SICK WLL180T User manual

WLL180T

Sensor Configuration for Individual Applications

MANUAL

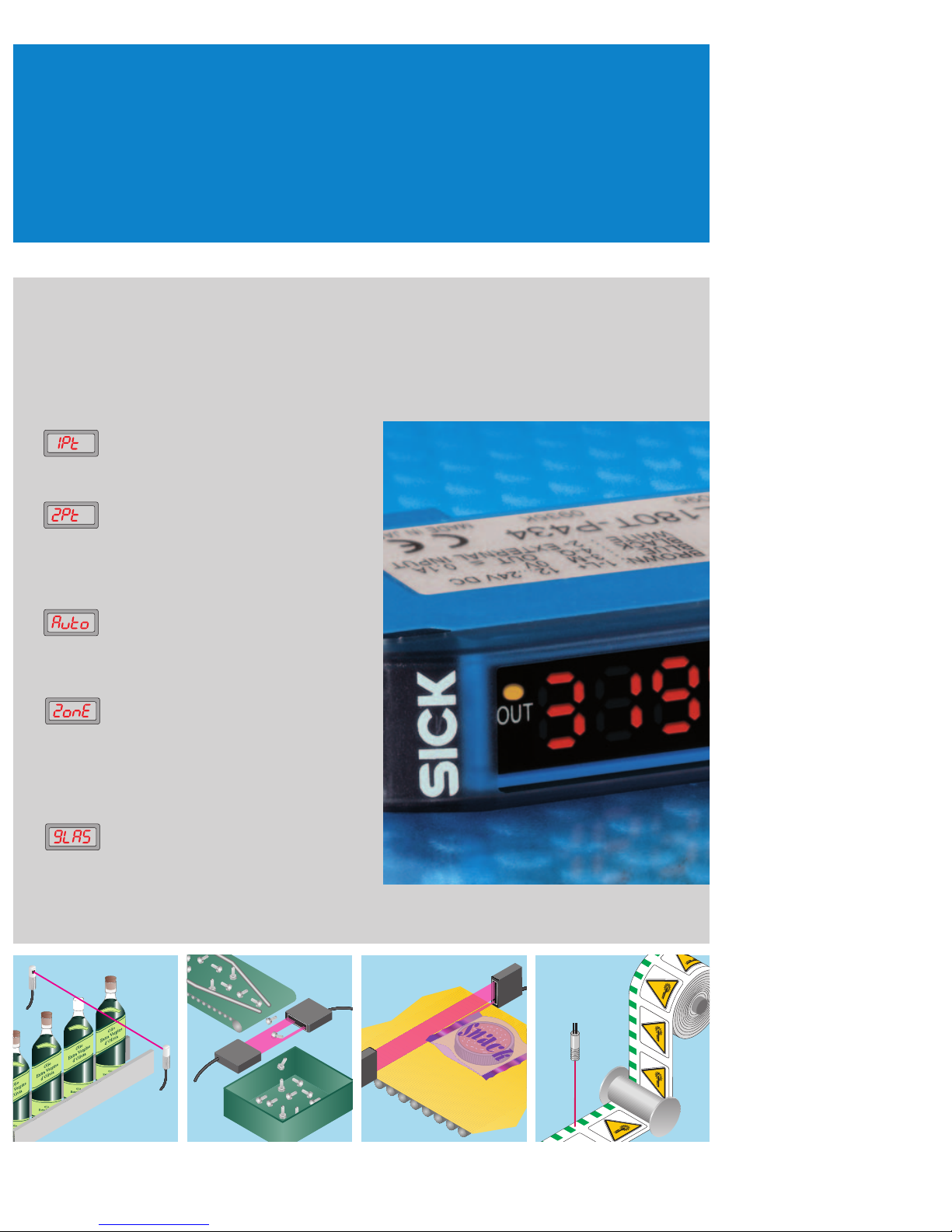

1-point Teach-in

Teach-in – quick and easy for standard

applications.

2-point Teach-in

Exact switching threshold adjustment

at the object and of the environment.

Ideal for applications with small system

reserves.

Auto Teach-in

Fully automatic switching threshold ad-

justment of moving objects. Even falling

or tiny objects are reliably detected.

Zone Teach-in

This so-called window technology learns

the object within a definable bandwidth

of the switching threshold. Ideal for the

detection of marks, or simultaneous

foreground and background suppression.

Teach-in of transparent objects

Teach-in with minimum sensitivity, reli-

ably detecting glass, films or small

objects.

Universal or individual –

application solutions.

Fast and reliable programming, menu driven and at the push

of a button: sensor properties and parameters are individually

programmed directly on the sensor.

Teach-in or manual adjustment? You decide!

Teach-in

2 s –

+

Application specific configuration

–

+

2 s

1.1 1-point Teach-in

1.2 2-point Teach-in

1.3 Auto Teach-in

1.4 Zone Teach-in

1.5 Teach-in of transparent objects

End End teach mode

2.1 Switching mode

2.2 Response time

2.3 Time delay setting

2.4 Expert menu/detailed settings

2.5 Reset

End back to operating mode

3.1 Set display value to zero

3.2 Display settings

3.3 Energy-saving mode

3.4 Reverse display

3.5 Hysteresis setting

3.6 External input configuration

3.7 Copy mode

3.8 Master Teach-in

3.9 ASC setting

3.10 Power setting of the sender LED

3.11 Keylock

End back to Expert menu

P. 6

P. 7

P. 8

P. 9

P. 10

P. 11

P. 12

P. 13

P. 14

P. 15

P. 16

P. 17

P. 18

P. 19

P. 20

P. 21

P. 22

P. 23

P. 24

P. 25

P. 26

Selection of the menu levels

Photoelectric sensor for fiber-optic cables

WLL180T – Easy handling, structured functions

and optimum functionality.

The photoelectric sensor for fiber-optic cables WLL180T with the SICK fiber-optic

cables of the LL3 series is especially suited to detecting very small objects,

objects in front of reflective backgrounds, and transparent and moving objects.

Fiber-optic cables are ideal for use in installations where space is restricted.

Locking, fiber-

optic cable

Status LED for

switching output

Numeric display for

nominal value (green)

and actual value (red)

Mode/

Enter

key Teach-in key

Arrow keys

2SICK 2010-08-02

Subject to change without notice

2010-08-02 SICK 3

Subject to change without notice

L+

M

Q1

Ext. Input

brn

blu

blk

wht

Switching output and external input

The external input can be configured as

teach-in or test input.

2X4-DIGIT NUMERIC DISPLAY

Dual 7-segment display for simultaneously showing nomi-

nal/actual values and for interactive operator guidance.

ASC –

AUTOMATIC SENSITIVITY CONTROL

For instance, automatically adapting the switching

threshold to compensate for contamination when

detecting transparent objects.

SHORTEST RESPONSE TIME

Detection of fast processes is an easy task for the

worlds fastest photoelectric fiber-optic sensor. With a

response time of only 16 μs objects can be detected

precisely. A small jitter contributes to the accuracy of

the detection.

Smallest changes in the level of the received light are

already sufficient for a reliable detection.

HIGH RESOLUTION SIGNAL PROCESSING

The power of the sender LED can be adjusted in three

stages: saturation, e.g. in case of highly reflective

objects, is prevented.

ADJUSTING THE LIGHT INTENSITY

OF THE SENDER LED

From monitoring to power control.

Monitoring simplifies many things, and technical highlights

provide many options, always enabling easy commissioning

and permanently reliable operation.

WLL180T Photoelectric sensors for fiber-optic cables

4SICK 2010-08-02

Subject to change without notice

Teach-in Adjustment options

1-point Teach-in

to quickly learn the switching point

1.1

Page 6

2-point Teach-in

to safely learn the switching point , ,

1.2

Page 7

Auto Teach-in

for Teach-in without stopping the production process , ,

1.3

Page 8

Zone Teach-in

for learning an upper and lower switching threshold

1.4

Page 9

Transparent Teach-in

transparent objects such as bottles and films

1.5

Page 10

For standard applications: Teach-in and the commissioning is complete.

