SHINE SPARX SINGLE User manual

SPARX SINGLE INSTRUCTION MANUAL

- English -

2 English

SparX Single

Professional Quality Grinding/Welding Helmet

WARNING Read and Understand All Instructions Before

Using the Equipment.

SAFETY WARNINGS

This helmet can only resist a certain amount of heat. Please do

not place hot electrode holders inside the helmet and please do

not place the helmet near naked ames or hot work surfaces.

Scratched or damaged visors and lenses must always be

replaced if broken, damaged or covered with spatter to the extent

that vision is impaired.

The user should conduct daily regular checks to ensure no

damage is evident. Materials that may get in contact with the

wearers skin could cause Allergic reactions to susceptible

individuals. Eye-protectors against high speed particles worn

over standard ophthalmic spectacles may transmit impacts, thus

creating a hazard to the wearer.

We recommend a use of the helmet and visors for a period of 5

years. The duration of use depends on various factors such as

use, cleaning storage and maintenance.

Please check regularly of the consumable components and

replace if serviceability or visibility is suspected to be affected, and

nally dispose when critical components not offered as spares

are suspected to be damaged or if serviceability is affected.

• This helmet is not suitable for laser welding.

• Never place this helmet on a hot surface.

• This helmet will not protect against explosive devices

or corrosive liquids.

• Do not make any modications to either the lens or

helmet, unless specied in this manual.

• Do not use replacement parts other than those speci

ed in this manual. Unauthorized modications and re

placement parts will void the warranty and expose the

operator to the risk of personal injury.

• Do not immerse the helmet in water.

• Do not use any solvents on the lter screen or helmet

components.

• Storing temperature: -20 °C ~ +85 °C (- 4 °F ~ +185

°F). The helmet should be stored in dry cool and dark

area, when not using it for a long time.

• Clean the lens surface regularly; do not use strong

cleaning solutions. Regularly replace the cracked/

scratched/pitted front lens.

CONTENTS

1. Instructions for use

2. Standards

3. Range of application

4. Preoperation and operation

5. Service and maintenance

6. Replacing the large visor

7. Replacing the outer ip visor

8. Part list and assembly

9. Shade calculation

10. Helmet marking explanation

1. INSTRUCTIONS FOR USE

Information manual for the Sparx Single welder protective helmets

comply with Paragraph 1.4 of Appendix II of the EC Regulations.

Sparx Single helmets offer permanent protection against UV/IR

rays, also face and eye protection from sparks caused by the

welding process.

Do not look directly at the welding rays with unprotected eyes

when the arc strikes. This can cause painful inammation of the

cornea and irreparable damage to the lens of the eye leading to

cataracts.

2. STANDARDS

The SparX single design and manfucaturing process complies

with CE EN175B EN166.

- English -

3English

3. RANGE OF APPLICATION

The Sparx Single is a universal welding cutting and Grinding

face shield. With the ip visor in its upper position, the user can

have the protection of either a clear visor suitable for grinding or

have the protection of a UV/IR shield for cutting or gas welding

depending on the IR rating.

With the ip visor lowered, the user can achieve a potentially high

IR rating up to shade 14.

In welding just prior to striking the arc, the user will have to look

under the ip visor initially to position the welding rod or nozzle.

Providing the main visor is UV/IR rated then the lter protects the

user’s eyes and skin completely against harmful radiation.

The recommended minimum safe working distance from the arc

is 500 mm.

Please note that when adding the upper and lower visor shades

together, the actual shade is one unit less i.e. shade 3 main Visor

and shade 8 ip visor gives a combined protection at shade 10.

