Contents

1 About this document........................................................................ 5

1.1 Purpose of this document........................................................................ 5

1.2 Scope......................................................................................................... 5

1.3 Target groups and structure of these operating instructions................ 5

1.4 Further information................................................................................... 6

1.5 Symbols and document conventions...................................................... 6

2 Safety information............................................................................ 8

2.1 General safety notes................................................................................ 8

2.2 Intended use............................................................................................. 8

2.3 Improper use............................................................................................. 8

2.4 Requirements for the qualification of personnel.................................... 8

3 Product description........................................................................... 10

3.1 Configuration of the safety controller...................................................... 10

3.2 Overview of the module............................................................................ 11

3.3 Configuration and function...................................................................... 11

3.4 Status indicators....................................................................................... 12

4 Project planning................................................................................ 13

4.1 Manufacturer of the machine.................................................................. 13

4.2 Operating entity of the machine.............................................................. 13

4.3 Design........................................................................................................ 13

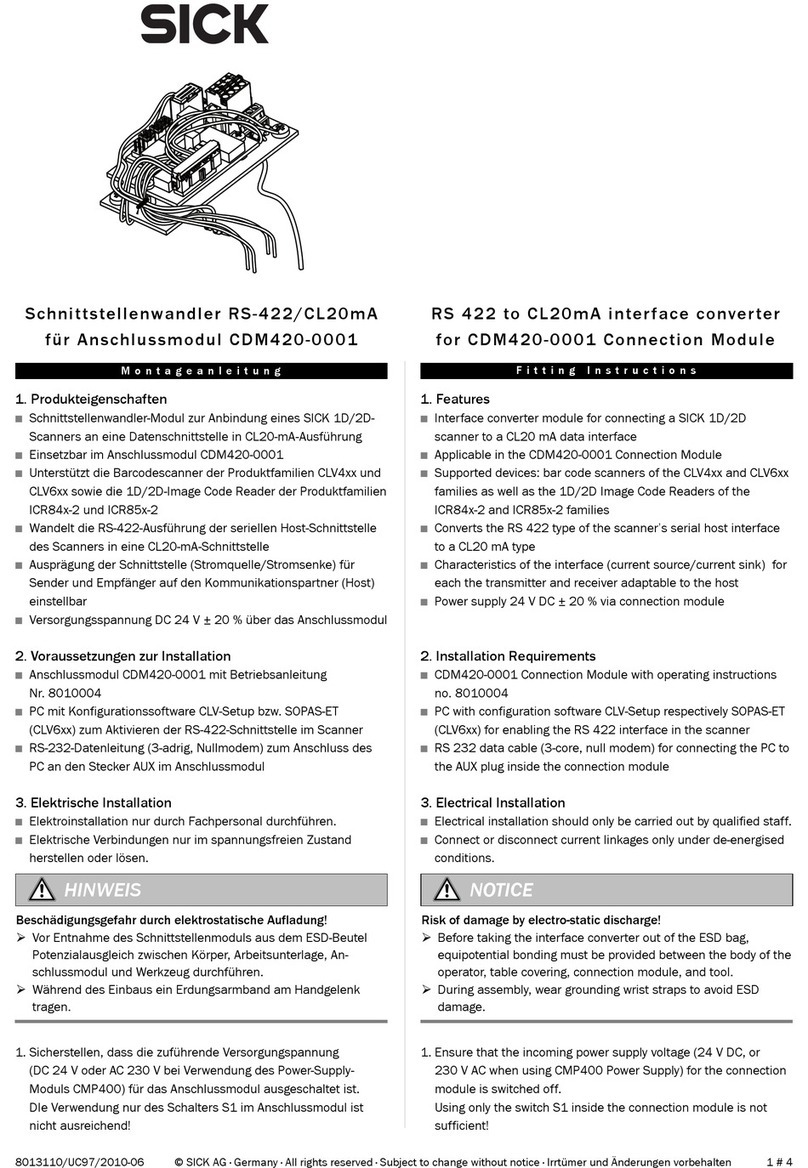

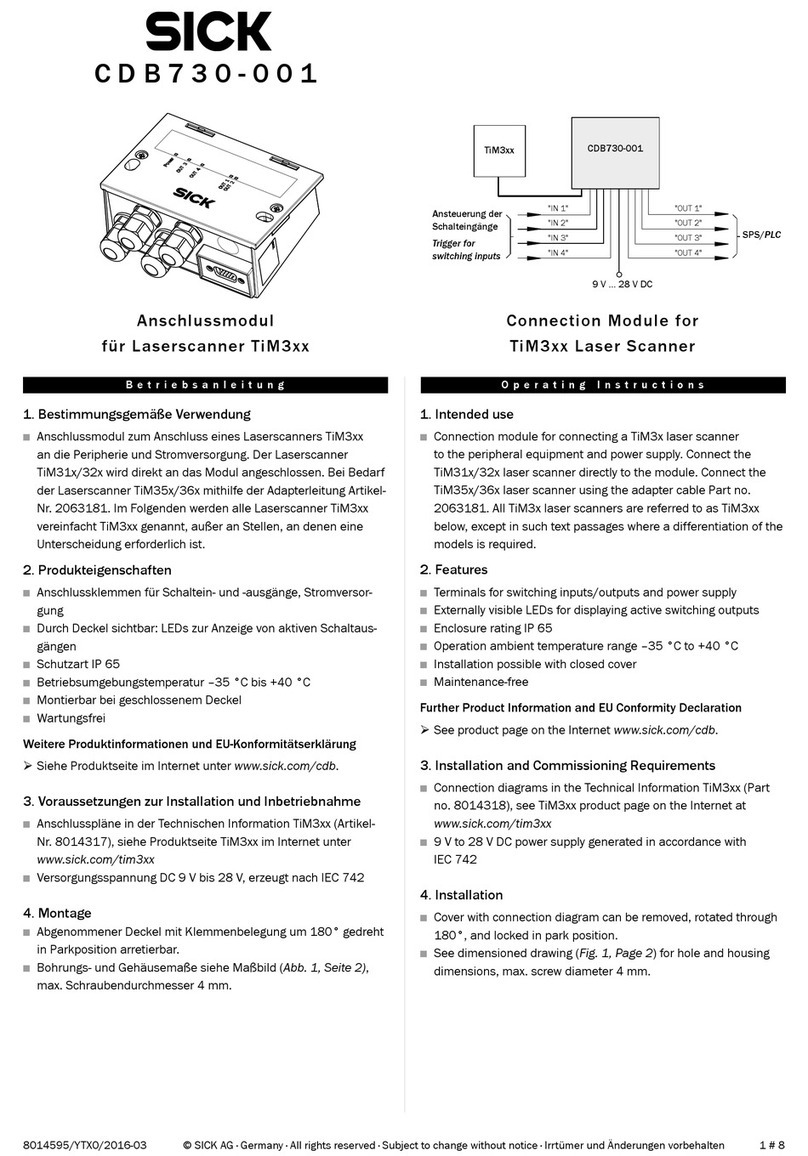

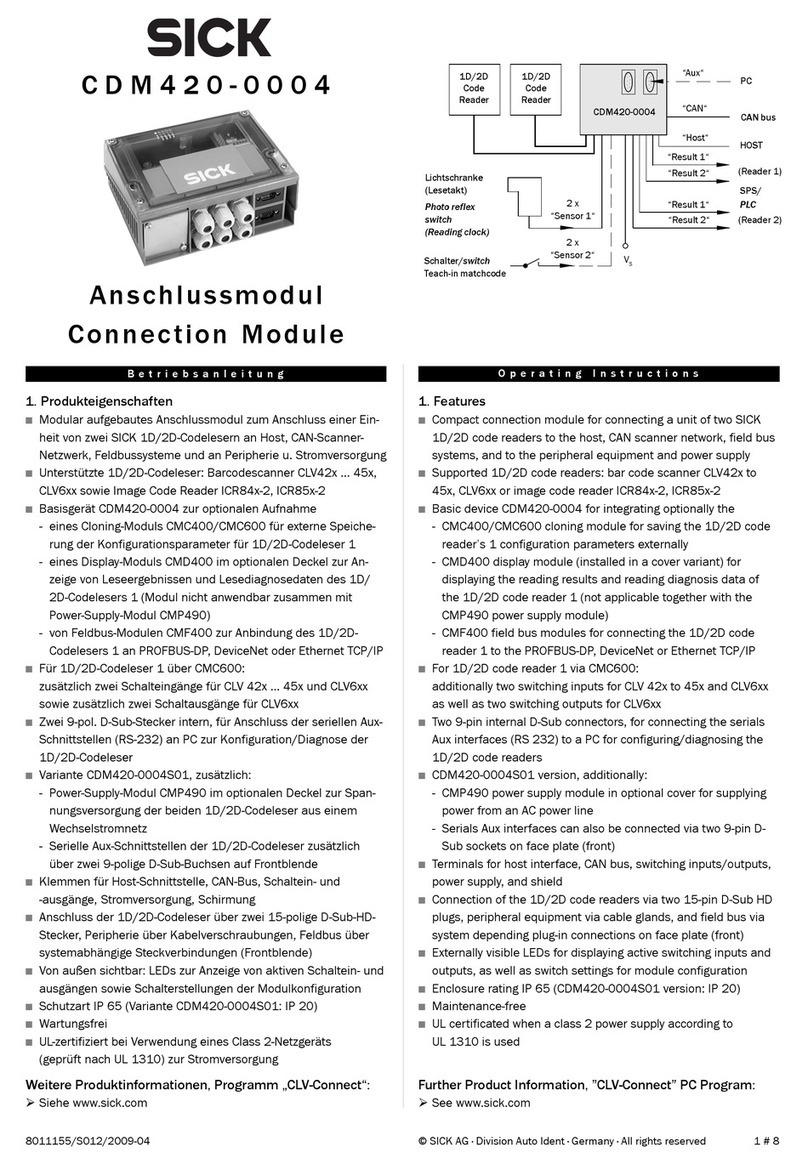

4.4 Electrical integration................................................................................. 15

4.4.1 Internal circuitry....................................................................... 15

4.4.2 Safety outputs.......................................................................... 15

4.5 Testing plan............................................................................................... 16

5 Mounting............................................................................................. 17

5.1 Safety......................................................................................................... 17

5.2 Mounting procedure................................................................................. 17

5.3 Module exchange...................................................................................... 17

6 Electrical installation........................................................................ 19

6.1 Safety......................................................................................................... 19

6.2 Device connection.................................................................................... 19

6.3 Coding........................................................................................................ 20

6.3.1 Coding front connector and module....................................... 21

7 Commissioning.................................................................................. 23

7.1 Check during commissioning and modifications.................................... 23

8 Operation............................................................................................ 24

8.1 Regular thorough check........................................................................... 24

CONTENTS

8024583/2020-11-10 | SICK O P E R A T I N G I N S T R U C T I O N S | Flexi IO XTDO1 3

Subject to change without notice