The manual or automatic adjustment with Teach-in is always the first step. The 5 different

Teach-in modes can be quickly and easily selected. Alternatively, the switching threshold can

be adjusted manually utilizing the display.

Manual adjustment of the switching threshold

–

+

Manual, step-by-step modification of the switching thresholds by operating the arrow keys.

After a few seconds, the display automatically jumps to the operating mode.

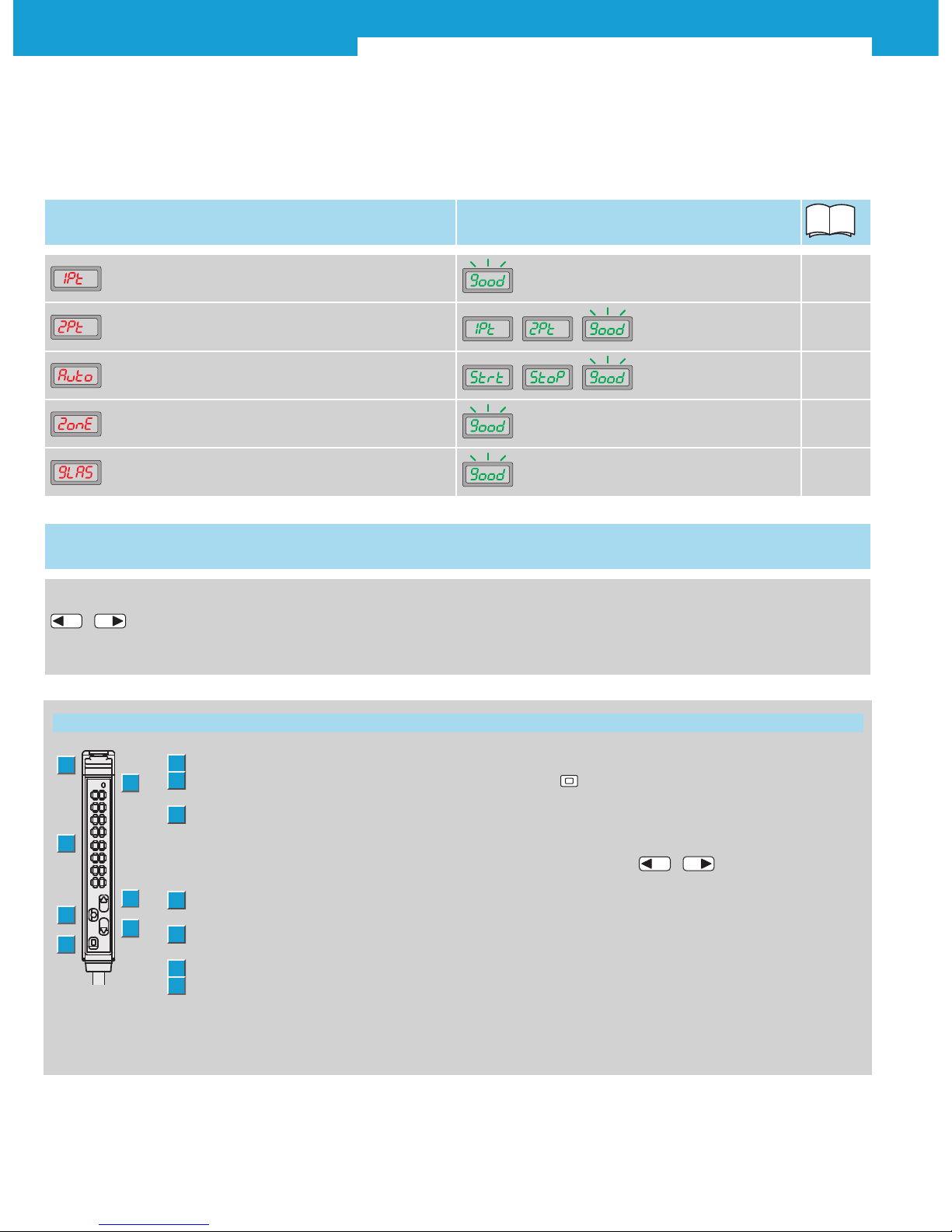

1Locking fiber-optic cable

2

Display LED orange: lights

when the switching output is active

3

Display, numeric: 4-digit

green: switching threshold, operating

mode,

red: current reception value, Teach-in/

function parameter

4

Arrow key < (manual switching threshold:

higher resp. next function parameter)

5

Arrow key > (manual switching threshold:

lower or previous parameter)

6Mode/Enter key (programming key)

7“Teach-in” key

Function keys of the sensor unit Further functions

Quick jump back from configuration mode to operating mode.

By pressing the -key for at least 2 seconds, the display

jumps from any position in the configuration menu back to the

main display.

Keylocks

Simultaneously pressing the –

+arrow keys for at

least 2 seconds in the RUN mode, locks or unlocks the keys

(display Loc/unloc).

1

2

3

4

6

5

7

WLL180T Photoelectric sensors for fiber-optic cables

2010-08-02 SICK 5

Subject to change without notice

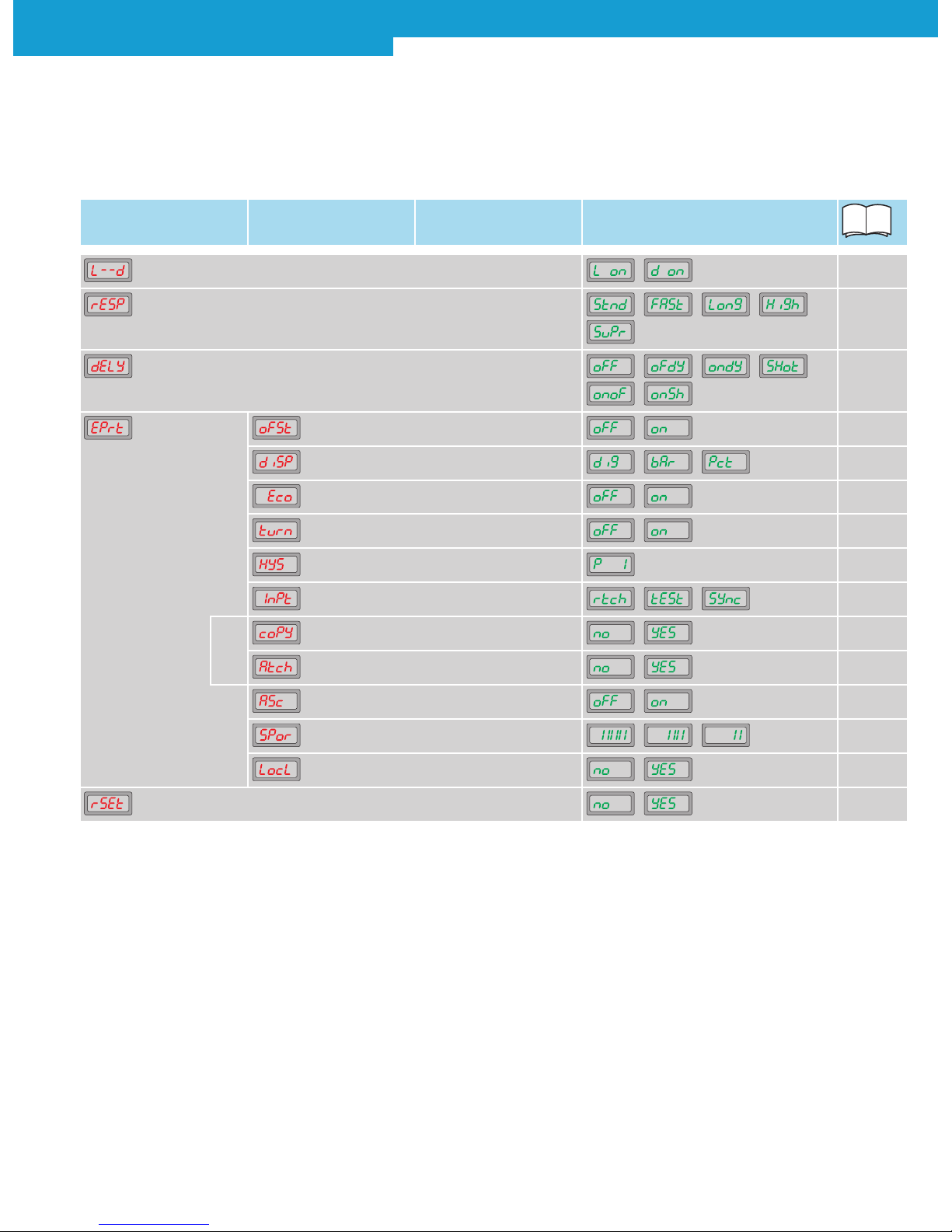

Application specific configuration: Utilising the entire functionality.