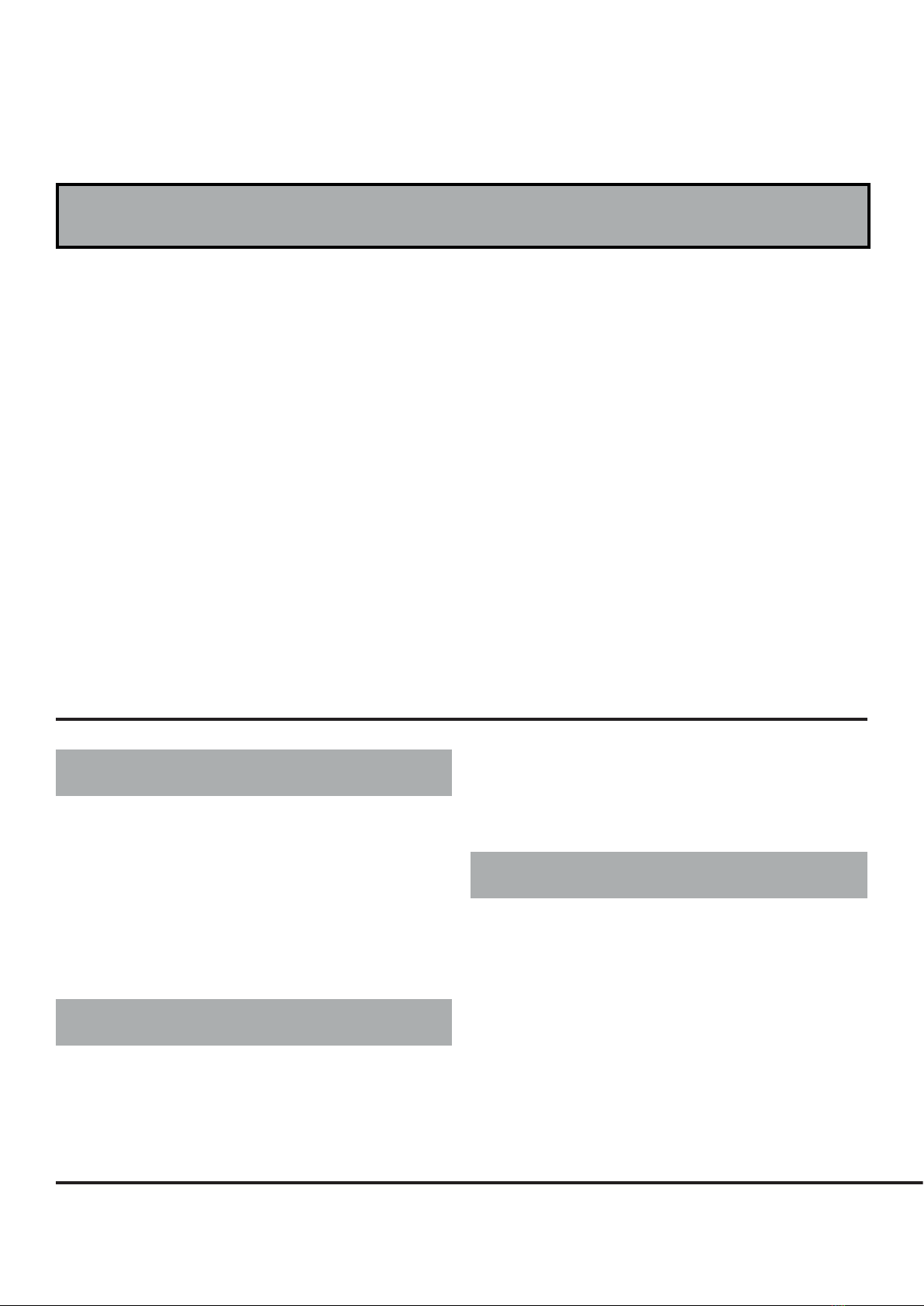

For the recommended lter shades see the chart below.

