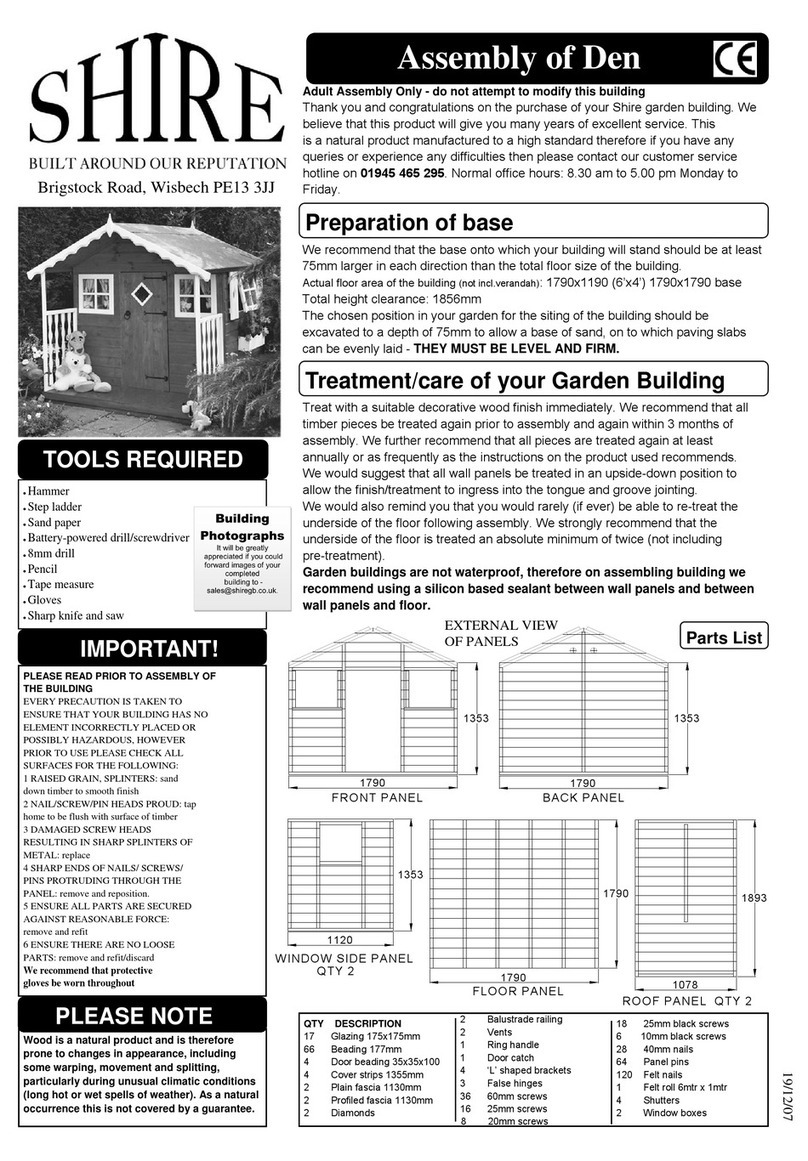

A Floor Assembly

Remove travel protection blocks

from bottom edge of panels. 1.

Ensure that your base is firm and

absolutely level.

2. Take two sections of floor and

secure together through floor

bearers (990mm side) using 3 x

60 mm screws. You will need to

turn the floor over to do this.

Repeat for other four pairs.

3. Take 6 pieces of 34x46x345

floor joiners and place between

each floor bearer. Nail half of the

widest part to the floor using 3 x 40

mm nails per piece.

4. Once floor joiners are fitted

between floor bearers, slide

another floor pair on top of floor

joiners and secure again using 3 x

40 mm nails per piece.

5. Along the front and back edge

of the completed floor fix two

34x46x1485 framework pieces.

Secure into floor bearers using 4

x 60 mm screws per framework

piece. Note: the 46mm edge sits

against the floor of the building.