If further adjustments need to be made beyond the normal threshold adjustment, the entire

functionality can be selected via a comfortable menu.

Configuration Level I Level II Adjustment options

Switching mode , 2.1

Page 11

Response time , , , , 2.2

Page 12

Time delay setting , , , ,

,

2.3

Page 13

Expert menu/

detailed settings

Set display value to zero , 3.1

Page 16

Display settings , , 3.2

Page 17

Energy-saving mode , 3.3

Page 18

Reverse display , 3.4

Page 19

Hysteresis setting 3.5

Page 20

External input configuration , , 3.6

Page 21

Bus

versions

Copy mode , 3.7

Page 22

Master Teach-in , 3.8

Page 23

ASC setting , 3.9

Page 24

Power setting of the sender LED , , 3.10

Page 25

Keylock , 3.11

Page 26

Reset , 2.5

Page 15

WLL180T Photoelectric sensors for fiber-optic cables

6SICK 2010-08-02

Subject to change without notice

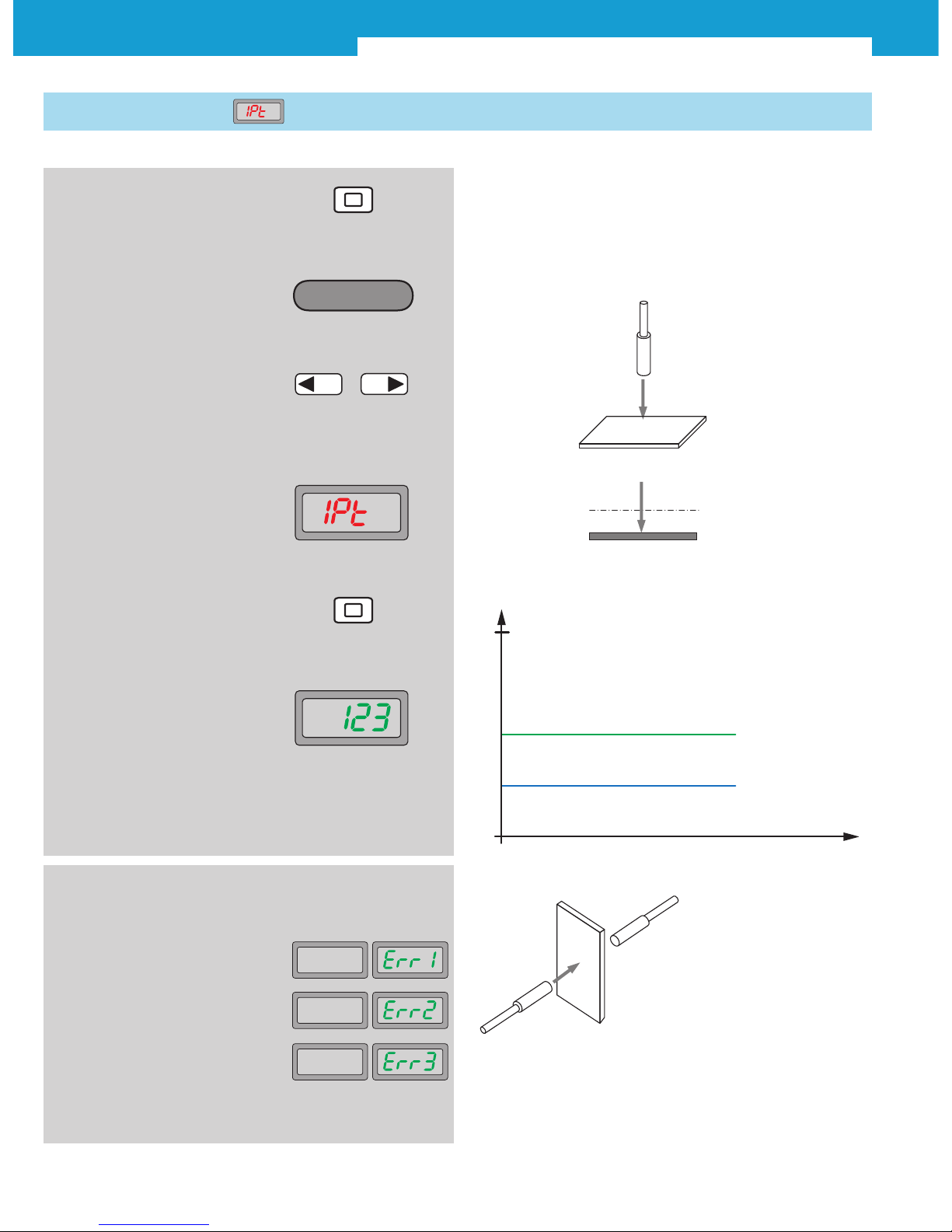

1.1 1-point Teach-in

1. Press Teach-in key for 2 s Easy setting of the switching threshold.

Secondary condition:

Diffuse type = object absent

Through-beam = object present

Adjust diffuse type to the background without object

2. Operating mode

Teach-in active

3. In the basic menu, select

required mode by pressing

the arrow keys

4. 1-point Teach-in is shown on

the display

5. Adjust diffuse type fiber to the

background without object and

press Teach-in key

6. Teach-in successful, set switch-

ing threshold blinks 3x and the

display returns to the main dis-

play

Teach-in

–

+

Adjusts the switching threshold with +10% according to the

light received.

Typical applications:

Standard applications,

no spurious effects expected,

max. system reserve.

Threshold level

Teach-in signal

+10%

0

t

Gain

}

In case of faulty input during Teach-in,

the following messages are shown:

Sensing level is too low

Sensing level is saturated

Difference of sensing level between

two points is too small

Switching threshold +10%

WLL180T Photoelectric sensors for fiber-optic cables

2010-08-02 SICK 7

Subject to change without notice

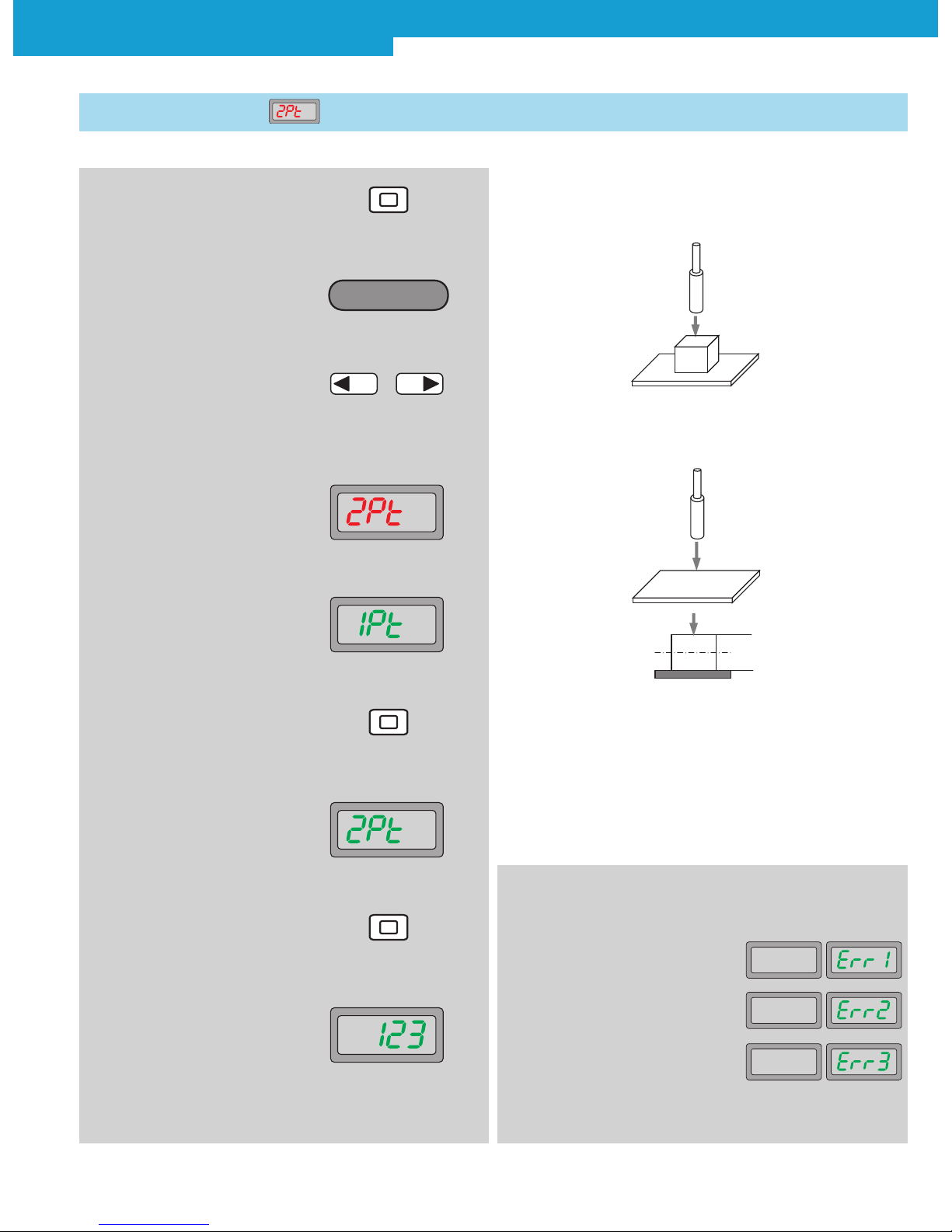

Exact adjustment of the switching threshold to object and ambient

conditions, in any order.

1st step: Teach-in with object

2. Operating mode

Teach-in active

3. In the basic menu, select

required mode by pressing

the arrow keys

4. 2-point Teach-in is shown on

the display

9. Teach-in successful, set switch-

ing threshold blinks 3x and the

display returns to the main dis-

play

Teach-in

–

+

6. Press Teach-in key

5. 1st point: adjust diffuse type

fiber with object present

8. Press Teach-in key

7. 2nd point: adjust diffuse type

fiber to the background with-

out object

2nd step: Teach-in without object

The switching threshold is defined between the 1st and 2nd point.

1.2 2-point Teach-in

Typical applications:

Exact switching point,

switching threshold is adapted to the object and ambient

conditions, create low system reserves.

1. Press Teach-in key for 2 s

In case of faulty input during Teach-in,

the following messages are shown:

Sensing level is too low

Sensing level is saturated

Difference of sensing level between

two points is too small

Switching threshold

1.

2.

WLL180T Photoelectric sensors for fiber-optic cables

8SICK 2010-08-02

Subject to change without notice

Automatic adjustment without stopping the production process.

1st step: start Teach procedure

2. Operating mode

Teach-in active

3. In the basic menu, select

required mode by pressing

the arrow keys

4. Auto Teach-in is shown on

the display

5. To start: press Teach-in key

Teach-in

–

+

6. Start

7. To stop: press Teach-in key

8. Stop

2nd step: stop Teach-in procedure

Allow one object or, even better, for several objects to pass.

1.3 Auto Teach-in

9. Teach-in successful, set switch-

ing threshold blinks 3x and the

display returns to the main dis-

play

Typical applications:

When objects can only be learned during the ongoing

process, e.g. ejection control.

1. Press Teach-in key for 2 s

In case of faulty input during Teach-in,

the following messages are shown:

Sensing level is too low

Sensing level is saturated

Difference of sensing level between

two points is too small

WLL180T Photoelectric sensors for fiber-optic cables

2010-08-02 SICK 9

Subject to change without notice

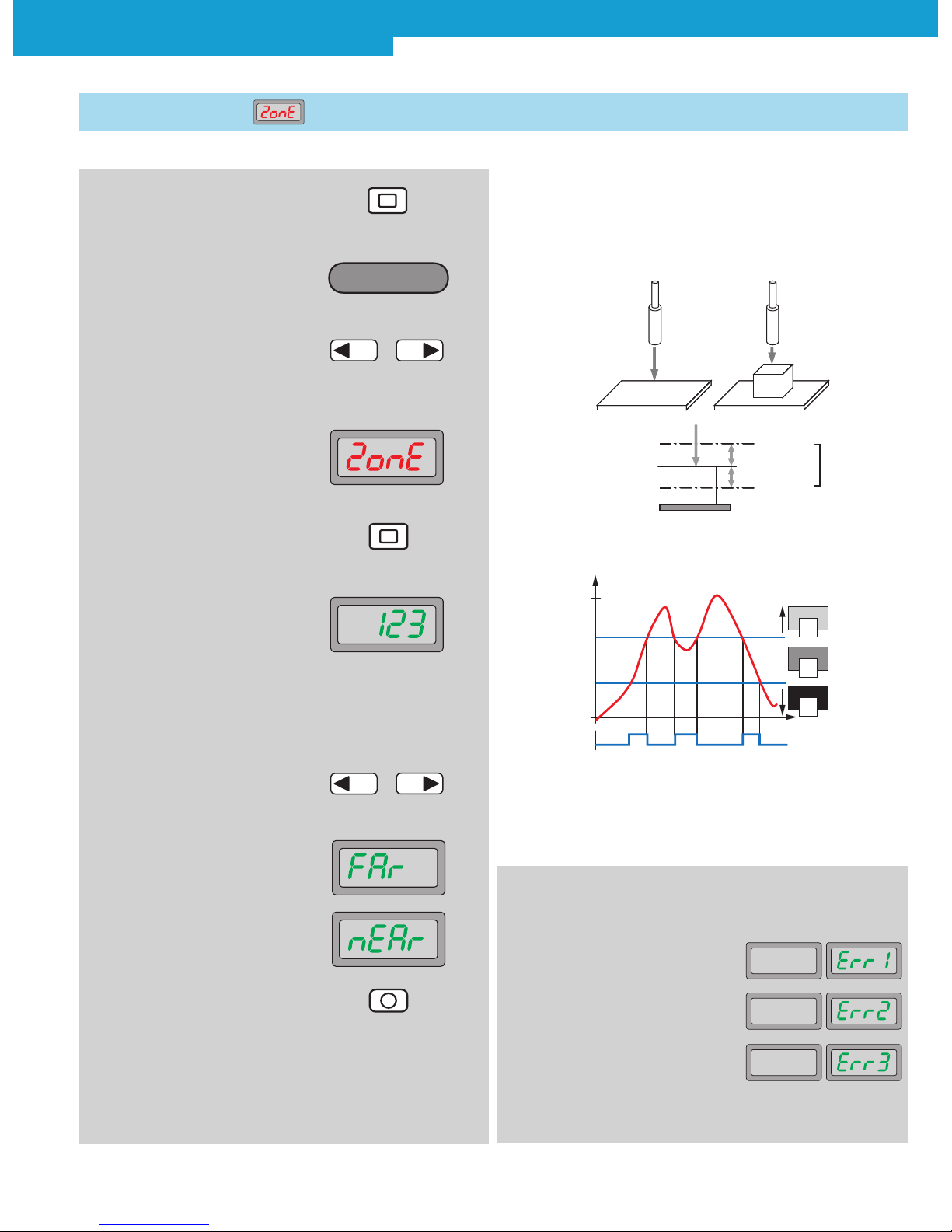

The switching point of the object is learned, and detected, within a

window. This window can be manually extended for the lower (far)

and higher (near) switching threshold, respectively.

Adjust diffuse type fiber to the background without and with object.

2. Operating mode

Teach-in active Teach-in

4. Zone Teach-in is shown on

the display

5. Press Teach-in key Adjusts the zone with ±10% according to the light received.

1.4 Zone Teach-in

Typical applications:

Ideal for mark detection, e.g. detecting no. 2 (see diagram above)

with variable window. Or “foreground suppression” and “back-

ground suppression” simultaneously.

