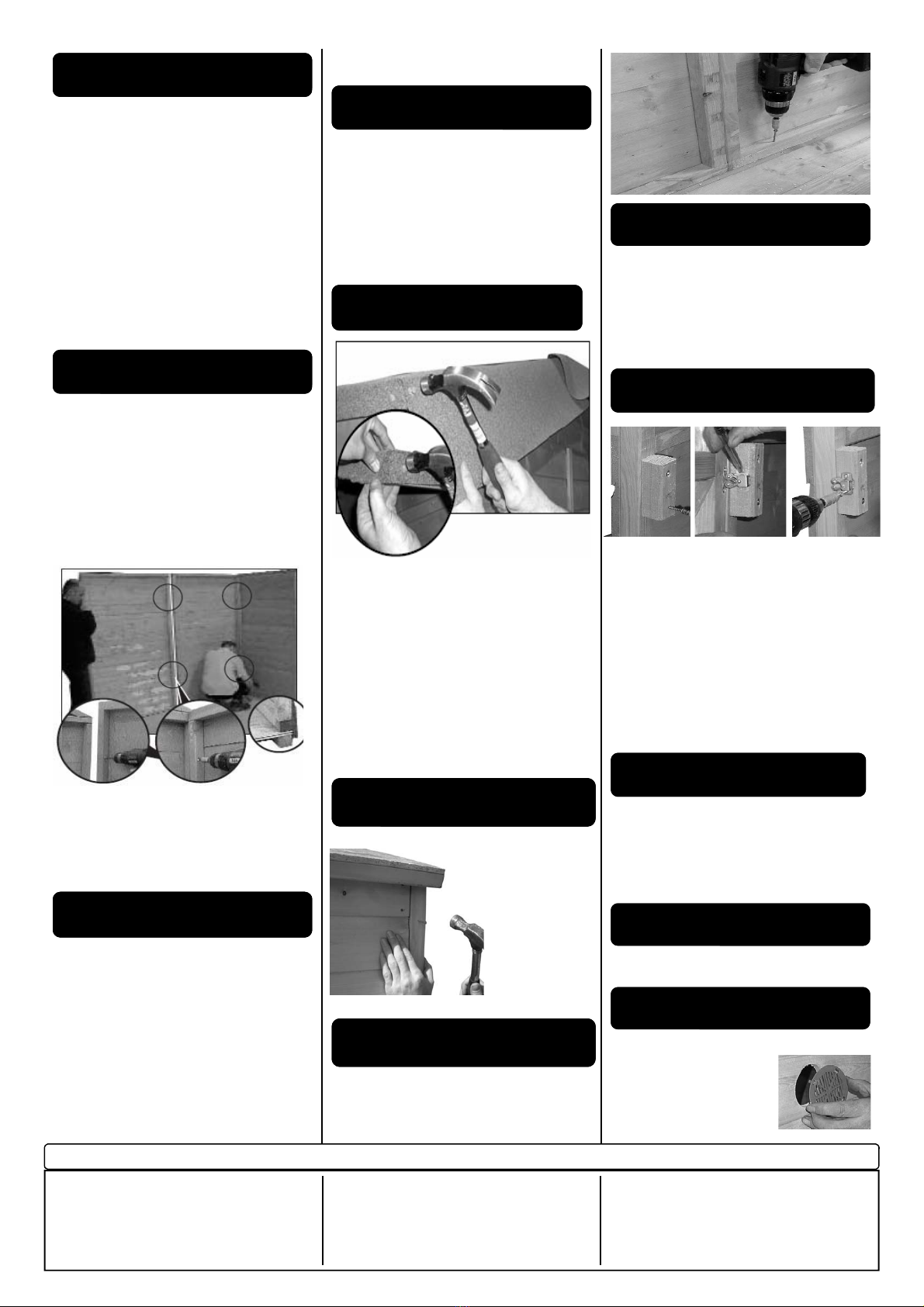

1. Fit the ring handle to the door inline with the

centre door framework using 4 x 25 mm black

screws.

2. Fit the false hinges to the outside of the door

at the top and bottom. Each is to fit as far as

possible onto the framework at the back of the

door. Secure using 2 x 25 mm black screws and

along the length of each hinge 2 x 10 mm black

screws per hinge.

