J Shepherd 05/04/2011 A

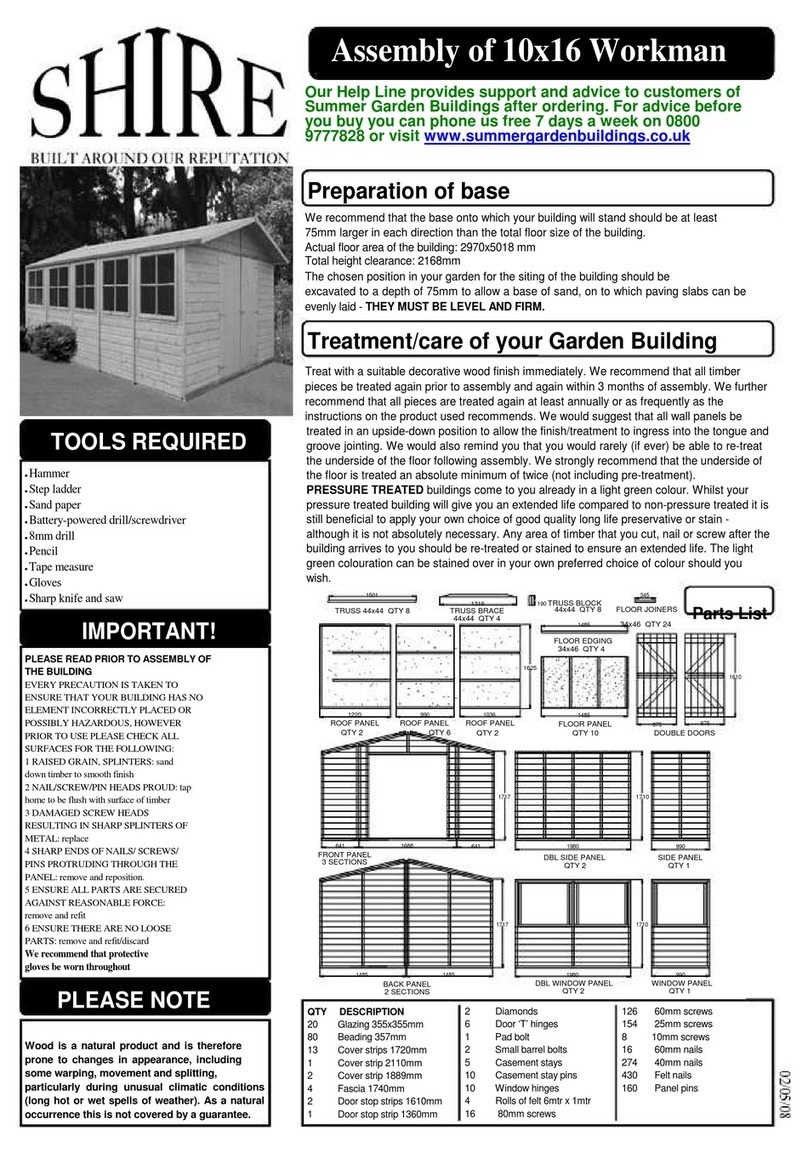

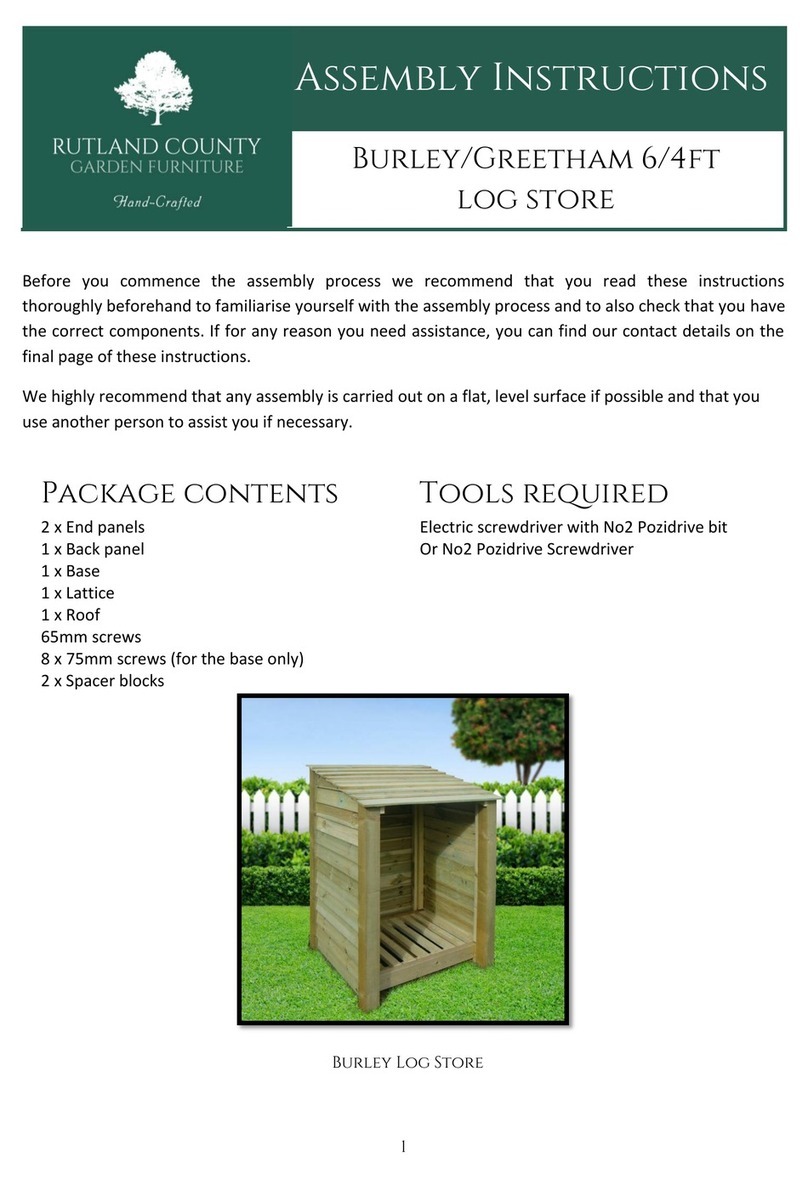

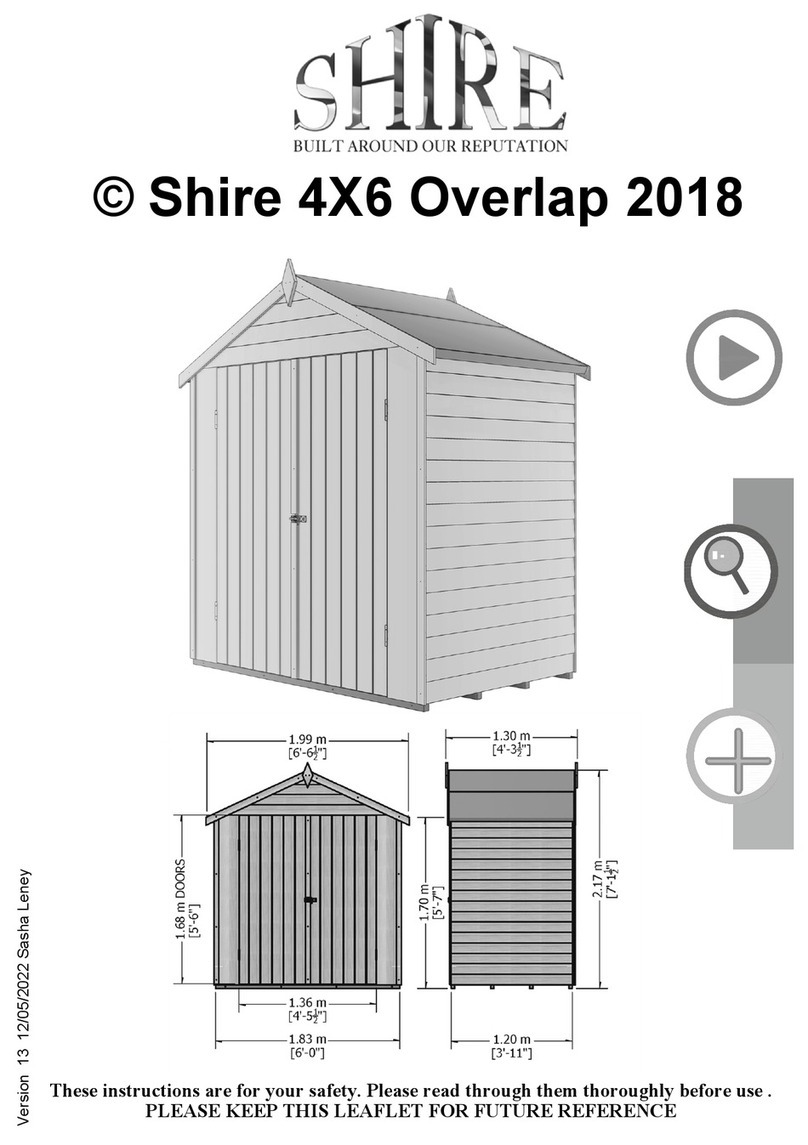

1. Check all components before

commencing with the construction

of your Elveden

2. Keep all timber dry or your building

will not fit together.

3. We also recommend that you seal

the corner log joints with silicone

sealant (not supplied).

4. We recommend a minimum of two

people required for assembly.

5. Read through all the instructions

before constructing your pine lodge.

6. You will see there is a set of lettered

drawings showing each side of the

building. You will find these letters

printed at one end of each log or in

the slot.