4. PREOPERATION AND OPERATION

Sparx Single grinding/ welding helmets are fully assembled and

ready to be used after minor adjustments. All welding helmets

are equipped with a comfortable headgear that can be adjusted

in three different ways:

1. Push and move to adjust the “head height”

2. “Rake adjustment” to limit the upper and lower helmet

positioning

3. Push and turn to adjust the “Head Size”

- English -

4 English

Before commencing work please inspect carefully the helmet

and the passive glass for any visible marks, cracks, pitted or

scratched surfaces; damaged surfaces even on protection plates

reduce vision impair protection. If protection plates are scratched,

damaged or built up with spatter please replace.

Welding helmets should not be dropped. Do not place heavy

objects or tools on or inside the helmet as they might damage

the components. If used properly, the welding lter requires no

further maintenance during its lifetime.

5. SERVICE AND MAINTENANCE

Only clean the Sparx Single with mild soap and water. Dry with a

clean cotton cloth.

Please note the use of solvents is strictly prohibited, as they will

damage the mask and lters.

Scratched or damaged visors must always be replaced.

The user must make daily regular checks to ensure that there

is no evident damage. Outer and Inner Visors are consumables

and must be replaced regularly with genuine certied spare parts.

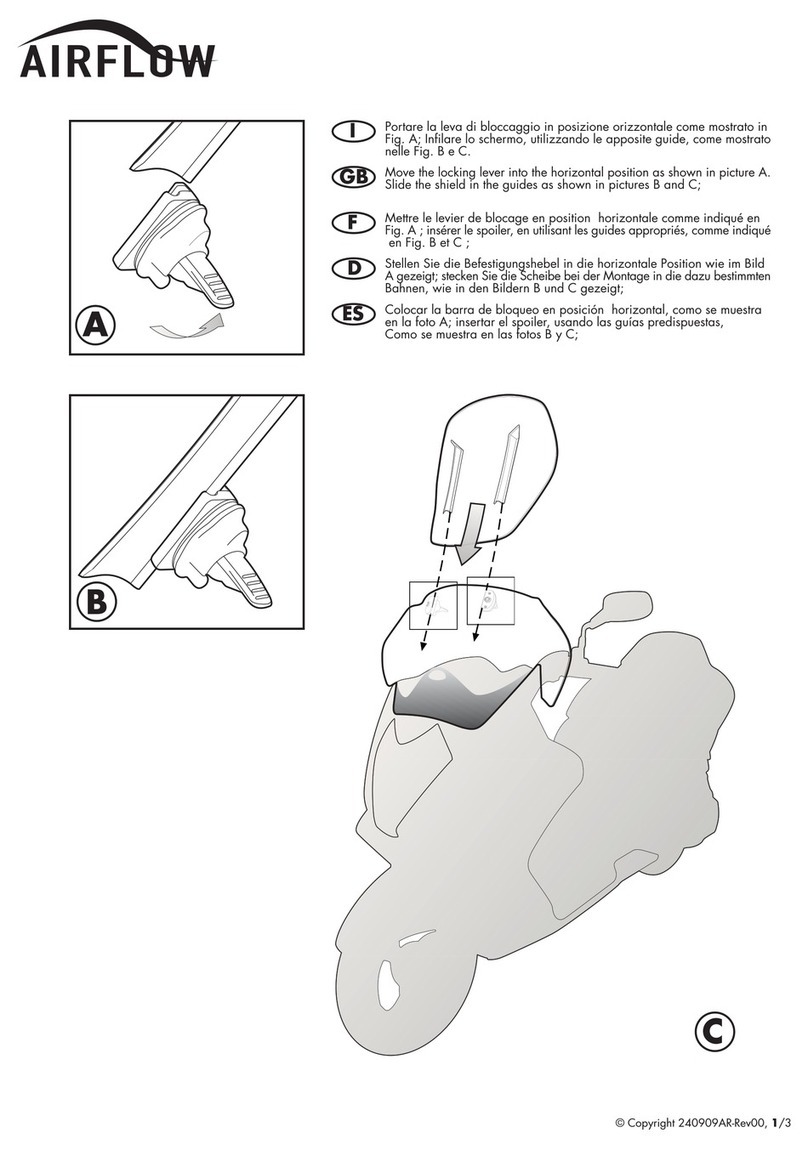

6. REPLACING THE LARGE VISOR

The Large Inner Visor is a protection lens and must be replaced

if broken, damaged or covered with welding spatter to the extent

that vision is impaired.