3. In the basic menu, select

required mode by pressing

the arrow keys

–

+

1. Press Teach-in key for 2 s

Optionally, the switching thresholds for close and

far ranges can be readjusted, via the arrow keys.

9. Press arrow key in

main display

10. Range (FAr) or (nEAr)

can be selected with arrow keys

11. Select far (FAr) or near (nEAr) range

by pressing the mode key

12. The value of the received light (red display) then appears, and

the threshold value (green display) flashes for about 5 seconds.

During this time, the threshold value for the selected range can

be set via the arrow keys.

6. Teach-in successful, set switch-

ing threshold blinks 3x and the

display returns to the main dis-

play

–

+

Threshold

Zone

Near

Far

Upper limit

Lower limit

10%

10%

Zone

10%

10%

t

4096

Q = ON/OFF

0

Gain

WLL180T – Zone Detection

2000

~2200

~1800

}

}

Extendable (near zone)

Extendable (far zone)

Threshold level

Min: + 10 %

Min: - 10 %

1

2

3

In case of faulty input during Teach-in,

the following messages are shown:

Sensing level is too low

Sensing level is saturated

Difference of sensing level between

two points is too small

WLL180T Photoelectric sensors for fiber-optic cables

10 SICK 2010-08-02

Subject to change without notice

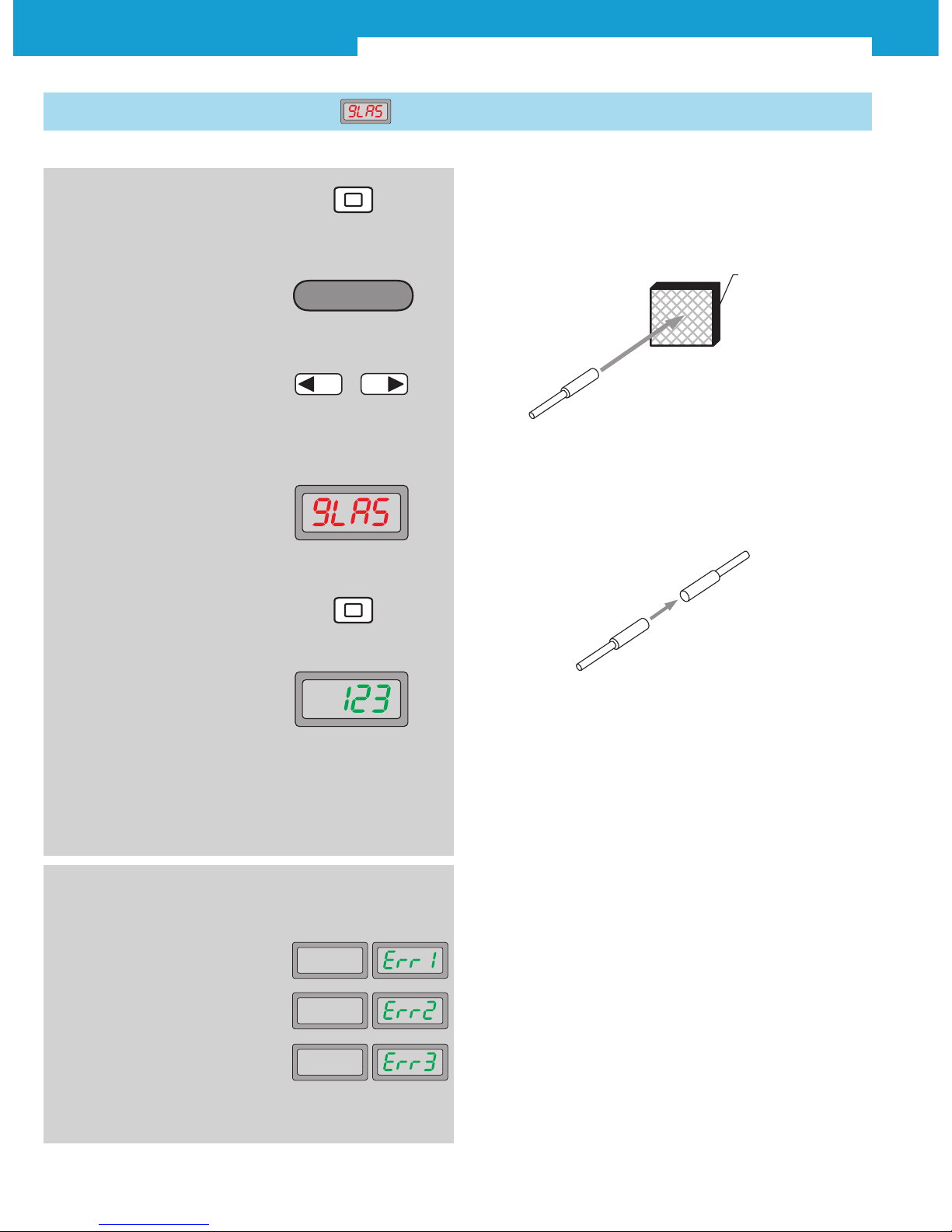

Mode is optimised for the detection of transparent objects.

Diffuse type:

Teach-in without object. Use reflector.

2. Operating mode

Teach-in active

3. In the basic menu, select

required mode by pressing

the arrow keys

4. Teach-in of transparent objects

is shown on the display

5. Press Teach-in key

Teach-in

–

+

Adjusts the switching threshold to 90% of the light received.

Through-beam system:

Perform Teach-in without object.

Adjusts the switching threshold to 90% of the light received.

1.5 Teach-in of transparent objects

Typical applications:

Detection of objects with low attenuation, such as glass, clear film

or very small objects.

1. Press Teach-in key for 2 s

6. Teach-in successful, set switch-

ing threshold blinks 3x and the

display returns to the main dis-

play

In case of faulty input during Teach-in,

the following messages are shown:

Sensing level is too low

Sensing level is saturated

Difference of sensing level between

two points is too small

Reflector

WLL180T Photoelectric sensors for fiber-optic cables

2010-08-02 SICK 11

Subject to change without notice

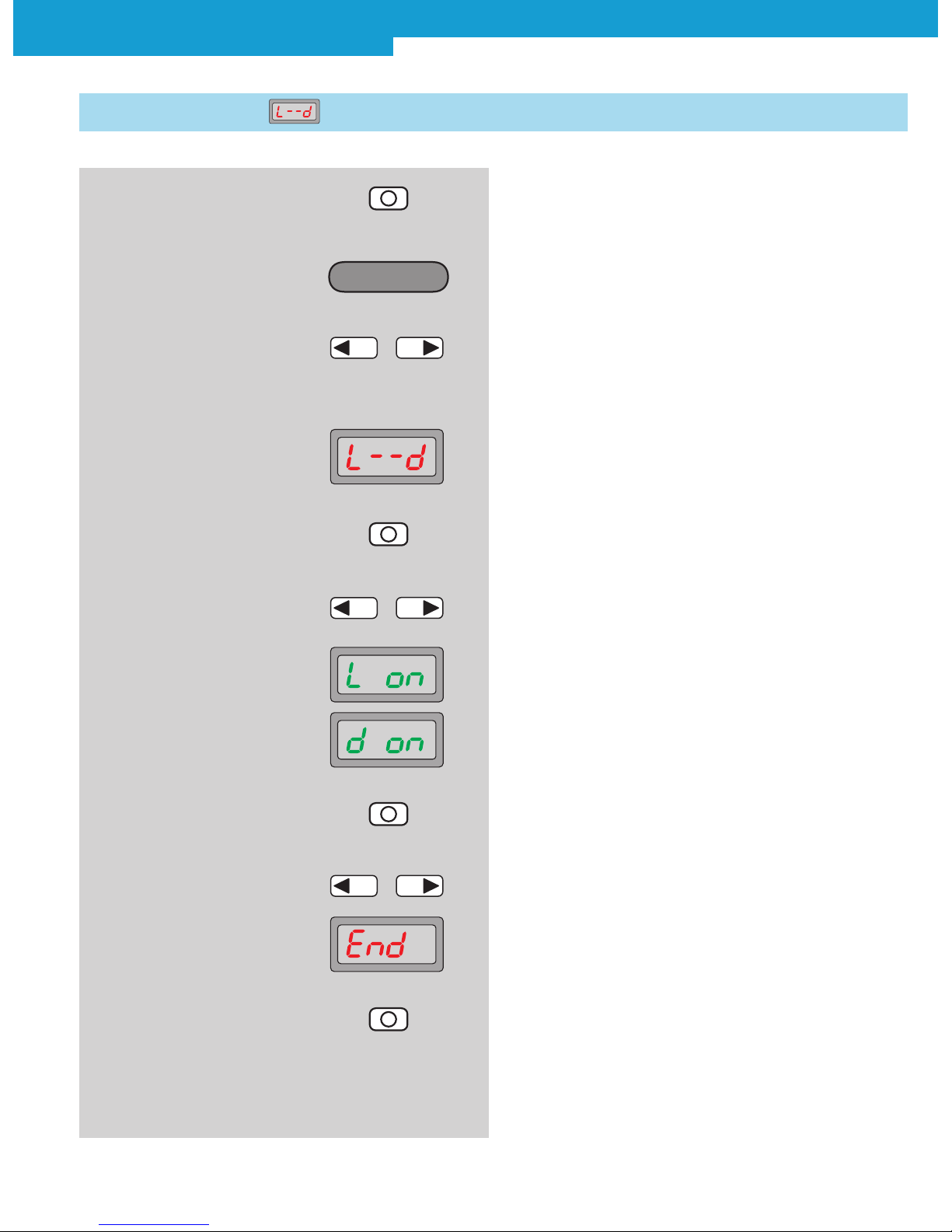

Switching mode (L--d),

L on: light-switching (factory setting),

d on: dark-switching.

2. Operating mode Configuring

active

4. Switching mode is shown on

the display

Configuring

1. Press Mode key for 2 s

6. Select between light-switch-

ing (L on) and dark-switching

(d on) by pressing the arrow

keys

–

+

2.1 Switching mode

7. Finish selection with Mode key

5. Press Mode key, setting option

flashes

8. Select ending the adjustment

(End)

–

+

9. Finish selection with Mode key

3. In the basic menu, select

required mode by pressing

the arrow keys

–

+

WLL180T Photoelectric sensors for fiber-optic cables

12 SICK 2010-08-02

Subject to change without notice

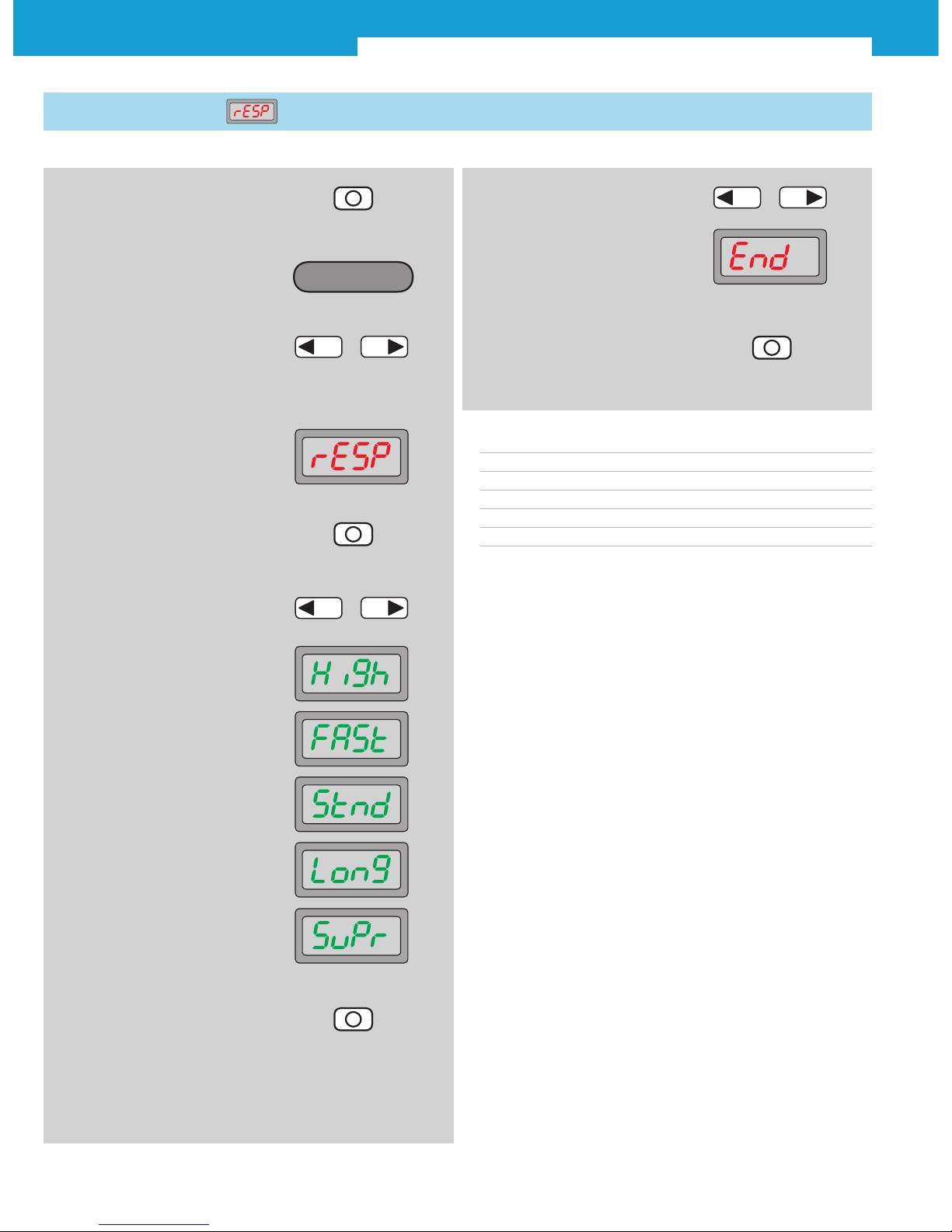

Response time switching frequency range

HiGh: 16 μs 31.25 kHz short

FASt: 70 μs 7.1 kHz reduced

Stnd: 250 μs 2 kHz standard (factory setting)

LonG: 2 ms 250 Hz high

SuPr: 8 ms 62.5 Hz super long

2.2 Response time

2. Operating mode Configuring

active

3. In the basic menu, select

required mode by pressing

the arrow keys

4. In the basic menu, select

required mode by pressing

the arrow keys

–

+

5. Response time is shown on

the display

–

+

6. Select between high-preci-

sion setting (LonG), stand-

ard setting (Stnd), fastest set-

ting (FASt), high speed setting

(HiGh) and super long setting

(SuPr) by pressing the arrow

keys

7. Finish selection with Mode key

9. Finish selection with Mode key

8. Select ending the adjustment

(End)

–

+

1. Press Mode key for 2 s

Configuring

WLL180T Photoelectric sensors for fiber-optic cables

2010-08-02 SICK 13

Subject to change without notice

2. Operating mode Configuring

active

4. In the basic menu, select

required mode by pressing

the arrow keys

5. Timer setting is shown

on the display

–

+

6. Press Mode key, setting option

flashes

7. Select between deactivation

(oFF), OFF delay (oFdY), ON

delay (ondY), One-Shot (SHot),

On-OFF-Delay (onoF) and On-

Shot (onSh) by pressing the

arrow keys

2.3 Time delay setting

3. Press Mode key

–

+

1. Press Mode key for 2 s

Option for various time delays and variable time range:

oFF = no time delay activated (factory setting),

oFdY = OFF delay (release delay),

ondY = ON delay (on delay),

SHot = One Shot (output active for set time window, regardless if

object is present),

onoF = ON and OFF delay (on and release delay),

onSh = ON delay One Shot (set time window (One Shot) is active

after response time (ON delay)).

Time delay selectable from 0,1 ... 9999 (0,1 ms ... 9999 ms)

Typical application:

Ignoring small variations of light intensity caused by dirt or

temperature and detecting only the objects. Slight differences

of light intensity can be detected without readjustment of the

sensitivity.