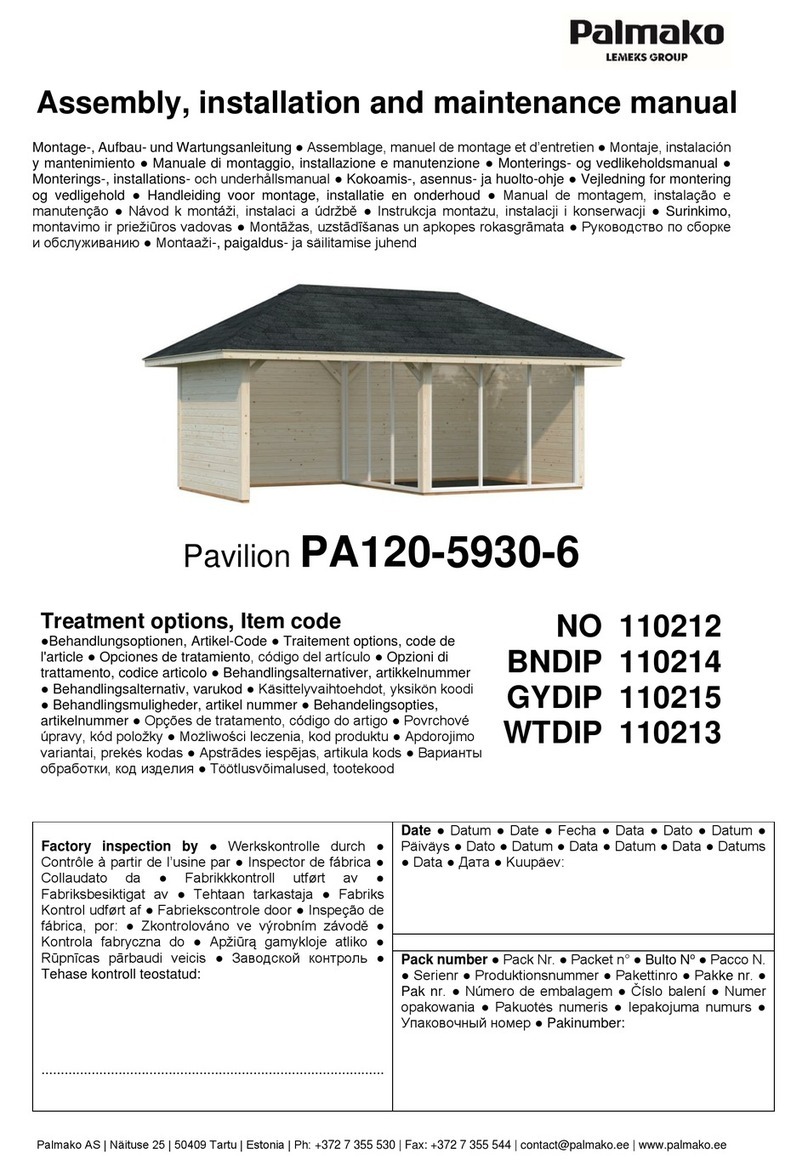

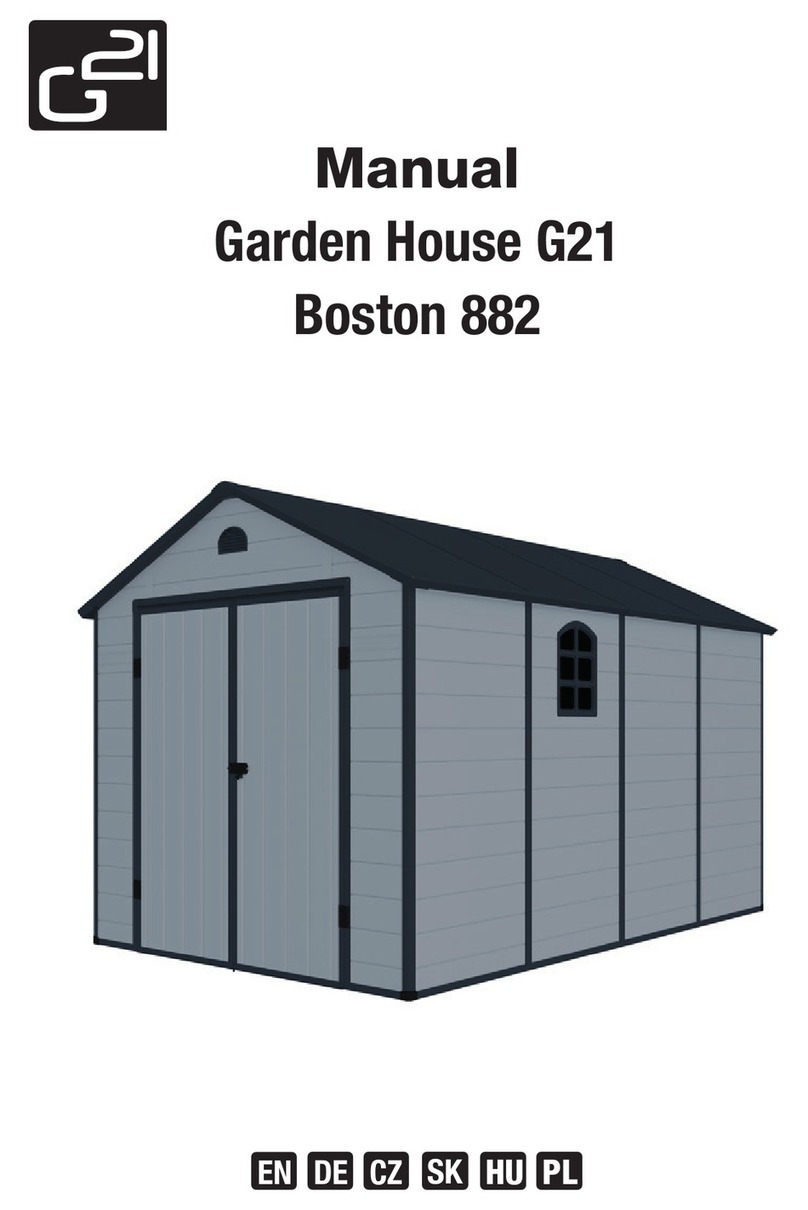

Assembly of Elveden 44mm log ©

Tools required

IMPORTANT!