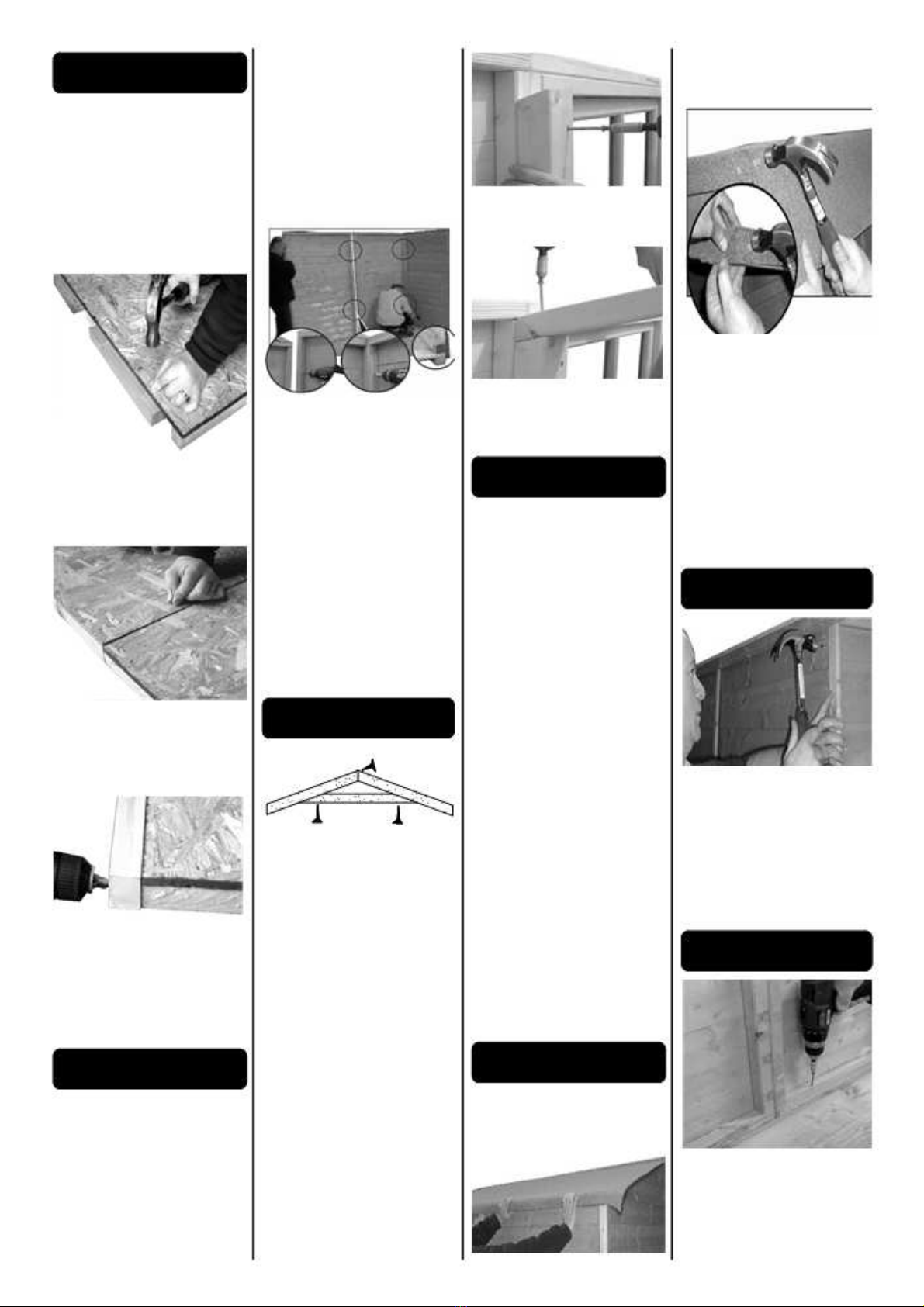

B Wall Assembly

Please see truss assembly before

beginning wall assembly.

1. Pre drill panels in 3 places, top,

middle and bottom.

2. Decide which side of the build-

ing you want your window panels

to go. Place one half of the back

panel onto the floor ensuring the

cladding has overhung the floor.

Place side/window panel next to

this and join together from the

inside using 3 x 60 mm screws.

You can start with either single or

double side/window panel.

The panels along the front and

back extend from floor edge to

floor edge, the side/window

panels sit inside the front and

back panels.

3. Place other back panel half

and secure using 3 x 60 mm

screws.

4. Fit other side/window panel

next to one already in position

and secure using 3 x 60 mm

screws.

5. Place side/window panel next to

back panel and secure using 3 x 60

mm screws.

6. Place remaining side/window

panels and secure using 3 x 60

mm screws.

7. The front panels are now ready

to be placed. Secure to side panels

and to each other using 3 x 60 mm

screws per panel.