10. Finish selection with Mode key

11. Select ending the adjustment

(End)

–

+

12. Finish selection with Mode key

9. For activated time stage,

setting the time value

–

+

8. Finish selection

Configuring

WLL180T Photoelectric sensors for fiber-optic cables

14 SICK 2010-08-02

Subject to change without notice

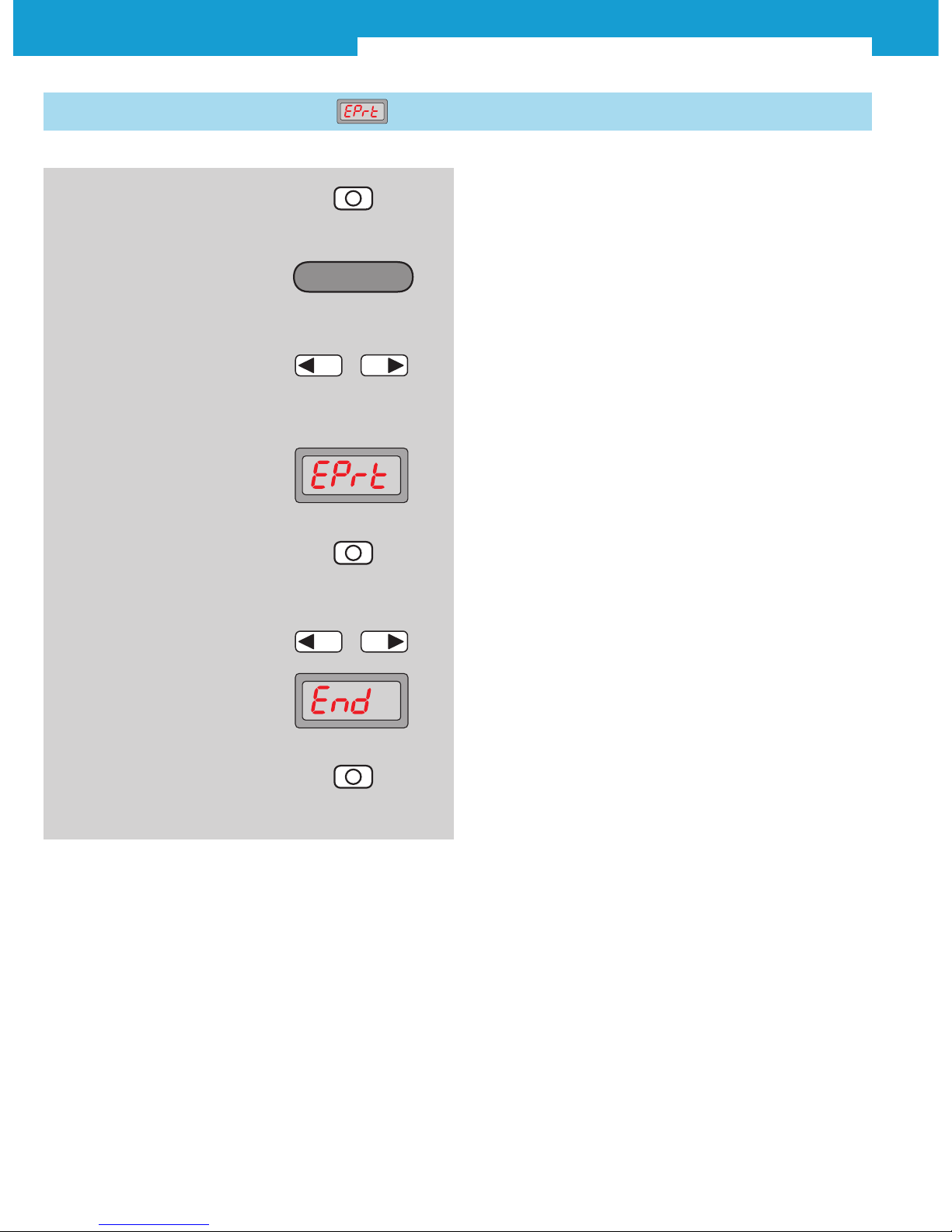

2.4 Expert menu/detailed settings

2. Operating mode Configuring

active

3. In the basic menu, select

required mode by pressing

the arrow keys

4. Detail adjustment is shown on

the display

5. Press Mode key.

Description of Expert menu

from page 16

–

+

6. Select ending the adjustment

(End)

–

+

7. Finish selection with Mode key

1. Press Mode key for 2 s

Configuring

WLL180T Photoelectric sensors for fiber-optic cables

2010-08-02 SICK 15

Subject to change without notice

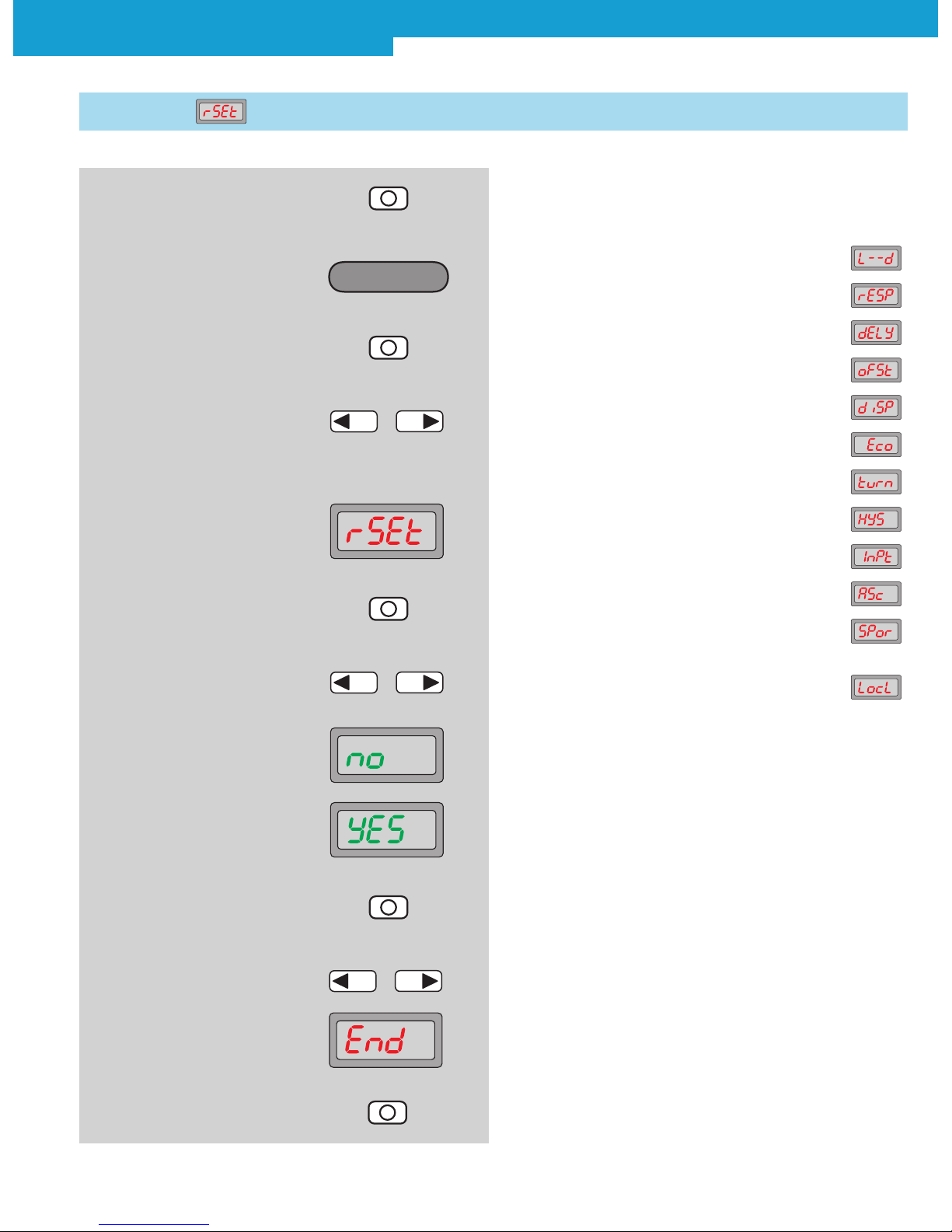

2.5 Reset

All operating modes are reset to the factory setting

“as-delivered ex works”.