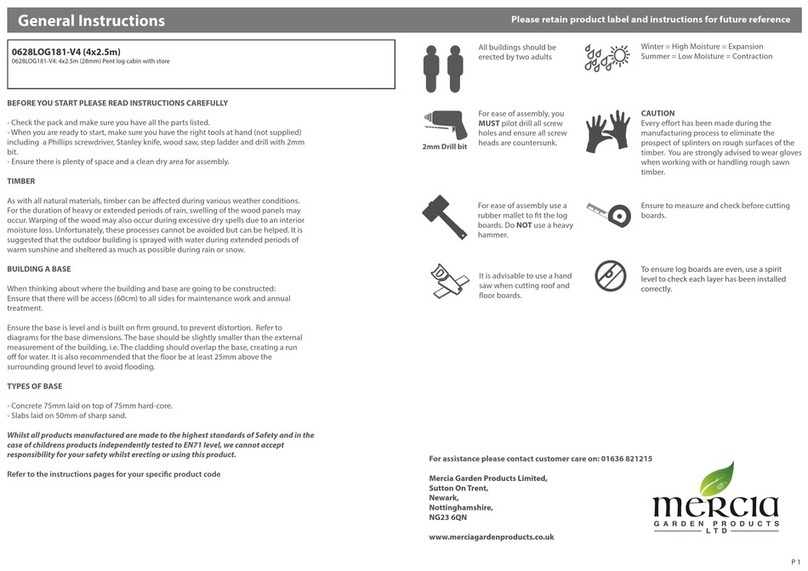

Wood is a natural product and is therefore

prone to changes in appearance, including

some warping, movement and splitting,

particularly during unusual climatic conditions

(long hot or wet spells of weather). As a natural

occurrence this is not covered by a guarantee.

PLEASE NOTE

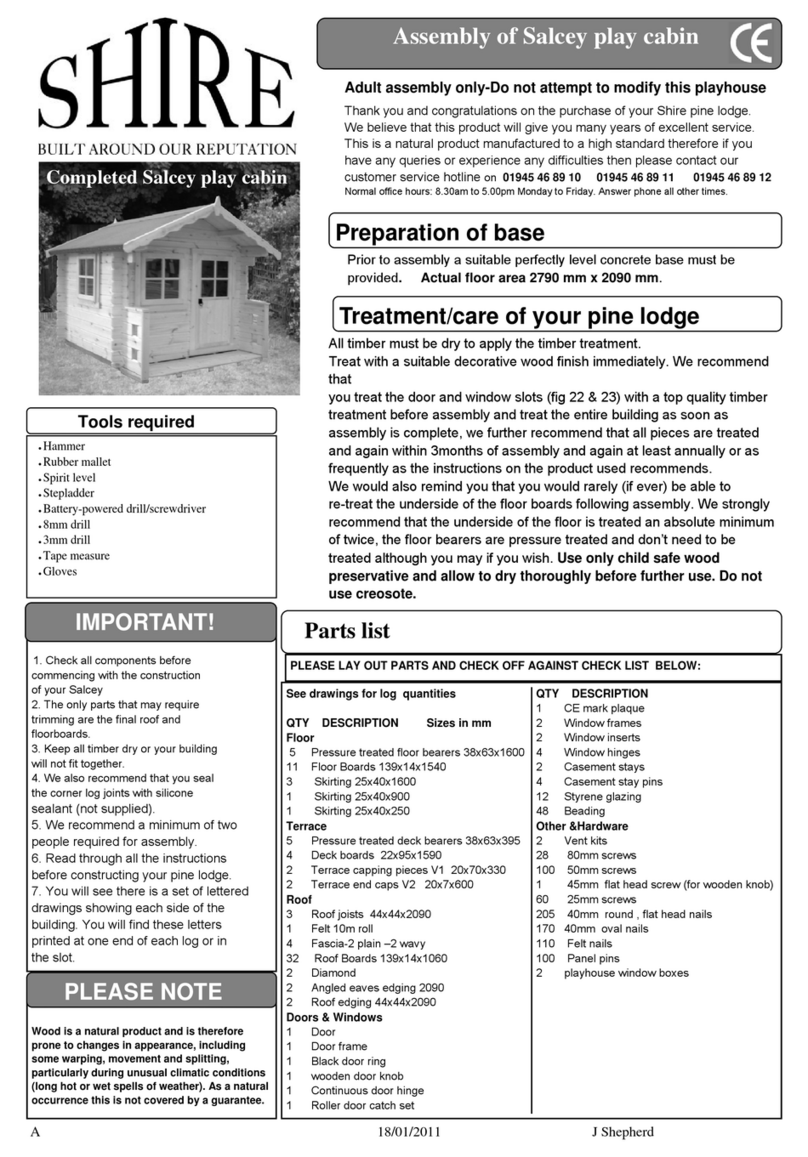

Completed Elveden

IMPORTANT!

