Index

-

-

F

FK

K-

-1

15

52

2R

R

T

Tr

ra

an

ns

sd

du

uc

ce

er

r

I

In

ns

st

tr

ru

uc

ct

ti

io

on

n

M

Ma

an

nu

ua

al

l

-

-

3

▊Index ▊

Page

Important notice ................................................................................................................1

Exclusion from liability ......................................................................................................2

Confirmation of the unit and package items ......................................................................2

Chapter 1 Safety Information.........................................................................................................5

1.1 Warning Symbols.......................................................................................................5

1.2 Cautions when handling.............................................................................................5

Chapter 2 Introduction...................................................................................................................7

2.1 Objectives of this unit.................................................................................................7

2.2 Measurement principles.............................................................................................7

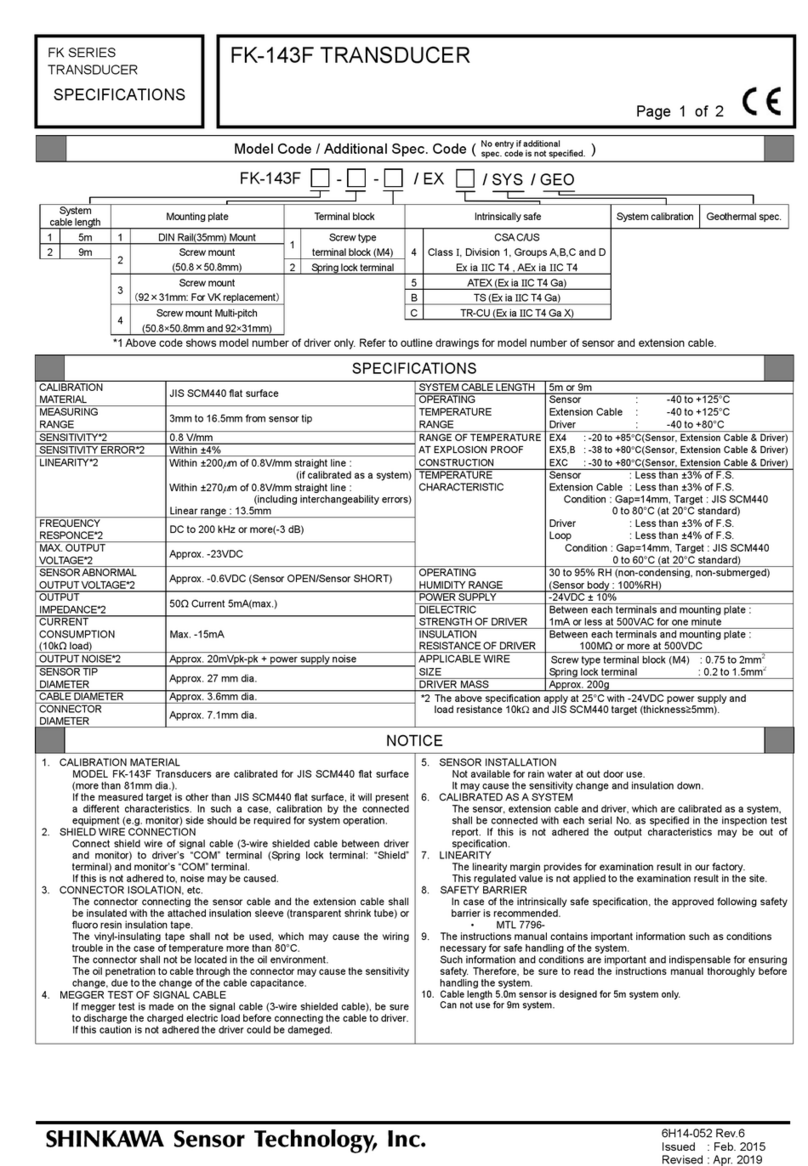

2.3 Specifications.............................................................................................................8

2.3.1 Specifications of this unit..............................................................................8

2.3.2 FL sensor specifications...............................................................................9

2.3.3 FW extension cable specifications.............................................................10

2.3.4 FK driver specifications..............................................................................10

2.3.5 Additional Specification code.....................................................................10

2.3.6 Recommended specifications for the monitor cable..................................11

2.4 Outer dimensions and part nomenclature ...............................................................12

2.4.1 FL sensor outer dimensions and part nomenclature.................................12

2.4.2 FW extension cable outer dimensions and part nomenclature.................13

2.4.3 FK driver (Spring lock terminal) outer dimensions and

part nomenclature......................................................................................14

2.4.4 FK driver (Screw type terminal block (M4)) outer dimensions and part

nomenclature..............................................................................................16

2.5 System configuration example.................................................................................18

Chapter 3 Installation...................................................................................................................19

3.1 Installation environment...........................................................................................20

3.1.1 FK driver installation environment..............................................................20

3.1.2 FL sensor installation environment............................................................21

3.2 FK driver installation ................................................................................................23

3.2.1 Installation of FK-152R□-2-□, FK-152R□-3-□, and FK-152R□-4-□...23

3.2.2 Installation of FK-152R□-1-□...................................................................24

3.3 FL sensor installation...............................................................................................25

3.3.1 When using the VZ-3A bracket (separately sold)......................................25

3.3.2 When using the VZ-10A sensor sleeve (separately sold)..........................26

3.3.3 Gap adjustment..........................................................................................27

3.4 Wiring connections...................................................................................................28

3.4.1 FW extension cable connection (When using the FW extension cable)...29

3.4.2 FL sensor connection.................................................................................30

3.4.3 FK driver (Spring lock terminal) and Monitor (VM monitor) connection....30