3. Lay front panel on a flat clean surface. Re-

move protective film from door glazing and lay

over the diamond shape cut out in the door.

Position the four angled and rebated door bead-

ing on top of the glazing and secure using 8 x 20

mm screws, 2 per piece.

Remove all travel protection blocks from bottom

edge of panels.

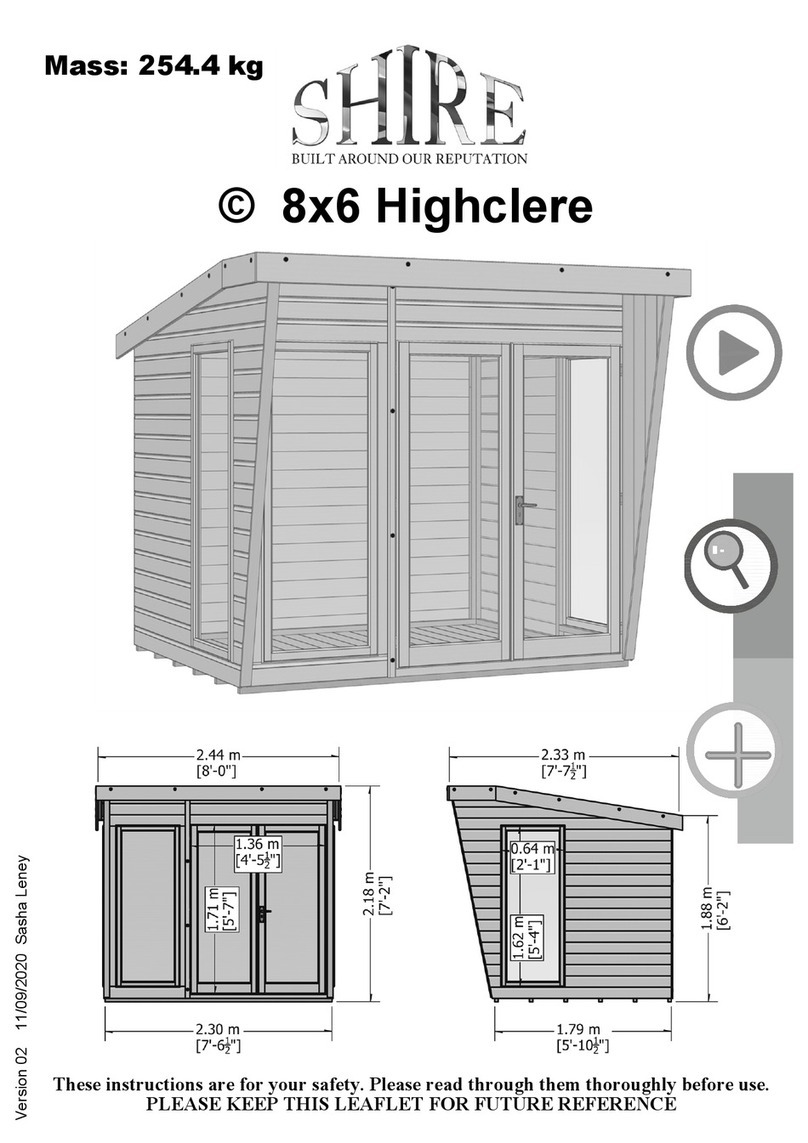

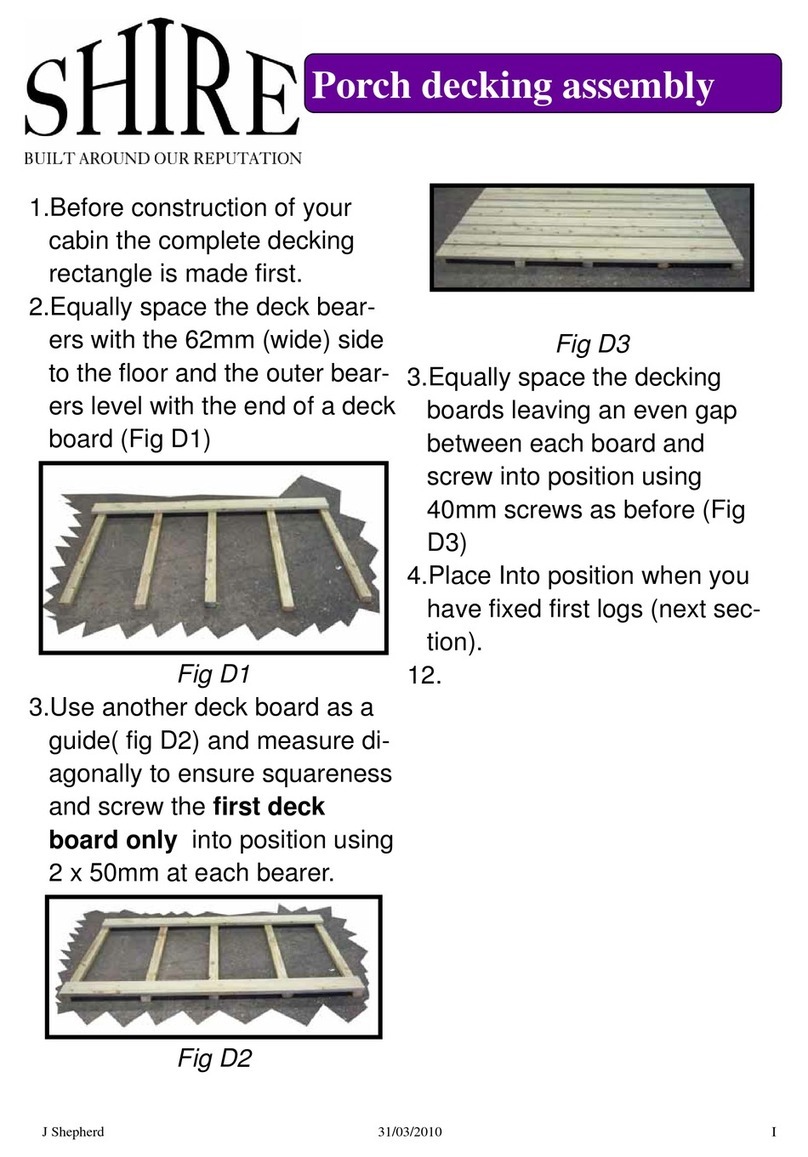

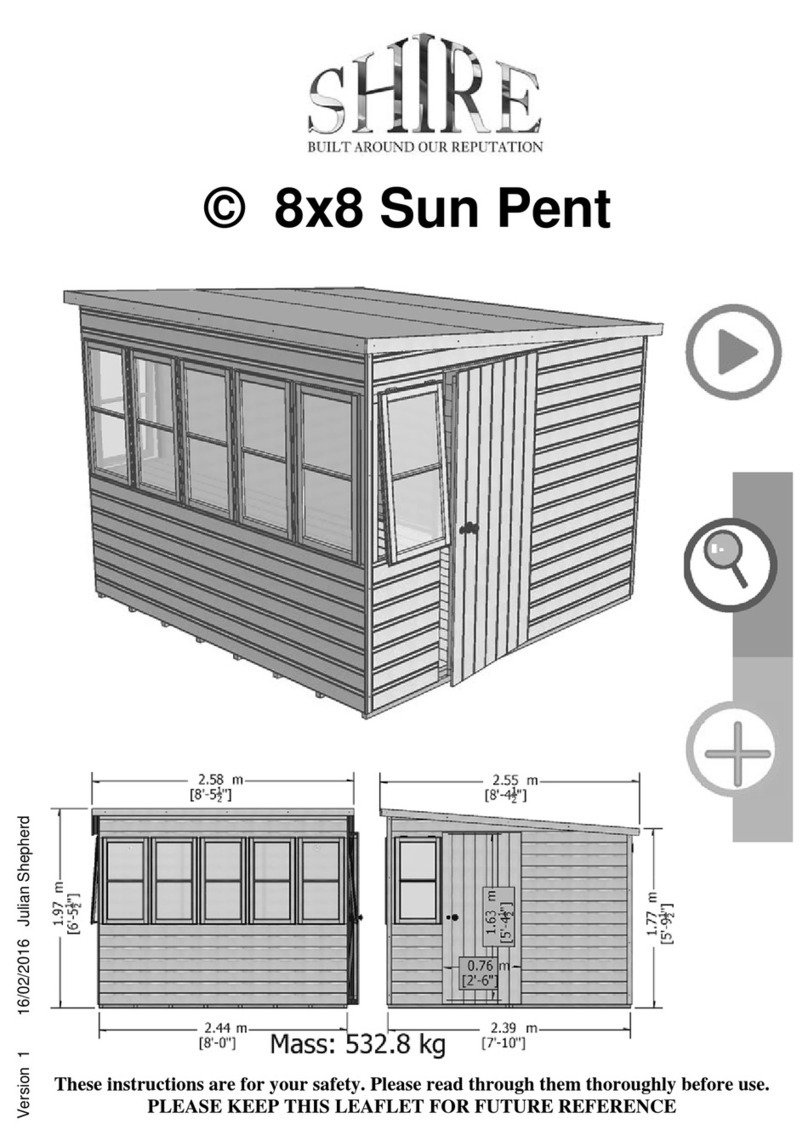

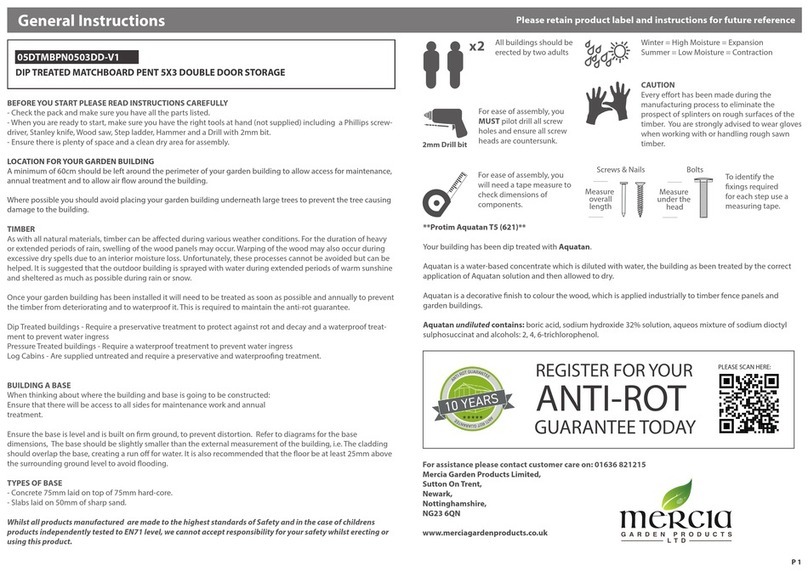

1. Ensure that your base is firm and absolutely

level.

2. Lay floor of building on base ensuring the

solid framework is at the front of the building.

3. Place back panel onto the floor ensuring the

cladding has overhung the floor. Place side

panel next to this and join together from the