The only parts that require cutting are the angled eaves edgings , final roof and floor boards and the skirting.

DO NOT CUT ANYTHING ELSE

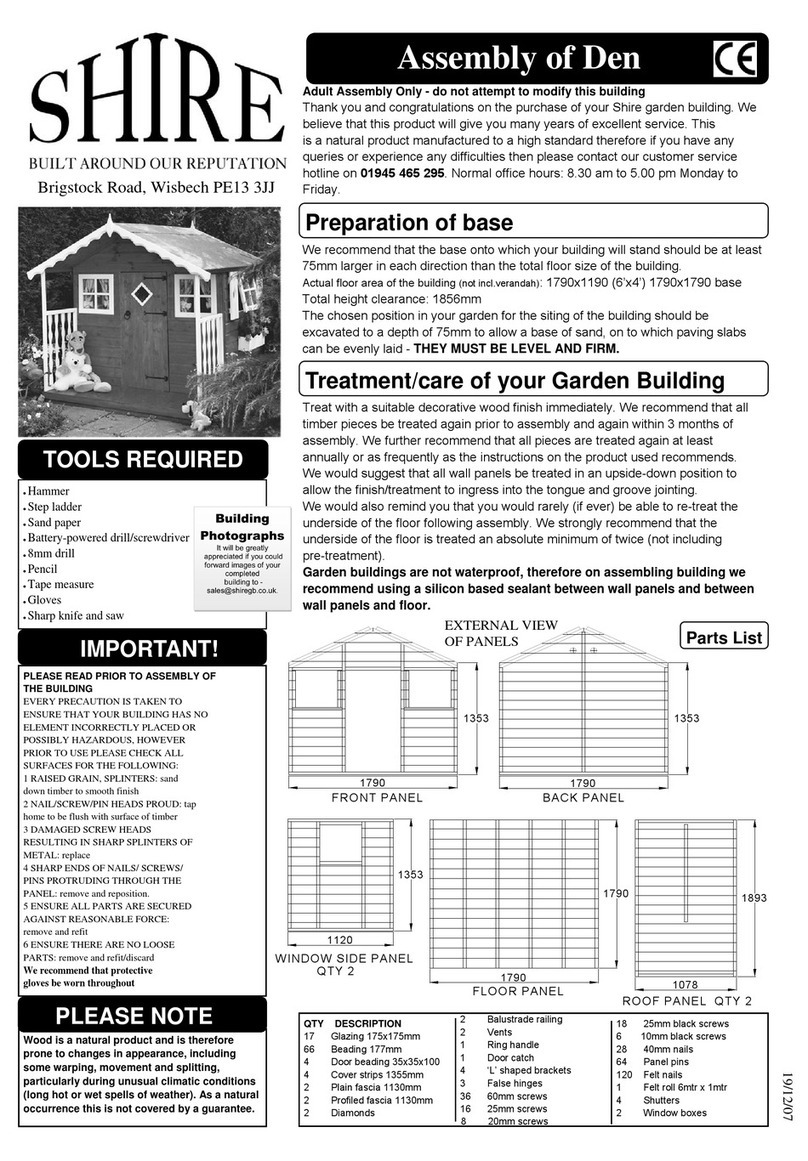

●Hammer

●Rubber mallet

●Spirit level

●Stepladder

●Battery-powered drill/screwdriver

●8mm drill

●3mm drill

●Tape measure

●Gloves

●Sharp knife and saw

●string●

Preparation of base

Thank you and congratulations on the purchase of your Shire pine lodge.

We believe that this product will give you many years of excellent service. This is

a natural product manufactured to a high standard therefore if you have any

queries or experience any difficulties then please contact our customer service

hotline on—

01945 46 89 10 01945 46 89 11 01945 46 89 12

Normal office hours: 8.30am to 5.00pm Monday to Friday.

