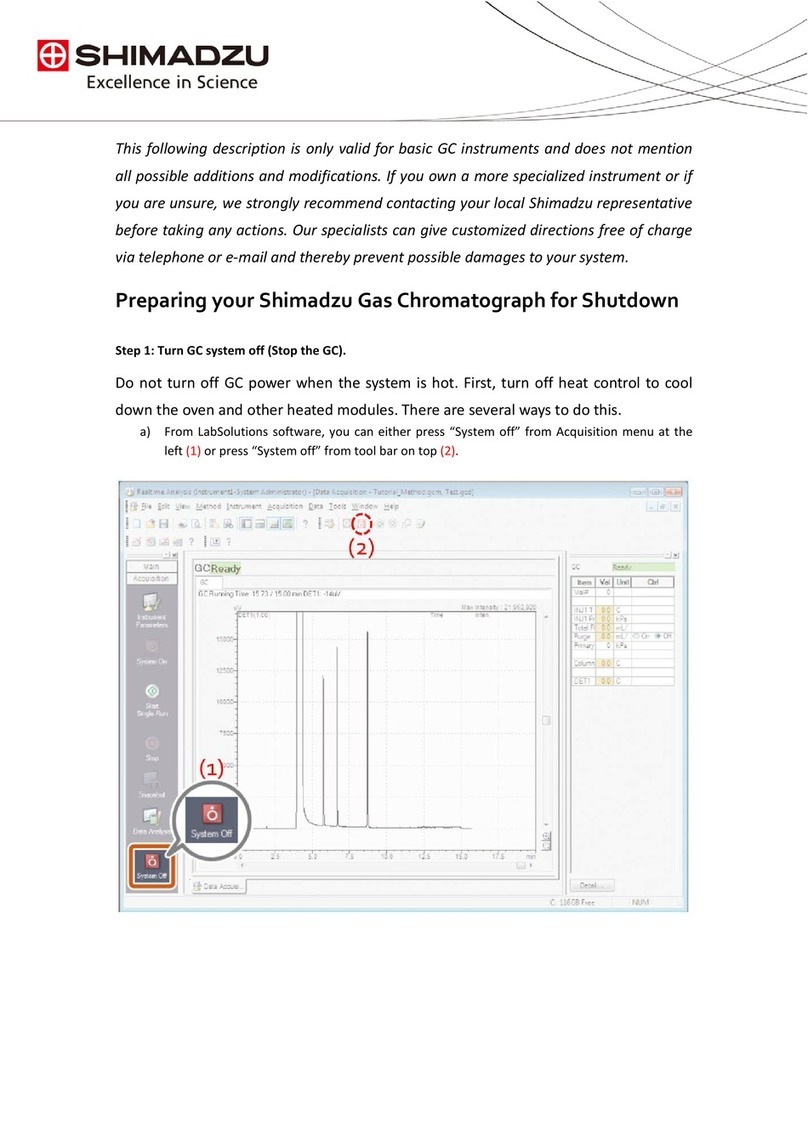

Shimadzu GC User manual

Shimadzu

Shimadzu iMLayer User manual

Shimadzu

Shimadzu Nexera CL Series Parts list manual

Shimadzu

Shimadzu AP W-AD Series User manual

Shimadzu

Shimadzu Nexera CL Series Instruction Manual

Shimadzu

Shimadzu GC-8A Series User manual

Shimadzu

Shimadzu LCMS-8050 User manual

Shimadzu

Shimadzu IonFocus User manual

Shimadzu

Shimadzu GCMS-QP2010 Series User manual

Shimadzu

Shimadzu GC-2014 User manual

Shimadzu

Shimadzu Shim-pack GIST-HP Series User manual

Shimadzu

Shimadzu ICPE-9000 User manual

Shimadzu

Shimadzu GCMS-QP2010 Series User manual

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual