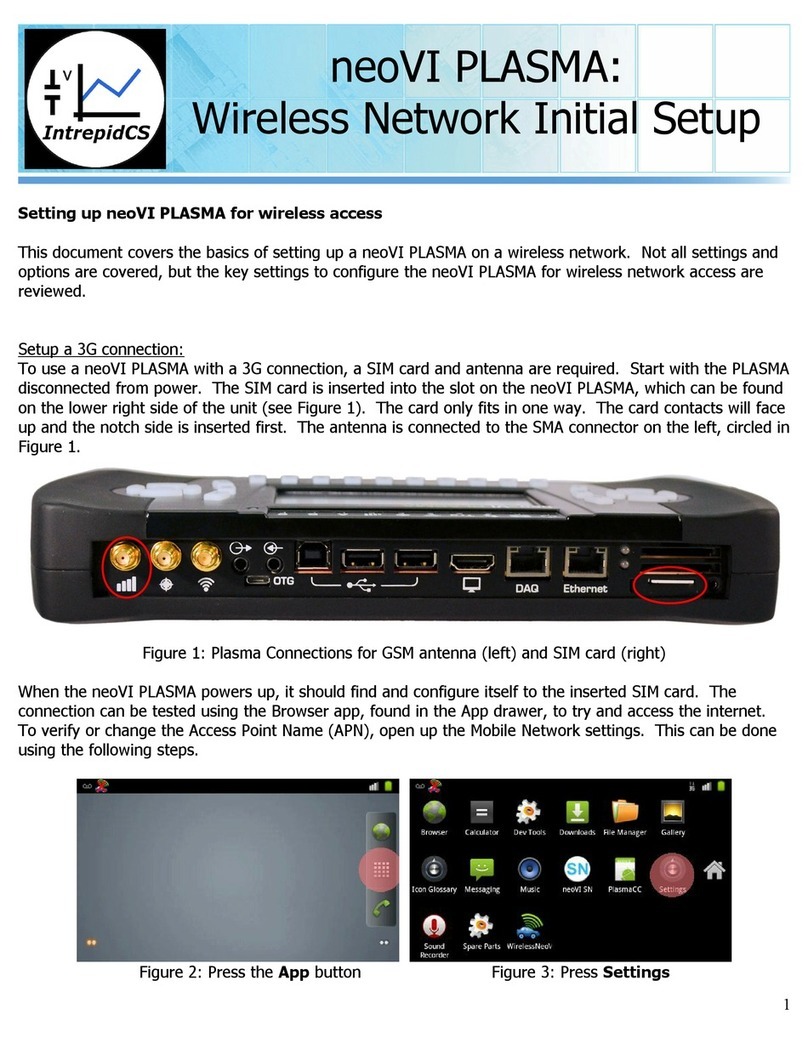

Sices DST4601/PX User manual

Filename: EAAM019704EN.docx

Rev. 04 Date: 08/05/2013

ID Document: EAAM0197

Product: DST4601/PX

ii User’s Manual

1. Definitions................................................................................................................3

2. Front Panel...............................................................................................................3

2.1 Selector (ref. to fig. 1)...........................................................................................4

2.2 Pushbuttons (ref. to fig. 1) ....................................................................................5

2.3 Indicators (ref. to fig. 1).........................................................................................7

2.4 Multifunctional display...........................................................................................8

2.4.1 Mode navigation (ref. to fig. 2)........................................................................9

2.4.2 Display area layout (ref. to fig. 3)..................................................................10

2.4.3 Top status bar (ref. to fig. 4).........................................................................10

2.4.4 Bottom status bar (ref. to fig. 5)....................................................................11

2.5 Display mode......................................................................................................11

2.5.1 Programming (P.xx) .....................................................................................11

2.5.1.1 Access codes.......................................................................................11

2.5.1.2 Setting the parameters.........................................................................12

2.5.1.3 How to input string value......................................................................13

2.5.1.4 Direct access to the previous page ......................................................13

2.5.1.5 Alarms and protection parameters .......................................................13

2.5.2 Status information(S.xx)...............................................................................13

2.5.3 Electrical measurements(M.xx) ....................................................................14

2.5.4 Engine measurements(E.xx)........................................................................14

2.5.5 PMCB(B.xx)..................................................................................................15

2.5.6 History logs(H.xx).........................................................................................15

2.6 Manual commands .............................................................................................15

2.6.1 Manual synchronization................................................................................15

2.6.2 Manual power regulation..............................................................................16

3. Special settings .....................................................................................................17

3.1 Selecting the language.......................................................................................17

4. Fuel pump (if installed) .........................................................................................17

4.1 Select function....................................................................................................17

4.2 Starting and stopping the fuel pump...................................................................18

5. Heating unit (if installed).......................................................................................18

User’s Manual 3

. NOTE: Read this manual carefully before operating the device.

(EN)

LOCKOUT - is used to indicate a fault that prevents the generator from operating and causes

automatic and immediate emergency engine shutoff.

POWER-OFF - is used to indicate a fault that prevents the generator from operating and causes the

standard automatic engine shutoff (including a cooling phase).

WARNING - is used to indicate a fault that requires the intervention of the operator without engine

shutoff.

The controls consist of a lockable selector (1) and 12 pushbuttons (2).

The front panel also has some luminous indicators (3).

KEY

1 - Selector

2 - Pushbuttons

3 - Indicators

4User’s Manual

Selector

position

Function

OFF/RESET

PROGRAM

The generator is disabled; warnings and lockouts are cancelled.

You can program the parameters.

MAN

Gen-set is in manual mode.

Press the START button to start the engine.

Press the STOP button to stop the engine.

MCB button and GCB button for the manual control of the

commutation/switches in accordance with system SW - HW configuration.

With BUS ON, synchronization is required.

AUTO

TEST

Gen-set is in automatic mode: all the functions are controlled automatically. The

combination of the buttons START and MODE lets you

activate/deactivate the TEST mode; the STOP button lets you stop the

generator (with a lockout).

Buttons MCB and GCB let you switchover the devices (only in the TEST

mode and on the basis of the type and plant configuration).

The activation of a suitably configured external input (or receiving a given

command via SMS or from a serial port) can force the starting of the generator

and the load outlet with the network connected or with the inhibition input on

(REMOTE START).

User’s Manual 5

Pushbuttons

Function

SHIFT

Dead key. If this is pressed with another button, it changes the button function.

When the page displays HELP, holding this button down displays the

HELPmessage on the bottom status bar.

LEFT/RIGHT

Horizontal scrolling buttons. These buttons let you select the previous or next

page on the display in all modes, except in the PROGRAM and HISTORY

LOGS mode.

In the PROGRAM mode they are used to position the cursor when entering the

strings. Used in combination with the SHIFT button, it can be used to

adjust the contrast.

To lower the contrast press the combination of buttons SHIFT + LEFT

. To increase the contrast press the combination of buttons SHIFT

+ RIGHT .

UP/DOWN

Vertical scrolling buttons. These buttons let you select the multifunctional

display mode.

In PROGRAM and HISTORY LOGS mode you can scroll the menus and the

variables / settings. You can increase/decrease the value of the variable to

change the settings. Used in combination with the SHIFT button you can

scroll through the menu ten entries at a time or increase/decrease the

variables ten units at a time. During the keyboard regulation phase you can

increase or decrease the engine speed (if set to synchronized) or the power

supplied (if in power mode).

ENTER

Lets you enter the programming mode and open submenus, change a variable,

and confirm the operation. Furthermore, you can enable the HISTORY LOGS

function and open the selected log, “acknowledge” any EEPROM errors at

power-up, in the manual synchronization and power setting phase, and enable

keyboard regulation.

EXIT

In programming mode, it cancels the changes made to a variable value, brings

up the previous menu level, or exits programming mode. If it is kept pressed for

at least two seconds in any menu, you exit the programming mode retaining the

current menu position for further programming access. Use the SHIFT

button to control the fuel pump manually. Used with the MODE button, it

resets the counters and reloads the default programming parameters (in the

version with CANBUS, it also lets you force the exit from BUS OFF mode).When

used during the keyboard regulation function, it aborts the function.

GCB

Used to command the General Circuit Breaker (GCB) or changeover. The

actual function depends also on the plant configuration. In parallel mode with at

least one other source powering the BUS, if the button is pressed it activates

the fast unload ramp before the circuit breaker opens.

In case no ramp is needed, simply keep it pressed for few seconds until the

GCB is opened.

6User’s Manual

Pushbuttons

Function

MCB

Used to command the Mains Circuit Breaker (MCB) or the changeover. The

actual function depends also on the plant configuration.

MODE

Used to acknowledge any kind of alarm and to silence the horn. Pressed at the

same time as the START button, it lets you enable/disable the TEST mode.

Used with the EXIT button, it resets the counters and reloads the default

programming parameters (in the version with CANBUS, it also lets you force the

exit from BUS OFF mode).

START

In MAN mode it is used to start the generator.

In AUTO mode it is used with the MODE button to enable/disable the

TEST state. Used with the STOP button at power up, it gives you access

to Gen-set special functions.

STOP

Used to stop the engine. In AUTO, TEST or REMOTE START mode it is also

used as a lockout. Pressed with the selector in OFF/RESET mode it runs the

LAMP TEST on all the luminous indicators. Used with the START button at

power up, it gives you access to Gen-set special functions.

User’s Manual 7

LED OFF

LED steady ON

LED flashing

Signalling

Function

ALARM

Signals at least one lockout or deactivation or unload anomaly.

Signals at least one lockout or deactivation which has not yet been

acknowledged with the “MODE/ACK” button

No lockouts, deactivations, or unload functions.

WARNING

There is at least one active warning.

Signals at least one lockout or warning, which has not yet been

acknowledged with the “MODE/ACK” button

No warnings.

INHIBIT

Signals an active inhibit command from digital input, clock/calendar

or load function

It means that the input status is active, but the set waiting time

hasn't elapsed.

It means that an inhibition command is active.

TEST

Signals TEST mode on

The TEST is enabled by a serial command, SMS, the REMOTE

TEST input function or the clock/calendar

Signals TEST mode off

SERIAL

PORTS

Indicates at least one of the two serial ports is active.

Signals that a command is being sent from one of the serial ports

(the second serial port is managed in signalling only if configured

as the COM port and not the I/O) expansion.

Indicates at least one of the two serial ports isn't active.

CAN0

Signals that the CAN0 interface is active and in ERROR-ACTIVE

mode. (J1939 or MTU)

Flashing at 25% ON signals a COM error (J1939 or MTU): the port

is in ERROR-PASSIVE mode.

Flashing at 75% ON signals a COM error (J1939 or MTU): the port

is in BUS-OFF mode.

Signals that CAN0 has been disabled.

CAN1

Signals that the CAN1 interface is active and in ERROR-ACTIVE

mode. Power Management Communication Bus (PMCB)

Flashing at 25% ON signals a COM error (J1939 or MTU): the port

is in ERROR-PASSIVE mode.

Power Management Communication Bus (PMCB)

Flashing at 75% ON signals a COM error (J1939 or MTU): the port

is in BUS-OFF mode.

Power Management Communication Bus (PMCB)

Signals that CAN1 has been disabled.

BUS LIVE

Signals BUS line ON.

Signals BUS line OFF.

Flashes at 50% if the BUS line voltage is out of tolerance range.

Flashes at 50% during the synchronization phase (opposite

sequence to MCB or GCB).

8User’s Manual

Signalling

Function

MAINS LIVE

Mains power is OFF or MAINS SIMULATION digital input is disabled.

Mains power is ON and stable in the range of tolerance, or MAINS

SIMULATION digital input is enabled from the set time.

Flashes at 50% during transition between the previous two states.

GENERATOR

LIVE

Generator voltage and frequency are not present.

Generator voltage and frequency are present and stead within the

tolerance range.

Flashes at 50% during transition between the previous two states.

ENGINE

RUNNING

The engine is OFF.

The engine is running

Cooling phase

MCB

The MCB is open.

The MCB is closed

Flashes at 25% ON if open after a closing command.

Flashing at 75% ON if the KG is closed after an opening command.

Flashing at 50% in synchronization phase with BUS LIVE indicator.

GCB

The MCB is open.

The MCB is closed

Flashing at 25% ON if the KG is open after a closing command.

Flashing at 75% ON if the KG is closed after an opening command.

Flashing at 50% in synchronization phase with BUS LIVE indicator.

The backlight lamp is managed by Gen-set, which switches it off after a programmable time

(P.492) if no buttons are pressed in the meantime. Press any button to switch the lamp ON

again, (we recommend using the SHIFT button as it has no function when used alone).

This function can be disabled by setting parameter P.492 to 0.

The contrast can be adjusted by pressing the SHIFT + LEFT buttons to decrease

the contrast or the SHIFT +RIGHT buttons to increase it.

User’s Manual 9

The display has different display modes with various pages

.

Mode

Page identifier

Programming

P.XX

Status information

S.XX

Electrical measurements

M.XX

Engine measurements

E.XX

PMCB

B.XX

History logs

H.XX

Generally, the UP and DOWN buttons are used to navigate between the modes.

Use the LEFT and RIGHT buttons to display the pages in the mode.

In some modes (ex.: mode P.xx and mode H.xx) to display the pages, press

the ENTER button, and then the UP and DOWN buttons to browse the pages.

Note: If the UP and DOWN buttons have to be used to manage functions in that mode, the

ENTER button must be pressed to activate these functions, and the EXIT button should

be pressed to deactivate the same.

Fig. 2 - Mode navigation

10 User’s Manual

Fig. 3 - Display areas

The top status bar contains information on navigation and times.

The current mode is shown in the relevant field of the top status bar (1a).

The mode identifier (1a), and the page identifier (1b) identify and refer to the page so there is no

chance of error.

The display on the top status bar (1d) with left , or right arrow buttons or both,

indicates there are other pages which can be viewed using the relevant LEFT and RIGHT

buttons.

E.01 ENGINE 03/04/06 18:23

Press.(Bar) Temp.(°C) Level(%)

Oil: xx.x –xxx.x xx.x

Coolant:xx.x –xxx.x xx.x

Fuel:xx.x –xxx.x xx.x

Actual Requested Lost

Torque (%): xxx xxx.x xxx

Speed (rpm):

xxxx

Batt.(Vdc):

xx.x

OFF |Engine stopped -

1

2

3

KEY:

1 - Status bar

2 - Data area

3 - Bottom status

bar

1

b

1c

1d

1e

1a

KEY:

1a - Mode identifier

1b - Page identifier

1c - Page title

1d - Pages to the left or

right

1e - Date and time

E.02 ENGINE 03/04/06 18:23

Fig. 4 - Top status bar

User’s Manual 11

The bottom status bar displays some information on the system status.

The operating mode (2a) is controlled by the lockable selector.

The system status (2b) displays part of the information on page S.01(status information), which is useful

for the operator, as it can be displayed also if other pages are being viewed and in other display modes.

In some pages, pressing the SHIFT button replaces the bottom status bar for the time the button is

held down with a HELP message. If the message is unavailable, the bar is cleared and restored when the

button is released.

WARNING: assigning incorrect value to one or more parameters can cause

malfunctions, damage to things and/or injury to people. The parameters must only be

changed by qualified personnel. Parameters can be protected by password (see par. Access

codes).

This mode lets you display and change the programming parameters.

Each programming parameter has a 3-digit numeric code (ex. P.101) to identify the variables

regardless of the language used.

