SHINE SPARX SINGLE User manual

SPARX SINGLE AIR INSTRUCTION MANUAL

- English -

2 English

Sparx Single Air

A true winner when it comes to multi-functional disciplines

WARNING Read and Understand All Instructions Before

Using the Equipment.

SAFETY WARNINGS

The respirator system is intended to be used to provide protection when

the user works in the contamination environment. The equipment is able

to lter the contaminated air via the lter build in to the blower and then

supply fresh air from breathing tube to the welding face shield, so that

the user can continue working in the contamination environment. It is

a combined face and breathing protection device for increased safety

and comfort during welding. Please read the instructions carefully

before unpacking. For proper use, see user instructions or contact the

manufacturers for help.

The system complies with the requirements of PPE Regulation 2016/425

and European Standard EN 12941: 1998+A2:2008 class TH3 P R S L.

The respirator system is designed to provide a supply of ltered air via

a breathing tube to a welding headpiece. The equipment can be used in

environments that require a TH3P class breathing protection device. It

protects against particulate contamination.

All components used in the respirator system must be manufacturer

approved parts, and must be used in accordance with the instructions

in this manual.

• The approval is not valid if the product is incorrectly used together

with non-approved parts or components.

• Only the particle lter and pre-lter can be used together with

this system. Filters from other manufactures should under no

circumstances be used.

Failure to follow these warnings and/or failure to follow all of the operating

instructions could result in severe personal injury.

• Before each use, inspect the respirator system for damage and

verify it operates properly. Before using the respirator system, test

air ow to verify it is providing an adequate volume of air.

• Always wear the respirator system and do not remove the head

top or turn off the air lter unit until outside the contaminated area,

otherwise, there is a risk of high concentration of CO2while the

oxygen level in the head top will fall, thus little or no protection is

given.

• If you are not sure about the concentration of pollution, or about

equipment performance, ask the industrial safety engineer.

Warnings:

• The respirator system devices should be used by well trained

personal and qualied persons only.

• Before using the devices, ensure you have understood that at very

high work rates the pressure in the device may become negative at

peak inhalation ow.

• Before and during using the devices, attention shall be drawn to

possible incorrect use and, where appropriate, the possibility of

looped hoses and or cables becoming caught up.

• Before or during using the devices, if the devices are in the power-

off state, little or no respirator protection is to be expected. This is

considered to be an abnormal situation.

• Please leave the work place and remove the headgear when the

devices are in the power off state. A rapid build-up of carbon dioxide

and depletion of oxygen within the hood may occur.

• The lters shall only be tted to the turbo unit and not directly to the

helmet

• The user should not confuse the markings on a lter relating to any

standard other than EN 12941 with the classication of this device

when used with this lter.

Do not:

• DO NOT use the SparX Single Air with the blower unit switched off

• DO NOT use the SparX Single Air in an atmosphere that is

immediately hazardous to user hygiene or health and/or has oxygen

content of less than 19,5% or contains unknown substances

• DO NOT use the SparX Single Air in an explosive atmosphere

• DO NOT use the SparX Single Air in conned spaces or areas of

poor ventilation

• DO NOT use the SparX Single Air in high winds

• DO NOT alter or modify in any way

• DO NOT touch any of the moving parts

• DO NOT allow water or other liquids to enter the impeller chamber,

the lter or battery compartment

The manufacturer is not responsible for injury due to the incorrect

use or incorrect choice of equipment.

Notied Body: Vyzkumny ustav bezpecnosti prace, v. v. i., Jeruzalemska 9, 116 52

PRAHA 1, Country: Czech Republic (Notied body number 1024).

CONTENTS

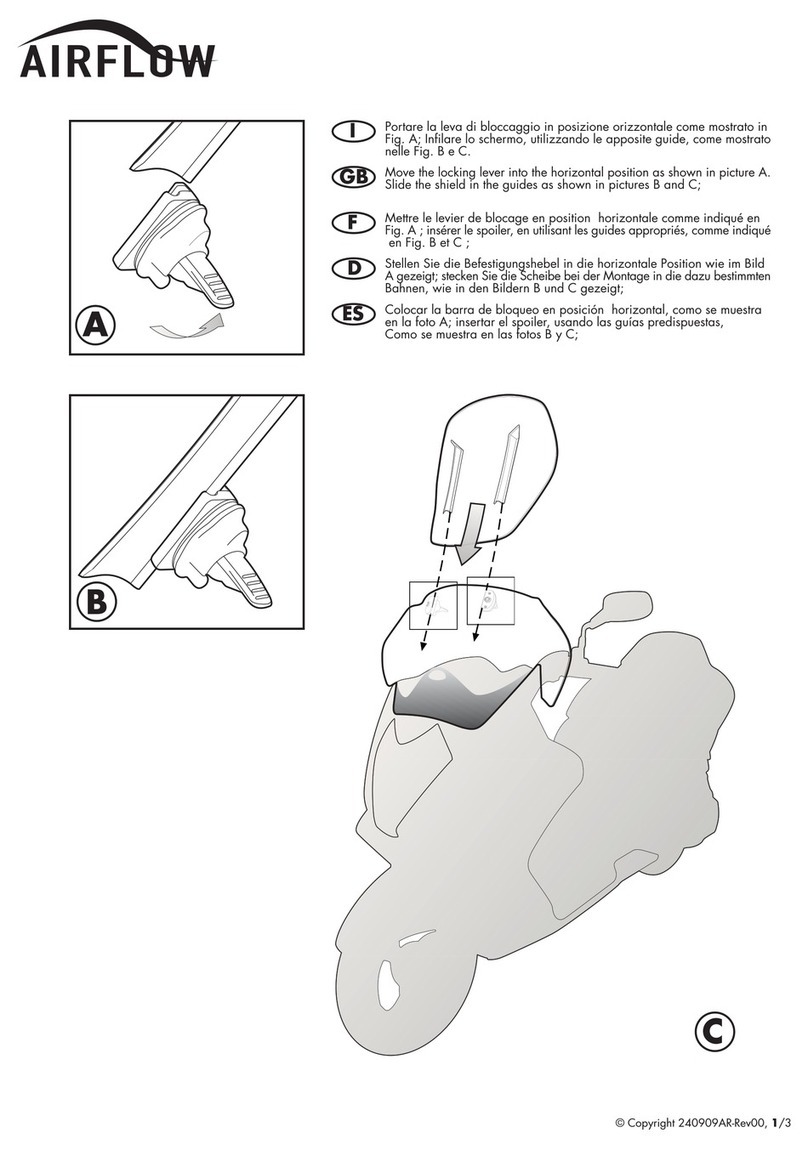

1. Unpacking and assembly

2. Filter replacement

3. Installing the battery and charging

4. Connecting the tube

5. Fitting

6. LCD

7. Maintenance and storage

8. Warranty

9. Installing the respirator system on the belt

10. Air ow and alarm test

11. Operation

12. Trouble shooting

13. Specication

14. Marking explanation

15. Parts list

- English -

3English

1. UNPACKING AND ASSEMBLY

While unpacking and assembling

• Check whether the correct number of components has been

supplied as in gure 1.

• Check that the apparatus is complete, undamaged and

correctly assembled

Any damaged or defective parts must be replaced before use.

The package must include:

1. The SparX Single Air helmet

2. The respirator protection system (turbo unit + lter + waist

belt)

3. Lithium-ion battery

4. The tube, its anti-re cloth and both end ttings

5. The shoulder harness

6. The air ow tester

7. The lithium-ion battery charger

8. The carrying bag

If any of the above components are not included in your kit,

please contact the supplier immediately.

2. FILTER REPLACEMENT

The pre-lter and lter expected lifetime is 12 months. When

under intensive use, check the lter cleanliness periodically

and if needed, change them more often than every 12

months.

- English -

4 English

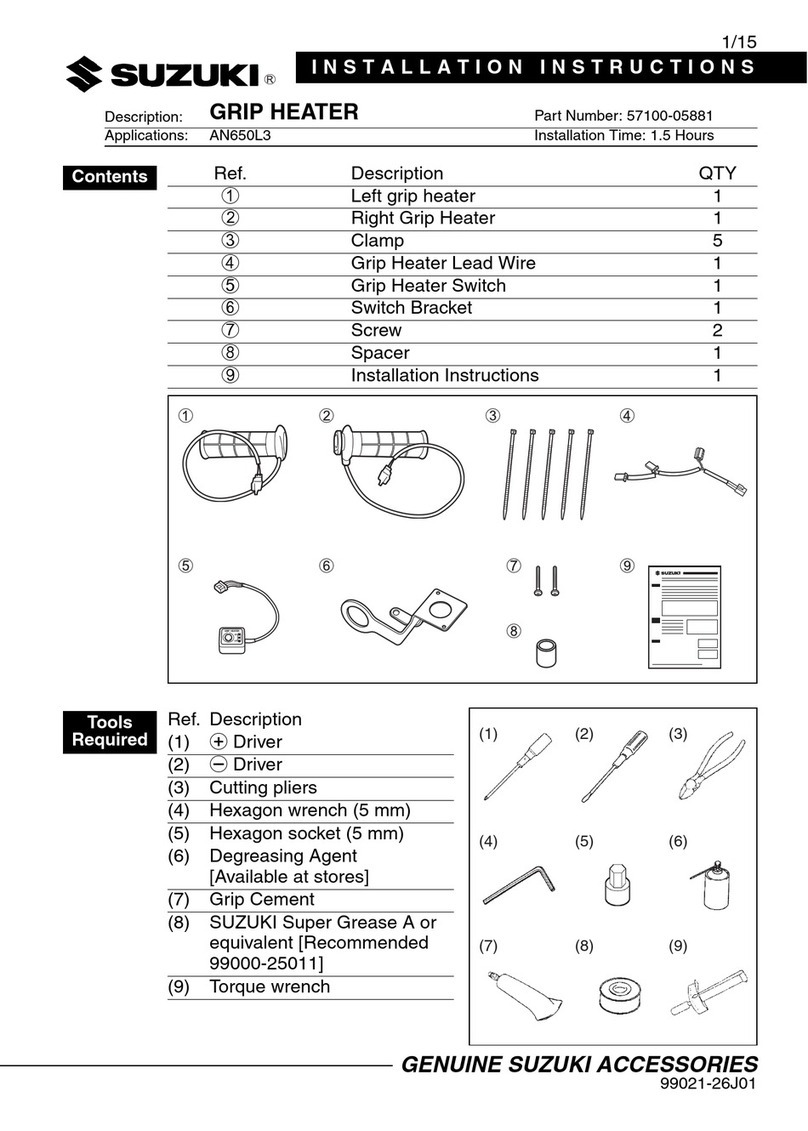

3. INSTALLING BATTERY & CHARGING

Battery indication:

• The battery is partially charged when delivered. It must be

charged to 100% (4 bars) before the rst use.

• It is recommended to charge the batteries to 100% before

each use

Charger:

• The charger must not be used for anything else than it was

designed for.

• Do not charge the battery in a potentially explosive area.

• The charger must only be used indoors

Battery storage:

• The battery will discharge itself after long storage periods

• Always charge the battery if the device was stored for more

than 15 days.

• When the battery is new or has been stored for more than 3

months, charge it and discharge it at least twice in a row to

reach the nominal/rated charge capacity

Battery charge:

1. Connect the battery to the charger. The connector is above

the battery.

2. Connect the charger to the mains.

3. The state of charge is displayed via a red LED on the mains

charger

4. Once the charge is nished, the oating charge becomes

active: the red LED switches off and a green LED switches

on.

5. Disconnect the charger from the mains

DO NOT keep the charger plugged to the mains if it’s not in use.

4. CONNECTING THE TUBE

Check that the respirator tube is strongly connected. If the tube

is broken, replace it.

- English -

5English

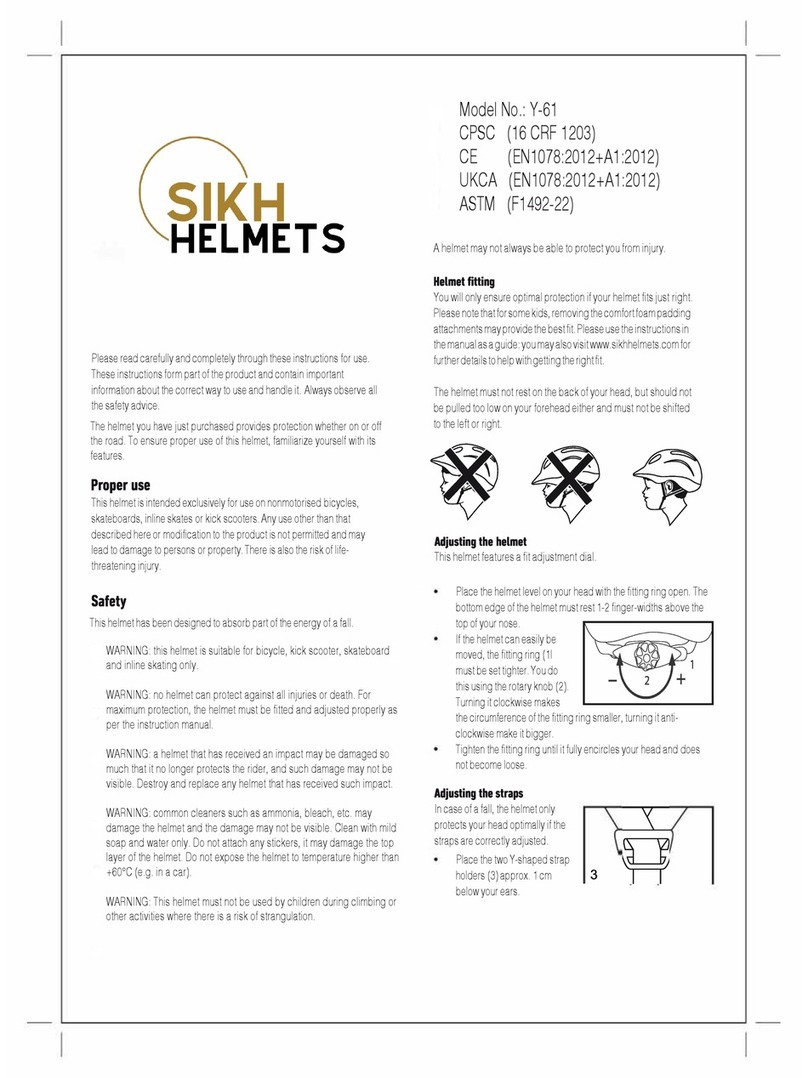

5. FITTING

Make sure the face seal is positioned properly, otherwise you can

not get sufcient sealing needed to offer the correct protection

factor.

6. LCD

LCD DISPLAY SCREEN

There is a LCD display screen on the SparX Single Air unit to

show the SparX Single Air working condition.

1. Shows the data of current air ow

2. Shows the level of the airow

3. Shows the lter condition

4. Shows the battery

5. Shows the temperature of the battery

Any of them will ash if there are SparX Single Air disfunctions.

7. MAINTENANCE AND STORAGE

Inspect the equipment daily and always check it if any sign of

malfunction occurs.

MAINTENANCE

• The respirator system unit must be checked regularly and

must be changed if it is damaged and causes leakage.

• The lter must be changed if it is broken, or it is blocked and

does not give enough airow.

• The breathing tube must be changed if it is broken or has

crevasse.

• The batteyr must be charged when the low battery alarm

rings.

• Use a soft cloth to wipe the external surfaces. DO NOT use

water.

• The lter should be replaced together with the pre-lter.

STORAGE

• The respirator system must be stored in a dry, clean area,

in the temperature range of -10 °C to +55 °C and relative

humidity less than 90%RH.

• If the equipment is stored at temperature below 0 °C, the

battery must be allowed to warm up to achieve full battery

capacity. The equipment must be protected from dust,

particles and other contamination.

• If the equipment is not going to be used for a long time,

the battery should be fully charged, removed from respirator

system unit and stored separately.

• Transport the equipment with original packaging box and

keep away from direct sunlight.

8. WARRANTY

• The SparX Single Air blower unit is guaranteed for a period

of 12 months from date of purchase against mechanical or

electrical defects.

• The SparX Single Air battery is guaranteed for a period of 6

months from the date of purchase.

The company undertakes to exchange or repair without charge,

any part found to be defective within this period alternatively and

at its discretion. The company may replace.

This guarantee is subject to:

• The SparX Single Air unit has been used solely for the

purpose for which it is intended.

• The SparX Single Air unit has not been subject to misuse,

accident, modication or repair.