inside using 2 x 60 mm screws.

4. Place remaining side panel in position. Join

together from the inside using 2 x 60 mm

screws.

5. The front door panel is now ready to be

placed. Join to side panels using 2 x 60 mm

screws each side.

1. Slide one roof panel into position using the

cut-out of the ridge as a guide. Repeat for the

other panel.

Please note that a small amount of planning may

be necessary to the tops of the walls to ensure a

snug fit.

2. Drill then screw roof sections together at the

ridge using 4 x 60 mm screws.

3. Secure down from the inside using 2 x 60 mm

screws per wall, fixing from the framework of

roof to framework of the gable walls.

4. Fix along the length of the building using 2 x

60 mm screws per side.

1. Trim uprights of balustrade as required.

2. Place balustrade in position. Secure upright

post of balustrade to roof panel from the inside

using 1 x 60 mm screw. Secure balustrade to

front panel using 2 ‘L’ shaped brackets and 25

mm screws, one at the top and one at the

bottom. Repeat for other side.

3. Secure balustrade to floor using 2 x 60 mm

screws, one per side.

1. Open roll of felt and lay out on an even

surface. Measure and cut the required 3 lengths

allowing an overhang of approx 50 mm on all

sides. Starting at the lower edge (the eaves)

place one piece of felt along the length of the

building. Secure the felt using felt nails spaced

at 100 mm intervals. Repeat for other side, but

do not nail along centre of building until the

piece of felt covering the ridge is in place.