The first line under the top status bar identifies the current menu with the menu number and the

relevant text.

A pair of numbers are displayed on the right in this line. The first indicates which entry in the menu is

selected or which page is displayed, the seconds indicates how many entries or pages can be

displayed in the current menu/submenu.

Access to the programming mode can be controlled by 4 different PASSWORD levels, which are listed

in order of priority.

1. SICES password

2. Manufacturer password

3. Installer password

4. User password

2a

2

b

2a - Operating mode

2b - System status

OFF |Engine stopped -

Fig. 5 - Bottom status bar

12 User’s Manual

Warning: If the password is lost, you can reconfigure it using a higher level

password. Contact our service centre if the “MANUFACTURER” password is lost.

In the first page (000-Access Code) of the SYSTEM menu, will ask you for the access code if one or

more passwords have been assigned.

If a password is set to 0, it is not assigned and not required.

The USER can only display and change the User Password.

The INSTALLER can change the User Password and the Installer Password.

The MANUFACTURER can change all three passwords.

SICES can display and change some critical parameters for configuring the plant, for

parallel function.

Warning: The critical parameters must not be changed by the user.

The Password setting pages are displayed in the SYSTEM menu, if the user is authorised to change

the settings.

In programming mode, when the Password is entered if the page for changing the password isn't

displayed, press EXIT to return to the previous menu and try opening the page again.

The set access code remains in the memory for about 10 minutes after programming has been

completed. After that it must be entered again to access the programming mode.

Enable the mode with the ENTER button.

Use the UP and DOWN buttons to select a menu and the ENTER button to open the

same. Select the variable or submenu with the UP and DOWN buttons. Pressing ENTER

when there are no submenus, displays the page of variables for the menu entry.

The value of the variable is displayed in square brackets, for example: [400]

To change the variable, press ENTER ; the square brackets [ ] will flash. Use the UP and

DOWN buttons to change the value and press ENTER to confirm or EXIT to abort.

To change the variables, the lockable selector must be OFF. Some variables can only be changed

with the lockable selector in another position other than OFF.

If you cannot change a variable in any condition, this is shown as follows:<400>

showing that the parameter cannot be changed in this status.

To exit the programming menu, use the EXIT button.

User’s Manual 13

For some parameters you will have to set a value for the string data.

In this case, pressing ENTER makes the square brackets [ ] around the variable flash, and a

cursor appears under the first character of the string. Using the LEFT and RIGHT buttons,

you can select which character to change. Use the UP and DOWN buttons to change the

character selected. Repeat the procedure for each character that needs changing.

Use ENTER (confirm) or EXIT (abort) to end the procedure.

You can open the last programming page displayed directly. This is possible if, when exiting

programming mode, instead of going back though the menus until you exit programming, you hold

down EXIT for approximately 2 seconds.

The same is true when accessing the programming mode after Gen-set has automatically exited

programming. This is the case, if no programming operations are performed for 60 consecutive

seconds or if the lockable selector is switched to MAN or AUTO.

Protections and alarms can generally be configured using dedicated variables. Generally, the trip

time can also be configured.

Setting the trip time to 0 disables the protection.

In this way, information on the system status is provided.

You can scroll through the various pages using the LEFT and RIGHT buttons.

Page S.01 displays information on the system status. Part of this information is shown on the bottom

status bar.

The alarms page (S.02) is displayed automatically in the case of an anomaly. This page also

contains the diagnostic information on motors with the J1939 or MTU interface.

- communication status of bus.

There are three possible indications:

- ERROR-ACTIVE: normal operation

- ERROR-PASSIVE: communication is working despite faults (errors).

-BUS-OFF: Gen-set has interrupted the connection to the bus due to too many errors.

14 User’s Manual

Communication error counters display. If the cause of the malfunction has been removed, in

this page you can force exit from the BUS-OFF mode by holding down the MODE +

EXIT buttons.