Push the plugs inside the helmet up, see position 1, the Inner

Visor will be released from the helmet; Then pull the Inner Visor

out, see position 2.

Insert the visor, it is necessary to locate the button into the

corresponding hole in the helmet, then push the plugs inside the

helmet down and lock the visor

The user must always make sure the Visor is tted properly and

is locked well and there are no visible gaps.

See the illustrations.

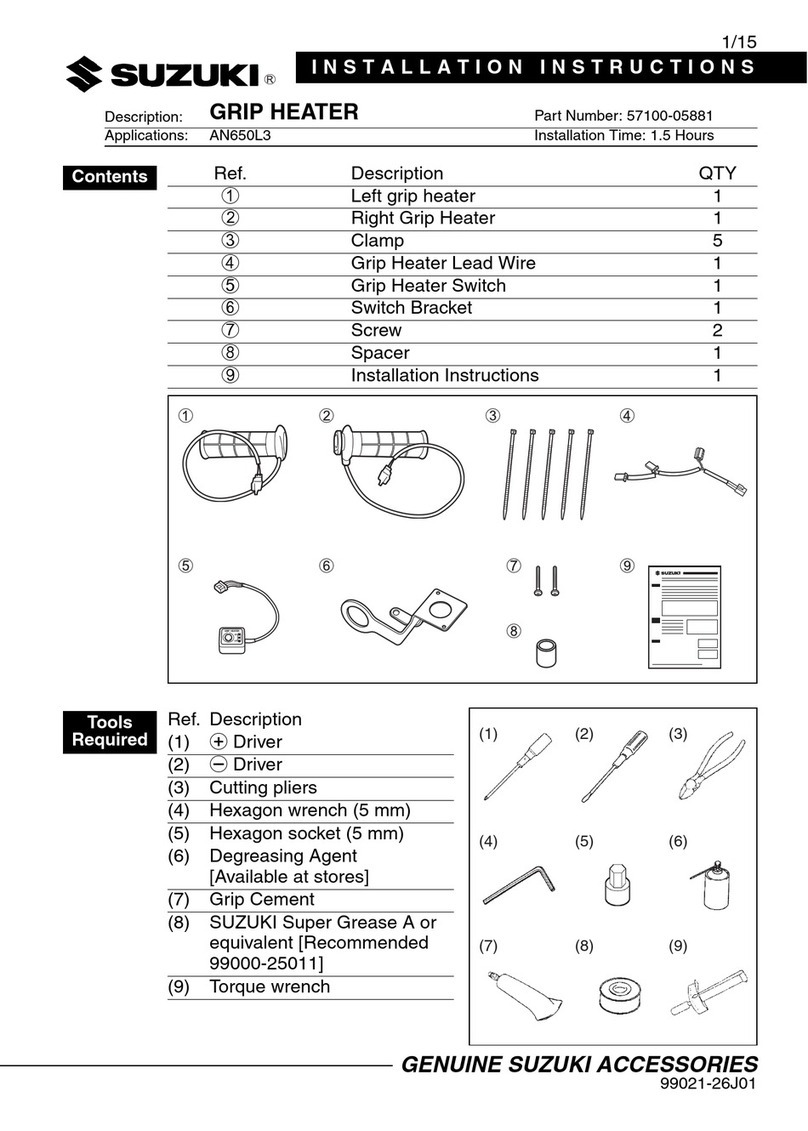

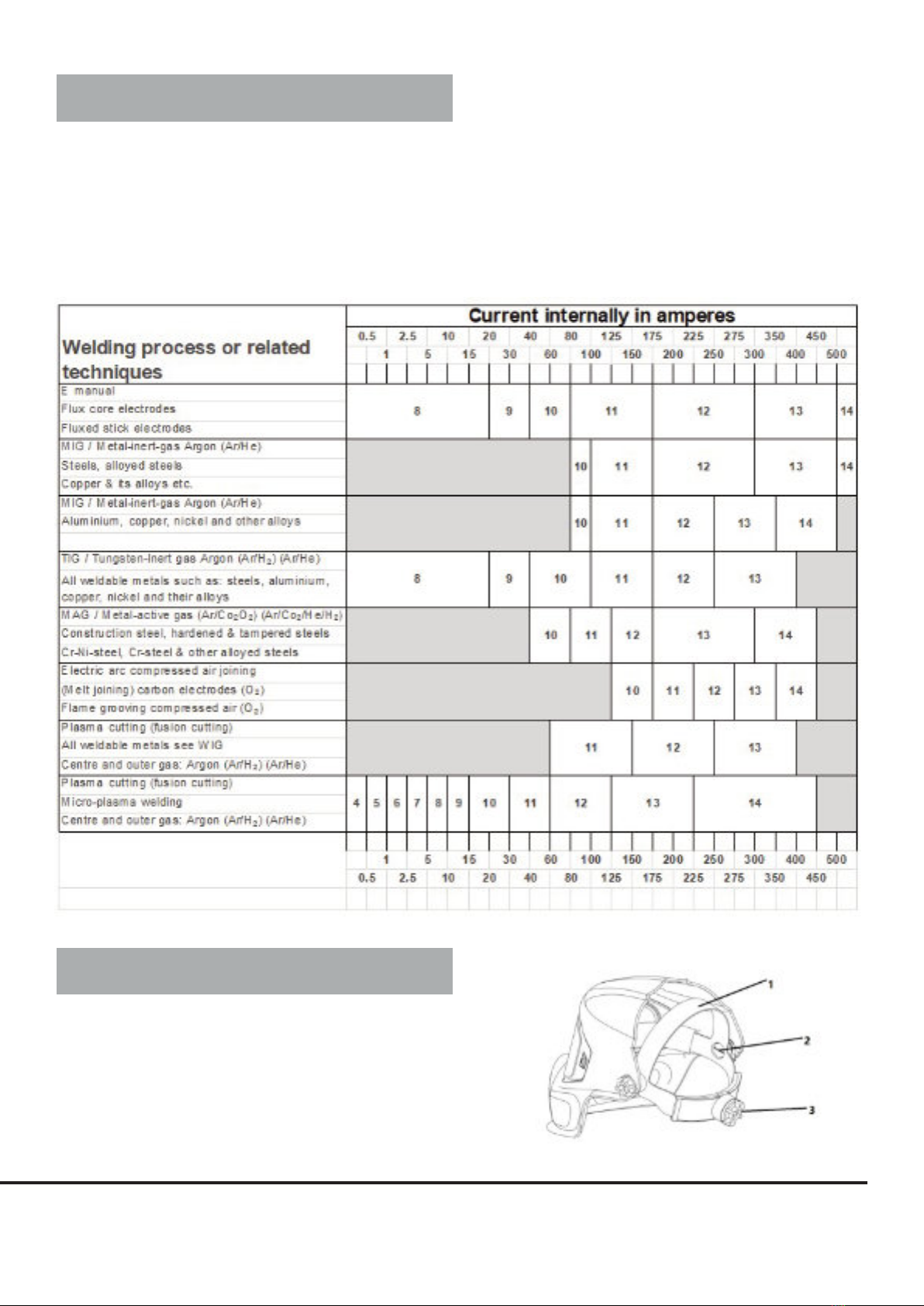

7. REPLACING THE OUTER FLIP VISOR

The Outer ip Visor is a protection lens and must be replaced if

broken, damaged or covered with welding spatter to the extent

that vision is impaired.