Answer phone all other times.

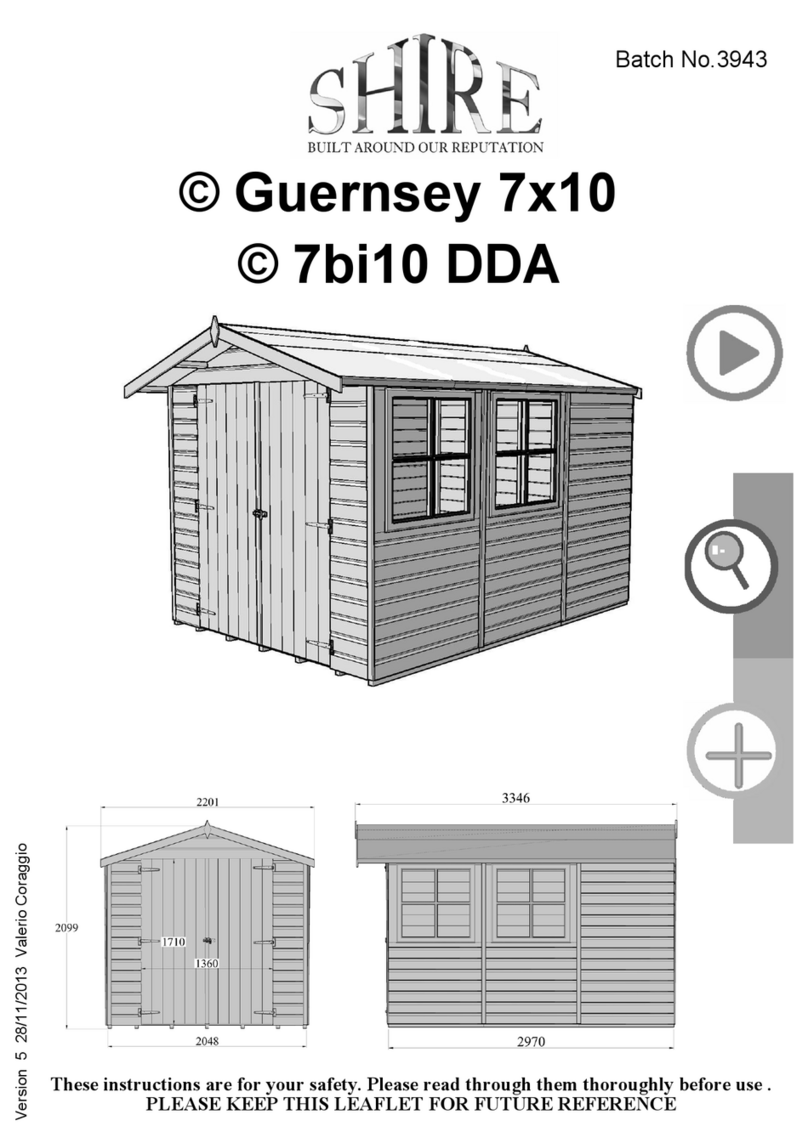

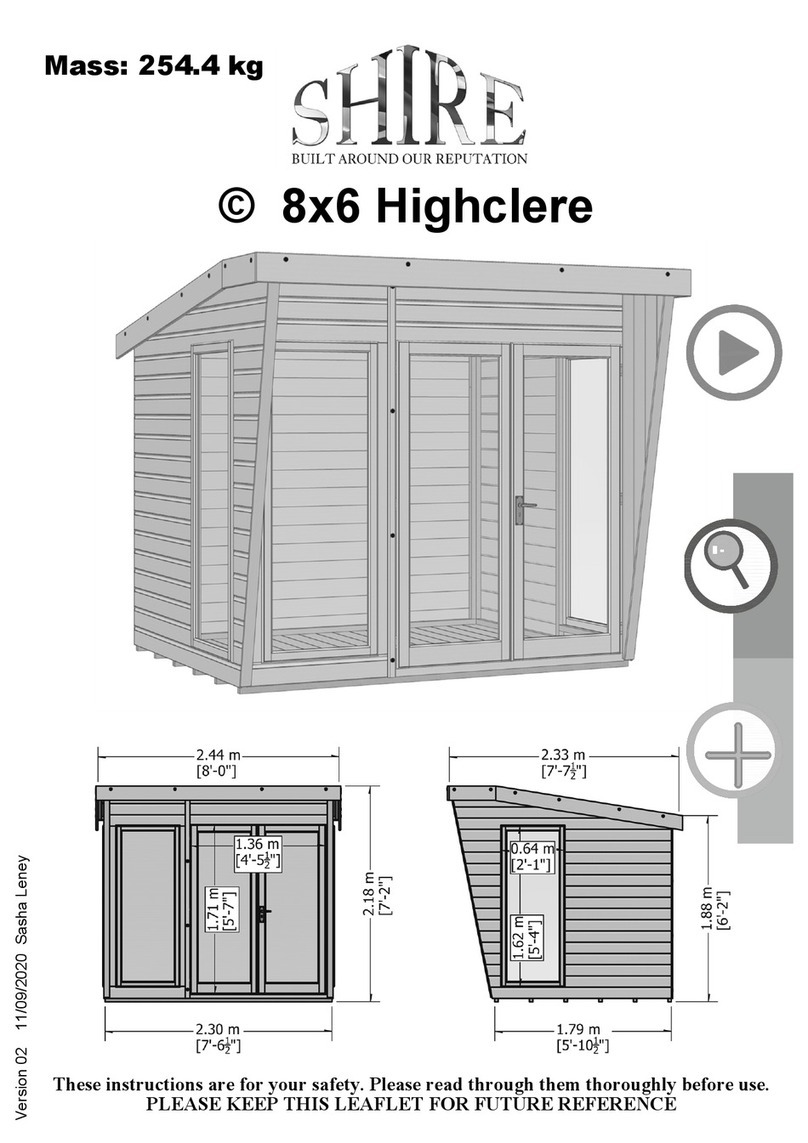

The base onto which you build your Cabin needs to be flat and level.

We only recommend you use concrete that is a minimum of 10 cm thick

Base size at least 4000mm x 7700mm

Please refer to section B and drawing pages 1& 2 .

Please note that the corner joints protrude over the edge of the base.

Treatment/care of your pine lodge

♦ See drawings for log quantities

♦ See yellow parts list sheet please quote ID number

and your order number in all correspondence

• All timber must be dry to apply the timber treatment.

• Treat with a suitable decorative wood finish immediately. We recommend

that you treat the door and window glazing rebates and beading with a top

quality timber treatment before assembly and treat the entire building as

soon as assembly is complete, we further recommend that all pieces are

treated and again within 3 months of assembly and again at least annually or

as frequently as the instructions on the product used recommends.

• Note the back of the door and window units unscrew so they can be

removed for painting

• We would also remind you that you would rarely (if ever) be able to re-treat

the underside of the floor boards following assembly.

• We strongly recommend that the underside of the floor is treated an

absolute minimum of twice.

• The floor bearers are pressure treated and don’t need to be treated although

you may if you wish. We also recommend that you seal the external corner

joints (fig E2) with silicone sealant (not supplied)

• LUBRICATE LOCK It is extremely important that you lubricate your

lock through the key hole and all moving parts as soon as possible

after assembly and at least at monthly intervals thereafter . Also en-

sure that you regularly operate the lock especially during the winter

or when not in use.

We recommend the wearing of non-slip

protective gloves throughout the

assembly process. We also recommend the wearing of steel capped protective

shoes, protective head gear, safety glasses and full length clothing. If step

ladders are to be used we recommend one person holds the ladder whilst the

other is using them. If necessary a third person should be used. Do not attempt

to erect the building in windy conditions. Follow any safety precautions quoted

by the manufacturer for any equipment you use.

• Every precaution has been taken to ensure that your building has no element

incorrectly placed or possibly hazardous. However prior to use please check

for raised grain or splinters and sand if necessary. Check that all elements

are secure against reasonable force.

IMPORTANT SAFETY INFORMATION