- engine diagnostic codes, according to the SAE J1939 standard or MTU specifications. In the

case of the J1939 standard, when a signal is present the SPN and FMI fault's codes, the

number of occurrences (OC), a specific diagnostic code of the family of engines (DTC), and an

explanatory text are displayed. For MTU engines the SPN, FMI and OC are not shown, but the

DTC code and an alphanumeric description are always displayed.

The engine diagnostic codes are stored (even if the engine removes them) until the

yellow/red indicator light warning from CanBus is acknowledged with the MODE button.

Page S.03 reports the status of the serial communication and CAN networks. In the case of

operating errors, check the information in this page. When using a GSM modem the phone

company and radio signal are also shown.

Page S.04, as well as containing some generic information, also contains information on the fuel

pump.

Page S.05 (available only if the DICHRON expansion module or an external (SYNCHRO-CHECK)

synchroscope is installed in the system) will display a synchroscope with the main electrical BUS

and GENERATOR magnitudes, the engine speed and the phase error, otherwise the external

synchroscope is powered.

Page S.06 displays the state of the digital inputs and outputs acquired by Gen-set.

Page S.07 displays the state of the analog inputs and outputs acquired by Gen-set.

You can scroll through the various pages using the LEFT and RIGHT buttons.

This lets you display the measurements taken by Gen-set on the electric lines.

Page M.01 displays the electrical magnitudes of the generator.

Page M.02 displays the electrical magnitudes of the network or bus.

Page M.03 shows the total and phase power values, active, reactive and apparent, power factor and

energy counters of the generator.

Page M.04 is used during synchronization. If the DICHRON expansion unit is connected, a

synchroscope is also shown in this page. Using the synchroscope displayed or an external

synchroscope, with the lockable selector in position MAN you can perform the manual

synchronization (see par. 2.6.1).

Page M.05 shows the parameters used to monitor the parallel function. In this page you can change

the power supplied in the network parallel applications using the BASE LOAD and

IMPORT/EXPORT function.

The engine related measurements are shown in this mode. The page number displayed may

depend on the type of engine (J1939, MTU or without communication interface).

Some parameters may only be shown for some engine models.

User’s Manual 15

Page B.01 reports status information related to the PMCB network. This includes the number of

network devices, the operating mode of the load function, the identifier of the pilot generator and

the list of priorities.

Page B.02 shows the measurements concerning the generation of energy by the single generators

and all the generators in the PMCB network.

Page B.03 shows the value of the active and reactive powers for each generator connected to the

BUS line.

Pressing ENTER in this mode, opens the programming menu of the load function

parameters directly.

See the following document for the meaning of the parameters: EAAM0193XX(Parameters

Table).

In this mode, you can access events and data recording databases.

A number and time/date stamp identify each record.

The number is shown in the top right line of the multifunctional display with the total number of

records.

When the archive is full, a new record overwrites the old one; so the identification number may

change in time.

Enable the mode with the ENTER button. A menu will guide you through the selection of the

required function.

WARNING: Before proceeding with manual synchronization, check the

configuration is set so the circuit breaker cannot close in the case of a phase speed

alignment error.

With the lockable selector in the MAN position, depending on the plant type and on how the panel

is wired, you can command the closing of the GCB or MCB with manual synchronization.

In order to use this procedure, the DICHRON expansion module or an external (SINCHRO-

CHECK) synchroscope must be installed.

In MAN mode, with the engine and the generator running and network/bus voltages present (BUS

LIVE indicator steady on), the function can be activated by pressing the button of the open circuit

breaker (MCB or GCB ).

When the button is pressed, the circuit breaker will not close, but the manual SYNCHRO function is

activated and synchronization page M.04 is displayed automatically. If the DICHRON module is

used, the page will display a synchroscope, otherwise the external synchroscope will be powered.

16 User’s Manual

To adjust the engine speed and/or voltage manually, press the ENTER button and the MODE

button to select speed and voltage regulation; use the UP and DOWN buttons to

change the percentage value (%). When the synchroscope indicates the circuit breaker can be

closed, press the circuit breaker button again (MCB or GCB ) and hold it down until

the circuit breaker has closed.

