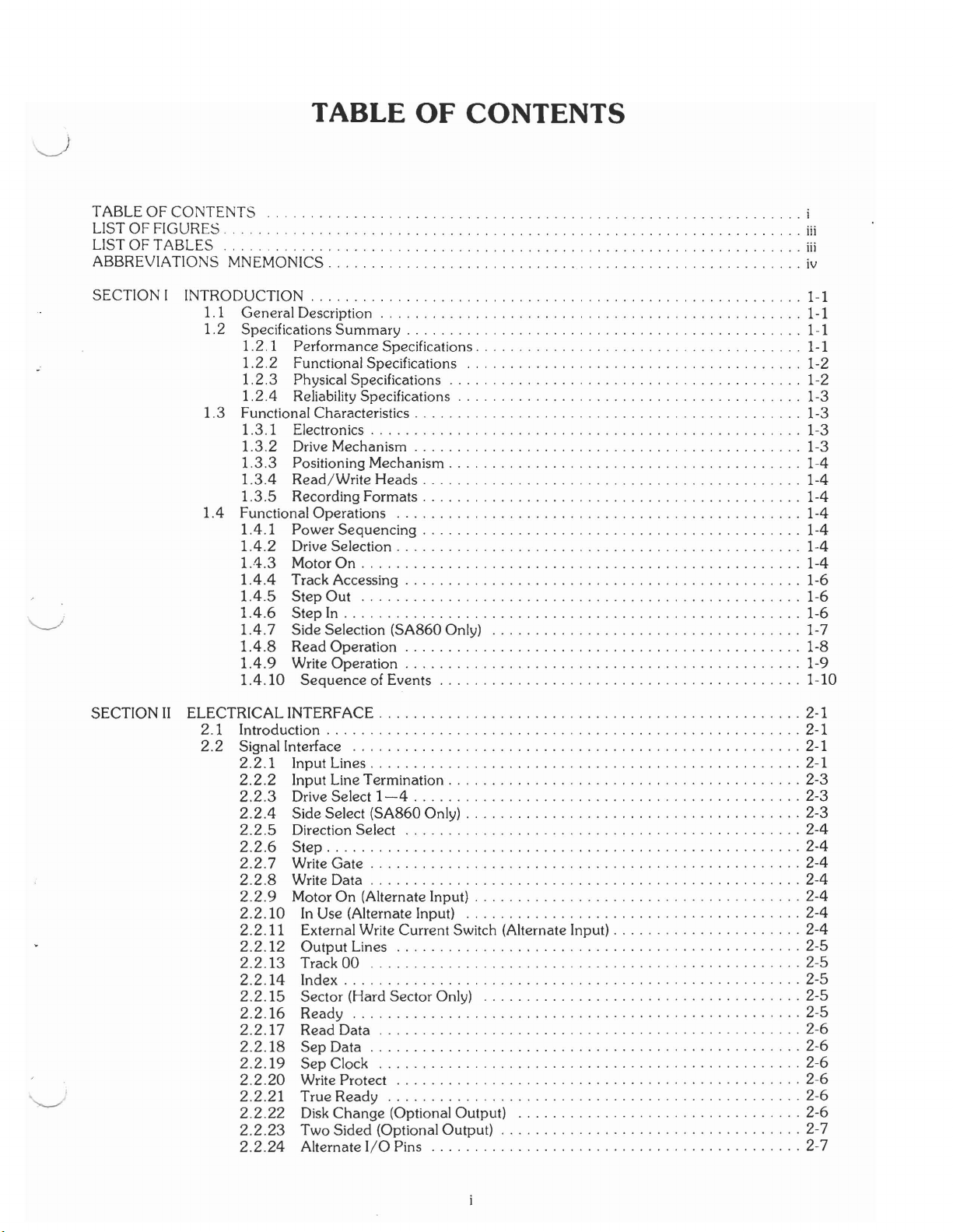

TABLE OF CONTENTS (CONT.)

2.3

Power Interface 2-7

2.4

Frame

Ground.

. . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

SECTION

III

PHYSICAL INTERFACE . . . . . . . . 3-1

3.1

Introduction.....

. . . . . . . . . . . . . . .

..

,3-1

3.2

J1/P1

Connector , . . . . . . . . . . . . . . . . 3-1

3.3

J2/P2

Connector

3-2

SECTION

IV

THEORY OF OPERATIONS , , 4-1

4.1 GeneraIOperations 4-1

4.2

Read/Write Operations 4-1

4.3

Read/Write

Head

, ' ' 4-3

4.4

Write Circuit Operation

4-4

4.5

Read Circuit Operation 4-5

4.6

Drive Motor Control 4-6

4.7

Track Accessing , , , , . 4-6

4.7.1

Stepping 4-6

4.7.2

Carriage Actuator 4-6

4.7.3

Actuator Control Logic. , , , 4-7

4.7.4

Track Zero Indicator

4-9

SECTION VMAINTENANCE, ,5-1

5.1 Maintenance Equipment 5-1

5.1.1

Alignment Diskette

..

,5-1

5.1.2

SA809

Exerciser

,......................................

5-1

5.1.3

Special Tools 5-1

5.2

Diagnostic Techniques 5-2

5.2.1

Soft Error Detection and Correction 5-2

5.2.2

Write Errors 5-2

5.2.3

Read Errors 5-2

5.2.4

Seek

Errors 5-2

5.3

Trouble-Shooting , , 5-2

5.4

Adjustments 5-5

5.4.1

Side 1Downstop Adjustment (SA860 Only) 5-5

5.4.2

Head Radial Alignment

,.

5-5

5.4.3

Read/Write Head(s) Azimuth Check 5-7

5.4.4

Head

Amplitude Check 5-8

5.4.5

Track

00

Detector Assembly 5-8

5.4.6

Track

00

Carriage Limiter

5-8

5.4.7

Index Sector Timing

5-8

5.4.8

Door Lock , , ,

5-9·

5.4.9

Ejector/Bail

5-10

5.4.10

Stepper Motor ,5-11

5.5

Removals

and

Replacements 5-12

5.5.1

Faceplate and Door Knob , , 5-12

5.5.2

Drive Motor Assembly 5-12

5.5.3

Top Plate Assembly 5-12

5.5.4

Spindle Hub Assembly , , , 5-13

5.5.5

PCB Assembly 5-14

5.5.6

Door Lock Assembly .5-14

5.5.7

Side 1Arm Assembly

(SA8600nly)

,..........

.5-14

5.5.8

Head

and Carriage Assembly

5-14

5.5.9

Clamp Hub Assembly 5-15

5.5.10

Bail

Assembly , . . . . . . . . . . . . 5-15

5.5.11

Track

00

Detector 5-15

5.5.12

Index/Sector

LED

Assembly .

5-15

5.5.13

Index/Sector

Detector Assembly .

..

5-16

ii