In the event of a claim, contact the retailer from which the SparX

Single Air was purchased.

This guarantee does not cover normal wear and tear.

- English -

6 English

9. INSTALLING ON THE BELT

Make sure the belt is securely fastened.

- English -

7English

10. AIR FLOW AND ALARM TEST

AIR FLOW TEST

The airow must be tested before using.

If the marble can’t reach the minimum ow level, do not use the

system. Change the lter or the battery and retest the air ow. MUST TEST

AIR FLOW ALARM TEST

If the alarm does not work, please repair or change respirator system.

- English -

8 English

11. OPERATION

• The respirator system will turn off the turbo unit if the OFF button is pressed for more than 3 seconds.

• The respirator system will cut off the entire circuit and switch to sleep mode if the turbo unit has turned off for more than 30

minutes. Pressing the ON button can activate the system.

• The respirator system must be operated in the temperature range of -5°C to +55°C and relative humidity less than 90%RH.

12. TROUBLE SHOOTING

Problem Probable cause Action

• Motor is stuck

• Motor is damaged

• Blower structure

failure caused by

outer force

• Circuit failure

Check and remove

physical failure and

restart the system.

Return to dealer if

LCD still shows E01

• Motor is damaged

• Motor impeller rubs

blower shell

• Circuit has ecessive

current

Check and remove

physical failure and

restart hte system.

Return to dealer if

LCD still shows E02

• Low battery Change the battery

• Filter blocked

• Tube blocked

• Remove

obstruction

and/or change

the lter

• Clean the tube

• Battery high

temperature

Stop working and

rest

No air ow, no

alarm

• No power

• Battery contact

damaged

Charge the battery

and check battery

contact

Battery run time is

too short

• Battery is not fully

charged

• Filter is blocked

• Battery is damaged

• Charge the

battery

• Remove

obstruction

and/or change

the lter

• Change the

battery

Air supply to hood

smells unusual

• Filter is broken

• Tube is broken

• ADF helmet is

broken

Leave current area

immediately

•Change lter

• Change tube

• Change ADF

helmet

Supply insufcient

air to helmet

• Breathing tube

broken off

• Breathing tube

broken

• Filter is blocked

• Check the tube

connection

to hood and

respirator

system unit

• Change

breathing tube

• Remove

obstruction,

change lter

- English -

9English

13. SPECIFICATION

Size (blower assembly) 9-2/5 x 6-1/2 x 2-3/4 in. (240 x 165 x 70 mm)

Weight 2.4 KG

Particle Filter 1*TH3 P R SL

Air Flow Manufacturer minimum design ow rate: 165 L/Min

Nominal airow:

• Level 1: 170 L/Min

• Level 2: 200 L/Min

• Level 3: 230 L/Min

Noise level Max 75dB

Operate Temperature 23℉ to 131℉ (-5°C ~ 55°C)

Storage Temperature 14℉ to 131℉ (-10°C ~ 55°C)

Battery Type 1. Standard Battery Rechargeable Li-ION 4400mAh

2. Heavy duty Rechargeable Li-ION 6800mAh

Expected Battery

Operation Time

Battery Charging Time

Standard Battery Heavy-Duty Battery (Optional)

• Level 1 > 10h • Level 1 > 15h

• Level 2 > 8h • Level 2 > 12h

• Level 3 > 6h • Level 3 > 10h

3.5 Hours 5 Hours

Battery Life 500 Charges

Run Time Dependent On Air Flow Rate and Filter Load.

LCD Display Air ow level and data

Battery capacity

Filter status

Belt Size 35-2/5 x 51-2/5 in. (900mm x 1300mm)

14. MARKING EXPLANATION

Powered ltering device

• EN 12941:1998 respirator protective decies – Powered lter devices incorporating a helmet or hood – requirements, testing,

marking.

• TH3 P R (SL) classication of the unit. “TH3” denes the level of protection “P R” indicates the lter type (“P” = particle lter, “R”

= Reusable type of particle lters) and “SL” reects the lter has been tested against particles of liquid and solid matter.

Warning sound indicator

• The SparX Single Air PAPR has sound and vibration alarm function. Each grid stands for a period of 100ms. Grey is the beep

sound and blank grid is a quiet period. If several continued grids are in grey hen there’s a continuous beep sound. For example,

when the current is overloaded, the system sounds like beep~beep~beep~~~~~.