At any time, pressing EXIT disables the speed manual commands and you can change page.

Changing the page aborts the manual synchronization procedure.

Note: The function described can only be used if the system hasn't been configured to use an

external potentiometer to regulate the speed; in this case the speed can only be changed using the

potentiometer.

Make sure that after the circuit breaker closes, the speed reference is set as

close as possible to the nominal value so Gen-set can regulate the power properly.

Warning: As some slow power ramps may have been set, check the command

against the “Power reference” value shown in the same page and not against the

value of the power actually produced.

In network parallel applications with BASE LOAD or IMPORT/EXPORTfunctions, you can regulate

the power supplied manually without having to change the parameter that defines the regulated

power directly.

Go to page M.05, press the ENTER button and the MODE button to select either

"power reference" and/or "power factor reference"; using the UP button to increase the value

and the DOWN button to decrease the value set as a percentage (%). The value to be

changed is highlighted as a negative.

Press the ENTER button to exit the regulation procedure.

Note: The function described is only available if no external potentiometer has been configured for

power regulation.

User’s Manual 17

Gen-set can display messages in various languages.

To select another language, turn the lockable selector to OFF/RESET, and when you power up

Gen-set press the STOP and START buttons simultaneously until the following

message appears on the display:

Special Function

Function [RESERVED]

Press the ENTER button, use the UP and DOWN buttons to scroll to [LANGUAGE],

then press ENTER again; you will now be asked to enter the password.

Press ENTER and use the UP and DOWN buttons to set the password value to 1.

When you enter the correct password, the language selection page will be displayed.

Press ENTER and use the UP and DOWN buttons to set the right language; confirm

with the ENTER button.

To exit the special mode, power down Gen-set, wait for a few seconds, then power it up again.

Note:in this phase do not press the STOP and START buttons.

Gen-set implements the full management of the fuel pump, to pump fuel from the storage tank to

the tank on the generator. The pump can be managed automatically or manually using the controls

on the front panel.

With the lockable selector in the MAN, AUTO or TEST position, select the “STATUS

INFORMATION S.xx” mode using the UP and DOWN buttons. Scroll through the pages

with the LEFT or RIGHT buttons until you reach page S.04. In this page you can start

the standard setting procedure by pressing the ENTER button (square brackets flashing

[xxxxxxx]), and then use the UP and DOWN buttons to change the command:

AUTOMATIC (the pump starts automatically when the low fuel level sensor

sends a signal, and stops pumping when the max. fuel level is reached)

MANUAL-ON (pump on - the pump starts and will only stop when the max. fuel

level is reached).

18 User’s Manual

MANUAL-OFF (pump off)

Press the ENTER button to confirm the selection.

Note: The second option (MANUAL-ON) can be inhibited by Gen-set, in relation to the fuel level

(the pump will not start when the tank is full).

With the lockable selector in position MAN, AUTO or TEST, from any page or mode, you can

open page “S.04 fuel pump page” with the sequence of buttons SHIFT and EXIT

.

Pressing the sequence of buttons SHIFT and EXIT again, you can change the fuel

pump command from:

MANUAL-ON (pump on - the pump starts and will only stop when the max. fuel

level is reached).

ANUAL-OFF (pump off)

You can use Gen-set to set the temperature the heating unit is turned on or off in the

programming mode as described in paragraph 4 by changing the PREHEATING parameter.

If the OFF switching temperature is set lower or equal to the ON switching temperature, the

heating unit is disabled.

SSSTTTTTGHTY

1

This document is owned by SICES s.r.l.. All rights reserved. SICES s.r.l. reserves the right to modify

this document without prior notice.

SICES has made any effort to ensure that the information herein provide are correct; in any case

SICES does not assume any liability for the use these information.

The disclosure by any means of this document to third parties is not allowed.

Other Sices Controllers manuals