The Outer ip Visor is held on a visor holder which is xed on the

shell by two screws. To remove the Visor, loosen the two screws

(No.1), The Visor (No.2) can then be removed.

To replace, change a new visor and t onto the holder (No.3) by

tighten the two screws

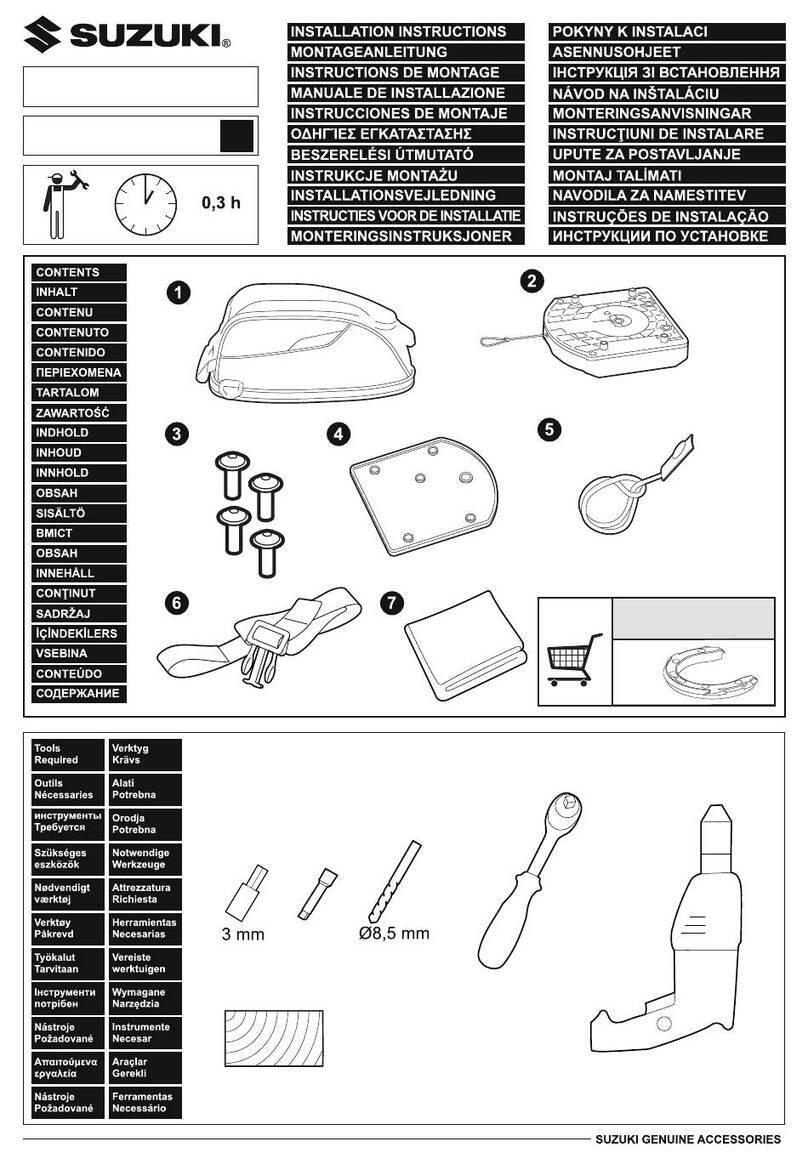

8. PART LIST AND ASSEMBLY

ITEM DESCRIPTION PART NO.