Factory settings:

Switching mode: ON light-switching

Response time: Standard = 250 μs

Time stage: Off

Set display value to zero: Off

Display: Numeric display

Energy-saving mode: Off

Reverse Display: Off

Hysteresis setting: Standard = 5

Input setting: Teach-in input

ASC setting: Off

Power of the sender LED: Standard =

highest power

Keylock: Level 1

2. Operating mode Configuring

active

4. In the basic menu, select

required mode by pressing

the arrow keys

5. Reset is shown on the display

6. Press Mode key

7. Select between “no” and “YES”

by pressing the arrow keys

8. Finish selection with Mode key

–

+

–

+

9. Select ending the adjustment

(End)

–

+

10. Finish selection with Mode key

3. Press Mode key

1. Press Mode key for 2 s

Configuring

WLL180T Photoelectric sensors for fiber-optic cables

16 SICK 2010-08-02

Subject to change without notice

The current reception value is set to zero.

Adjusted switching threshold values are adapted.

on: Function active

oFF: Function deactivated (factory setting)

2. Operating mode Configuring

active

3. In the basic menu, select

Expert mode by pressing the

arrow keys

4. Expert mode is shown on

the display

Configuring

–

+

9. Select between “on” and “oFF”

by pressing the arrow keys

–

+

3.1 Set display value to zero

5. Press Mode key

10. Finish selection with Mode key

8. Press Mode key

6. In Expert mode, select

Set to zero by pressing the

arrow keys

7. Set to zero is shown on

the display

–

+

11. Close Expert mode with

arrow key

–

+

12. Finish selection with Mode key

13. Select ending the adjustment

(End)

14. Finish selection with Mode key

–

+

1. Press Mode key for 2 s

WLL180T Photoelectric sensors for fiber-optic cables

2010-08-02 SICK 17

Subject to change without notice

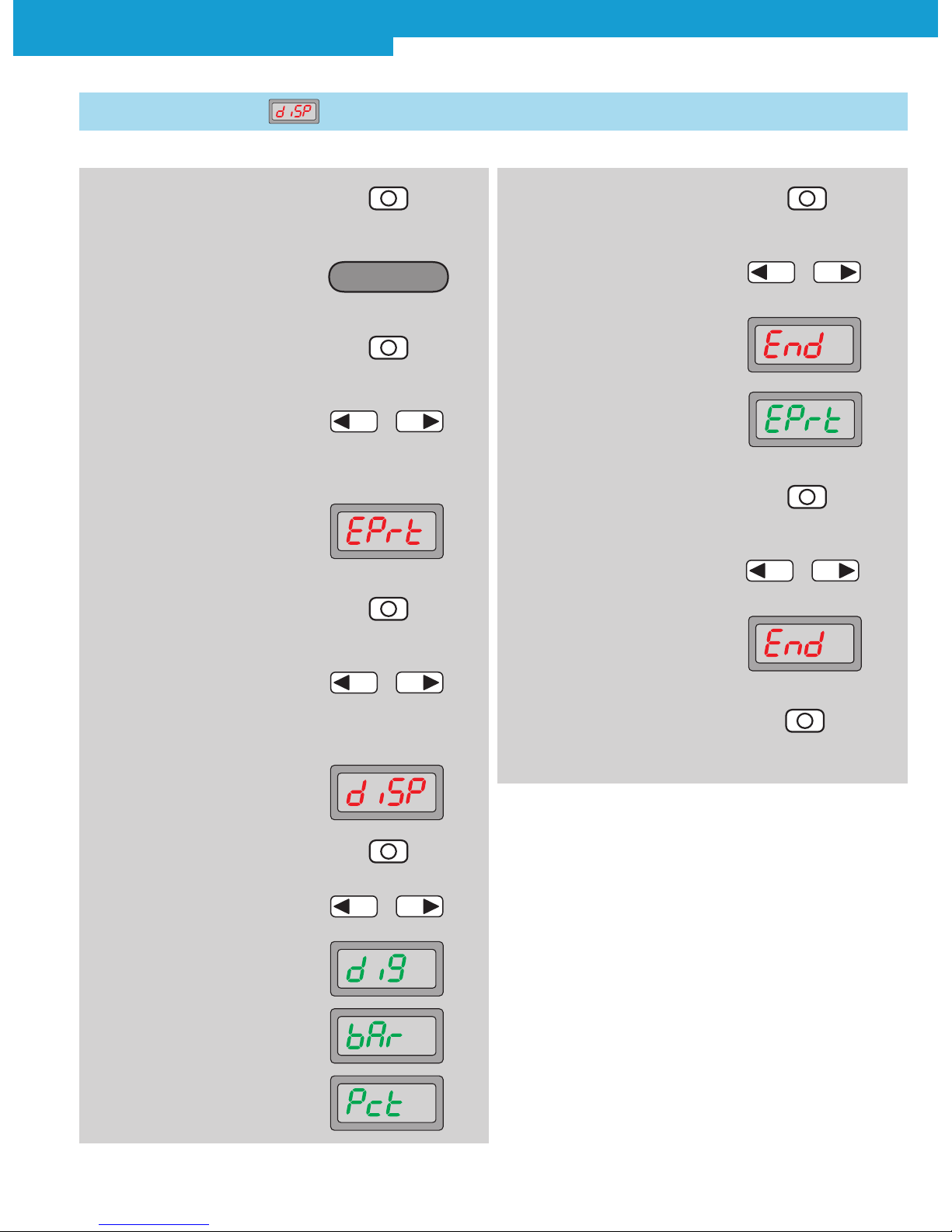

3.2 Display settings

2. Operating mode Configuring

active

4. In the basic menu, select

Expert mode by pressing the

arrow keys.

5. Expert mode is shown on

the display

Configuring

–

+

7. In Expert mode, select display

settings by pressing the arrow

keys

–

+

6. Press Mode key

8. Display settings are shown

10. Select between numeric

display (diG), bar display (bAr)

and percentage display (Pct)

using arrow keys

11. Finish selection with Mode key

12. Close Expert mode with arrow

key

–

+

9. Press Mode key

3. Press Mode key

–

+

diG: Numeric display (factory setting),

bAr: bar display,

Pct: Percentage display.

13. Finish selection with Mode key

14. Select ending the adjustment

(End)

15. Finish selection with Mode key

–

+

1. Press Mode key for 2 s

WLL180T Photoelectric sensors for fiber-optic cables

18 SICK 2010-08-02

Subject to change without notice

3.3 Energy-saving mode

Energy-saving mode is activated. Nominal value (green) display

will be switched off 20 seconds after a key has been pressed and

the actual value (red) display will be dimmed. Therefore the energy

consumption is reduced.

Pressing any key will activate the display.

14. Finish selection with Mode key

13. Select ending the adjustment

(End)

–

+

11. Close Expert mode with

arrow key

–

+

12. Finish selection with Mode key

2. Operating mode Configuring

active

6. In Expert mode, select

required mode by pressing

the arrow keys

7. Eco is shown on the display

8. Press Mode key

9. Select between “oFF” and “on”

by pressing the arrow keys

10. Finish selection with Mode key

–

+

–

+

5. Press Mode key

1. Press Mode key for 2 s

3. In the basic menu, select

Expert mode by pressing the

arrow keys

4. Expert mode is shown on

the display

–

+

Configuring

Table of contents

Popular Laboratory Equipment manuals by other brands

Waters

Waters ACQUITY UPLC M-Class System guide

Idexx

Idexx Quanti-Tray Sealer PLUS user manual

Elster Instromet

Elster Instromet EnCal 3000 Quad Hardware manual

dosatron

dosatron D14MZ10 Troubleshooting

Agilent Technologies

Agilent Technologies Intuvo 9000 Installation and First Startup

cytiva

cytiva Ettan IPGphor Cup Loading Manifold user manual