- English -

10 English

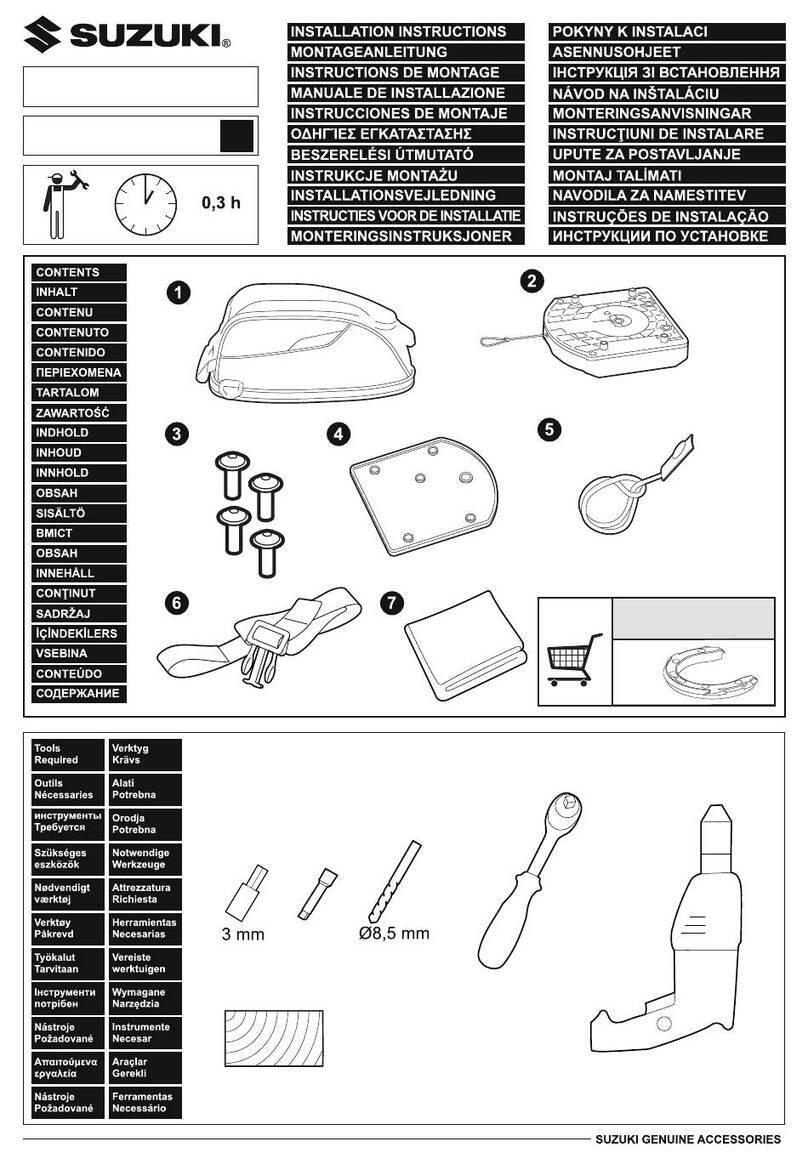

15. PARTS LIST

ATTENTION if any of these conditions is not kept or

followed, the warranty is automatically invalid.

Drawing

No.

Part No. Description

1 13.02.410 SparX Single

prepared for air

helmet

2 13.02.412 SparX Single Air

Face Seal

3 13.02.111 Airduct with

headgear

4 13.02.411 Inner visor clear

lens

5 13.01.043 Lock sliders

6 13.03.101 Filter cover

7 13.03.104 Spark Arrestor

8 13.03.103 Pre-lter

9 13.03.102 P3 level lter

10 13.03.118 Turbo unit

11 & 12 13.03.108 Waist belt +

shoulder strap

13 13.03.111 Carrying bag

14 & 15 13.03.107 Breathing tube

hose and cover

16 13.03.106 Rechargeable

battery

13.03.114 Heavy duty

battery

17 13.03.110 Battery charger

18 13.03.109 Air Flow Tester

Other manuals for SPARX SINGLE

1

Table of contents

Other SHINE Motorcycle Accessories manuals