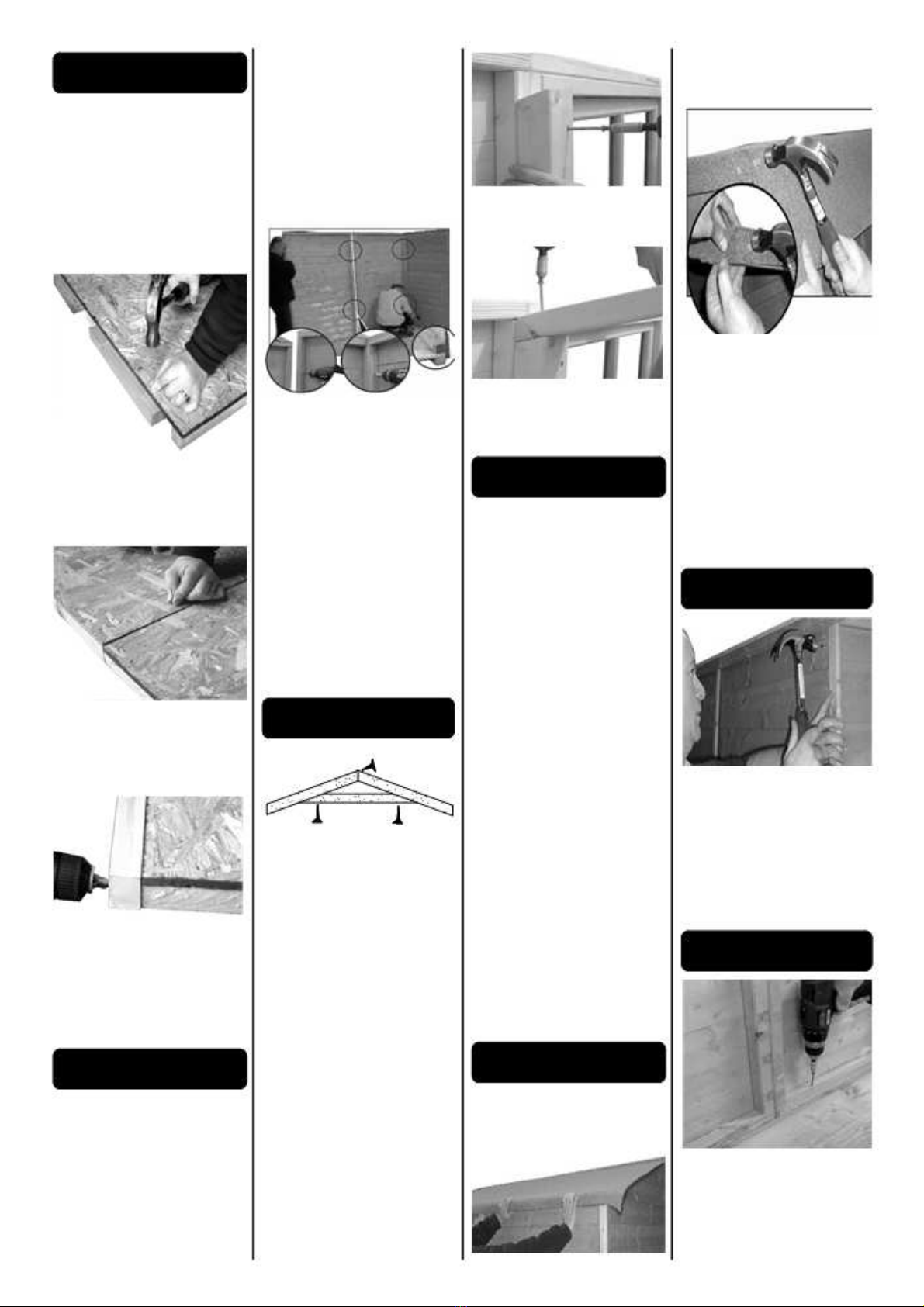

C Truss Assembly

You can use framework of back

panels as a template to construct

the truss. Lay back panels down.

1. Take the two pieces of truss

framework and the one piece of

bracing bar framework and place

together to make an ‘A’ shape.

2. Secure together at the ridge

using 1 x 60 mm screw.

3. Screw bracing bar into truss

using 1 x 60 mm screw at each

end.

4. Mark the position of the lower

angled side of the truss support

block on the back panel frame.

5. Measure from top of framework

of adjoining side panel to mark

previously made. Measure and

mark from top of framework of

adjoining side panels and centre

position of double panels. The

mark is where the lower angled

side of the truss block will be

placed.

6. Secure truss blocks in position

using 2 x 60 mm screws per

block.

7. Place the truss on top of the

two opposite support blocks and

secure using 2 x80 mm screws

per side. Repeat for other trusses

D Roof Assembly

1. Staring at the back slide one

1036x1625 mm roof panel into

position using the cut-out of the

ridge as a guide. Make sure the

panel is flush with the back of the

building and resting on one half of

the truss.

Repeat for the other side.

2. Screw roof panels together at the

ridge from the inside using 3 x 60

mm screws.

3. Secure roof panels into frame-

work of gable ends using 3 x 40

mm nails per side.

4. Place the 990x1625 mm roof

panels next to the back ones and

resting on both trusses. Secure

panels together at the ridge from

the inside using 3 x60 mm

screws. Repeat for all 990 panels.

5. Place the 1220x1625 mm

panels at the front using the cut-

out of the ridge as a guide and

resting on the truss. Secure at

ridge and into gable walls.

6. Secure panels into trusses at

the ridge using a total of 16 x 60

mm nails.

7. Secure along the length of the

building into framework of walls

using 12 x 40 mm nails per side.

E Felt Roof

1. Measure and cut the required

four lengths allowing an overhang

of approx 50 mm on all sides.

Starting at the lower edge (the

eaves) place one piece of felt

along the length of the building.

Secure the felt using felt nails

spaced at 100 mm intervals, but

do not nail along centre of

building until the piece of felt

covering the ridge is in place.

2. Place another strip along the

length of building overlapping the

first strip and overlapping the

ridge. Nail into position along both

edges of this piece and at both

ends using felt nails spaced at

approx 100 mm intervals.

Repeat for other side of roof.

F Corner Strips

1. Fix the corner strips in position

where the panels meet using 4 x

40 mm nails per strip. Place

another 1720 mm strip in the

centre of the double window

panel and centre of plain panel.

There are 3 longer cover strips,

these are for the front and back

panel joins.

G Secure Walls

1. Secure wall panels to the floor

on the inside of the building

through framework into floor

bearers using 2 x60 mm screws

per panel.