1 Headgear of Sparx Single 13.01.041

2 Sweat band of Headgear of Sparx Single 13.01.042

4 Large Inner Visor Sparx Single DIN 1 (clean) 13.02.411

4 Large Inner Visor Sparx Single DIN 2 13.05.005

4 Large Inner Visor Sparx Single DIN 3 13.05.006

4 Large Inner Visor Sparx Single DIN 5 13.05.007

5 Outer visor holder & screws (ip up clip) 13.05.003

6 Outer Flip Visor Sparx Single DIN 5 13.05.008

6 Outer Flip Visor Sparx Single DIN 8 13.05.009

- English -

5English

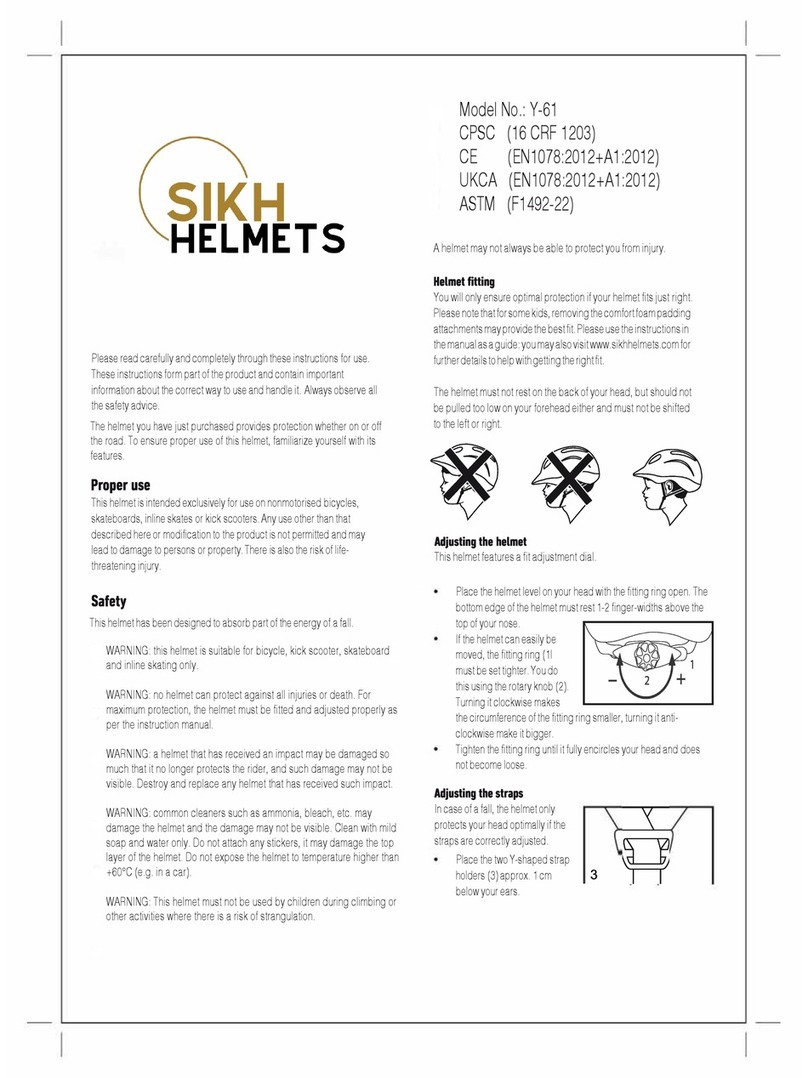

9. SHADE CALCULATION

Sparx Single have various shade options. To calculate the shade

of Sparx Single, plus the inner visor shade with outer visor shade,

then minus 1(inner visor +outer visor-1).

Examples: Shade 9,

Inner Visor: Shade 2

Outer Visor: Shade 8

Total shade of the helmet :(8+2-1) =9

10. HELMET MARKING EXPLANATION

Helmet Marking Explanation:

EN175 B CE - Manufacturer sign

EN175 - Number of Standard

B - Symbol of protection against high speed

particles (120 m/s)

Helmet Visor Marking Explanation:

CSS - Producer

1 - Optical Classication

B - Mechanical strength at 120 m/s

CE - CE conformance mark

ATTENTION if any of these conditions is not kept or

followed, the warranty is automatically invalid.

Other manuals for SPARX SINGLE

1

Table of contents

Other SHINE Motorcycle Accessories manuals