2. Place the last piece of felt at the ridge of the

building. This piece will overlap both of the other

pieces of felt. Nail into position along both edges

of this piece and at both ends.

1. Fix the corner

strips in position

where the panels

meet using 3 x 40

mm nails per strip.

1, Secure wall panels to the floor on the inside of

the building through framework into floor bearers

using 2 x 60 mm screws per panel.

1, Nail the 4 fascia boards to gable ends using 3

x 40 mm nails per piece.

2. Trim of any excess felt with cutting knife

against the edge of the fascia board.

3. Nail diamonds on top of and in the centre of

the fascia board using 2 x 40 mm nails per

diamond.

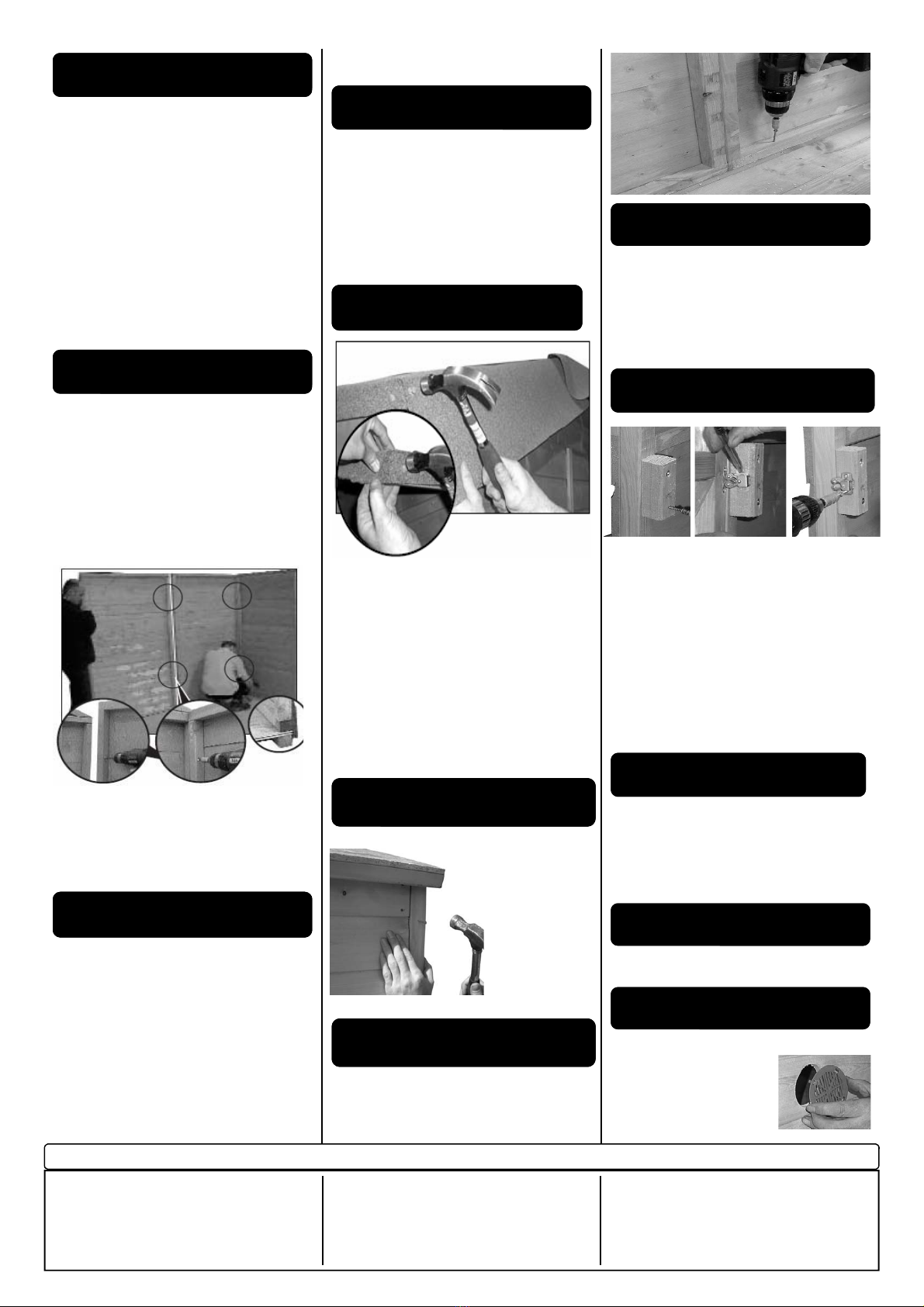

1. Drill 2 holes into the wood block and

secure to inside of door opening flush with

aperture using 2 x 60 mm screws.

2. Secure door catch to inside of door approx.

centrally alongside of the wood block and

secure using 2 x 25 mm screws.

3. Close the door and attach the door catch

together and mark the required position of the

door catch housing. Secure using 2 x 25 mm

screws.

1. Place glazing material into the aperture of

each window.

2. Hold into position with four pieces of beading.

Secure into position using 2 x 15 mm panel pins

per piece of beading. Repeat for all window

apertures.

1. Secure shutters to the building from the inside

using 2 x 25 mm screws per shutter.

1. Secure the window boxes to the building from

the inside using 2 x 25 mm

screws per box.

VENT - push fit vents into the

apertures of back panel.

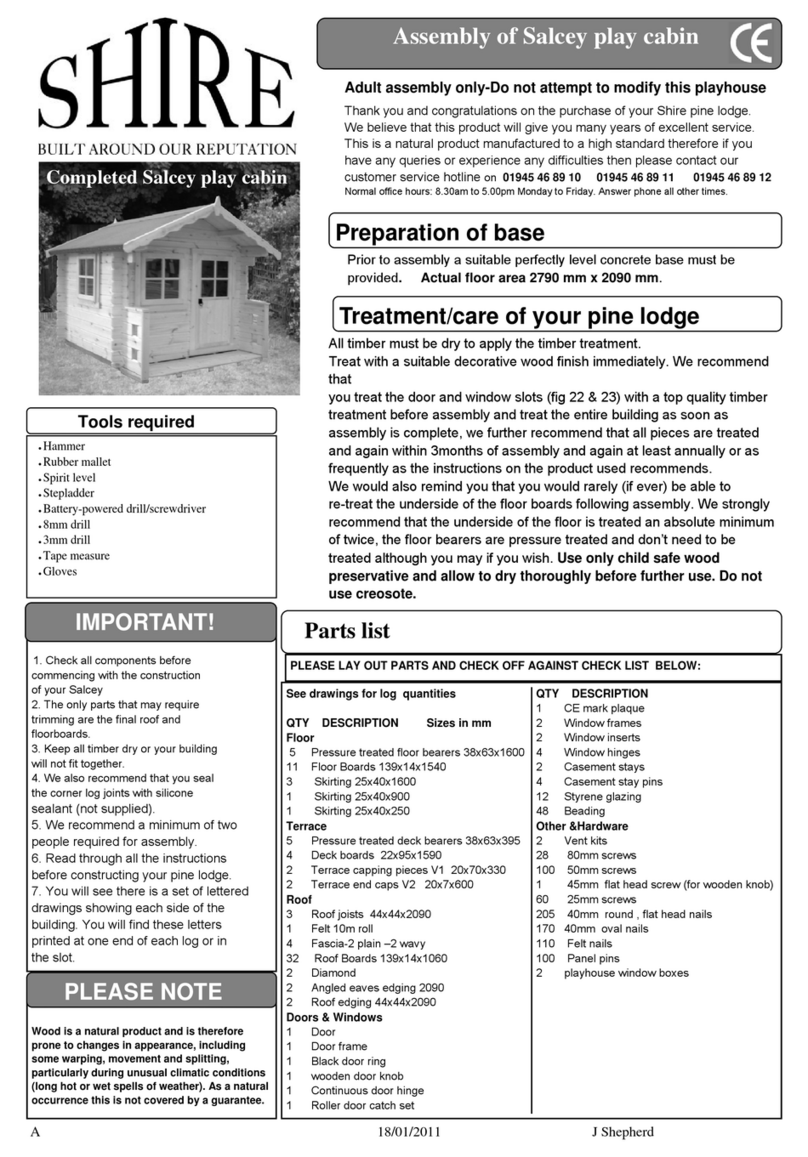

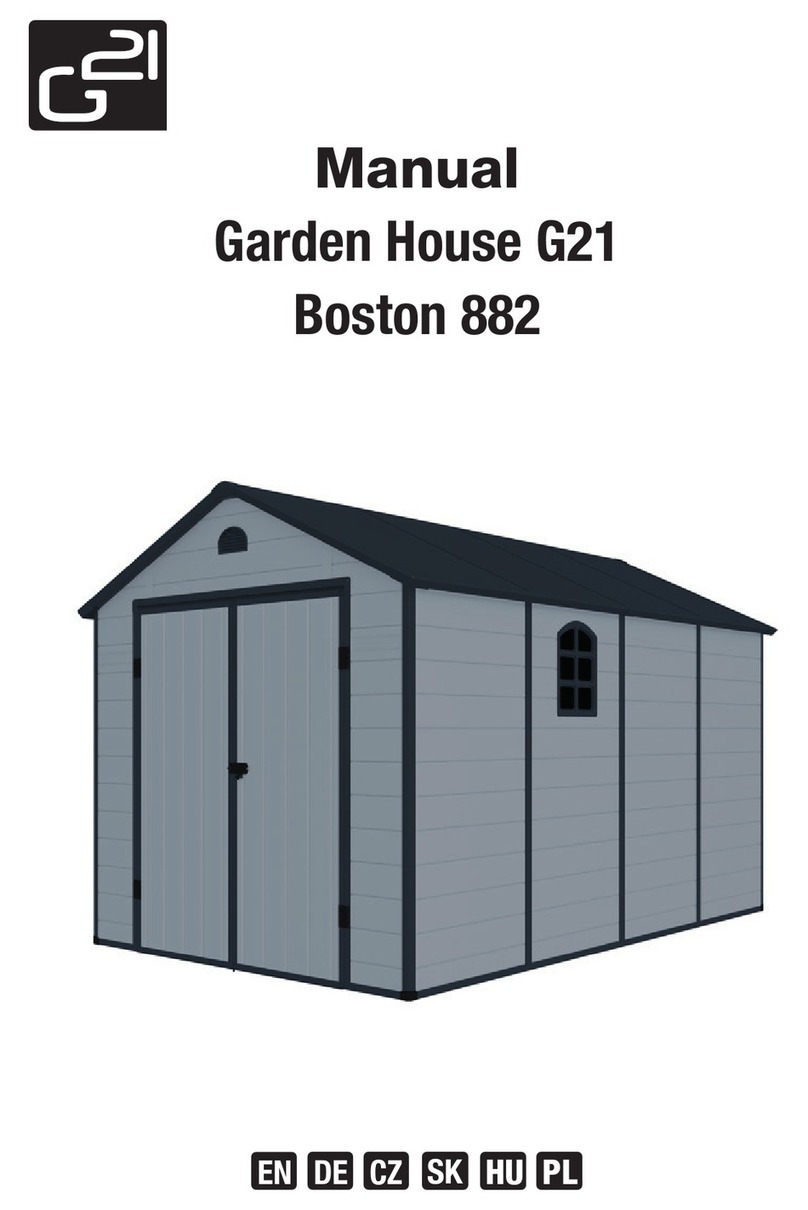

A Front Panel

B Walls

C Roof Assembly

D Balustrade

E Felt Roof

F Corner strips

G Secure Walls to Floor

H Fascia & Diamonds

I Door Catch

J Glazing

K Shutters

LWindow Boxes

Assembly Completion Checklist

1Check and ensure that no raised grain or splinters

are evident on timber components. Sand down any

raised grain or splinters using fine grade sandpaper.

2Check that all screw, nail and pin heads are properly

tapped home and are not proud of the timber surface.

3Check and ensure that no screws, nails or pins

protrude through any panel.

4 Check and ensure that all parts are properly secured

against reasonable force.

5Do not apply decorative wood finish/treatments to wet

or damp timber. Please observe the instructions of

the wood finish/treatment manufacturer.

6 Adults need to check the playhouse regularly and

maintain the playhouse in good condition to provide a

safe environment. Do not use if damaged. If damaged

the playhouse should be properly and safely repaired

before further use by children.